Forget about your everyday sticky situations – we’re diving deep into the captivating world of super glue. Have you ever wondered if there are different types of this adhesive wonder? Well, get ready to be amazed as we embark on a thrilling journey through various super glue types and their incredible applications.

Super glue, also known as cyanoacrylate adhesive, is a game-changer that has transformed industries ranging from crafting to automotive repairs. But did you know that there’s more than one type of this magical bonding solution? Knowing the different types available can help you find the perfect match for your specific needs, whether you’re a pro or just a casual DIY enthusiast.

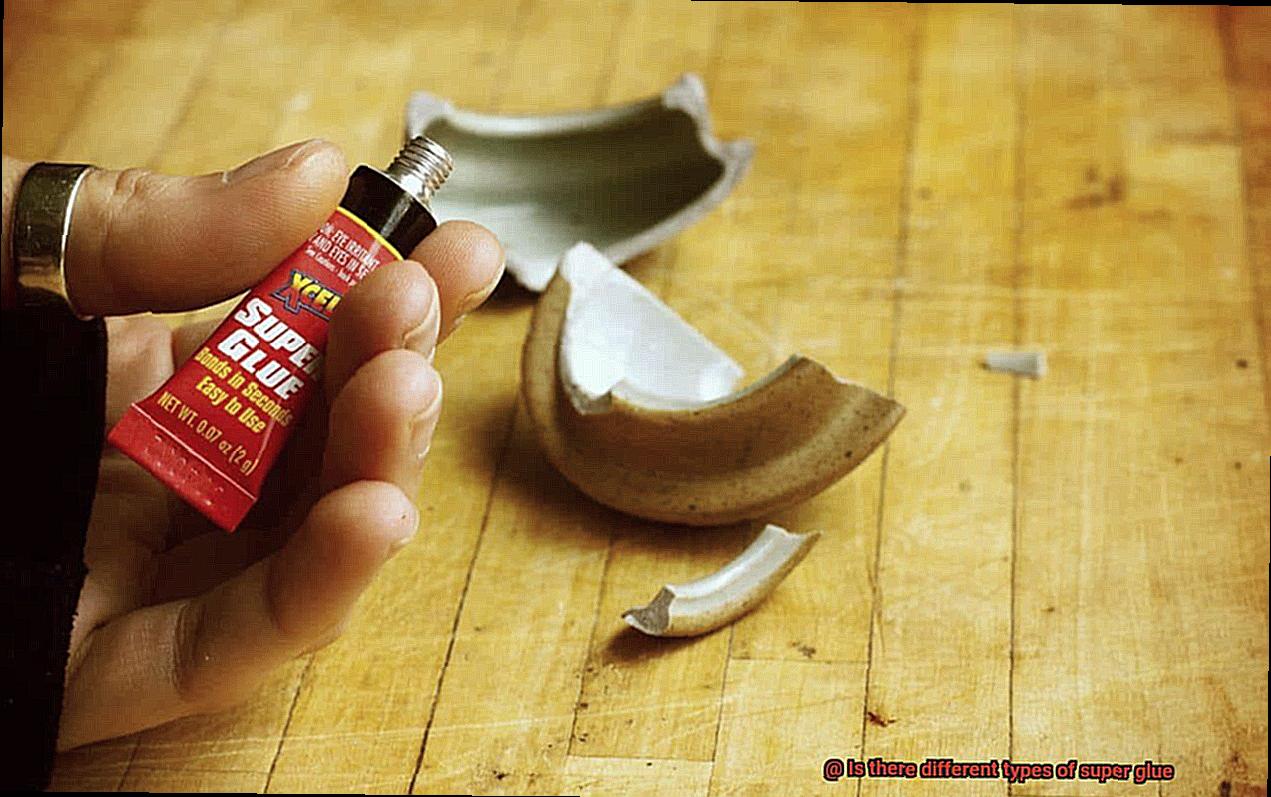

Let’s start with the classic: standard cyanoacrylate adhesive. This stuff is fast-drying and crazy strong, making it perfect for bonding non-porous materials like plastic, glass, metal, and ceramics. Whether you’re fixing a broken figurine or creating intricate jewelry pieces, this versatile adhesive is your go-to choice.

But wait, there’s more. If flexibility is what you need in an adhesive, look no further than flexible super glues. These bad boys provide reliable adhesion while still allowing for some movement or expansion after drying. Rubber, leather, and wood will stick together like best friends with this type of super glue.

Now things get hot – literally. High-temperature resistant super glues are designed to withstand extreme heat without breaking a sweat. Perfect for applications involving soldering or bonding in high-temperature environments (think electronics and automotive), these tough cookies won’t let you down when things get heated.

Precision is key when it comes to delicate tasks, which is why precise super glue exists. Also known as brush-on or gel adhesive, these babies have a thicker consistency and come with handy applicators like small brushes or nozzles. Say goodbye to messy mishaps and hello to controlled and precise bonding – perfect for assembling delicate electronics or fixing your favorite jewelry pieces.

But wait, there’s one more trick up super glue’s sleeve: dual-component super glues. These babies consist of two separate components, like epoxy resin and hardener, that create the strongest bond imaginable when mixed in the right ratio.

Heavy-duty industrial projects or demanding mechanical repairs? Dual-component super glue has got your back.

What is Super Glue?

Contents

- 1 What is Super Glue?

- 2 Different Types of Super Glues

- 3 Bonding Strength

- 4 Setting Time or Curing Time

- 4.1 The Role of Cyanoacrylate: The Superhero Ingredient

- 4.2 Types of Super Glue: From Everyday to Industrial Strength

- 4.3 Factors Influencing Setting Time: Unveiling the Hidden Forces

- 4.4 Environmental Conditions: The Weather Gods’ Influence

- 4.5 Importance of Following Instructions: The Path to Unbreakable Bonds

- 5 Viscosity or Thickness

- 6 Specialized Types of Super Glue

- 7 Compatibility with Materials

- 8 Additional Features and Additives

- 8.1 Accelerators: Speeding up the Bonding Process

- 8.2 Flexibility and Impact Resistance: Adding Rubber Particles

- 8.3 Gap-Filling Capabilities: Fillers and Thickeners

- 8.4 Specialized Formulations: Tailored for Specific Materials

- 8.5 Environmental Resistance: Super Glue vs. the Elements

- 8.6 Built-In Applicators: Precision and Efficiency

- 9 Conclusion

Super Glue, also known as cyanoacrylate adhesive, is a remarkable invention that has revolutionized the world of bonding. With its incredible strength and versatility, it has become a go-to adhesive for various repairs and projects. In this blog post, we will delve into the wonders of Super Glue, exploring its properties, applications, and tips for optimal usage.

Properties that Make Super Glue Super:

Super Glue’s claim to fame lies in its ability to form strong bonds quickly. In just seconds, this adhesive undergoes a miraculous transformation from a liquid into a solid state through a process called polymerization. The result is an unbreakable bond that defies expectation and solves problems with astonishing speed.

Versatile Applications:

Super Glue’s versatility knows no bounds. Its superpowers extend to bonding materials such as metal, plastic, rubber, ceramic, wood, and even skin. From repairing broken household items to crafting intricate DIY projects, this adhesive is a versatile tool that saves the day in countless scenarios.

Types of Super Glue:

- Liquid: The most common form of Super Glue, available in tubes or bottles, allows for precise application and effortless spreading. Its fluid nature ensures seamless bonding, creating a flawless finish.

- Gel: With a thicker consistency than its liquid counterparts, gel-based Super Glue is the perfect choice when precision is paramount. Its controlled flow prevents messy drips or runs during application.

- Colored: Beyond the realm of transparency lies colored Super Glue. This vibrant variety not only boasts exceptional bonding properties but also helps maintain aesthetics when working with specific materials.

- Gap-Filling: When perfection requires bridging small gaps or uneven surfaces during bonding, gap-filling Super Glue comes to the rescue. Its slightly thicker consistency fills imperfections seamlessly, leaving no room for doubt.

Tips for Successful Bonding:

- Prioritize cleanliness and dryness when preparing surfaces for Super Glue application. This ensures optimal adhesion and a bond that stands the test of time.

- Tread cautiously, for Super Glue sets in the blink of an eye. Precision and proper alignment are of utmost importance to achieve flawless results.

- For challenging materials like polyethylene or polypropylene, consider specialized adhesives tailored to their unique properties. These alternatives provide the perfect solution for bonding these stubborn substances.

- In cases where flexibility or resistance to high temperatures is crucial, exploring alternative bonding options might be necessary to meet your project’s demands.

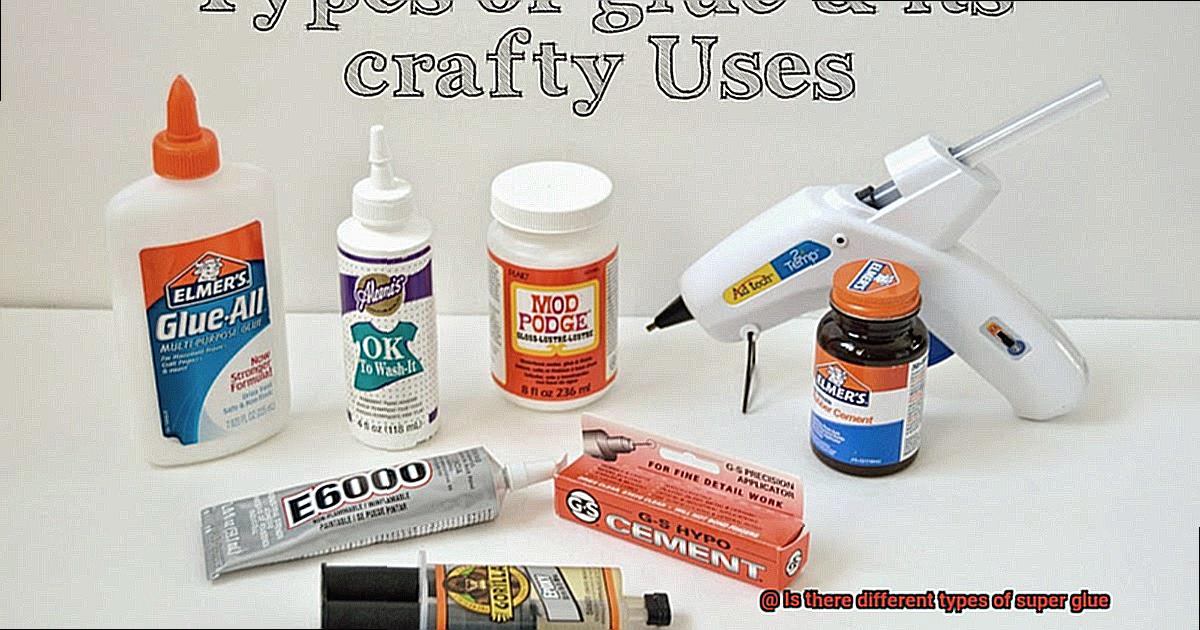

Different Types of Super Glues

Super glues are remarkable adhesives that form strong bonds between various materials, making them an indispensable tool for countless projects. However, not all super glues are created equal. In this in-depth analysis, we will delve into the diverse world of super glues, exploring their unique properties, specific applications, and how to choose the perfect type for your individual needs.

Cyanoacrylate Glue – The Celerity Maestro:

Among the most prevalent super glues is cyanoacrylate glue, renowned for its lightning-fast bonding prowess and exceptional adhesive properties.

Regardless of whether you are working with metal, plastic, rubber, or wood, cyanoacrylate glue effortlessly creates robust and enduring bonds in record time.

Epoxy Adhesive – The Resilient Warrior:

When it comes to tackling demanding tasks or withstanding high stress and temperature conditions, epoxy adhesive reigns supreme. This type of super glue consists of two components that must be skillfully mixed before application.

Once applied, it forms an incredibly robust and long-lasting bond, making it the ideal choice for repairs or bonding surfaces subjected to heavy strain.

Gel-Based Super Glues – No More Mess:

Bid farewell to the frustrations of dealing with messy liquid super glues that have a tendency to drip everywhere.

Gel-based super glues come to your rescue with their thicker consistency, ensuring they stay precisely where you need them without any running or dripping.

These glues offer excellent control during vertical applications and are particularly adept at filling gaps.

Specialty Super Glues – Tailored for Unique Challenges:

Super glues are not a one-size-fits-all solution. Some are specially formulated for specific materials or purposes. For instance, there are super glues specifically designed for bonding glass or ceramic surfaces, while others are tailored for flexible materials such as leather or fabric.

By selecting the appropriate specialty super glue, you can achieve optimal bonding results tailored to the unique challenges of your project.

Additional Features – Super Glues with Extraordinary Abilities:

Advancements in super glue technology have paved the way for glues with enhanced features. Some super glues are water-resistant, making them perfect for projects exposed to moisture.

Others possess heat-resistant properties, ensuring their bond remains intact even under high temperatures. These variations in properties cater to diverse applications and environments, allowing you to choose a super glue with extraordinary abilities suited to your specific needs.

Choosing the Right Super Glue:

To select the optimal super glue for your task, consider the materials you need to bond and the conditions it will encounter. Take time to read the labels and instructions on the packaging, as they provide valuable information about which type of super glue is best suited for your unique requirements.

Remember that not all super glues work equally well on all materials, so it’s prudent to conduct a small test on an inconspicuous area before applying it to the entire surface.

Bonding Strength

Not all super glues are created equal when it comes to bonding strength. In this blog post, we will explore the differences between regular and industrial-grade super glue and shed light on how their bonding strengths vary to help you choose the right product for your needs.

Regular Super Glue:

Regular super glue offers a strong bond that is suitable for most everyday applications. It can effectively bond materials such as metal, plastic, rubber, ceramics, and wood. This type of super glue is ideal for common household repairs or craft projects. However, it may not perform as well on porous surfaces or in extreme conditions.

Industrial-Grade Super Glue:

Industrial-grade super glue is specifically engineered to provide superior bonding strength and durability. It is designed to withstand harsh environments, extreme temperatures, and high levels of stress.

This type of super glue finds its applications in industries such as automotive, construction, aerospace, and electronics. It can bond a wide range of materials including metals, composites, glass, and some plastics that regular super glue may struggle to adhere to.

Chemical Composition and Additives:

The bonding strength of super glue is primarily determined by its chemical composition. The main ingredient in super glue is cyanoacrylate, which forms strong bonds through polymerization when it comes into contact with moisture.

The presence of additional additives like rubber or resin can enhance the bonding strength and flexibility of the glue. Rubberized super glues are perfect for materials that undergo frequent movements or vibrations as they provide greater flexibility and resistance to cracking.

Surface Preparation:

Proper surface preparation plays a crucial role in maximizing the bonding strength of super glue. Cleaning and roughening the surfaces to be bonded can significantly enhance the adhesive properties of the glue. Certain materials may require specific primers or activators to ensure optimal bonding strength.

Conclusion:

In summary, there are different types of super glue available, each offering varying levels of bonding strength. Regular super glue is suitable for most everyday applications, while industrial-grade super glue provides superior bonding strength for more demanding scenarios. Understanding the bonding strength of different super glue options is essential for selecting the right product that will effectively meet your bonding needs. So, unleash the power of the perfect super glue and confidently tackle your next project with ease.

Research:

Bonding strength is a crucial factor to consider when it comes to super glue. Different types of super glue offer varying levels of bonding strength, and understanding these variations can help users choose the right product for their specific needs.

Super glues generally fall into two categories based on their bonding strength: regular super glue and industrial-grade super glue. Regular super glue typically offers a strong bond that is suitable for most everyday applications. It is commonly used for bonding materials such as metal, plastic, rubber, ceramics, and wood. However, it may not be as effective on porous surfaces or in extreme conditions.

On the other hand, industrial-grade super glue is specifically designed to provide superior bonding strength and durability. It is formulated to withstand harsh environments, extreme temperatures, and high levels of stress. This type of super glue is commonly used in industries such as automotive, construction, aerospace, and electronics. Industrial-grade super glue can bond a wide range of materials including metals, composites, glass, and even some plastics that regular super glue may struggle to adhere to.

The bonding strength of super glue is determined by its chemical composition and the presence of additional additives. The primary ingredient in super glue is cyanoacrylate, which forms strong bonds through a process called polymerization. When cyanoacrylate comes into contact with moisture, it reacts and forms long chains of polymers that create a strong adhesive bond.

Setting Time or Curing Time

The mesmerizing secret lies in its setting time, also known as curing time. In this article, we will embark on a thrilling journey into the world of super glue, unraveling the mysteries behind its setting time and discovering the key factors that influence it. So, grab your glue and let’s dive deep into this enchanting realm.

The Role of Cyanoacrylate: The Superhero Ingredient

Cyanoacrylate is the superhero ingredient that reigns supreme in most super glues. When it comes into contact with moisture, it unleashes a chemical reaction that causes rapid polymerization, resulting in strong and resilient bonds. This extraordinary fast-setting property makes super glue an ideal choice for quick fixes and on-the-go projects.

Types of Super Glue: From Everyday to Industrial Strength

Super glue comes in various types, each with its own unique setting time. Regular super glue offers a robust bonding solution for everyday applications, while industrial-grade variations are designed to withstand extreme conditions in demanding industries. Depending on your project’s requirements, choose the right type of super glue that perfectly suits your needs.

Factors Influencing Setting Time: Unveiling the Hidden Forces

Surface Conditions: The nature of the surfaces being bonded plays a pivotal role in setting time. Porous or absorbent surfaces may require more time for the glue to fully set, as they tend to absorb some of the adhesive, slowing down the curing process. In contrast, non-porous surfaces like glass or metal facilitate faster setting times.

Environmental Conditions: The Weather Gods’ Influence

Temperature and humidity wield their power over setting time. Higher temperatures expedite the curing process, while colder temperatures slow it down. Low humidity levels may prolong setting time, while high humidity can accelerate it. Thus, the weather gods significantly impact the magical transformation of super glue.

Importance of Following Instructions: The Path to Unbreakable Bonds

To unlock the true potential of super glue, it is paramount to heed the manufacturer’s instructions regarding setting time. Applying gentle pressure to the bonded surfaces during this critical period enhances bond strength. Allow sufficient curing time before subjecting the bond to stress or load for maximum durability.

Viscosity or Thickness

Today, we’ll unravel the mysteries of viscosity and explore how it impacts the bonding process. Whether you’re a DIY enthusiast, a craft lover, or simply curious about glue, this article is for you.

The Viscosity Spectrum:

Super glue comes in a variety of viscosity levels—thin, medium, and thick. Let’s dive into each category and discover their unique characteristics:

Thin Super Glue:

- Flows like water, effortlessly seeping into every nook and cranny

- Perfect for porous materials and precise applications

- Sets quickly, forming an incredibly strong bond

Medium Super Glue:

- Strikes a delicate balance between flowability and gap-filling ability

- Versatile for bonding plastics, ceramics, wood, and metal

- Provides reliable strength and durability

Thick Super Glue:

- Boasts a gel-like consistency that refuses to budge

- Ideal for vertical or overhead applications and filling larger gaps

- Takes slightly longer to set but delivers exceptional strength once cured

Factors to Consider:

When selecting the right viscosity for your project, keep these factors in mind:

Material Compatibility:

Think about the materials you’re bonding. Thin super glue is perfect for delicate surfaces, while thick super glue thrives on non-porous ones.

Bonding Strength:

Need a quick and robust bond? Opt for thin super glue. For heavier objects or gap-filling magic, thick super glue is your go-to.

Some manufacturers offer variations within each viscosity category. This means you can pick your preferred consistency within the thin or thick options—customizing your experience to perfection.

Specialized Types of Super Glue

In this article, we will delve into the world of specialized super glue and explore how each type is used for specific purposes.

Gel Formula: The Hero of Precision and Control

The gel formula is like the superhero of super glues. With its thicker consistency, it is perfect for vertical applications or situations where precision is key. Imagine fixing a delicate figurine or attaching a hook to the wall without worrying about the glue dripping or sliding off. The gel formula gives you extra control and allows you to reposition your objects before it sets completely.

Flexible Super Glue: Bonding with Flexibility

Flexibility is essential when bonding materials like rubber, leather, or certain plastics. That’s where flexible super glue comes in. This specialized type provides a strong and durable bond while still allowing some give in the material. It’s great for fixing worn-out shoes, sealing cracks in hoses, or even securing automotive interior components.

Heat-Resistant Super Glue: Conquering High Temperatures

When things heat up, you need a super glue that can handle the heat. Heat-resistant super glue is specially formulated to withstand high temperatures without losing its adhesive properties. Whether you’re bonding metal components in engines, securing electrical wires, or fixing heat-sensitive materials like ceramics or glass, this type of super glue has got your back.

Wood and Fabric Super Glue: Penetrating Pores for Strong Bonds

Woodworking enthusiasts and crafters rejoice. There are specialized super glues designed specifically for porous materials like wood and fabric. These glues have additives that allow them to penetrate the pores of the material, creating a strong and lasting bond. So whether you’re repairing furniture or fixing tears in your favorite shirt, these super glues are here to save the day.

Quick-Setting Formulas: The Need for Speed

Sometimes, you need a super glue that works at lightning speed. Quick-setting formulas are perfect for those urgent repairs or time-sensitive projects. With these super glues, you can bond materials in just seconds and move on with your day.

Compatibility with Materials

Look no further than super glue, the fast-drying adhesive that can bond almost anything together. But before you grab that bottle of super glue, it’s important to understand compatibility with materials and how it can affect your projects.

Compatibility with materials refers to the ability of a specific adhesive, such as super glue, to form a strong bond with different types of materials. The chemical composition of the adhesive plays a crucial role in determining its compatibility. Different adhesives have variations in their chemical makeup, which can affect how well they bond with certain materials.

Super glue generally works well with non-porous materials like glass, metal, plastic, and ceramics. These smooth surfaces provide an ideal environment for the adhesive to form a strong bond. However, when it comes to porous materials like wood or fabric, super glue may not be as effective.

Wood surfaces, for example, need to be clean and free from any oils or finishes for the glue to work effectively. Some types of wood, such as oily tropical hardwoods or those with high moisture content, may not bond well with super glue. In such cases, alternative adhesives like epoxy or polyurethane-based adhesives may offer better bonding capabilities.

Fabrics, with their porous nature, can also be challenging to bond with super glue. The adhesive may not penetrate the fibers effectively, resulting in a weak bond. To ensure a strong bond on fabrics, it is advisable to use fabric-specific adhesives or sewing techniques.

Flexibility is another factor to consider when choosing an adhesive. Super glue can become brittle over time when exposed to temperature changes or vibrations. This makes it less suitable for materials that require flexibility in their bonds, such as rubber or flexible plastics. Specialized versions of super glue are available for these specific materials, offering better adhesion and flexibility compared to regular super glue.

To ensure compatibility with a specific material, it is crucial to read the manufacturer’s instructions or labeling on the adhesive packaging. They often provide guidelines on the types of materials the adhesive is suitable for and any precautions or special instructions for use.

In cases where super glue is not compatible with a particular material, alternative adhesives like epoxy or polyurethane-based adhesives can be considered. These adhesives offer better bonding capabilities with a wider range of materials, including porous ones.

Remember, even with compatible materials, proper surface preparation and application techniques are crucial for a strong bond. Clean the surfaces, apply the adhesive sparingly, and allow sufficient curing time for the best results.

Additional Features and Additives

In our previous discussion, we discovered the power of super glue and its limitations when it comes to certain materials. But fear not, for today we’re diving into the world of additional features and additives that can take your super glue game to the next level. Get ready to unleash the full potential of this superhero adhesive.

Accelerators: Speeding up the Bonding Process

Imagine having a time-sensitive project or dealing with materials that require quick bonding. That’s where accelerators come in handy. These chemicals turbocharge the curing process, allowing for faster bond formation. Say goodbye to waiting around and hello to instant adhesion.

Flexibility and Impact Resistance: Adding Rubber Particles

Sometimes, life gets a little shaky, and regular super glue might not be up to the task. Fear not, as some types of super glue contain rubber or elastomer particles that provide added flexibility and impact resistance. Whether you’re working on machinery or securing objects that endure frequent handling, this feature ensures your bond stays strong, even in dynamic environments.

Gap-Filling Capabilities: Fillers and Thickeners

Working with uneven or porous surfaces? No problem. Certain super glues incorporate fillers or thickeners to improve gap-filling capabilities. From glass fibers to powdered metals, these additives ensure a secure bond even on challenging surfaces. No more worrying about those pesky gaps ruining your project.

Specialized Formulations: Tailored for Specific Materials

Just like superheroes have different powers, super glues can be specially formulated for specific materials or conditions. Need to bond plastics, metals, ceramics, wood, or fabrics? Don’t fret. These specialized formulations take into account the unique properties of each material, ensuring optimal adhesion strength and durability.

Environmental Resistance: Super Glue vs. the Elements

For those demanding environments, traditional super glue might not cut it. But fear not, for there are super glues that offer resistance to environmental factors such as moisture, heat, or chemicals. Whether you’re facing high humidity or extreme temperatures, these adhesives will stay strong and reliable.

Built-In Applicators: Precision and Efficiency

Applying super glue with precision can sometimes feel like a daunting task. That’s why some types of super glue come with built-in applicators or dispensing systems. From fine needle-like tips for precise control to brush applicators for even spreading, these features ensure accurate application and a hassle-free experience.

_vR15u0vmms” >

Also Read: Super Glue – Glue Things

Conclusion

Yes, there are indeed different types of super glue available in the market. Super glue is not a one-size-fits-all adhesive solution. Manufacturers have developed various formulations to cater to different needs and materials. From quick-setting super glues that bond instantly to specialized formulas for specific surfaces like metal or plastic, there is a wide range of options to choose from.

Whether you’re working on a delicate craft project or repairing broken household items, having the right type of super glue can make all the difference. Some variants offer increased flexibility, perfect for applications that require some movement or bending. Others provide exceptional strength and durability, ideal for heavy-duty repairs or industrial use.

Furthermore, certain super glues are designed with specific features in mind. For example, there are gel-based formulas that don’t drip or run, making them easier to apply on vertical surfaces without creating a mess. Additionally, some super glues come with added properties like resistance to water or heat, enhancing their performance in challenging conditions.

It’s important to read the labels and product descriptions carefully when choosing a super glue. Understanding the specific characteristics and intended applications of each variant will help you select the most suitable option for your project. Whether it’s bonding wood, ceramics, fabric, or even glass, there is likely a specialized super glue available that will meet your requirements.

In conclusion, yes, there are different types of super glue tailored for various materials and purposes. By selecting the right variant based on your needs and understanding its unique features, you can ensure successful bonding and repairs every time.