Are broken things driving you crazy?

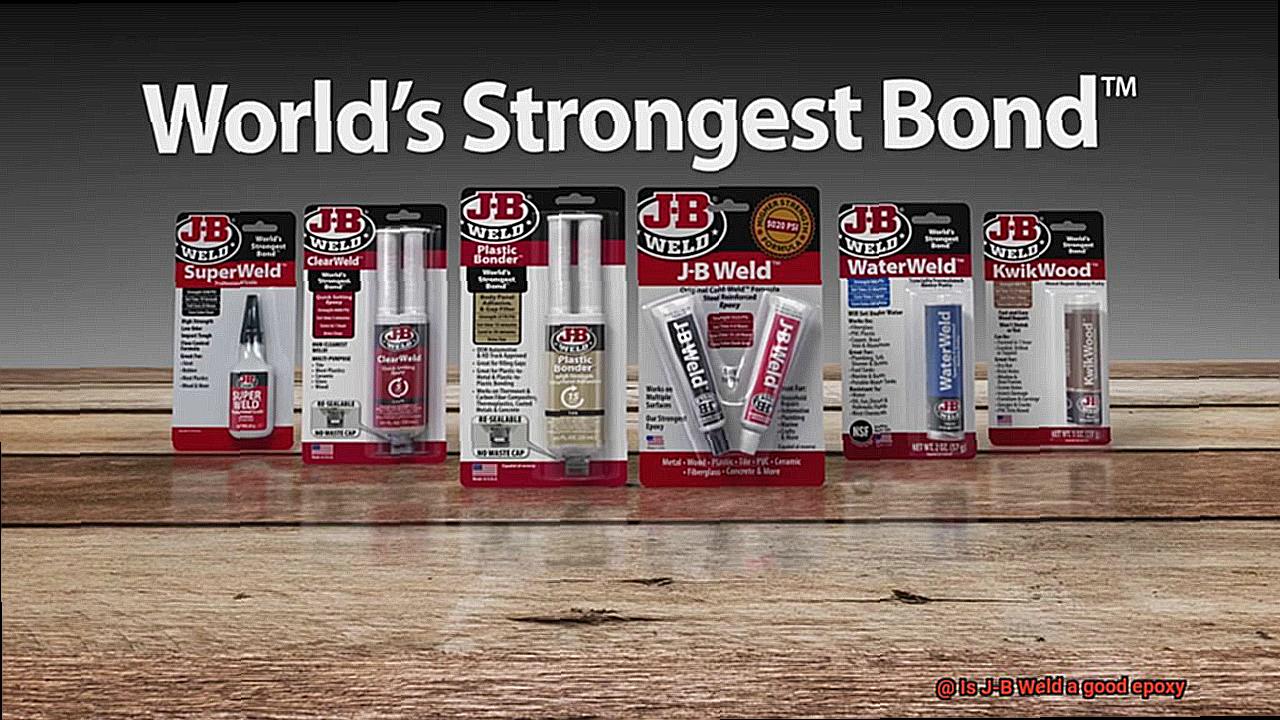

From shattered vases to split table legs, a reliable epoxy can be a lifesaver. Enter J-B Weld, the superhero of adhesives.

But does it really live up to the hype? In this blog post, we’ll uncover the truth about J-B Weld as an epoxy.

So buckle up and let’s find out if J-B Weld is truly the cream of the crop in the world of epoxies.

Advantages of J-B Weld

Contents

When it comes to adhesive options, J-B Weld stands out as a reliable and versatile choice. With its exceptional bonding strength, resistance to high temperatures and chemicals, quick setting time, durability, easy application process, and specialized formulations, J-B Weld has become a go-to epoxy adhesive for professionals and DIY enthusiasts alike. In this comprehensive guide, we will explore the advantages of using J-B Weld, its various applications, and some important considerations for optimal results.

Exceptional Bonding Strength:

- Bonds a wide range of materials (metal, wood, plastic, ceramic)

- Withstands heavy loads and vibrations

- Ideal for automotive repairs and household fixes

Resistance to High Temperatures and Chemicals:

- Withstands temperatures up to 550 degrees Fahrenheit

- Resistant to chemicals and acids (gasoline, oil, hydraulic fluids)

- Suitable for machinery and equipment repairs

Quick Setting Time and Durability:

- Sets within 4-6 hours, reaches full strength within 15-24 hours

- Minimizes downtime for fast repairs

- Withstands harsh conditions and heavy loads

Sanding and Painting Compatibility:

- Can be sanded and painted over once fully cured

- Provides a seamless finish for professional-looking results

Easy Application Process:

- User-friendly two-tube system (epoxy resin and hardener)

- Simply mix equal parts before application

- Accessible to users with limited adhesive experience

Specialized Formulations:

- Tailored products for automotive repairs, marine fixes, high-temperature applications

- Allows users to choose the most suitable product for specific needs

How to Use J-B Weld

J-B Weld is a versatile epoxy adhesive known for its strength and durability. Whether you are fixing a broken metal tool, repairing a cracked ceramic pot, or bonding two pieces of wood together, J-B Weld can get the job done. In this article, we will guide you through the steps to effectively use J-B Weld for a strong and durable bond.

Step 1: Prepare the Surfaces

Before applying J-B Weld, it is crucial to clean and prepare the surfaces that will be bonded together. Use a solvent like acetone or rubbing alcohol to remove any dirt, grease, or rust. This will ensure better adhesion. Additionally, roughen the surfaces with sandpaper or a file to create a rough texture that the adhesive can grip onto.

Step 2: Mix the Components

Measure equal parts of the J-B Weld epoxy resin and hardener. It is important to follow the recommended ratio provided by the manufacturer. Thoroughly mix the components in a disposable container using a stirring stick or small spatula. Ensure that the mixture is well combined before proceeding.

Step 3: Apply the Adhesive

Once the components are mixed, apply the J-B Weld evenly and thinly on the prepared surfaces. You can use a spatula, brush, or any suitable tool depending on your application. Work quickly as J-B Weld has a short working time before it starts to set.

Step 4: Press Firmly Together

After applying the adhesive, press the surfaces firmly together to create good contact between the adhesive and materials being bonded. This will ensure a strong and durable bond. If needed, use clamps or weights to hold the pieces in place while the adhesive cures.

Step 5: Allow Sufficient Curing Time

The curing time for J-B Weld may vary depending on temperature and humidity. Refer to the instructions provided by the manufacturer for specific curing times. It is recommended to allow at least 24 hours for full curing before subjecting the bond to stress or load. This will ensure that the adhesive has fully cured and reached its maximum strength.

Step 6: Finishing Touches

Once the adhesive has fully cured, remove any excess or squeezed out adhesive by scraping or sanding. J-B Weld can be sanded, drilled, and painted, allowing further customization or finishing of the bonded surfaces. This gives you the flexibility to achieve the desired look and functionality.

Applications for J-B Weld

If you’re a DIY enthusiast or a professional in need of a reliable adhesive, look no further than J-B Weld. This remarkable epoxy adhesive has gained a loyal following due to its exceptional versatility and ability to tackle a wide range of applications. Let’s dive into the various uses of J-B Weld and explore why it has become such a popular choice.

- Automotive Repairs: When it comes to fixing cracked engine blocks, radiators, and exhaust systems, J-B Weld is the go-to solution. Its unrivaled strength and durability make it the perfect adhesive to withstand the rigorous demands of the automotive world.

- Metal Repairs: Need to fix a broken tool or appliance? J-B Weld can handle it with ease. Specially formulated to bond metal objects securely, this adhesive provides long-lasting repairs that can endure even the most challenging conditions.

- Versatile Bonding: Whether you’re working with wood, plastic, ceramic, or fiberglass, J-B Weld has got you covered. It excels at bonding different materials together, ensuring a strong and reliable connection for any project.

- Plumbing Repairs: Leaky pipes or broken PVC fittings? Fear not, as J-B Weld can seal leaks and fix broken parts in your plumbing system. With this adhesive, you can save time and money on costly repairs.

- Concrete Structures: Cracks in your driveway or foundation? J-B Weld to the rescue. Its exceptional bonding strength makes it perfect for repairing and reinforcing concrete structures, providing peace of mind and structural integrity.

- DIY Projects and Crafts: DIY enthusiasts are head over heels for J-B Weld’s versatility in their projects. From repairing jewelry to creating models and crafting unique pieces, this adhesive opens up endless possibilities for creativity and innovation.

- Industrial Applications: In industries like aerospace and marine, where high temperatures and exposure to chemicals are common, J-B Weld is the trusted choice. Its resistance to extreme conditions makes it ideal for demanding repairs and maintenance tasks.

Limitations of J-B Weld

Today, we’re going to dive into the world of J-B Weld, the superhero of adhesives. While it has many impressive qualities, it’s essential to understand its limitations to ensure you choose the right glue for your project. So, grab your cape and let’s explore.

Temperature Resistance:

J-B Weld might be strong, but it has its kryptonite: extreme heat. While it can withstand high temperatures to some extent, excessive heat can weaken its bond strength. For applications involving intense heat, consider specialized adhesives designed for high-temperature environments.

Curing Time:

Patience is a virtue when using J-B Weld. Its curing time can be relatively long, often requiring 24 hours or more for full hardness and maximum strength. If you’re working on time-sensitive projects or immediate use of the bonded object is necessary, explore faster-curing alternatives.

Material Compatibility:

J-B Weld is a versatile adhesive, but not invincible against all materials. It bonds well with metals, ceramics, plastics, and wood; however, it struggles with low surface energy materials like polyethylene or polypropylene due to their non-stick surfaces. For these materials, seek out specialized adhesives tailored to their unique properties.

Flexibility:

Flexibility is key in some applications, but J-B Weld isn’t known for its elasticity. Once cured, it forms a rigid bond that limits movement and flexibility. If your project involves vibrations, shocks, or dynamic loads, opt for flexible or elastic adhesives that can handle the challenge without compromising the bond integrity.

Aesthetics:

While J-B Weld saves the day functionally, it may not always save the day aesthetically. The adhesive dries to a dark gray color, which may not blend well with certain surfaces or materials. If visual appeal is a priority, explore alternative adhesives that offer a more pleasing finish.

Preparation for Using J-B Weld

Whether you’re a beginner or experienced in the world of adhesives, these preparation steps will help you achieve optimal bonding performance and ensure long-lasting results.

So, let’s dive in.

Clean the surfaces:

- Thoroughly clean the surfaces to be bonded by removing dirt, grease, oil, or contaminants.

- Use a mild detergent or solvent to clean the surfaces.

- Rinse well and dry the surfaces completely.

Roughen the surfaces:

- Enhance bond strength by lightly sanding or abrading the surfaces.

- Create a slightly rough texture for better adhesion.

- Be careful not to overdo it, as excessive roughening can weaken the materials.

Mix the epoxy:

- Follow the manufacturer’s instructions to mix the J-B Weld epoxy accurately.

- Use a clean container and thoroughly stir the resin and hardener together until well-blended.

Remove air bubbles:

- Let the mixed epoxy sit for a few minutes to allow air bubbles to rise to the surface.

- Gently tap or stir the mixture to release these bubbles without introducing more air.

Protect surrounding areas:

- Before applying the epoxy, use masking tape or barrier sheets to protect surrounding areas that shouldn’t come into contact with it.

- Wear gloves to avoid direct contact with the epoxy.

Apply evenly:

- Use a disposable applicator like a brush or wooden stick to apply an even and consistent layer of epoxy on both surfaces.

- Avoid excessive application to prevent messiness and weak spots in the bond.

Align and press firmly:

- Carefully align the surfaces to be bonded and press them together firmly.

- Maintain pressure for the recommended curing time specified by the manufacturer.

- This ensures proper bonding and allows the epoxy to cure effectively.

Clean up excess adhesive:

- After the epoxy has cured, clean up any excess adhesive that may have squeezed out during the bonding process.

- Use a suitable solvent or gently scrape off the excess with a razor blade or plastic scraper.

Success Stories with J-B Weld

J-B Weld, the epitome of strength, durability, and reliability in adhesive solutions, has amassed a treasure trove of success stories from satisfied users.

This remarkable epoxy has proven its effectiveness in a wide array of applications, earning its status as the go-to adhesive for any bonding needs. Let’s delve into some of the most noteworthy success stories associated with J-B Weld:

Automotive Repairs:

- Cracked Engine Blocks: Countless car owners have been spared the agony of costly engine replacements by utilizing J-B Weld to fix cracked engine blocks or cylinder heads. With its extraordinary bond and heat resistance, this epoxy fearlessly withstands the extreme conditions inside an engine.

- Exhaust System Repairs: J-B Weld has also come to the rescue for those grappling with exhaust system leaks. By providing a secure seal, it prevents hazardous fumes from escaping and ensures peace of mind on the road.

Home Repairs:

- Plumbing Leaks: Whether it’s metal, plastic, or ceramic, J-B Weld can flawlessly adhere to a variety of materials, making it the perfect solution for sealing leaks in pipes and fittings. Users have triumphantly resolved plumbing issues with this versatile epoxy.

- Metal Object Restoration: The strength and versatility of J-B Weld have breathed new life into numerous objects. From resurrecting a cracked cast iron skillet to reviving precious antique metal furniture, this epoxy enables seamless repairs that stand the test of time.

DIY Projects:

- Custom Auto Parts: Enthusiasts have harnessed the exceptional bonding capabilities of J-B Weld to fashion personalized auto parts like brackets or mounts. This epoxy empowers them to create automotive masterpieces that reflect their unique vision.

- Artistic Creations: The limitless creative possibilities unlocked by J-B Weld have fueled the passions of DIY enthusiasts worldwide. Crafting exquisite sculptures and functional art pieces has never been easier, thanks to this epoxy’s unwavering bonding powers.

Tool Repairs:

- Broken Tools: J-B Weld has come to the rescue of countless individuals faced with broken tools. By skillfully applying this epoxy to the fractured parts and allowing it to cure, users have resurrected their beloved tools, reinstating their full functionality.

Tips and Tricks for Using J-B Weld

J-B Weld is no ordinary adhesive; it is a superhero in the world of bonding. With its strength and versatility, J-B Weld can save the day. However, like any superhero, it needs guidance to reach its full potential. Here are some tips and tricks to help you become a J-B Weld master.

Cleanliness is Key:

Before embarking on your bonding adventure, ensure that the surfaces you intend to bond are clean and free from dirt, grease, or rust. These contaminants can weaken the bond. Use a degreaser or solvent to wipe away unwanted grime, ensuring a clean slate for J-B Weld to work its magic.

Rough it Up:

Smooth surfaces may be visually appealing, but they do not provide an optimal grip for J-B Weld. To enhance adhesion, use sandpaper or a file to roughen up the materials you are bonding. This creates a textured surface that allows for a stronger and more reliable connection.

Mixing Matters:

To unlock J-B Weld’s powers, proper mixing is vital. The epoxy resin and hardener come in separate tubes and need to be combined in equal parts. Prepare a disposable mixing container and a stir stick, and blend the two components until you achieve a uniform color. This ensures that both components are fully activated and ready to create a strong bond.

Apply with Finesse:

The application process plays a crucial role in achieving a successful bond. Use a disposable brush or applicator to spread J-B Weld evenly over the surfaces you are bonding. Avoid applying an excessive amount of epoxy, as excess heat during curing can weaken the bond. A thin and even application ensures optimal results.

Pressure is Key:

Give your bond some love by applying pressure after applying J-B Weld. Clamps, weights, or tape can hold the materials together while the epoxy works its magic. Applying pressure ensures that the adhesive is in full contact with the surfaces being bonded, promoting a strong and durable connection. Follow the recommended curing time for best results.

Taming Excess Epoxy:

Once your bond is secure, it’s time to tidy up. Carefully remove any excess or squeeze out using a razor blade or sandpaper. Be gentle to avoid damaging the bond while achieving a polished finish. This step adds a final touch to your project, ensuring a clean and professional appearance.

Remember: Compatibility is Crucial.

While J-B Weld is a mighty adhesive, it does have its limitations. Before using it on specific materials, check the product label for compatibility. Some plastics, such as polyethylene or polypropylene, may not be suitable for bonding with J-B Weld. It is always advisable to test the adhesive on a small area first, especially for critical or load-bearing applications.

Alternatives to J-B Weld

In the vast world of adhesives, J-B Weld stands strong as a reliable epoxy adhesive. However, sometimes you must venture beyond its realm to find the perfect glue for your specific project needs. Whether it’s availability, cost, or particular requirements, alternatives exist that can deliver similar or even superior performance. Buckle up as we embark on an exhilarating journey to explore the top alternatives to J-B Weld and uncover their unique advantages.

Loctite Epoxy Weld Bonding Compound:

Specifically designed to forge unbreakable bonds between metal surfaces, this adhesive reigns supreme in the realm of metal bonding. With its formidable strength and durability, it conquers both small repairs and grand projects alike. Versatility is its trump card, allowing it to tackle a diverse range of applications with ease.

PC Products PC-7 Two-Part Epoxy Adhesive Paste:

This adhesive paste is renowned for its unwavering strength and unparalleled flexibility. It forms unyielding connections across various materials – metal, wood, ceramics, and plastics tremble before its might. Its long working time offers the precision necessary for flawless application and allows ample room for adjustments.

Devcon 5-Minute Epoxy:

For those seeking the need for speed, this epoxy adhesive is a shining star. With a lightning-fast curing time of only 5 minutes, it is tailor-made for projects that demand swift bonding. It triumphs over an array of materials – metal, glass, ceramics, and plastics – ensuring a bond that withstands the test of time.

Gorilla Epoxy:

Embracing an environmentally friendly approach, this adhesive leads the charge towards sustainability. Resistant to water and capable of bonding various materials with unwavering strength, it leaves no toxic trail in its wake. Breathe easy as you work, for its application emits no overpowering odors.

3M Scotch-Weld Epoxy Adhesive DP420:

Prepare to be amazed by this two-part epoxy adhesive, a force to be reckoned with. Its strength and durability surpass expectations, exhibiting exceptional resistance to chemicals, temperature fluctuations, and impact. It stands tall in the face of demanding applications, proving its unwavering reliability.

R3r0UZ7txzs” >

Conclusion

After careful analysis and evaluation, it is safe to say that J-B Weld is indeed a remarkable epoxy.

Its exceptional bonding strength and durability make it a go-to choice for various repair and construction projects. Whether you’re fixing a broken pipe or joining metal parts, J-B Weld delivers reliable results that withstand the test of time.

Its versatility extends beyond just metals, as it can also be used on wood, ceramics, plastics, and more. With its easy application process and quick curing time, J-B Weld ensures efficiency without compromising quality.

Trustworthy and dependable, this epoxy is a valuable addition to any DIY enthusiast or professional’s toolbox.