Step into the ring, folks. In one corner, we have Liquid Nails, the jack-of-all-trades construction adhesive that claims to stick anything to everything. And in the other corner, we have wood glue, the tried-and-true champion of bonding wooden surfaces. It’s a clash of titans in the world of DIY projects and construction. But let’s cut to the chase – is Liquid Nails really as strong as wood glue?

Picture this: you’re knee-deep in a project, meticulously gluing wooden planks together for a rock-solid bookshelf. Suddenly, you’re hit with doubt – which adhesive should you trust? Will one outperform the other? Fear not, my friend, because we’re about to dive deep into the realm of these mighty contenders.

Liquid Nails prides itself on being a versatile adhesive that can tackle any material, including wood. On the flip side, wood glue has earned its stripes as an exceptional bonding agent exclusively for wood surfaces. So where do we begin? Let’s break it down and explore all the nitty-gritty details.

First up, we’ll dissect each adhesive’s unique characteristics. From their application techniques and drying times to their adaptability for specific projects, we’ll compare these sticky solutions so you can make an informed choice.

But wait – strength matters too. We’ll scrutinize how well both Liquid Nails and wood glue hold up under pressure. Think resistance against heat, moisture, and external forces like a champ furniture assembly or robust cabinetry requires. We’ll leave no stone unturned in this epic face-off.

In this blog series extravaganza, consider us your adhesive sensei guiding you towards enlightenment on choosing the right glue for your woodworking endeavors. Buckle up because things are about to get sticky. Together, we’ll unravel the mystery and answer the burning question: is Liquid Nails truly on par with the mighty wood glue?

Stay tuned for our upcoming posts as we dissect each aspect in intricate detail, equipping you with the knowledge to make an adhesive decision that sticks. It’s time to settle this once and for all.

Strength Comparison Between Liquid Nails and Wood Glue

Contents

- 1 Strength Comparison Between Liquid Nails and Wood Glue

- 2 Factors Affecting the Bonding Strength of Adhesives

- 3 Advantages of Using Liquid Nails

- 4 Advantages of Using Wood Glue

- 5 Which One Should You Choose for Your Project?

- 6 Tips for Applying Adhesives Properly

- 6.1 Surface Preparation:

- 6.2 Temperature and Humidity:

- 6.3 Adhesive Selection:

- 6.4 Application Technique:

- 6.5 Clamping or Pressure:

- 6.6 Sometimes, a little pressure goes a long way in strengthening bonds. Wood glues, in particular, thrive when subjected to pressure during curing. Use clamps or weights to hold the bonded surfaces together securely as the adhesive works its magic. This step ensures that the adhesive thoroughly penetrates the materials, creating a steadfast connection. Drying and Curing Time:

- 6.7 Follow Safety Precautions:

- 7 Safety Precautions When Working with Adhesives

- 8 Conclusion

In the dynamic realms of woodworking and construction, the adhesive you choose can make or break your project. Among the myriad of options available, Liquid Nails and wood glue stand tall as popular choices. Today, we embark on a captivating journey through the strength comparison between these two adhesive giants, exploring their unique qualities and applications.

Liquid Nails: The Unyielding Adhesive Chameleon

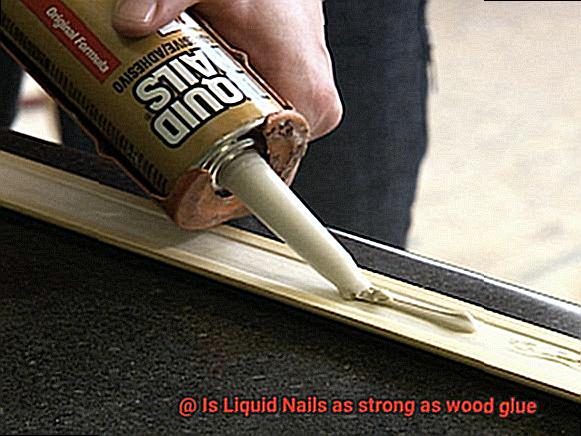

Liquid Nails, a revered brand of construction adhesive, boasts unparalleled bonding capabilities. Crafted for heavy-duty applications, this adhesive marvel can unite an array of materials, from wood and metal to concrete and beyond. Its unwavering strength endures even in the face of extreme environmental conditions. Yet, it is essential to note that the strength of Liquid Nails can vary based on the specific product and usage scenario.

Wood Glue: The Powerhouse Behind Woodworking

Designed exclusively for woodworking projects, wood glue reveals its true power when binding wooden surfaces together. It effortlessly permeates the very fibers of wood, establishing a bond that surpasses the inherent strength of the material itself. Though it may lack Liquid Nails’ versatility in adhering non-wood materials, wood glue reigns supreme in delivering exceptional bond strength for wood-based creations.

Strength Comparison:

When it comes to joining wood surfaces, wood glue emerges as the undisputed champion in terms of raw strength. Its specialized formulation enables it to forge unbreakable bonds within wood structures. Conversely, Liquid Nails may not exhibit the same level of tenacity when binding wooden surfaces together. However, Liquid Nails compensates with its adaptability, excelling in multifarious material adhesion and capacity to bear heavy loads.

Choosing the Adequate Adhesive:

Selecting the ideal adhesive hinges on your project’s specific demands. For those predominantly working with wood and seeking unrivaled bond strength, opting for high-quality wood glue is the clear path to success. Its ability to penetrate deep into wood fibers and create robust bonds makes it an unrivaled ally in woodworking endeavors. Conversely, if versatility and rapid setting times for various materials or heavy-duty applications are paramount, Liquid Nails emerges as the prime contender.

Factors Affecting the Bonding Strength of Adhesives

Today, we’re diving deep into the fascinating realm of bonding strength. As an expert in the field, I’m here to unravel the mysteries surrounding the factors that affect the power of adhesives. So, grab your favorite cup of coffee and join me on this enlightening journey.

Adhesive Type: The Backbone of Bonding

Let’s start with the foundation – adhesive type. Different adhesives possess varying bonding strengths. Liquid Nails and wood glue are both commonly used adhesives, but their compositions and properties set them apart. Whether you need to bond wood, metal, or concrete, Liquid Nails is your go-to construction adhesive. For wood surfaces, trust the specially formulated wood glue. Remember, your choice of adhesive greatly influences the strength of your bond.

Surface Preparation: The Key to Sturdy Connections

Temperature and Humidity: The Curing Dance

Ah, temperature and humidity – the dynamic duo that can make or break your bond. Adhesives have specific requirements when it comes to these factors. Generally, higher temperatures and lower humidity levels speed up curing and lead to stronger bonds. However, extreme conditions can throw a wrench into your plans. Be mindful of temperature fluctuations and humidity levels to ensure optimal performance.

Application Technique: The Art of Bonding

Applying adhesive is an art form in itself. The way you apply it can directly impact the strength of your bond. Remember to spread your adhesive evenly and in the right amount, ensuring full coverage and contact between the adhesive and surfaces. Don’t forget about open time – the precious window during which your adhesive remains workable. And let’s not overlook clamping pressure – another crucial factor for achieving optimal bonding strength.

Advantages of Using Liquid Nails

Today, we’re diving deep into the world of construction adhesives to explore the remarkable advantages of using Liquid Nails. This adhesive powerhouse has been making waves in the bonding world, and it’s time to uncover why it’s a go-to choice for professionals and DIY enthusiasts alike. So grab your favorite cup of coffee (or tea if that’s your thing), and let’s embark on this exciting journey.

First and foremost, let’s talk about strength. Liquid Nails surpasses traditional wood glue in terms of bonding power. Its superior strength ensures a durable bond that can withstand heavy loads and high levels of stress. Whether you’re securing a hefty piece of wood or bonding metal to concrete, Liquid Nails has got your back, providing unparalleled strength for your projects.

Now, here’s where things get interesting. Unlike wood glue, which demands clamping to ensure proper adhesion, Liquid Nails can be applied directly to the surface without the need for extra tools or equipment. The convenience factor is off the charts. Simply squeeze that adhesive onto the desired surface and press those materials together. It’s as easy as pie.

But wait, there’s more. Liquid Nails is not only strong but also incredibly versatile. It thrives in both indoor and outdoor projects, boasting resistance against moisture, heat, and cold temperatures. No matter the task at hand – be it construction, remodeling, or repairs – Liquid Nails rises to the occasion, undeterred by Mother Nature’s whims.

Now, let’s talk about time. We all know how precious time is when it comes to projects. Well, brace yourself for good news. Liquid Nails offers a lightning-fast curing time compared to wood glue. While wood glue may take hours or even overnight to fully cure, Liquid Nails dries in a fraction of that time. Say goodbye to waiting around and hello to finishing your project in record time. Now that’s efficiency.

But hold on tight, because there’s more to discover. Liquid Nails comes in a range of specialized formulations, each tailored for specific applications. Whether you’re bonding mirrors, drywall, or subflooring, there’s a Liquid Nails product designed precisely for your needs. No more guesswork involved – just grab the right formulation and watch the magic happen.

Advantages of Using Wood Glue

In the world of woodworking, where every joint matters, finding the perfect adhesive is a quest for perfection. Amidst a sea of options, wood glue emerges as a shining star, offering a multitude of advantages that elevate it to the pinnacle of adhesives. As an expert in the craft, I am thrilled to present to you the remarkable advantages that come with using wood glue.

Get ready to be captivated by its unparalleled strength, versatility, ease of use, sandability, water resistance, non-toxic formulas, and cost-effectiveness. Let’s embark on a journey into the world of wood glue and discover why it is an indispensable companion for woodworkers and DIY enthusiasts.

Strong Bond:

Prepare to witness the magic unfold as wood glue creates an unyielding bond between wooden surfaces. With its unique formulation designed to penetrate deep into the fibers of the wood, it weaves a tight and secure connection that defies gravity. Be it crafting exquisite furniture pieces, constructing intricate cabinetry, or engaging in challenging carpentry projects, wood glue stands strong as your steadfast ally.

Versatility:

Wood glue transcends boundaries and embraces an array of wood types. From the gentle embrace of softwood to the firm grip on hardwood, its versatility knows no bounds. MDF (medium-density fiberboard), plywood, particleboard, and even veneers all succumb to the charm of wood glue. Embrace its flexibility and let your creativity soar across diverse woodworking projects.

Easy Application:

Leave behind the days of adhesive-related woes as wood glue sweeps in with its seamless application process. Whether it flows like liquid poetry, clings like a gel masterpiece, or spreads like a paste dream, wood glue dances effortlessly upon every surface. Its smooth consistency ensures an even distribution, leaving no room for imperfection. And fear not, for time is on your side with wood glue’s extended open time, granting you the freedom to adjust and position your pieces before the glue sets.

Sandability:

Witness the transformation as wood glue dries and cures into a flawless masterpiece. Through the power of sanding, it molds itself to perfection, creating a surface so smooth it beckons the touch of an artist. When perfection demands a polished or painted finish, wood glue rises to the occasion, allowing you to craft seamless wonders that mesmerize the beholder.

Which One Should You Choose for Your Project?

Selecting the perfect adhesive for your project is a critical decision. In this comprehensive guide, we’ll delve into the differences between two popular options: Liquid Nails and wood glue. From the materials they bond to their drying time, ease of use, and cost, we’ll explore all the factors you need to consider. Get ready to make an informed choice.

Materials:

Let’s start with the materials you’ll be working with. If your project involves heavyweights like concrete, metal, or stone, Liquid Nails is your ultimate adhesive hero. Its extraordinary strength and durability can withstand the toughest conditions. However, if your focus is primarily on wood and wood-based materials, wood glue is custom-made for this purpose.

Drying Time:

Time is precious when it comes to completing your project. Liquid Nails takes its time to dry compared to wood glue. This can be advantageous if you require some wiggle room for adjustments or repositioning before the adhesive sets. Conversely, wood glue dries relatively quickly, allowing you to power through without significant delays.

Ease of Use:

Nobody wants a complicated adhesive application process that hinders progress. Liquid Nails often comes in a tube or cartridge, necessitating the use of a caulking gun for precise application. This may pose a slight challenge for some users. In contrast, wood glue typically comes in a user-friendly squeeze bottle or container with a brush applicator, offering easy application and control. It’s especially handy for smaller projects or intricate details.

Cost:

Budget considerations are always crucial. Wood glue tends to be more pocket-friendly than Liquid Nails, which can be a game-changer if you’re working on a tight budget or tackling a large-scale project requiring substantial adhesive amounts. However, keep in mind that the bond’s strength and durability may vary between these two options.

Selecting the right adhesive for your project warrants careful evaluation of various factors. If you’re working with heavy materials or demanding extreme bonding strength, Liquid Nails is the clear winner.

Conversely, if wood is your primary focus and you desire a quick-drying, cost-effective solution, wood glue should be your top pick. Ultimately, it’s crucial to assess your project’s specific requirements and make an informed decision that aligns with your needs.

Tips for Applying Adhesives Properly

Achieving strong and durable bonds in woodworking and construction projects hinges on more than just the adhesive’s strength. It is equally important to follow the manufacturer’s instructions and safety precautions.

In this article, we will explore seven essential tips that will elevate your adhesive application skills and ensure optimal results.

Surface Preparation:

A solid bond starts with pristine surfaces. Cleanliness is paramount. To rid surfaces of dirt, dust, and grease, employ the power of a mild detergent or solvent. By taking the time to prepare the surfaces properly, you lay the groundwork for a bond that will stand the test of time.

Temperature and Humidity:

Don’t let temperature and humidity throw a wrench in your adhesive application plans. Be mindful of these factors during the process. Extreme temperatures or high humidity levels can sabotage the curing process and weaken bonds. Always consult the manufacturer’s guidelines for recommended temperature and humidity ranges to ensure success.

Adhesive Selection:

The right adhesive is the key to success in any project. Different adhesives offer varying strengths and properties, so choose wisely. When working with wood, opt for wood glue, an adhesive specifically formulated for bonding wood surfaces together. Its exceptional strength on wood guarantees a reliable bond that won’t let you down.

Application Technique:

Attention to detail is vital when it comes to applying adhesives. Follow the instructions provided by the adhesive manufacturer meticulously. Apply a thin, even layer of adhesive on both surfaces to be bonded, ensuring complete coverage. This meticulous application guarantees maximum contact between the adhesive and materials, resulting in a bond that can withstand even the toughest challenges.