If you’re anything like me, your trusty hot glue gun is always within arm’s reach for all sorts of projects. It’s the go-to tool for fixing broken treasures or unleashing your creativity with stunning crafts.

But, just like any tool in our arsenal, hot glue guns have their limitations that can leave us scratching our heads or even cursing under our breath. In this blog post, we’ll delve deep into the world of hot glue guns and uncover the frustrating drawbacks that sometimes lurk behind that melting adhesive.

So, strap on your goggles and let’s explore the hidden limitations of this seemingly magical tool.

Temperature Limitations

Contents

- 1 Temperature Limitations

- 1.1 Temperature Range: The Key to Success

- 1.2 Heat-Sensitive Materials: Handle with Care

- 1.3 Adhesion on Challenging Surfaces: The Need for Texture

- 1.4 High Temperature Applications: Know Your Limits

- 1.5 Limited Bond Strength and Flexibility: A Matter of Choice

- 1.6 Temperature Control and Precision: The Power of Adjustable Settings

- 1.7 Safety Considerations: Handle with Caution

- 2 Limited Bond Strength

- 3 Limited Flexibility

- 4 Drying Time

- 5 Difficulty in Precision Application

- 6 Limited Bonding Materials

- 7 Potential for Burns

- 8 Limited Repositioning or Removal

- 9 Conclusion

Hot glue guns are indispensable tools in craft rooms and DIY workshops, offering versatility and convenience. However, to achieve optimal results, it is crucial to understand the temperature limitations of these adhesive guns. In this article, we will explore the temperature boundaries that hot glue guns operate within and discuss how these limitations can impact their effectiveness in various applications.

Temperature Range: The Key to Success

Hot glue guns typically operate within a temperature range of 250°F to 400°F (121°C to 204°C). This carefully calibrated range ensures optimal glue flow and bonding effectiveness. Straying outside this temperature range can compromise the performance of the glue and weaken the bond.

Heat-Sensitive Materials: Handle with Care

One significant limitation of hot glue guns is their unsuitability for heat-sensitive materials. Delicate fabrics like silk or nylon can easily succumb to damage or ruin when exposed to the high temperatures of a hot glue gun. To preserve the integrity of these materials, it is advisable to choose alternative adhesives such as fabric glue or adhesive sprays.

Adhesion on Challenging Surfaces: The Need for Texture

Smooth, non-porous surfaces like glass or metal pose challenges for hot glue adhesion due to the lack of texture. To overcome this limitation, it is recommended to roughen the surface or explore specialized adhesives tailored for these materials. However, when working with porous surfaces like wood, paper, and fabric, hot glue excels in providing strong bonds.

High Temperature Applications: Know Your Limits

Hot glue is not suitable for applications where the bonded object will be exposed to direct sunlight or extreme heat. The high temperatures can cause the glue to soften or melt, resulting in weakened or failed bonds. If your project anticipates exposure to high temperatures, consider opting for specialized adhesives that can withstand these conditions.

Limited Bond Strength and Flexibility: A Matter of Choice

While hot glue is effective for lightweight applications, it may not provide the same level of bond strength as other adhesives like epoxy or super glue. Additionally, hot glue can become brittle when cooled, limiting its effectiveness in applications that require flexibility. For projects demanding high bond strength or flexibility, alternative adhesives should be considered.

Temperature Control and Precision: The Power of Adjustable Settings

Some hot glue gun models offer limited temperature settings, which may not be suitable for all applications. To ensure precise temperature control or work with low melting point adhesives for delicate projects, investing in a hot glue gun with adjustable temperature settings is recommended.

Safety Considerations: Handle with Caution

Hot glue guns operate at high temperatures, posing a risk of burns if proper safety precautions are not followed. Exercise caution when handling the gun and avoid direct contact with the skin. The metal nozzle of the gun can also become hot during use, so take care to avoid accidental burns.

Limited Bond Strength

Today, we embark on a journey into the world of glue, specifically the beloved hot glue gun. While this versatile tool has earned its place in countless projects and repairs, it is crucial to grasp its limitations, especially when it comes to bond strength. So, gather your glue sticks as we delve into the boundaries of hot glue’s adhesive power.

Lightweight Materials Rule:

Hot glue works wonders for lightweight materials like paper, fabric, and certain plastics. Its ability to create a sufficiently strong bond for these materials is well-known. However, for heavy-duty applications or materials that demand a robust and long-lasting bond, hot glue falls short.

Brittle Bond Blues:

Over time, hot glue can become brittle, particularly when exposed to extreme temperatures or fluctuations. This brittleness weakens the bond, making it prone to breakage. Therefore, relying on hot glue for projects requiring durability is not recommended.

Moisture Meltdowns:

Hot glue has no affinity for moisture. It lacks resistance to water, meaning prolonged exposure can degrade its adhesive properties. If you’re aiming for water-resistant projects, hot glue might not be your best ally.

Smooth Surfaces Snub:

Glass, metal, and ceramics present a challenge for hot glue bonding due to their smooth surfaces. With limited surface area for effective adhesion, hot glue struggles to create a strong bond. In these cases, alternative adhesives should be considered.

Structural Shortcomings:

When it comes to structural applications or projects requiring high durability, hot glue falls short. For woodworking endeavors demanding a reliable and long-lasting bond, wood glue or epoxy should be your go-to options.

Trial-and-Error Triumphs:

Despite its limitations, hot glue still has its place in crafting and DIY projects. Its quick drying time allows for immediate use and adjustments, making it ideal for temporary fixes or prototyping. However, always keep in mind its limitations and choose the right adhesive for each specific project.

Limited Flexibility

Limited flexibility refers to the constraints and drawbacks associated with the use of hot glue guns. These limitations can affect the performance and suitability of hot glue in various applications. Here are the key aspects of limited flexibility when it comes to hot glue:

- Inflexibility: Hot glue, once it dries, becomes stiff and rigid. This lack of flexibility makes it unsuitable for projects that require bending or stretching, such as attaching fabrics or materials with some give. Unlike more flexible adhesives, hot glue may crack or break when subjected to stress, resulting in the detachment of glued items.

- Surface Compatibility: Hot glue works best on porous materials like wood, fabric, and paper. However, its adhesion on smooth or non-porous surfaces like glass, metal, or plastic is limited. This can lead to weak bonds that easily peel or separate over time. When working with shiny surfaces, it is advisable to explore alternative adhesive options.

- Temperature Sensitivity: Hot glue guns operate at high temperatures to melt the adhesive and facilitate easy application. However, this temperature sensitivity means that hot glue can soften or melt again if exposed to heat. Consequently, using hot glue in environments with high temperatures or near heat sources can compromise its effectiveness.

- Removal Challenges: While hot glue provides a strong bond, it can be difficult to remove without causing damage to the underlying surface. Unlike solvents that dissolve or soften other adhesives, hot glue requires mechanical force to separate bonded items. This can be time-consuming and risky for delicate materials or surfaces.

Drying Time

It is essential to delve deeper into the limitations associated with drying time when using hot glue guns. This comprehensive guide will explore the intricacies of drying time, empowering you to make informed decisions and optimize your project outcomes.

The Art of Timing:

- Drying time for hot glue can vary based on multiple factors, including the temperature of the glue gun and the ambient room temperature.

- In colder environments, the glue may take longer to dry, while higher temperatures can expedite the drying process, potentially hindering material repositioning or adjustment.

- Carefully assessing your working environment is crucial to creating optimal drying conditions.

Balancing Strength and Flexibility:

- Hot glue tends to dry rigidly, making it ideal for projects that demand robust bonding.

- However, this rigidity can pose limitations for projects requiring flexibility or movement.

- When adhering fabrics or other pliable materials, hot glue may render them stiff and brittle, compromising their natural pliability.

Surface Compatibility:

- Certain surfaces, such as glass, metal, and specific plastics, may not adhere well to hot glue due to their lack of surface texture or porosity.

- For superior bonding results with these materials, exploring alternative adhesives specifically designed for their unique properties becomes imperative.

Temperature Sensitivity:

- Extreme temperatures can adversely affect hot glue’s durability.

- Exposure to high heat or cold conditions may cause the glue to soften or become brittle, ultimately weakening the bond.

- Considering alternative adhesives that exhibit superior resistance to temperature fluctuations ensures project longevity.

- Hot glue is not inherently waterproof and may degrade when exposed to prolonged water or moisture.

- Projects requiring water resistance necessitate the use of dedicated waterproof glues to ensure optimal performance and durability.

Difficulty in Precision Application

Achieving precise application with a hot glue gun can be quite challenging. In this article, we will explore the difficulties associated with using hot glue guns for precision work and provide practical tips and techniques to overcome these challenges.

Thick Consistency:

The thick consistency of hot glue presents a major hurdle in achieving precise application. Unlike liquid or super glue, hot glue tends to spread quickly once applied, resulting in messy and uneven applications. Controlling the amount and placement of the adhesive becomes a real struggle.

Fast-Drying Nature:

The fast-drying nature of hot glue is another obstacle in precision application. Once dispensed from the gun, hot glue cools down and hardens rapidly, leaving little time for adjustments or repositioning. This can be particularly frustrating when working on intricate or delicate projects that require meticulous placement.

Nozzle Size and Shape:

Many hot glue guns come with a standard-sized nozzle that may not be ideal for precise work. The larger nozzle size makes it difficult to accurately apply small amounts of glue. Additionally, it can limit access to tight or hard-to-reach areas, further complicating precision application.

High Temperature:

Hot glue guns operate at high temperatures to melt the adhesive, making it challenging to control the flow and prevent excessive spreading. The temperature sensitivity of hot glue can also affect its compatibility with certain surfaces, making precision application even more difficult.

Overcoming the Challenges:

Smaller Nozzle Attachment:

Consider using a smaller nozzle attachment if available for your hot glue gun. These attachments offer greater control over the amount and placement of the glue, allowing for improved precision in application.

Practice and Experimentation:

To enhance precision application with a hot glue gun, practice various techniques such as applying small dots or lines of glue instead of larger blobs. Experiment with different pressure and speed to find the right balance for your specific project. With time and experience, you will develop a better feel for achieving accurate glue placement.

Alternative Adhesives:

For projects that demand the utmost precision, consider using alternative adhesives like liquid glue or epoxy. These adhesives often provide better control and accuracy compared to hot glue, especially when working on intricate or delicate items.

Limited Bonding Materials

Today, we are going to explore the limitations of these versatile tools when it comes to bonding materials. While hot glue guns are incredibly useful, it’s important to be aware of their drawbacks for your next project.

First and foremost, let’s talk about plastics. Hot glue is not the best choice for bonding certain plastics like polyethylene and polypropylene. These plastics have low surface energy, making it challenging for hot glue to adhere properly. So, when working with these materials, consider using epoxy or super glue for a stronger bond that won’t let you down.

Now, let’s move on to porous materials such as fabric or foam. Hot glue can struggle to create a strong surface bond with porous surfaces. Instead of forming a sturdy connection, it tends to seep into the tiny pores, compromising the overall strength of the bond. To tackle this issue, opt for fabric glue or specialized adhesives designed specifically for porous materials.

If you’re planning to work on load-bearing structures or heavy objects, hot glue may not be your go-to adhesive. While it works wonders for lightweight items, it may not have the strength necessary to withstand significant pressure or weight. For these applications, consider using structural adhesives or mechanical fasteners that are specifically designed to handle heavy loads.

Now, let’s talk about temperature. Hot glue is not suitable for high-temperature environments. When exposed to heat, the adhesive can soften and lose its bond, resulting in a messy and unreliable connection. So, if your project requires resistance to high temperatures, make sure to choose alternative adhesives that can handle the heat.

Lastly, let’s address long-term durability. While hot glue is great for temporary bonds, it may not be the best option for projects that require longevity. Over time, hot glue bonds can weaken due to factors like temperature changes, moisture exposure, or simply the natural aging of the adhesive. For more permanent and durable bonding, epoxy or specialized adhesives are highly recommended.

In conclusion, while hot glue guns are fantastic tools for various crafting and DIY projects, they do have limitations when it comes to bonding certain materials, load-bearing applications, high temperatures, porous surfaces, and long-term durability. Therefore, it’s crucial to consider these limitations and choose the appropriate adhesive for each specific project to ensure the best results.

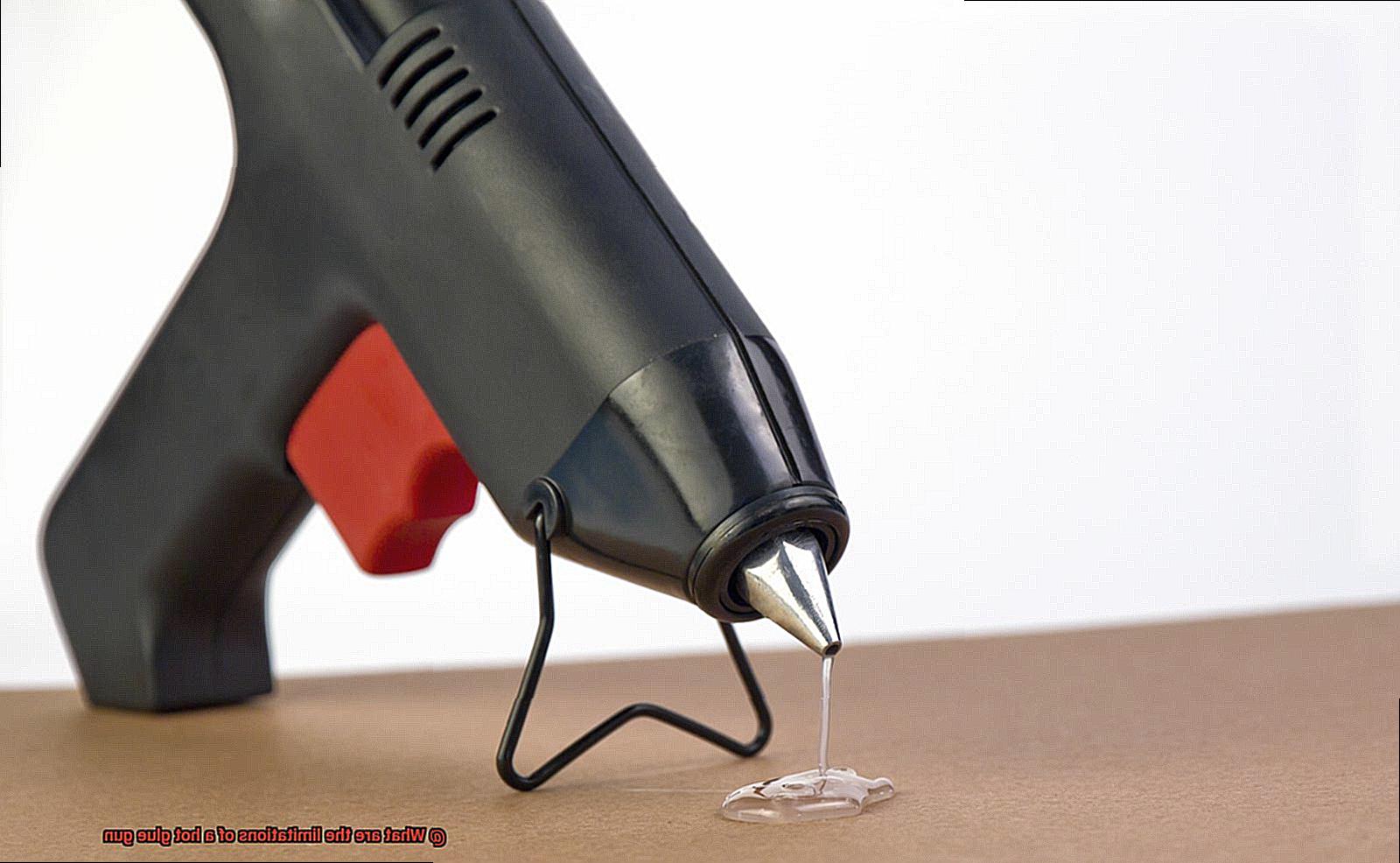

Potential for Burns

Hot glue guns are a crafter’s best friend, but it’s crucial to be aware of their limitations and potential risks. In this blog post, we’ll delve into one of the primary concerns when using a hot glue gun – the potential for burns. We’ll explore why burns can occur, how to prevent them, and other safety tips to keep in mind. So grab your glue gun and let’s embark on this creative journey with caution.

The Heat is On:

- The scorching temperature of the glue gun itself poses a significant risk of burns if mishandled.

- Never touch the searing metal tip of the gun while it’s in use or immediately after.

- For added protection, don gloves or employ tools like tweezers or pliers to handle the fiery glue gun.

Beware of Hot Glue Spills:

- Accidental spills or drips of hot glue can result in excruciating burns upon contact with bare skin.

- Exercise extreme caution when applying glue or removing excess from projects.

- It’s wise to have a first aid kit nearby as a precaution against any potential accidents.

Mind Your Surroundings:

- Unintentional contact between hot glue and flammable materials can lead to severe burns or even fires.

- Always work in a well-ventilated area and keep flammable objects far away from the glue gun’s heat source.

- Allow the glue gun to cool down completely before storing it to prevent inadvertent burns during handling.

Limited Repositioning or Removal

Today, we’re going to dive into the world of glue guns and explore the limitations that come with using these trusty tools. While hot glue guns are known for their quick-drying and strong bonding properties, they do have their fair share of challenges when it comes to repositioning or removing the glue. So, let’s arm ourselves with knowledge and discover how to minimize these limitations.

Limited Repositioning: Dance with Precision

Hot glue sets like a wildfire, leaving little room for adjustments. This can be frustrating when working on projects that require delicate placement or demanding alignment. To minimize this limitation, here are a few tips to dance with precision:

- Plan and prepare: Choreograph your project by ensuring all materials are properly aligned before applying the glue.

- Temporary positioning: Use tape or clamps to hold items in place until the glue dries, allowing you to make those final adjustments.

- Practice makes perfect: Test the alignment before gluing to avoid any missteps on your crafting dance floor.

High Temperature Woes: The Heat is On

The intense heat of a hot glue gun can cause delicate materials like fabrics or plastics to melt or deform when attempting to reposition or remove the glue. The heat is on, but fear not. Here’s how you can overcome this challenge:

- Gentle heating: Grab your hairdryer and give the glue a gentle breeze of warmth to soften it before attempting removal.

- Be cautious: Like a skilled dancer, avoid applying excessive heat or prolonged exposure to prevent further damage.

Sticky Residue Remains: Cleaning up the Dance Floor

Hot glue has a knack for leaving behind stubborn residue, especially on porous surfaces or those with intricate textures. Fear not, as there are ways to combat this sticky situation:

- Dissolving agents: Whip out your secret cleaning moves and try using rubbing alcohol or acetone on a cotton swab or cloth to dissolve the glue residue.

- Test on inconspicuous areas: Before busting out your best cleaning routine, test the solvent on a small, hidden area to ensure it won’t damage your material.

UBIHBYJI6Wc” >

Conclusion

The limitations of a hot glue gun are worth considering before diving into any project. While these versatile tools have their advantages, they also come with some drawbacks.

Firstly, hot glue guns have temperature limitations. They can only reach a certain heat level, which may not be sufficient for certain materials or applications. This can limit the types of projects you can tackle with a hot glue gun.

Secondly, hot glue guns are not suitable for high-stress or heavy-duty applications. The adhesive strength of hot glue is generally weaker compared to other types of adhesives like epoxy or construction adhesive. So if you need something that requires a strong bond, a hot glue gun may not be the best choice.

Additionally, hot glue guns have limited precision and control. The melted glue tends to flow quickly and can be challenging to manipulate precisely. This can make it difficult to achieve intricate or delicate work.

Another limitation is the drying time of hot glue. It usually takes several minutes for the glue to cool and fully set. This means you need to hold your project in place until the adhesive hardens, which can be time-consuming and inconvenient.

Furthermore, hot glue is not suitable for all surfaces. It may not adhere well to certain materials like glass or metal, requiring alternative adhesives for those specific applications.

Lastly, safety precautions should always be taken when using a hot glue gun. The high temperature of the melted glue poses a risk of burns if mishandled or accidentally touched.

In conclusion, while hot glue guns are handy tools with numerous applications, they do have their limitations.