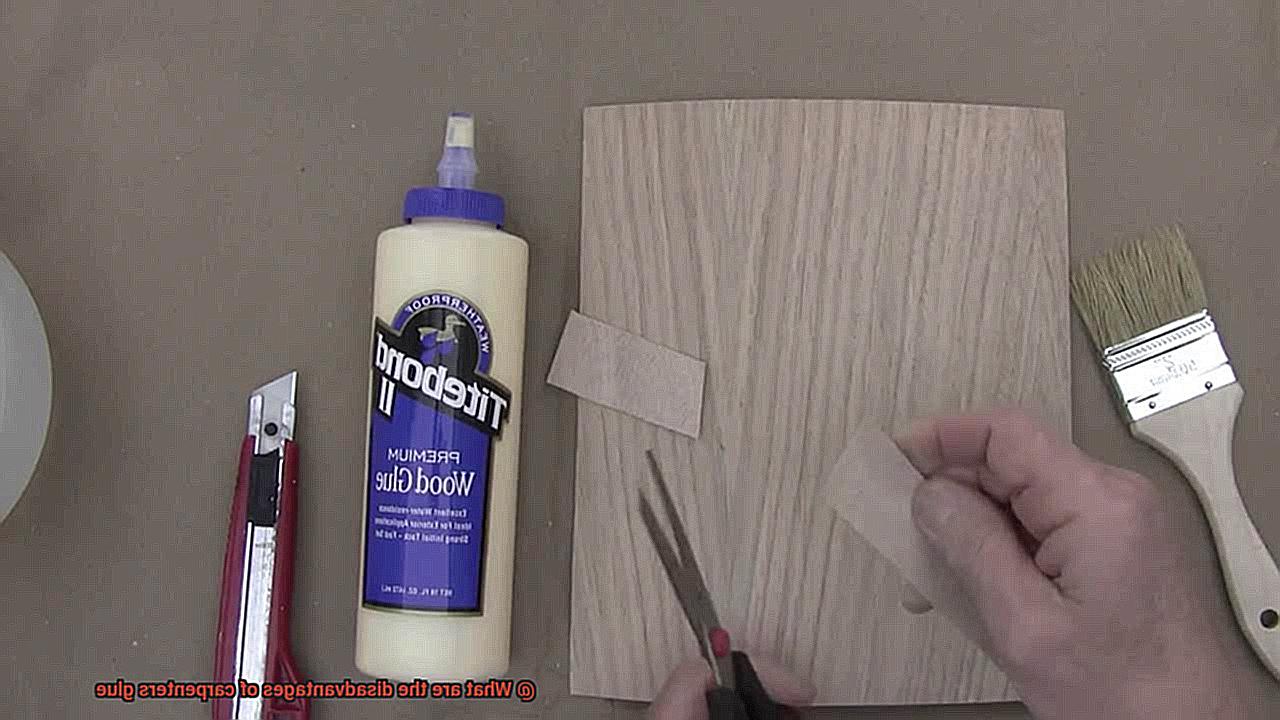

Craftsmanship and woodworking projects often rely on the trusty adhesive known as carpenters glue. This versatile glue has been a go-to for bonding wood, plywood, and other materials for years. But just like any tool, it’s important to know its limitations.

In this blog post, we’ll explore the downsides of using carpenters glue. By understanding these quirks, you can make informed decisions to ensure project success. Whether you’re a seasoned pro or a DIY enthusiast, uncovering the disadvantages of carpenters glue will arm you with the knowledge needed to use it effectively.

We’ll dive into some persistent drawbacks associated with carpenters glue. From frustratingly long drying times to limited strength in certain situations, we’ll give you a comprehensive overview of these limitations. Our goal is to educate and empower you in selecting the most appropriate adhesives for your woodworking ventures.

So let’s delve into the sticky world of carpenters glue and uncover its potential pitfalls that may impact your projects.

Long Drying Time

Contents

Carpenters glue, also known as wood glue or PVA glue, is a staple in the world of woodworking. Its affordability and ease of use make it a go-to adhesive for many projects. However, one common complaint that often arises is its long drying time.

In this article, we will delve into the reasons behind this phenomenon and provide practical tips to help you overcome any challenges associated with it.

Factors Affecting Drying Time:

- Evaporation Process: Carpenters glue relies on the evaporation of water to form a strong bond. As the water evaporates, the glue solidifies and creates a tight grip between wood surfaces. However, this process takes time and is influenced by various environmental conditions.

- Humidity: High humidity levels can significantly extend drying time. The presence of moisture in the air slows down the evaporation process, resulting in longer drying times. It is crucial to consider the humidity levels in your workspace and make necessary adjustments if needed.

- Temperature: Cold temperatures hinder water evaporation, leading to even longer drying times. Working in a well-heated environment or utilizing clamps or heaters can help accelerate the drying process in colder conditions.

- Glue Thickness: The thickness or amount of glue applied also affects drying time. Thicker layers of glue take longer to dry compared to thin layers. Applying a thin and even layer of glue can expedite the drying process, ensuring faster results.

Mitigating Long Drying Times:

- Patience: To ensure strong and durable bonds, allow sufficient drying and curing time before subjecting glued surfaces to stress or pressure. Rushing the process can result in weak joints that may fail over time. Remember, patience is a virtue when it comes to carpenters glue.

- Alternative Adhesives: If time sensitivity is a concern, consider using fast-drying alternatives like cyanoacrylate (super glue) or epoxy for projects that require quick bonding. These adhesives offer rapid curing times and may be more suitable for time-sensitive applications.

Limited Gap-Filling Ability

In the world of woodworking, choosing the right adhesive is paramount for creating durable and sturdy joints. Among craftsmen, carpenters glue, also known as wood glue or carpenter’s adhesive, is a popular choice. However, it’s crucial to recognize its limitations. In this article, we will delve into why carpenters glue has limited gap-filling ability and explore alternative solutions for projects requiring effective gap-filling.

The Challenge of Filling Gaps:

Uneven Surfaces:

- Carpenters glue struggles to fill gaps between two pieces of wood when working with uneven surfaces.

- The adhesive’s ability to create a strong bond is hindered by these irregular surfaces, resulting in weaker joints that may eventually fail.

Not Perfectly Fitted Pieces:

- Carpenters glue is less effective when joining pieces of wood that don’t fit together perfectly.

- In such cases, the limited gap-filling ability can lead to weaker bonds between the wood pieces.

Factors Affecting Gap-Filling Ability:

Viscosity:

- Compared to other adhesives, carpenters glue has relatively low viscosity.

- Its thinner and more liquid consistency makes it easier to apply but limits its effectiveness in filling gaps.

Pressure Requirements:

- Achieving a strong bond with carpenters glue necessitates applying pressure during the drying process.

- However, limited gap-filling ability makes it challenging to exert sufficient pressure on uneven surfaces or loosely fitted wood pieces.

Alternative Solutions for Gap-Filling Projects:

Thicker Adhesives:

- For projects prioritizing gap-filling, consider using thicker adhesives such as epoxy or construction adhesive.

- These adhesives possess superior gap-filling abilities and can create stronger bonds even on uneven surfaces or loosely fitted wood pieces.

Proper Surface Preparation:

- To maximize the strength of the bond with carpenters glue, ensure that the surfaces being glued together are clean, flat, and properly aligned.

- This minimizes gaps and allows the adhesive to create a more solid bond.

Susceptible to Moisture

Carpenters glue is the ultimate companion for woodworking projects, boasting a strong bond and unmatched versatility. However, a formidable enemy lurks in the shadows: moisture.

In this article, we will embark on a journey to unravel the mysteries of moisture susceptibility and explore its potential consequences. But fret not. We will also equip you with alternative options and ingenious techniques to triumph over this challenge.

Understanding the Susceptibility:

Carpenters glue, also known as PVA glue, relies on a water-based formula that excels on dry surfaces. Yet, when confronted with moisture, its performance unravels. The glue softens, swells, or even dissolves, betraying the very purpose it was chosen for. Picture your painstakingly crafted woodworking masterpiece crumbling under the weight of a mere droplet.

Warping Woes:

Moisture’s impact extends beyond weakening the glue; it infiltrates the wood it clings to. Exposure to moisture coerces wood to expand or warp, leaving structural integrity hanging by a thread and jeopardizing seamless joints. This menace is particularly treacherous in humid domains like bathrooms or steamy kitchens.

Mold and Mildew Mayhem:

Moisture ensnared within glued joints creates an idyllic haven for mold and mildew. These unwelcome guests tarnish the visual appeal of your creation and unleash havoc upon its strength and durability. Who would want their wooden masterpiece adorned with fuzzy invaders?

Alternatives and Precautions:

To vanquish the perils of moisture susceptibility, consider embracing alternative adhesive options such as epoxy glue. Renowned for their water resistance, epoxy glues forge an unbreakable bond even in moisture-laden realms.

In cases where carpenters glue must brave potentially moist environments, strategic preparation is paramount. Shield the glued surface from direct water contact by applying a waterproof sealant or finish, bestowing upon it an armor that extends its lifespan.

Limited Strength on Certain Materials

Woodworkers often rely on the strength and reliability of carpenters glue to hold their projects together. However, this adhesive has its limitations, particularly when it comes to non-porous materials such as metal, glass, or plastic. In this passage, we will explore the properties of carpenters glue and how it interacts with different materials, highlighting its limited strength on non-porous surfaces.

Understanding Carpentry Glue:

Carpenters glue, also known as wood glue or carpenter’s adhesive, is specifically formulated to bond well with porous surfaces like wood. It works by penetrating the wood fibers and forming a strong bond as it cures. The result is a sturdy joint that can withstand the test of time.

The Nemesis: Non-Porous Materials:

Unfortunately, carpenters glue does not perform as effectively on non-porous materials. Unlike wood, these materials do not allow the glue to penetrate and adhere effectively, resulting in weaker bonds. Trying to bond two pieces of metal with a glue that cannot stick to it is like expecting a fish to climb a tree.

The Heat and Cold Factor:

Another limitation of carpenters glue is its vulnerability to extreme temperatures. When exposed to high heat or freezing conditions, the glue can weaken and lose its bonding strength. This poses a problem for applications where the glued joints may encounter such conditions, potentially leading to joint failure.

Water Woes:

Moisture is another Achilles’ heel for carpenters glue. While some wood glues are water-resistant or waterproof, carpenters glue typically lacks these properties. When exposed to water or moisture, the glue can weaken and deteriorate over time, compromising the integrity of the bond. Watching your carefully crafted project slowly dissolve in the rain would be devastating.

Drying Times:

It’s important to note that carpenters glue is not known for its quick drying times. Unlike some other adhesives that cure rapidly, carpenters glue requires a longer drying period. This can be inconvenient for projects that require immediate use or handling.

Shelf Life Concerns:

Lastly, it’s crucial to consider the shelf life of carpenters glue. Over time, the adhesive can deteriorate and become less effective. If stored improperly or past its expiration date, the glue may lose its bonding strength and fail to create a strong bond. Always check the label and ensure you’re working with fresh glue.

Irreversible Bonding

Today, we’re delving into the concept of irreversible bonding and its implications in this craft. While carpenters glue is a trusted companion in the workshop, understanding its limitations is crucial for successful woodworking endeavors. So, grab your safety goggles and prepare to explore the unbreakable bond that holds wood together… forever.

Limited Adjustments and Corrections:

Imagine working on a delicate project when suddenly, you realize an error or need to reposition a piece. With carpenters glue, reversing the bond becomes an uphill battle. Unlike some other adhesives, carpenters glue forms a permanent bond that resists separation without causing damage. This limitation can be frustrating when working on intricate designs or projects requiring precise alignment.

Restricted Repairs and Modifications:

Woodworking is an art, and like any masterpiece, it might require repairs or modifications down the road. Unfortunately, irreversible bonding can make these tasks challenging. If a component becomes damaged or needs replacement, removing the glued parts often requires extensive effort and may result in further damage. In some cases, starting from scratch may be the only option.

Reduced Reusability:

As responsible woodworkers, we strive for sustainability and minimal waste. However, irreversible bonding with carpenters glue can hinder these efforts. Salvaging or repurposing components from old projects becomes difficult when separating glued joints leads to irreversible damage. This limitation can lead to increased waste and reduced sustainability in our craft.

Disassembly Dilemmas:

Wooden furniture often needs to be moved or transported, but glued joints may not withstand the stress involved. Irreversible bonding can pose challenges during disassembly, potentially leading to damage or breakage. This limitation can be particularly frustrating when trying to preserve or transport cherished pieces.

While carpenters glue provides strong and durable bonds for woodworking projects, it’s important to consider its limitations. Irreversible bonding restricts adjustments, repairs, and modifications, reduces reusability of materials, and can pose difficulties during disassembly.

By understanding these disadvantages, we can make informed decisions about the appropriate adhesive for our woodworking needs.

Strong Odor

We all know that carpenters glue is an exceptional adhesive when it comes to joining pieces of wood together. However, the potent smell that accompanies it can be overwhelming and far from enjoyable. In this post, we will delve into expert tips on how to diminish the overpowering smell of carpenters glue. Let’s embark on this aromatic adventure.

Ventilation: Your Secret Weapon

Proper ventilation is key when combating strong odors. Utilizing carpenters glue in well-ventilated spaces or taking your woodworking projects outdoors can significantly expedite the dissipation of those pungent fumes. So throw open those windows, set those fans whirring, and let nature work its magic.

Gear Up for Protection

Prioritizing personal safety is paramount, especially when handling potentially noxious odors. Donning a respirator or a mask specifically designed for chemical fume protection provides an additional layer of defense against inhaling those robust glue odors and any lurking volatile organic compounds (VOCs) that may pose harm.

Embrace Low-Odor or Odorless Alternatives

Did you know that some manufacturers offer low-odor or even odorless versions of carpenters glue? These innovative alternatives can prove to be a game-changer for individuals sensitive to strong smells. When shopping for your next batch of wood glue, keep an eye out for these options and elevate your woodworking experience to a more pleasant olfactory realm.

Follow the Instructions: A Recipe for Success

We have all been guilty of skimming instructions from time to time, but when it comes to carpenters glue, adhering to the manufacturer’s guidelines can make a world of difference. Properly applying and clamping the glued pieces during the drying process ensures a robust bond without resorting to excessive amounts of glue that amplify the odor issue. Take a moment to peruse those guidelines and save yourself from a headache-inducing glue overload.

The Art of Proper Storage

Proper storage practices can greatly minimize the strong odor of carpenters glue. Keep your adhesive tightly sealed in its original container and store it in a cool, dry location. This will impede the evaporation of VOCs, preserve the glue’s efficacy, and simultaneously reduce the intensity of that pungent aroma.

Limited Temperature Resistance

Carpenter’s glue, renowned for its formidable bonding strength, is a go-to adhesive in the woodworking community. However, it is crucial to recognize its limitations, particularly its limited temperature resistance. In this article, we will explore the drawbacks of carpenter’s glue when exposed to heat and discuss alternative adhesive options better suited for high-temperature environments.

The Heat Effect:

Carpenter’s glue is not engineered to withstand high temperatures, making it vulnerable in specific woodworking applications. When subjected to heat sources like direct sunlight or elevated room temperatures, the adhesive can soften and lose its grip. This compromises the integrity of bonded joints, potentially jeopardizing the structural stability of your woodworking projects.

Alternative Adhesives:

To overcome the shortcomings of carpenter’s glue, consider exploring alternative adhesives with superior heat resistance. Epoxy and polyurethane glues excel in high-temperature environments, making them ideal choices when heat exposure is a concern. These adhesives maintain their strength even when faced with scorching conditions, ensuring lasting bonds for your woodworking masterpieces.

Recommended Applications:

While carpenter’s glue may not fare well in hot environments, it still performs excellently within its recommended temperature range. For woodworking projects that will not encounter extreme heat, carpenter’s glue remains a reliable choice for achieving robust bonds. From cabinets to tables, this adhesive provides exceptional durability as long as temperature extremes are avoided.

Alternatives to Carpenters Glue

While carpenter’s glue is a popular choice, it does have limitations, particularly when it comes to heat resistance. In this article, we will delve into alternative options to carpenter’s glue that offer superior strength and stability in high-temperature environments.

Epoxy Adhesive:

Epoxy adhesive is the ultimate choice for bonding challenging materials like metal or plastic. It creates an incredibly strong bond and is resistant to water and chemicals. However, one must keep in mind that epoxy requires mixing two components before use and has a longer curing time compared to carpenter’s glue.

Polyurethane Adhesive:

Ideal for various materials such as wood, metal, and plastics, polyurethane adhesive offers versatility and high strength. It is also resistant to water and temperature changes. However, it tends to be more expensive than carpenter’s glue and may require clamping during the curing process.

Cyanoacrylate Adhesive (Super Glue):

For quick bonding with instant results, cyanoacrylate adhesive, commonly known as super glue, is a go-to option. It works well on non-porous surfaces and excels at small repairs or bonding delicate materials. Nevertheless, its bond may not be as strong as carpenter’s glue when used on porous materials like wood.

Contact Adhesive:

When laminating countertops or attaching veneer to furniture, contact adhesive proves ideal. This type of glue bonds through contact between two surfaces, providing flexibility and allowing for repositioning before setting. However, it can be messy to work with and emits strong fumes, necessitating proper ventilation during application.

Construction Adhesive:

For heavy-duty bonding of large surfaces or heavy materials like drywall, concrete, or plywood, construction adhesive is the optimal choice. It boasts a strong bond and is resistant to moisture and temperature changes. Nonetheless, its thick consistency and longer curing time may limit its suitability for smaller woodworking projects.

q8dfuMbTbek” >

Conclusion

Carpenters glue, while a popular choice for woodworking projects, does come with its fair share of disadvantages. One major drawback is its long drying time. Unlike other types of adhesives that bond quickly, carpenters glue can take several hours or even overnight to fully dry and set. This can be frustrating for those who are working on time-sensitive projects or need immediate results.

Another disadvantage of carpenters glue is its lack of flexibility once it has dried. Once the glue has hardened, it becomes rigid and unforgiving. This means that if any parts need to be adjusted or realigned after the glue has been applied, it can be difficult or even impossible to do so without damaging the workpiece.

Furthermore, carpenters glue is not suitable for all materials. It works well on porous surfaces like wood but may struggle to adhere to non-porous materials such as metal or plastic. This limits its versatility and makes it necessary to have multiple types of adhesives on hand for different projects.

In addition, carpenters glue is not waterproof. If exposed to moisture or high humidity, the bond created by the glue can weaken or break altogether. This makes it unsuitable for outdoor applications or areas prone to water exposure.

Lastly, carpenters glue can leave behind visible residue and require meticulous cleanup. If not removed properly, this residue can interfere with paint or finish application, resulting in an unprofessional-looking final product.

In conclusion, while carpenters glue is a popular choice for woodworking projects due to its strong bonding capabilities, it does have some significant disadvantages including long drying times, lack of flexibility once dried, limited suitability for certain materials, vulnerability to moisture damage, and potential residue issues.