Are you curious about whether white glue can withstand water once it dries? Perhaps you’re working on a project that requires a water-resistant adhesive or accidentally spilled liquid on your artwork that was glued with white glue. Whatever the reason, you want to know if white glue can hold up even when submerged in water.

White glue, also known as school glue, is a versatile PVA (polyvinyl acetate) adhesive that bonds porous surfaces such as paper, cardboard, fabric, and wood. It is popular in classrooms and crafting environments due to its ease of use and fast-drying capabilities. However, the question of its water resistance remains unanswered, leading to speculation and confusion among users.

Water-resistance is an essential factor for white glue because it determines its durability and longevity in various applications. In this blog post, we will explore different aspects of white glue and its water-resistance capabilities. We will delve into the chemistry behind PVA glue, what happens when it comes into contact with water, and how to ensure you choose the right type of white glue for your project. By the end of this post, you’ll be equipped with all the knowledge needed to determine if your favorite white glue is up to the task of weathering wet conditions. So stick around.

Types of White Glue

Contents

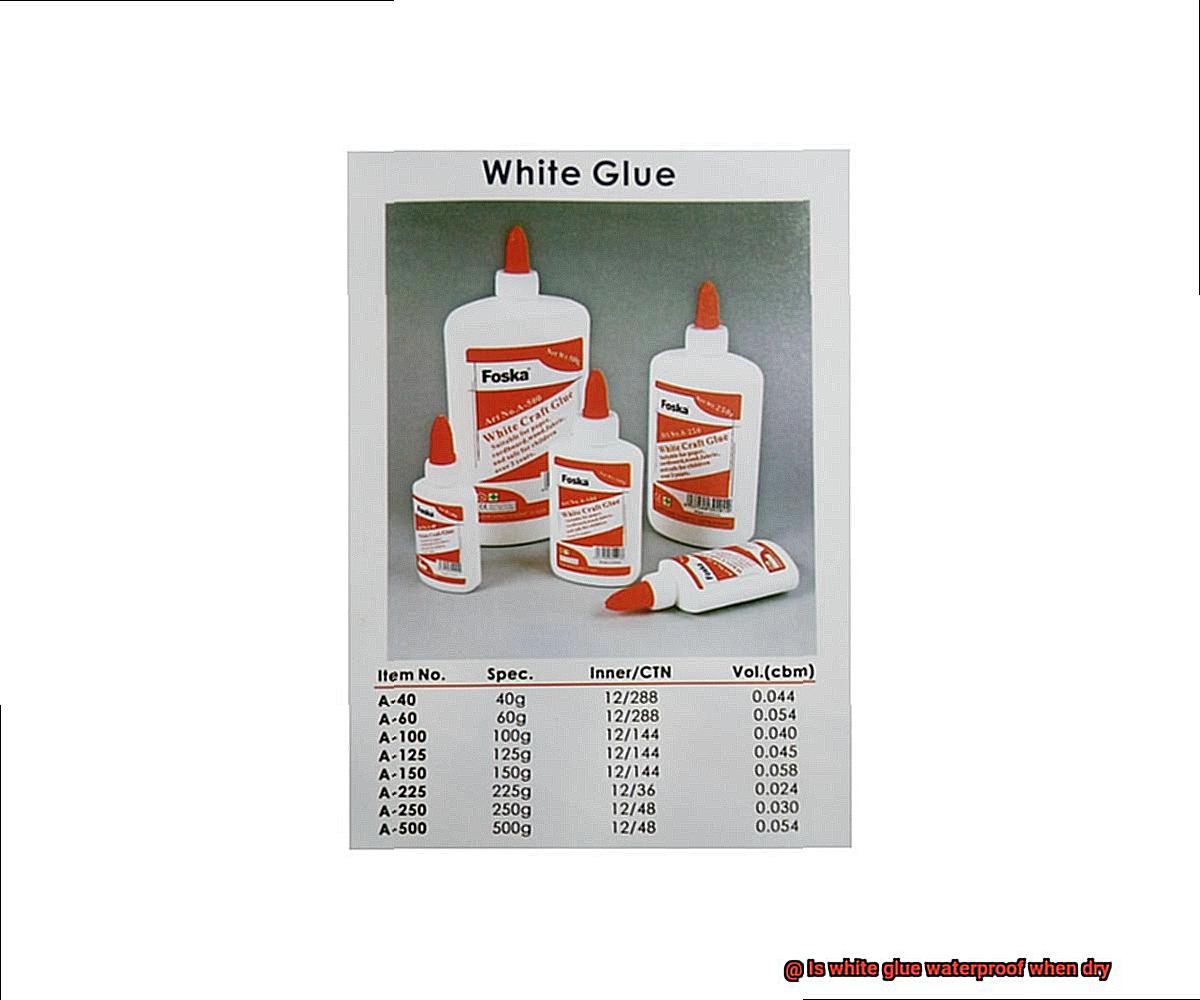

White glue, also known as school glue or PVA glue, is a versatile adhesive that can be used for a variety of projects. However, it’s important to choose the right type of white glue for your project based on its water resistance properties. There are two main types of white glue: polyvinyl acetate (PVA) and polyvinyl alcohol (PVOH).

PVA glue is the most commonly used type of white glue. It is made from a synthetic polymer that creates a strong bond between surfaces. When wet, it is water-soluble, which makes it easy to clean up with water. Once it dries, it becomes water-resistant but not completely waterproof. This means that if a surface glued with PVA glue gets wet, the bond may weaken or break down over time.

If your project requires higher water resistance, then PVOH glue may be the better option for you. It offers more protection against moisture and humidity and is commonly used in packaging and labeling applications. However, PVOH glue dries white and can be difficult to remove if it gets on clothing or other surfaces.

It’s important to note that PVA glue does offer some level of water resistance when dry.

So, if your project only requires minimal water resistance, then PVA glue should work well for you. Regardless of which type of white glue you choose, make sure to follow the manufacturer’s instructions carefully to ensure the strongest possible bond between surfaces.

Is White Glue Waterproof When Dry?

The answer is not cut and dry, as it depends on the type of white glue you are using.

Generally, most types of white glue, including school glue or PVA glue, are not waterproof when dry.

If the glued surface comes into contact with water, the bond may weaken or dissolve entirely. However, some brands of white glue claim to be water-resistant or even waterproof when dry.

These glues are often marketed as outdoor or wood glues and designed to withstand exposure to moisture and other environmental factors.

It’s essential to note that even with water-resistant or waterproof white glue, the bond’s strength may still be affected by prolonged exposure to water or other liquids. Therefore, it’s best to read the label and follow the manufacturer’s instructions for optimal results.

If your project requires a stronger and more durable bond in moist conditions, other types of adhesives may be better suited for your needs.

Marine adhesive or epoxy are specifically designed for use in wet or humid conditions, making them a better choice for projects exposed to water or other liquids regularly.

Factors That Determine Water Resistance

The answer isn’t as simple as a yes or no. Several factors come into play when determining the water resistance of white glue. As an expert in this area, I’ve researched and discovered the key factors that impact the overall effectiveness of white glue when exposed to water or moisture.

Firstly, the type of adhesive used in the glue is a significant factor in determining water resistance. Silicone-based adhesives are naturally more resistant to water than other types of adhesives, such as PVA glue commonly used in white glue.

Another factor that affects water resistance is the thickness and consistency of the glue when applied. Thicker and more viscous glues tend to form a stronger bond with surfaces, preventing water from seeping through.

In contrast, thinner and runnier glues may not provide adequate water resistance.

The surface being glued also plays a vital role in determining water resistance. Porous surfaces like wood or paper tend to absorb moisture over time, weakening the bond created by the glue.

On the other hand, non-porous surfaces like metal or plastic are less likely to absorb moisture and maintain a stronger bond even when exposed to water.

Temperature and humidity are additional factors that can impact the overall water resistance of white glue.

Higher temperatures and humidity levels can increase the likelihood of the glue breaking down or weakening over time, making it more susceptible to damage from exposure to water.

Therefore, it’s essential to store your white glue in a cool and dry place away from humidity.

Thickness of the Glue Layer

To create a waterproof seal with white glue, it’s crucial to understand the role that layer thickness plays in the bonding process.

In general, a thicker layer of glue is less likely to be waterproof than a thinner layer. When glue is applied, it takes time to dry completely. The thicker the layer of glue, the longer it takes to dry. During this drying time, the glue may absorb moisture from the environment, which can weaken its bond and compromise its waterproofing ability. This is why it’s best to apply a thin layer of glue and allow ample drying time before exposing it to water.

However, keep in mind that even a thin layer of white glue may not be fully waterproof when dry. The type and quality of the glue also play a critical role in determining its waterproofing ability. Some brands of white glue are specifically formulated to be waterproof, while others may not be as effective.

Moreover, the surface material being glued together can also impact the waterproofing ability of white glue. Some materials are naturally more porous and absorbent than others, which can make it more difficult for the glue to create a completely watertight seal.

Increasing Water Resistance with Multiple Layers

We have an effective solution for you – multiple layers of white glue. By using this technique, you can significantly increase the water resistance of your projects and protect them from moisture.

So, how does it work? Firstly, apply a thin layer of white glue to the surface of your project and allow it to dry completely. Once dry, add another layer of white glue on top of the first one and wait for it to dry again. Repeat this process until you have applied several layers of white glue to the project.

The idea behind this technique is that each layer of glue creates a stronger barrier between the water and the surface of your project. This creates a shield that works wonders in increasing its resistance to water and moisture.

However, keep in mind that using multiple layers of white glue may not make your project completely waterproof. If it will be exposed to a lot of water or moisture, you may need to use a specialized waterproofing product in addition to the multiple layers of white glue.

Alternatives to White Glue for Waterproof Bonding

There are several alternatives to white glue that can provide a waterproof bond.

One popular alternative is epoxy. This two-part adhesive is perfect for heavy-duty projects, creating a strong and durable bond that is also resistant to heat and chemicals. However, it’s important to note that epoxy can be difficult to work with and requires proper ventilation due to its strong odor.

If you need a fast-drying adhesive for small projects or repairs, cyanoacrylate glue (aka super glue) is an excellent option. It creates a strong and water-resistant bond on a variety of surfaces.

For those who prefer natural options, hide glue made from animal collagen has been used for centuries in woodworking and instrument making. Not only does it create a strong bond, but it can also be easily reversed with heat and moisture.

Lastly, polyurethane glue is another alternative for waterproof bonding. As it cures, it expands to fill any gaps in the surfaces being bonded. This glue is water-resistant and can be used on various surfaces such as wood, metal, and plastic.

zumPCy2wuKg” >

Conclusion

To wrap things up, the answer to whether white glue is waterproof when dry is not a simple “yes” or “no.” It all depends on the type of white glue you use and its water resistance capabilities. Ordinary school glue, also known as polyvinyl acetate (PVA) glue, does offer some level of water resistance but is not entirely waterproof. On the other hand, polyvinyl alcohol (PVOH) glue provides higher protection against moisture and humidity.

Several factors affect the water resistance of white glue, including the adhesive type, layer thickness and consistency, surface material being glued together, temperature, and humidity levels. For added water resistance in your projects, applying multiple layers of white glue can create a stronger barrier between water and your project’s surface.

However, if you require a stronger bond in damp conditions or regularly exposed to water, consider using marine adhesive or epoxy instead of white glue. Other alternatives for waterproof bonding include cyanoacrylate glue (also called superglue), hide glue made from animal collagen, and polyurethane glue.

In conclusion, understanding different types of adhesives’ properties will help you choose the right one for your project’s specific needs.