Sick of glue that just can’t cut it?

Contents

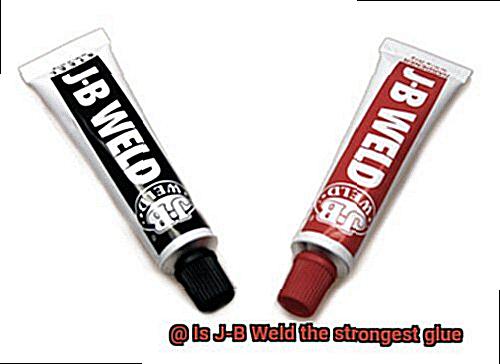

Whether you’re dealing with a busted chair or a DIY disaster, finding an adhesive that actually works can be a real headache. But don’t sweat it, because I’ve got the ultimate solution: J-B Weld, the strongest glue out there.

This stuff is no joke – it’s known for its insane strength and rock-solid durability, making it the top choice for pros and DIY fanatics alike. With J-B Weld in your toolbox, you’ll be able to fix anything from metal and wood to plastic and ceramics.

Get ready to witness some serious glue power.

What is J-B Weld?

In the world of adhesives, one name stands tall when it comes to unmatched strength and durability – J-B Weld. This versatile epoxy adhesive has become synonymous with bonding different materials together, making it the go-to solution for countless projects. Whether you are a seasoned professional or a DIY enthusiast, understanding the marvel of J-B Weld can revolutionize your repair and construction endeavors.

Unyielding Bonding Capabilities:

J-B Weld’s power lies in its two-part composition – a resin and a hardener. When these components are combined in equal amounts, a chemical reaction occurs, resulting in a bond that simply cannot be broken. This adhesive boasts exceptional tensile strength, enabling it to withstand significant pulling or stretching forces without ever compromising the bond. Additionally, J-B Weld excels in shear strength, effortlessly resisting any forces attempting to slide or tear the bonded surfaces apart.

Versatility at its Finest:

One of J-B Weld’s most captivating features is its remarkable versatility. This adhesive can be applied to an extensive range of materials, including metal, wood, plastic, ceramic, glass, concrete, and more. From automotive repairs to household fixes and even industrial projects, J-B Weld has proven its reliability time and time again. So whether you need to mend a broken engine block, repair a leaky pipe, or fix a cracked piece of furniture, J-B Weld is the dependable solution you can trust.

Resilience that Withstands the Elements:

Another remarkable quality of J-B Weld is its resistance to various environmental factors. It thrives under extreme temperatures, resists water exposure, withstands chemical interactions, and even dampens vibrations while maintaining its bond strength. This resilience allows for confident indoor and outdoor applications.

Proper Application for Optimal Results:

To unleash the full potential of J-B Weld, proper surface preparation is crucial. Ensure that the surfaces to be bonded are clean, dry, and free from any grease or contaminants. Thoroughly mix the resin and hardener components, then apply the adhesive evenly for a secure bond. While J-B Weld is renowned for its strength, it’s essential to note that other adhesives may cater specifically to certain materials or applications with even greater bonding capabilities. Consulting with experts or product manufacturers can help you make the most suitable adhesive choice for your project.

How Does J-B Weld Work?

J-B Weld, the adhesive phenomenon that makes repairs seem like magic, is truly a marvel in the world of adhesives. This two-part epoxy is composed of a resin and a hardener, which, when mixed together, unleash an unstoppable bonding force.

The secret lies in the chemical reaction that occurs when the resin and hardener combine. As they interact, the molecules in the epoxy cross-link, forming bonds of incredible strength. Picture it as if these molecules are holding hands and refusing to let go. It’s this interlocking molecular structure that sets J-B Weld apart from other adhesives.

But what really makes J-B Weld shine is its ability to bond to virtually any material. Whether it’s metals, wood, ceramics, glass, or plastics, this adhesive is like a chameleon, seamlessly blending in with any surface it encounters. It’s like having a superhero adhesive at your disposal.

Now, let’s dive into the fascinating curing process. Once the epoxy is mixed, it begins its transformation from a liquid-like consistency to a solid state. This process takes time and patience. The curing time can vary depending on factors such as temperature and humidity. Generally, it takes around 4-6 hours for J-B Weld to reach initial set and 15-24 hours for it to fully cure. Trust me, my friend, patience is key.

During the curing process, J-B Weld becomes resistant to heat, chemicals, and moisture. It transforms into a robust adhesive that can withstand the harshest conditions. No matter what life throws at it, J-B Weld won’t budge.

But there’s another trick up J-B Weld’s sleeve – its gap-filling genius. Thanks to its high viscosity, meaning it’s thick and sticky, this adhesive can effortlessly flow into gaps and adhere to rough or irregular surfaces. Even in tricky repair situations where surfaces may not be perfectly aligned, J-B Weld creates strong bonds that hold everything together.

Advantages of Using J-B Weld

Prepare to be amazed as we explore the incredible advantages offered by this remarkable product.

First and foremost, let’s talk about the jaw-dropping bonding strength of J-B Weld. This adhesive is a true powerhouse, capable of creating bonds so strong they can handle high pressure, temperature fluctuations, and even vibrations without breaking a sweat. You can rely on J-B Weld to provide a bond that will stand the test of time.

Now, let’s dive into the versatility of J-B Weld. Unlike other glues that are picky about the materials they can bond, J-B Weld is like the coolest kid in school who can hang out with anyone. It has the ability to bond metal, wood, plastic, ceramic—basically anything you throw at it. Whether you’re fixing a broken tool or patching up a cracked plastic component, J-B Weld has got your back.

But that’s not all—J-B Weld also laughs in the face of harsh conditions. It is resistant to water, chemicals, acids, and oils, meaning it won’t be affected by exposure to moisture or corrosive substances. No matter what challenging circumstances you’re working in, J-B Weld will keep your bond strong and unaffected.

Let’s take a moment to appreciate how easy it is to use J-B Weld. Even if you’re new to using adhesives, you’ll find it a breeze. Simply mix the epoxy resin and hardener together in equal proportions, apply it to the surfaces you want to bond, and voila. Plus, its extended working time allows you to position and align your materials with precision before the adhesive sets.

And here’s the best part—the setting time of J-B Weld is pretty impressive too. Within just 4-6 hours, your bond will achieve substantial strength, allowing you to move forward with your project without waiting around forever. While full curing may take up to 24 hours or longer depending on environmental factors, you’ll still be able to get things done in a timely manner.

Now let’s talk temperature. J-B Weld can handle the heat, my friends. With a resistance of up to 550°F (287°C), it’s perfect for repairs in automotive engines, exhaust systems, and other hot environments. It’s like having a fireproof sidekick by your side.

Last but certainly not least, let’s discuss the cost-effectiveness of J-B Weld. Compared to other high-strength adhesives on the market, this superhero glue won’t break the bank. Whether you’re a DIY enthusiast or a professional repair technician, you can enjoy the benefits of J-B Weld without emptying your wallet.

Disadvantages of Using J-B Weld

J-B Weld, the superhero adhesive, comes with its share of drawbacks that every user should be aware of. Let’s explore the main disadvantages of using J-B Weld and why they matter.

First and foremost, the curing time of J-B Weld is a significant drawback. Unlike instant adhesives that bond surfaces in a blink of an eye, J-B Weld requires several hours to fully cure. If you’re in a rush or lack the patience to wait for the adhesive to set properly, this can be a major inconvenience.

Another disadvantage is the limited flexibility of J-B Weld once it has cured. While it initially forms a strong bond, over time it can become brittle and may not hold up well in situations where there is constant movement or vibration. For automotive repairs or plumbing projects where flexibility is crucial, other options may be more suitable.

Moreover, J-B Weld may struggle to adhere well to surfaces that are oily, greasy, or contaminated with dirt. Proper surface preparation is key to achieving a strong bond with this adhesive. So if you’re dealing with dirty or greasy materials, be prepared to thoroughly clean them before applying J-B Weld.

Temperature resistance is another limitation of J-B Weld. While it can withstand moderate temperatures, extreme heat or cold conditions may cause it to fail. So if your project involves temperature fluctuations outside its comfort zone, carefully consider whether J-B Weld is the right choice.

Lastly, removing or repairing objects bonded with J-B Weld can be quite challenging. Its strong bond makes it difficult to disassemble parts or make modifications without causing damage. This can be a significant drawback if you anticipate the need for adjustments or repairs in the future.

Factors that Affect the Strength of an Adhesive

Unlocking the secrets of strong adhesive bonds is essential for achieving reliable and long-lasting connections. Whether you’re a DIY enthusiast or a professional in the industry, understanding the factors that affect adhesive strength is crucial. In this article, we will delve into the science behind adhesive strength and explore how surface preparation, adhesive type, substrate materials, cure time and temperature, joint design, and environmental conditions all play a vital role in determining the strength of your glue joints.

Surface Preparation:

Imagine trying to stick two pieces of paper together without removing oily fingerprints or dust particles. It’s a recipe for failure. The same principle applies to adhesive bonding. Thoroughly cleaning surfaces, roughening them, or using solvents to eliminate contaminants creates an ideal bonding area for the adhesive to grip onto.

Adhesive Type:

Not all adhesives are created equal. Different types offer varying strengths and are engineered for specific purposes. Super glue provides rapid bonding and high strength across various materials, while J-B Weld epoxy adhesives are renowned for their exceptional strength and durability even in harsh conditions. Choosing the right adhesive type is crucial for achieving maximum strength.

Substrate Materials:

The materials being bonded have a significant impact on adhesive strength. Some adhesives work well on certain materials but provide weak bonding on others. Adhesives are often formulated to work best with specific substrates like metal, plastic, wood, or glass. Understanding the compatibility between adhesive and substrate is essential when selecting the appropriate adhesive.

Cure Time and Temperature:

Adhesives undergo a curing process where they harden and reach their full strength. Following manufacturer instructions regarding cure time and temperature is crucial for optimal bonding results. Inadequate cure time or low temperatures can result in weaker bonds, while excessive cure time or high temperatures may degrade adhesive properties.

Joint Design:

The design of the joint or how surfaces are bonded together can impact adhesive bond strength. Factors such as joint type, surface area in contact, and adhesive layer thickness all influence overall strength. Sometimes, reinforcing joints with mechanical fasteners or structural elements enhances adhesive bond strength.

Environmental Conditions:

The environment to which adhesive bonds are exposed can also affect their strength. Temperature, humidity, chemical exposure, and UV radiation are all factors that impact adhesive performance. Choosing an adhesive specifically formulated to withstand intended environmental conditions is vital for long-lasting and robust bonding.

Is J-B Weld the Strongest Glue?

When it comes to finding the strongest glue on the market, J-B Weld is a name that often comes up. Known for its formidable bonding capabilities, J-B Weld has become a go-to adhesive for DIY enthusiasts and industry professionals alike. But is it truly the strongest glue out there? Let’s delve deeper into its characteristics and explore other factors to consider.

Tensile strength is a crucial factor in determining the strength of a glue. It refers to its ability to resist pulling or stretching forces. In this area, J-B Weld shines brightly, making it perfect for applications where a robust bond is required. Whether you’re repairing metal objects or bonding heavy-duty materials, J-B Weld can handle the task with ease.

Furthermore, J-B Weld excels in adhesion properties. It can seamlessly bond to a wide range of materials, including metals, ceramics, plastics, and even wood. This versatility makes it a popular choice for various projects, ensuring you have a reliable adhesive for all your needs.

J-B Weld also boasts exceptional temperature resistance. It can withstand extreme heat or cold, making it suitable for applications that involve exposure to these conditions. Whether you’re fixing something in your car engine or working on an outdoor project, J-B Weld has got you covered when it comes to temperature resilience.

However, while J-B Weld is undoubtedly a strong glue, it’s important to note that there may be other adhesives on the market that offer similar or even greater strength in specific applications. For instance, if you’re working with non-porous materials like glass or ceramics, specialized glues tailored for those materials may offer better performance in those situations.

Ultimately, the strength of a glue depends on the specific requirements of your project. It’s always recommended to consult with adhesive experts or follow manufacturer recommendations to ensure you select the most appropriate glue for your application. So while J-B Weld is widely regarded as one of the strongest glues available, it’s worth exploring other options if needed.

Alternatives to J-B Weld

While J-B Weld is undeniably a formidable adhesive, there are numerous alternatives available in the market that can meet your specific needs. Let’s explore some of these alternatives in detail, weighing their advantages and disadvantages to help you make an informed decision.

- Epoxy Putty: Epoxy putty is a two-part adhesive, comprised of a resin and a hardener. When combined, it forms a robust and long-lasting bond. One of the standout features of epoxy putty is its exceptional resistance to heat, chemicals, and impact, making it ideal for applications that require durability. However, it’s worth noting that epoxy putty may take longer to cure compared to other alternatives.

- Polyurethane Adhesive: If versatility is what you seek, polyurethane adhesive should be on your radar. This adhesive bonds well with an array of materials including metals, plastics, wood, and concrete. Additionally, it can withstand high temperatures, moisture, and vibrations, making it highly suitable for industries such as construction, automotive, and marine. However, keep in mind that polyurethane adhesive may not offer the desired flexibility or resistance to high temperatures in certain applications.

- Cyanoacrylate Adhesive (Super Glue): For quick fixes or projects demanding swift bonding, cyanoacrylate adhesive, commonly known as super glue, is an excellent alternative. This fast-drying adhesive forms an incredibly strong bond between surfaces. It excels at bonding various materials efficiently and rapidly even in minimal amounts. Nonetheless, bear in mind that super glue may not be the best choice for applications that necessitate flexibility or resistance to high temperatures.

- Welding: When it comes to joining metal surfaces, welding reigns supreme by providing superior strength compared to adhesive bonding methods. By melting the metals together, welding creates a robust bond commonly utilized in industrial settings. However, it’s important to note that welding requires specialized equipment and expertise, making it less accessible for DIY enthusiasts.

- Mechanical Fasteners: Sometimes, simplicity prevails, and the tried-and-true method of using screws, bolts, or rivets can be the perfect alternative. Mechanical fasteners offer a secure and reliable connection between materials. Furthermore, they can be easily undone if necessary, making them widely used in construction, woodworking, and automotive industries.

Remember, the strength of your bond hinges on various factors. Therefore, it is crucial to carefully consider the specific materials, application requirements, and adhesive properties before selecting an alternative to J-B Weld. Always adhere to the manufacturer’s instructions for optimal results.

Tips for Getting the Best Results from J-B Weld

J-B Weld is a mighty adhesive that can fuse nearly anything together. Whether you’re fixing a shattered toy, repairing a cracked pipe, or even constructing something new, J-B Weld is your go-to glue. However, to ensure the mightiest bond possible, there are some tips and tricks you should keep in mind. In this article, we’ll explore essential tips for getting the best results from J-B Weld.

Clean Surfaces: The Foundation of Success

Before applying J-B Weld, cleanliness is king. Dirt, grease, oil, or rust can play the villain to your adhesive’s effectiveness. Use a degreaser or an alcohol-based cleaner to scrub the surfaces you’re bonding. Let them dry completely before proceeding.

Roughen the Surface: Creating Texture for Triumph

For superior adhesion, roughen the materials you’re bonding. Sandpaper or a wire brush is your best sidekick for creating a slightly rough texture. This roughness increases the surface area and gives the epoxy more grip, making it stick like a superhero.

Mix with Precision: The Perfect Potion for Power

J-B Weld consists of two separate components – a resin and a hardener. To unlock their full potential, mix them in the correct ratio as stated in the instructions. Use a clean disposable container and mix until the color is uniform. This meticulous mixing ensures that the epoxy will cure properly and unleash its maximum strength.

Apply Evenly: Spreading Success

When applying J-B Weld, spread it evenly on both surfaces being bonded. Grab your trusty spatula or disposable applicator and apply a thin layer of epoxy. Don’t go overboard, as excess squeeze-out can weaken the bond’s strength. Remember, an even application ensures an unbreakable connection.

Clamp or Hold: Locking in Super Strength

After applying J-B Weld, grasp victory by clamping or holding the bonded surfaces together tightly. This heroic move achieves maximum contact and guarantees a powerful bond. Utilize clamps, tapes, or any other suitable method to keep the parts together until the epoxy cures. The stronger the hold, the stronger the bond.

Allow Sufficient Curing Time: Patience for Perfection

J-B Weld needs time to cure and become invincible. Curing time varies based on factors like temperature and humidity. Follow the instructions provided with the product regarding curing time and avoid disturbing the bond until it has fully cured. Remember, great things come to those who wait.

H4xX7VecgzA” >

Conclusion

When it comes to the question of whether J-B Weld is the strongest glue, the answer is a resounding yes. This incredible adhesive has gained a reputation for its unparalleled strength and durability. With its unique formula, J-B Weld can bond together a wide range of materials, from metal to wood to plastic. It forms an incredibly strong bond that can withstand even the toughest conditions.

What sets J-B Weld apart from other glues is its exceptional holding power. Once applied, it creates a bond that is virtually unbreakable. Whether you’re repairing a broken tool or fixing a cracked surface, J-B Weld will provide a long-lasting solution that you can rely on.

But it’s not just about strength – J-B Weld also offers versatility. Its ability to adhere to various surfaces makes it suitable for countless applications. From automotive repairs to household fixes, this glue can tackle them all with ease.

Furthermore, J-B Weld is easy to use. Its simple application process ensures that anyone, regardless of their level of expertise, can achieve professional-quality results. Just mix the two components together and apply it to the desired area – it’s as straightforward as that.

In addition to its exceptional strength and ease of use, J-B Weld also boasts excellent resistance properties. It can withstand extreme temperatures and harsh environments without losing its bonding capabilities. Whether you’re dealing with freezing cold or scorching heat, this glue will hold up under pressure.

So when it comes down to it, there’s no denying that J-B Weld is indeed the strongest glue out there. Its unbeatable strength, versatility, ease of use, and resistance make it the go-to choice for any bonding needs.