We all know that finding the perfect adhesive is essential for our beloved creations to stand the test of time. And when it comes to bonding wood, one adhesive springs to mind – wood glue. But hold your horses, because today we’re going to uncover its not-so-pretty side.

In this blog post, we’ll dive deep into the disadvantages of wood glue, shining a light on potential drawbacks you may encounter while using this popular adhesive. By understanding these downsides, you’ll be armed with knowledge to make informed decisions in your woodworking projects. Whether you explore alternatives or implement preventive measures, you’ll be ready to tackle any challenges head-on.

So get ready as we pull back the curtain on the sticky truth and examine the limitations of wood glue. From its less-than-stellar strength in certain applications to its potential struggles with moisture and heat, we’re covering it all. So grab your virtual tool belt and join us as we venture into the lesser-known side of wood glues.

Limited Moisture Resistance

Contents

Limited moisture resistance in wood glue can have detrimental effects on various applications. The key issues that may arise include joint failure, decreased adhesive strength, damage from weather elements, difficulties in bonding non-porous materials, and reduced lifespan of the glue bond.

When wood glue is exposed to moisture, it weakens and deteriorates over time, leading to joint failure. This means that glued pieces of wood can separate or come apart, compromising the structural integrity of projects like furniture or cabinets that may be exposed to high humidity or wet conditions.

Moisture also gradually diminishes the adhesive strength of wood glue. This weakens the bond between wood pieces, increasing the likelihood of joint failure. In load-bearing structures or heavy-duty woodworking projects, where strong and durable bonds are crucial, this can be a significant problem.

Outdoor applications like outdoor furniture or decking are particularly susceptible to damage from rain, snow, and other weather elements. Limited moisture resistance causes the glue to degrade and lose its adhesive properties, resulting in premature deterioration of the project.

Wood glue is not suitable for bonding non-porous materials like glass, metal, or plastic. These materials require specialized adhesives with better adhesion and moisture resistance. Using wood glue on non-porous surfaces will likely result in weak bonds and potential failure.

The limited moisture resistance of wood glue also reduces the lifespan of the bond between two pieces of wood. Over time, exposure to moisture causes the glue to break down, resulting in a loss of adhesion and eventual separation of the glued joint.

Slow Curing Time

Wood glue is known for its slow curing time, which can be both advantageous and disadvantageous depending on the situation. Let’s delve into the pros and cons of this characteristic in more detail:

Advantages:

- Flexibility: The slow curing time of wood glue allows for more flexibility in positioning and adjusting wood pieces before the bond becomes permanent. This is particularly beneficial for complex or intricate woodworking projects where precise alignment is crucial. Woodworkers have the freedom to make adjustments and ensure a perfect fit before the glue sets.

- Strong bond: Wood glue forms a strong and durable bond when fully cured. The slow curing time allows the glue to penetrate the wood fibers, creating a robust and long-lasting bond. This is especially important for projects that require structural integrity, such as furniture or cabinetry.

Disadvantages:

- Time-consuming: The slow curing time of wood glue can be frustrating for users who require quick bonding. Waiting for the glue to dry can significantly delay project completion, especially when working on tight deadlines. It’s important to factor in the curing time when planning projects to avoid unnecessary delays.

- Alignment and stability issues: When using wood glue, it is crucial to clamp the pieces of wood together until the glue fully cures. However, with slow curing time, there is an increased risk of the pieces shifting or moving before the glue has dried completely. This can result in misaligned joints or weakened bonds, compromising the overall quality of the project.

- Environmental factors: The slow curing time can be further extended in humid or cold environments. Moisture and temperature play a significant role in the drying process, causing it to take even longer for the glue to set. Woodworkers working in certain climates or during specific seasons need to be aware of this challenge and plan accordingly.

To mitigate these disadvantages, there are strategies that can be employed:

- Accelerators or activators: These products are designed to speed up the drying process of wood glue. Applying them to the surfaces before using the glue can significantly decrease the overall curing time. However, it’s important to follow the manufacturer’s instructions and use these products appropriately.

- Clamping and external pressure: When using wood glue with slow curing time, it is recommended to use clamps or other forms of external pressure to ensure proper bonding while waiting for the glue to dry. This helps prevent any movement or shifting of the wood pieces during the curing process, ensuring precise alignment and strong bonds.

Limited Gap-Filling Ability

Wood glue, a popular choice for woodworking projects, has its limitations, particularly when it comes to gap-filling ability. Understanding why wood glue may not be suitable for certain applications is crucial for achieving strong and reliable bonds.

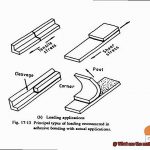

One of the primary factors contributing to wood glue’s limited gap-filling ability is its dependency on physical contact between surfaces. Wood glue works best when the surfaces being bonded fit tightly together, allowing the adhesive to penetrate the wood fibers and create a strong bond. However, if there are any gaps present, the glue may struggle to fill them adequately, resulting in weaker bonds and potential structural issues over time.

In addition to its physical contact dependency, wood glue faces challenges in filling small gaps or irregularities. The viscosity of wood glue, which is generally thicker compared to other adhesives like epoxy or super glue, makes it difficult for the adhesive to flow into small gaps and crevices effectively. This further hinders its ability to fill voids and create robust bonds.

Applying sufficient pressure is another obstacle when using wood glue. Clamping or applying pressure is often necessary to ensure a secure bond. However, if there are gaps between the wooden surfaces, it becomes challenging to apply enough pressure to close them while still maintaining a tight fit between the pieces.

While there are specialized wood glues available in the market claiming improved gap-filling abilities through additives or modifiers, they might still not be as effective as adhesives specifically designed for gap-filling purposes. Therefore, it is crucial to consider alternative adhesives that better suit the specific requirements of a project if a strong bond with gap-filling properties is desired.

Irreversible Bond

An irreversible bond is a characteristic of wood glue that can be both beneficial and problematic in woodworking applications. On one hand, an irreversible bond ensures a strong and permanent connection between two pieces of wood. This can be advantageous when creating sturdy furniture or structures that require long-lasting durability. However, this permanence can also present challenges when adjustments, modifications, or repairs are needed.

One major drawback of an irreversible bond is the difficulty in separating glued pieces once they have dried and set. This can pose significant challenges when design changes or errors occur. Breaking the bond may require excessive force or damage to the wood, potentially compromising the integrity of the project. If you anticipate the need for future adjustments or modifications, wood glue may not be the best option.

Moreover, the irreversible nature of wood glue limits your ability to make fine-tuning adjustments once it has dried. If you need to address any errors or make alterations, it can be difficult or even impossible to do so without damaging the wood surface. This frustration can result in time-consuming tasks such as scraping, sanding, or cutting away the glued area.

Additionally, repair and maintenance can be problematic with an irreversible bond. If a component of your furniture or woodworking project needs replacement or repair, removing the glued parts without causing further damage can be challenging. This can compromise the integrity of the overall structure and make repairs more complicated.

To mitigate these issues, it is important to understand the limitations of wood glue’s irreversible bond. In situations where adjustability, repairability, or easy disassembly is important, exploring alternative bonding methods such as mechanical fasteners or reversible adhesives might be a better choice.

Limited Versatility

Wood glue, while a reliable adhesive for woodworking projects, has certain limitations that restrict its versatility. Understanding these limitations is essential to ensure successful bonding and to explore alternative options for different materials or applications.

One significant limitation of wood glue is its inability to bond materials other than wood. Unlike super glue or epoxy, which can adhere to various surfaces like plastic, metal, or glass, wood glue is specifically designed for wood bonding. If you need to join different materials together, you will need to use a different type of adhesive suitable for those specific materials.

In addition, wood glue may not adhere well to smooth or sealed surfaces. It relies on absorption into wood fibers for a strong bond, making it less effective on non-porous surfaces. This limitation can be problematic when working with certain types of wood that have naturally smooth or oily textures. In such cases, alternative adhesives capable of bonding non-porous surfaces should be considered.

Furthermore, wood glue is not recommended for outdoor applications or in environments with high moisture levels. It is not waterproof and can degrade when exposed to water or excessive humidity. Therefore, if your project requires constant moisture or weather exposure, such as outdoor furniture or structures, using a waterproof adhesive would be more appropriate.

Compared to instant glues that bond surfaces within seconds, wood glue has a relatively slow drying time. It typically requires several hours or overnight drying time to achieve full strength. This can be inconvenient if you need quick results or are working on a time-sensitive project. In such cases, considering fast-drying adhesives may be more suitable.

Lastly, wood glue can be messy and challenging to clean up if not used with care. Its tendency to drip and spread easily can lead to unwanted stains on surfaces or clothing. To avoid any accidental spills or damages, it is important to take precautions and protect surrounding areas when using wood glue.

Considerations for Choosing Wood Glue

Choosing the right wood glue for your woodworking project is crucial for its success. There are several considerations to keep in mind when selecting the appropriate adhesive for your needs.

Firstly, consider the type of wood you are working with. Different wood types have varying characteristics, such as porosity and moisture content, which can affect how well the glue bonds. Ensure you choose a wood glue that is compatible with the specific type of wood you are working with to achieve a strong and durable bond.

Next, think about the setting time of the wood glue. Faster drying glues allow you to move forward with your project more quickly, but they may not provide as strong of a bond compared to slower-drying options. Assess whether speed or strength is more important for your project before making a decision.

Bonding strength is another crucial consideration. The strength of the bond provided by the wood glue is essential, especially for load-bearing structures like furniture or cabinetry. Look for wood glues with high bonding strengths to ensure the stability and longevity of your project.

Temperature and humidity conditions also play a role in choosing the right wood glue. Some wood glues perform better in high humidity environments, while others are more suitable for low humidity conditions. Choose a wood glue that is compatible with the temperature and humidity levels your project will be exposed to for optimal bonding performance.

Finally, consider ease of use and clean-up. Squeeze bottles or applicators make precise application easier, while some glues may require additional tools or mixing before use. Additionally, some wood glues can be easily cleaned up with water, while others may require solvents or scraping. Choose a wood glue that aligns with your preferences and project requirements.

Alternative Adhesives to Consider

When it comes to alternative adhesives, there are a plethora of options to consider. Wood glue may be the go-to choice for many woodworking projects, but sometimes it may not be the best option. In such cases, exploring alternatives can open up a whole new world of possibilities.

First on the list is epoxy, a versatile adhesive that can bond a wide variety of materials, including wood. What sets epoxy apart is its strong and durable bond, capable of withstanding heavy loads and temperature fluctuations. This makes it ideal for projects that require extra strength and durability. However, it’s important to note that epoxy can be more expensive than wood glue and requires careful handling and mixing.

Another alternative adhesive worth considering is polyurethane glue. Renowned for its exceptional bonding strength and ability to expand to fill gaps, polyurethane glue is also resistant to moisture. This makes it an excellent choice for outdoor applications where exposure to the elements is a concern. However, keep in mind that polyurethane glue takes longer to cure and requires clamping during the drying process.

For small repairs or projects that demand instant bonding, super glue, also known as cyanoacrylate glue, is an excellent option. Known for its quick and strong bond, super glue excels at precision bonding and delivering rapid results. However, due to its limited gap-filling capabilities, it may not be suitable for larger woodworking projects.

Contact cement is yet another alternative adhesive worth exploring. This strong adhesive bonds quickly and provides a flexible bond, making it perfect for laminating surfaces together. However, it may not be as suitable for structural applications where extra strength is required.

Lastly, specialty adhesives like hide glue or animal-based glues offer unique advantages in specific woodworking applications. Hide glue, with its reversible properties and ability to create a strong bond, has been used in furniture making for centuries. However, it does require special preparation and may not be as convenient as other modern adhesives.

Tips for Working with Wood Glue

Wood glue is a versatile adhesive commonly used in woodworking projects. To ensure successful use of wood glue, it’s important to follow these tips:

Choose the right type of wood glue for your project. Different formulations, such as PVA (polyvinyl acetate) glue, epoxy glue, and polyurethane glue, have different properties and strengths. Consider the specific requirements of your project and select the appropriate type of wood glue.

Prepare the surfaces before applying the glue. Clean the surfaces thoroughly, ensuring they are free from dust, debris, and any previous finishes. Sand the wood to remove imperfections and create a smooth surface for optimal bonding.

Apply the right amount of glue. Too little glue may result in weak bonds, while too much can lead to messy squeeze-out. Apply a thin and even layer of glue to both surfaces being bonded. Use a brush or roller to spread the glue evenly and ensure all areas are covered.

Use clamps or other methods to secure the joint. Apply pressure to the glued surfaces to ensure a strong bond. Depending on the size and complexity of your project, choose appropriate clamps like bar clamps or pipe clamps to hold the pieces together until the glue sets.

Allow sufficient drying time for the glue to fully cure. The drying time varies depending on factors like temperature, humidity, and glue type. Follow the manufacturer’s instructions regarding drying times and avoid rushing the process to ensure strong and durable bonds.

Clean up excess glue immediately. Wood glue is easier to clean up when it’s still wet. Use a damp cloth or sponge to wipe away any excess glue before it dries. If the glue has dried, carefully scrape it off using a chisel or similar tool.

Understand the limitations of wood glue. While wood glue is strong and versatile, it has limitations. It may not be suitable for surfaces exposed to extreme heat or moisture. Additionally, it may not bond well with certain materials like metal or plastic. Consider these limitations and choose the appropriate adhesive for specific applications.

uaNckEMncQE” >

Conclusion

In conclusion, wood glue may be a go-to adhesive for woodworking enthusiasts, but it does have its fair share of drawbacks. One major downfall is its lackluster resistance to moisture. When faced with even a hint of dampness, wood glue can weaken and crumble, resulting in joint failure and a shortened lifespan for your bond. It’s definitely not the best choice for projects that will be exposed to the elements.

Another disadvantage of wood glue is its sluggish curing time. While this slow process allows for flexibility and ultimately creates sturdy bonds, it can be a real test of patience. Waiting around for the glue to dry can lead to alignment issues and make you question the stability of your project. And don’t even get me started on how factors like temperature and humidity can drag out this already tedious process.

Wood glue also falls short when it comes to filling gaps. Its reliance on physical contact between surfaces means that it struggles to adequately fill those pesky little spaces between your pieces of wood. This can result in weaker bonds and potentially cause structural problems down the line.

Let’s not forget about one more drawback: wood glue’s irreversible nature. Sure, it forms an unbreakable connection between two pieces of wood, but that also means making adjustments or repairs becomes a nightmare. Trying to undo what you’ve glued together without causing damage? Good luck.

Lastly, wood glue is pretty limited in its versatility. It’s specifically designed for bonding wood only, so don’t expect it to work miracles on non-porous surfaces or materials other than wood.

To combat these disadvantages, consider exploring alternative adhesives like epoxy, polyurethane glue, super glue, contact cement, or specialty adhesives tailored to your project’s specific needs.