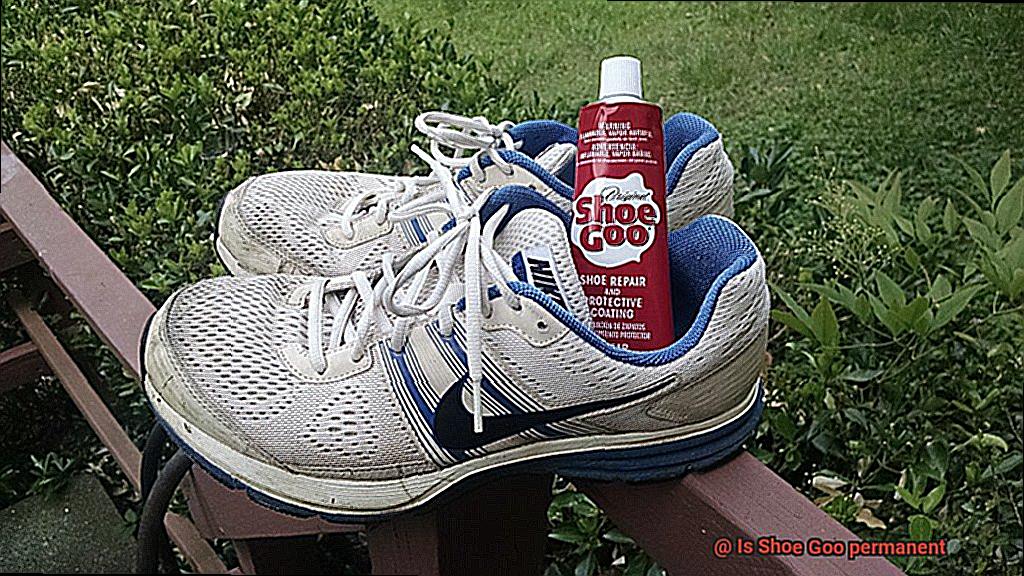

Picture this: you’re staring at your favorite pair of shoes, on the verge of giving up. It’s a heart-wrenching moment, isn’t it? But fear not, fellow shoe enthusiasts, because I’m about to introduce you to the magical wonder known as Shoe Goo.

Now, Shoe Goo might sound like an odd name, but trust me when I say it’s a lifesaver for shoe lovers everywhere. This adhesive masterpiece has gained a reputation for tackling even the toughest shoe disasters with ease.

From worn-out soles to cracked heels, Shoe Goo has become the ultimate solution for shoe repair.

So what sets Shoe Goo apart from other adhesives? Well, let me tell you – this stuff is pure magic. With its unique blend of flexibility, durability, and adhesive power, it’s bound to leave you in awe. Originally developed for skateboarders who put their shoes through extreme conditions, Shoe Goo has proven time and time again that it can handle anything.

Thanks to its strong yet flexible formula, Shoe Goo acts as a versatile adhesive that bonds effortlessly with various shoe materials like rubber, leather, fabric, and plastic. It’s a reliable fix that often outlasts the original damage. Whether your sneakers need a touch-up or your boots require some serious rehabilitation, Shoe Goo is here to save the day.

But here’s the burning question: Is Shoe Goo really permanent? Can it truly offer a long-lasting solution to our footwear problems? Well, stick around as we delve deeper into the nature of Shoe Goo – its permanence and potential limitations.

So if you’ve ever felt devastated by a damaged sole or torn upper, don’t despair. We’re about to uncover the incredible world of Shoe Goo and explore just how permanent its impact can be on our beloved footwear’s lifespan. Get ready to be amazed.

How Does Shoe Goo Work?

Contents

- 1 How Does Shoe Goo Work?

- 2 Factors That Affect The Longevity of Shoe Goo’s Bond

- 3 Benefits of Using Shoe Goo

- 4 Preparing the Surface Before Applying Shoe Goo

- 5 Other Uses for Shoe Goo

- 6 Is Shoe Goo Permanent?

- 7 Alternatives to Using Shoe Goo

- 8 Tips for Prolonging the Life of Your Shoes with Shoe Goo

- 9 Conclusion

We’ve all experienced the frustration of trying to salvage a beloved pair of shoes that have been worn down or damaged. Enter Shoe Goo, an extraordinary adhesive designed specifically for repairing and protecting shoes.

In this article, we will delve into the science behind Shoe Goo and explore how it creates a strong and durable bond with various shoe materials.

The Science behind Shoe Goo:

Shoe Goo is not your ordinary adhesive; it is a thermoplastic elastomer adhesive, which means it possesses a flexible and rubbery nature that can be melted and solidified. Its unique formulation is what sets it apart, allowing it to adhere to a wide range of shoe materials such as leather, rubber, fabric, and even plastic.

Bonding Process:

When applied to a damaged area on a shoe, Shoe Goo undergoes a chemical bonding process with the molecules of the shoe material. This results in an incredibly strong and durable connection that is resistant to heat, water, and most chemicals.

This makes Shoe Goo the perfect solution for repairing shoes subjected to harsh conditions or frequent wear and tear.

Key Features of Shoe Goo:

- Unyielding Tensile Strength: One of the main factors contributing to Shoe Goo’s effectiveness lies in its exceptional tensile strength. This means it can withstand pulling forces without breaking or losing its bond, providing long-lasting durability.

- Flexibility in Motion: Shoe Goo boasts high elongation properties, allowing it to stretch without compromising its bond. This makes it ideal for fixing areas of shoes that experience bending or flexing, such as soles or toe sides. It moves with your feet, ensuring your repaired shoes are comfortable and functional.

- Shield Against Wear and Tear: Walking or running often exposes shoes to rough surfaces that cause wear and tear over time. Shoe Goo forms a protective layer over damaged areas, preventing further deterioration and extending the lifespan of your shoes. It acts as a shield against abrasion, preserving the integrity of your footwear.

- Enduring Flexibility: Even after drying, Shoe Goo remains flexible. This flexibility allows the repaired area to move and bend naturally without cracking or breaking the bond. It ensures that your shoes retain their ability to flex and move with your feet during various activities, maintaining both comfort and functionality.

Factors That Affect The Longevity of Shoe Goo’s Bond

Shoe Goo is here to save the day. This remarkable adhesive possesses the power to breathe new life into your worn-out footwear. But how can you ensure that Shoe Goo’s bond endures for the long haul? Let’s delve into the factors that influence the durability of this remarkable glue.

First and foremost, surface preparation is key. Before applying Shoe Goo, it is vital to thoroughly clean the surface, banishing any trace of dirt, dust, or grease. This meticulous cleansing ensures a stronghold, resulting in a bond that will stand the test of time. Skipping this crucial step would be a grave mistake.

Next up, let’s consider the temperature and humidity during application. Extreme temperatures and high humidity levels can impact the curing process of Shoe Goo. To achieve optimal results, apply this adhesive at room temperature, with moderate humidity levels. It’s all about finding that Goldilocks zone – not too hot, not too cold.

Now, let’s discuss application technique. Follow the manufacturer’s instructions diligently. Apply an even layer of Shoe Goo without excessive squeezing or spreading. This judicious approach guarantees proper coverage and bonding. Remember, less is more in this case – no need to go overboard.

Patience truly is a virtue when it comes to Shoe Goo. After applying the adhesive, allow ample time for it to cure properly. Waiting at least 24 hours before subjecting the repaired item to any stress or activity will guarantee a bond that is both sturdy and enduring. Good things do come to those who wait.

The type of material being repaired also plays a role in Shoe Goo’s longevity. While this versatile adhesive works wonders on materials like rubber, leather, vinyl, and canvas, its effectiveness may vary on certain plastics or slick surfaces. Consider compatibility between Shoe Goo and the material you’re repairing for optimal results.

Last but certainly not least, consider the stress and wear that the bonded area will endure. Continuous flexing, stretching, abrasive surfaces, and harsh chemicals can weaken the bond over time. Carefully assess the intended use of the repaired item to determine if Shoe Goo is indeed the right choice for your specific application.

Benefits of Using Shoe Goo

Shoe Goo is here to save the day. This incredible adhesive is designed specifically for repairing and protecting shoes, and it comes with a host of benefits that will leave you wondering how you ever lived without it.

Extends the lifespan of your shoes:

Investing in high-quality shoes is a smart move, but over time, wear and tear can take its toll. Instead of tossing them aside, use Shoe Goo to repair them. This adhesive has strong bonding properties, allowing you to fix damaged soles or torn uppers. With Shoe Goo, you can breathe new life into your beloved shoes and extend their lifespan.

Versatility for all types of shoes:

Whether you’re a sneakerhead or a fashionista, Shoe Goo is suitable for all types of shoes. From sneakers to heels, boots to sports equipment like cleats or skate shoes, this adhesive can be applied to any material – rubber, leather, vinyl, canvas, fabric, you name it. Say goodbye to worrying about finding the right glue for each type of shoe you own.

Preventive measures for shoe preservation:

Why wait until your shoes are damaged to use Shoe Goo? Apply a thin layer on areas prone to wear and tear – like the edges of the soles or the toe caps. This proactive approach reinforces those areas and prevents them from deteriorating quickly. By using Shoe Goo as a preventive measure, you’ll significantly prolong the life of your shoes.

Water and moisture protection:

Don’t let rain or snow ruin your shoes. Shoe Goo acts as a protective barrier against water and moisture. Its waterproof properties keep your feet dry, making it perfect for outdoor activities or those living in areas with unpredictable weather. No more soggy shoes.

Invisible repairs:

Say goodbye to unsightly repairs. Shoe Goo dries clear, ensuring that your repaired shoes look as good as new. Once it has cured completely, it becomes nearly invisible on most materials, giving your shoes a seamless finish.

Easy and convenient application:

Using Shoe Goo is a breeze. Its tube packaging comes with an applicator tip, allowing for precise and controlled application. The adhesive is thick, so it won’t drip or run off while you’re repairing your shoes. Plus, it dries relatively quickly, usually within 24 hours, so you won’t have to wait long before stepping out in your freshly repaired shoes.

Preparing the Surface Before Applying Shoe Goo

Before you unleash the power of Shoe Goo to revive your worn-out shoes, it’s crucial to properly prepare the surface. This step is essential for ensuring maximum adhesion and long-lasting results. Here’s a step-by-step guide to prepping your shoes before applying Shoe Goo:

- Clean it up: Start by giving your shoes a good scrub with mild soap or detergent and warm water. Remove any dirt, dust, or oils that may be lurking on the surface. Make sure to dry them completely to avoid moisture interference.

- Trim away the loose bits: If there are any loose or peeling areas on the shoe or sole, use scissors or a sharp knife to trim them away. This creates a smooth surface for the Shoe Goo to adhere to.

- Roughen it up: Lightly sand the area you’ll be applying Shoe Goo to using fine-grit sandpaper. Sand in a back-and-forth motion to create a textured surface that improves adhesion.

- Clean again: After sanding, give your shoes another quick clean to remove any lingering dust or debris from the sanding process. A clean canvas is essential for a perfect Shoe Goo masterpiece.

- Tape it off: To prevent spills or smudges, use masking tape or painter’s tape to protect any areas you don’t want Shoe Goo on. This helps create clean edges and maintains a sleek appearance.

- Prime time: For enhanced adhesion, apply a thin layer of solvent-based primer or acetone to the surface, especially for materials like rubber or vinyl. Allow it to dry completely before moving on.

- Apply the magic: Follow the instructions on the packaging and apply an even and thorough layer of Shoe Goo over the desired area. Be generous but not excessive – just the right amount of magic will do.

- Let it cure: Step away and let the Shoe Goo dry for at least 24 hours before using your shoes again. This ensures that the adhesive has fully cured and provides a strong, long-lasting bond.

Other Uses for Shoe Goo

Step into a world of possibilities with Shoe Goo – the adhesive that goes beyond fixing shoes. Prepare to be amazed as we explore the diverse and unexpected uses of this magical glue.

From reinforcing footwear to DIY projects and artsy crafts, Shoe Goo is here to revolutionize your repair game. Join us on this journey of discovery.

Footwear Reinforcement:

Shoe Goo’s remarkable abilities extend beyond sneakers. Boots, sandals, and rubber rain boots can all benefit from the strong and waterproof seal provided by Shoe Goo. Embrace longevity and save money by giving your favorite shoes a new lease on life.

Repairing and Reinforcing Other Items:

Prepare to be blown away by the versatility of Shoe Goo. It’s not just for footwear; it can mend tears in backpacks, handbags, or even fabric upholstery. With its flexibility and ability to bond with various materials, it has become an indispensable tool in the DIY arsenal.

DIY Projects:

Calling all adventurers. Whether you’re camping, hiking, or exploring the great outdoors, Shoe Goo is your secret weapon. Seal tents and sleeping bags to keep them waterproof, or mend cracks in plastic containers and tools. With Shoe Goo, your equipment will be ready for any adventure.

Custom Grips for Sports Equipment:

Elevate your game on the tennis court or golf course with Shoe Goo. Apply layers of this magic adhesive to the handles of your sports equipment and experience improved grip and control like never before. Let Shoe Goo become your secret weapon to achieve greatness.

Arts and Crafts Enthusiasts:

Unleash your creativity with Shoe Goo’s clear formula. Attach gems, beads, or embellishments to glass, metal, or ceramics effortlessly. Watch as your imagination comes to life with the help of this versatile adhesive.

Protective Coating for High-Wear Items:

Bid farewell to worn-out skateboard wheels or damaged luggage. Shoe Goo can be your savior. Apply it as a protective coating on high-wear areas to create a tough barrier against abrasion and extend the life of these cherished possessions.

Unconventional Uses:

The resourcefulness of Shoe Goo enthusiasts knows no bounds. Some have used it to repair small cracks in car bumpers or seal leaks in inflatable objects like air mattresses and pool toys. While not recommended by the manufacturer, it’s fascinating to witness the inventive spirit of Shoe Goo users.

Is Shoe Goo Permanent?

Look no further than Shoe Goo. This popular adhesive is renowned for its strong bonding properties and ability to create a durable bond between various materials. But is Shoe Goo truly permanent? Let’s delve into the factors that can influence its longevity.

- Material matters: Shoe Goo is a formidable adhesive for rubber, leather, vinyl, canvas, and other common shoe materials. However, certain plastics or synthetic materials may not yield the same effective results. To ensure success, test a small area first when repairing these materials.

- Master the application: The key to maximizing Shoe Goo’s permanence lies in proper application. Thoroughly clean and prepare the surface before applying a thin layer of Shoe Goo evenly. Don’t rush the drying time either – it’s crucial for a strong and secure bond.

- Conditions can compromise: While Shoe Goo boasts a robust bond, extreme temperatures, excessive moisture, or heavy stress on the repaired area can eventually weaken it. If your shoes face harsh conditions or intense physical activities regularly, the permanence of Shoe Goo may be compromised.

- Damage done right: For everyday wear and tear repairs like shoe soles and heels, Shoe Goo is an excellent choice. However, more complex or extensive damage may require professional assistance or even replacing the shoes altogether.

Alternatives to Using Shoe Goo

As shoe lovers, we all dread the moment our favorite pair starts showing signs of wear and tear. But fret not. There are alternative solutions to Shoe Goo that can save your beloved footwear and give them new life.

Join me on an exciting journey as we delve into the world of shoe repair alternatives and find the perfect option for your heroic needs.

Epoxy Resin: The Ultimate Powerhouse

When it comes to mending soles and heavy-duty damage, epoxy resin emerges as a formidable contender. This two-part adhesive creates an unbreakable bond that withstands the toughest challenges. From leather to rubber and even fabric, epoxy resin conquers all materials with ease.

Super Glue: The Speedy Sidekick

When time is of the essence, super glue comes to the rescue as the trusty sidekick of shoe repair. Its fast-drying formula forms a strong bond between surfaces, making it perfect for quick fixes like detached soles or loose stitching. Just bear in mind that it may not offer the same long-term durability as Shoe Goo.

Shoe Repair Adhesives: Tailor-Made Solutions

For those seeking specialized solutions, look no further than purpose-built shoe repair adhesives. These products offer excellent bonding strength and flexibility, catering to different shoe materials. Whether you prefer liquid adhesives, adhesive films, or patches, these tailor-made options have got you covered.

Rubber Cement: The Crafty Hero

Don’t underestimate the humble rubber cement. While commonly associated with crafts, it also works wonders for shoe repairs. Its flexible bond and compatibility with rubber, leather, and fabric make it ideal for fixing small tears or holes.

Stitching: A Heroic Tradition

Sometimes, the old ways are still the best. For loose stitching on fabric or canvas shoes, a needle and thread can work wonders. Though not suitable for all repairs, stitching remains a reliable alternative when Shoe Goo or adhesives aren’t the best fit.

Tips for Prolonging the Life of Your Shoes with Shoe Goo

With Shoe Goo, a versatile adhesive designed specifically for shoe repair, you can breathe new life into your favorite footwear.

In this article, we will explore valuable tips and techniques to maximize the effectiveness of Shoe Goo, ensuring that your shoes last longer and look better than ever.

Act Swiftly for Longevity:

The key to prolonging the life of your shoes with Shoe Goo is to address wear and damage early. As soon as you notice signs of wear or tear, take action. By acting swiftly, you can prevent further deterioration and extend the lifespan of your beloved shoes.

Cleanliness is Next to Longevity:

Before applying Shoe Goo, ensure the repair area is clean and free from debris. Gently cleanse the damaged area with a mild soap or detergent, removing any dirt or grime that may interfere with adhesion. Once cleaned, dry the area thoroughly for optimal bonding.

Smooth Application for Strong Results:

When applying Shoe Goo, precision is paramount. Use a small brush or applicator to spread the adhesive evenly and smoothly over the damaged area. Avoid excessive application, as it can result in a messy and uneven finish. Remember, less is more when it comes to Shoe Goo.

Patience for Perfect Repair:

After applying Shoe Goo, exercise patience and allow ample drying time. Although it typically takes about 24 hours for Shoe Goo to dry completely, consult the product instructions for precise drying times. Rushing this stage compromises the adhesion and durability of your shoe repairs.

Care for Your Repaired Shoes:

To maximize the lifespan of your repaired shoes, proper care is essential. Shield them from extreme temperatures, excessive moisture, and abrasive surfaces. Regularly clean your shoes with a soft brush or cloth to remove dirt and stains, preventing further damage and ensuring they always look their best.

5RGDJoE-cFs” >

Conclusion

Shoe Goo, the magical adhesive that promises to fix your worn-out soles, is a topic of much debate. People want to know if it’s truly permanent or just a temporary fix. Well, let me tell you, Shoe Goo means business. Once applied, this wonder substance forms an unbreakable bond with your shoes that can withstand the test of time.

No longer will you have to worry about your favorite pair falling apart at the seams. Shoe Goo is here to save the day and make sure your footwear stays intact for as long as you need them. It’s like having a personal shoe doctor in a tube.

But don’t mistake its strength for rigidity. Shoe Goo remains flexible even after drying, allowing your shoes to move and bend naturally without any cracks or breaks. It’s like giving your beloved sneakers an extra layer of armor.

And let’s not forget about its versatility. Shoe Goo doesn’t discriminate when it comes to materials. Whether you’re dealing with rubber, leather, canvas, or even plastic, this adhesive can handle it all. Say goodbye to multiple adhesives cluttering up your shoe repair kit – Shoe Goo does it all.

Now, I know what you’re thinking – nothing lasts forever. And while that may be true for most things in life, Shoe Goo comes pretty close. It’s designed to withstand the wear and tear of everyday use, making it a reliable choice for those who want their shoe repairs to last.

So next time you find yourself in need of a quick fix for your worn-out kicks, reach for the trusty tube of Shoe Goo. With its permanent hold and durability, it’s sure to keep your shoes looking fresh and ready for action.