In a world that never stops spinning, where industries demand materials that can keep up with their breakneck pace, finding the perfect adhesive is like striking gold.

Whether you’re in the automotive biz or working your magic in construction, one question looms large: can hot melt glue survive a petrol showdown? Picture this: an adhesive that’s tough as nails and unflinching in the face of petrol’s fury.

Sounds too good to be true, right? Well, in this blog post, we’re diving headfirst into the mesmerizing world of hot melt glue and its ability to resist petrol.

We’ll explore its many applications, potential limitations, and separate fact from fiction. So buckle up and get ready for a wild ride through the truth behind hot melt glue’s petrol resistance.

What is Hot Melt Glue?

Contents

- 1 What is Hot Melt Glue?

- 2 What is Petrol or Gasoline?

- 3 How Does Petrol Affect Hot Melt Glue?

- 4 Factors that Determine the Petrol Resistance of Hot Melt Glue

- 5 Is Hot Melt Glue Specifically Designed to be Petrol Resistant?

- 6 Types of Polymers Used in Hot Melt Glue Composition

- 7 Temperature and Duration of Exposure to Petrol

- 8 Applications Where Hot Melt Glue Should Not Be Used

- 9 Conclusion

In the captivating world of adhesives, one adhesive reigns supreme – hot melt glue. This extraordinary adhesive, with its rapid drying properties and unyielding bonding capabilities, has become the go-to choice for a multitude of industries and applications. Join us as we embark on an exhilarating journey into the realm of hot melt glue, exploring its versatility, advantages, and limitations.

Unleashing Versatility:

Hot melt glue is the pinnacle of versatility, effortlessly bonding an extensive range of materials together. Wood, metal, plastic, fabric, foam, ceramics – you name it, and hot melt glue can fuse it. It is a transformative tool for DIY enthusiasts, manufacturers, and artists alike, making it an indispensable companion for woodworking projects, crafts, and product assembly.

Rapid-Drying Wizardry:

Prepare to be astonished by the lightning-fast drying time of hot melt glue. While other adhesives languish in hours-long curing processes, hot melt glue solidifies within seconds or minutes. This exceptional quick-setting time is a godsend for time-sensitive endeavors such as packaging or urgent repairs, ensuring that every task is completed with unparalleled efficiency.

Unbreakable Bonds:

Hot melt glue possesses an unfathomable strength that enables it to withstand colossal stress and load. Its adhesive properties make it an unrivaled choice for applications that demand durability and longevity. Whether you’re constructing furniture or mending household items, hot melt glue ensures an unbreakable bond that will never let you down.

Elegantly Simple:

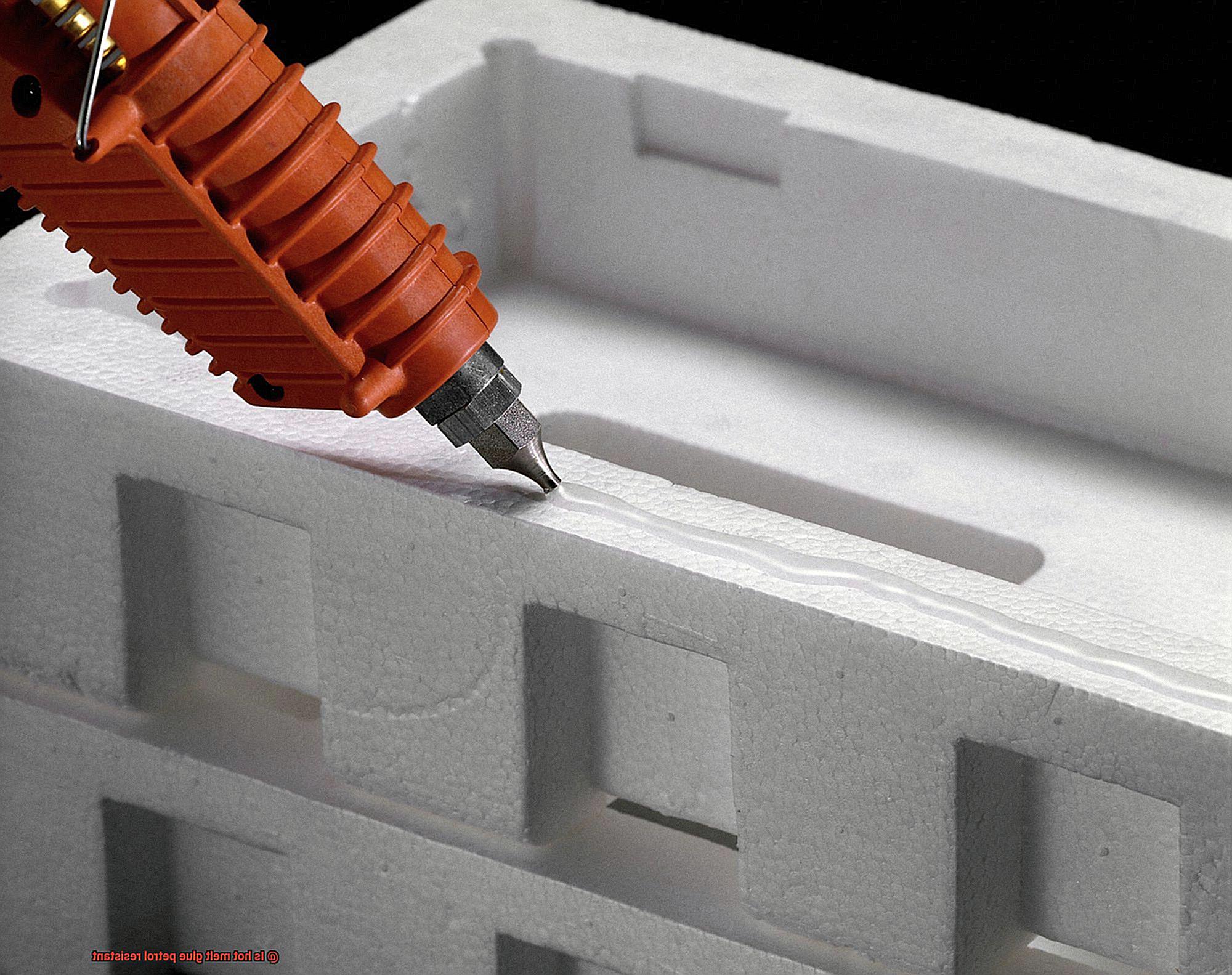

The beauty of hot melt glue lies in its simplicity. Armed with nothing more than a hot glue gun and the appropriate glue sticks or pellets, you hold the power to unleash its magic. Load the adhesive into the gun, watch as it melts into a molten masterpiece, and dispense it onto the desired surface. No complex mixing or curing processes are required – it’s a hassle-free and user-friendly adhesive masterpiece.

Advantages and Limitations:

Hot melt glue bestows upon us a wealth of advantages that surpass those of other adhesives. Its exceptional adhesion, resistance to moisture and humidity, and ease of use are unrivaled in the adhesive realm. However, it is crucial to acknowledge that hot melt glue may not be suitable for applications requiring high resistance to heat or chemicals. Extreme temperatures may cause the glue to soften or relinquish its adhesive prowess, while certain chemicals like petrol or gasoline may not harmonize with its magical formula.

What is Petrol or Gasoline?

Get ready to be amazed as we explore this flammable liquid fuel derived from crude oil. Known for its role in powering internal combustion engines, petrol is an essential resource that keeps the wheels turning in the global transportation industry.

The Origins of Petrol:

Crude oil, a fossil fuel found deep within the Earth’s crust, is the starting point for petrol. Through a refining process, crude oil is transformed into various components, one of which is petrol. This distillation process separates crude oil based on boiling points, resulting in the creation of petrol at specific temperatures.

The Chemistry Behind Petrol:

Chemically speaking, petrol is primarily composed of hydrocarbons – compounds made up of hydrogen and carbon atoms. These hydrocarbons come in different sizes and structures, giving rise to various types of petrol with different properties and octane ratings. Octane rating is a measure of a fuel’s resistance to knocking or pinging during combustion.

The Power of Petrol:

What makes petrol such a popular choice for fueling engines? Its volatility is key. Petrol has a high tendency to evaporate quickly at room temperature, making it an ideal fuel for internal combustion engines. This volatility allows it to vaporize rapidly and mix with air, leading to efficient combustion within the engine. As the fuel undergoes combustion, chemical energy is converted into mechanical energy, propelling vehicles forward.

Beyond Fuel: Petrol’s Versatility:

Petrol’s usefulness extends beyond its role as a fuel. It also serves as a powerful solvent in various industries. With its ability to dissolve grease, oils, and other contaminants from surfaces, petrol plays a vital role in cleaning and degreasing processes. Additionally, petrol acts as a feedstock for producing important chemicals like plastics, synthetic fibers, and detergents that we encounter in our daily lives.

Safety Precautions:

However, it’s important to handle and store petrol with caution due to its flammability. Safety precautions, such as using proper storage containers, implementing ventilation systems, and following correct handling procedures, are crucial to prevent accidents or fires associated with petrol.

Conclusion:

In conclusion, petrol or gasoline is a fascinating flammable liquid fuel derived from crude oil. Its role in powering internal combustion engines makes it indispensable for transportation and industry worldwide. With its volatile nature and unique chemical composition, petrol provides the energy required for efficient combustion. Nonetheless, it’s important to handle and store petrol carefully to ensure safety.

How Does Petrol Affect Hot Melt Glue?

Hot melt glue is a versatile adhesive that transforms from a molten state to a solid bond. But what happens when this sticky superhero encounters its nemesis, petrol? In this article, we will delve into the chemistry between petrol and hot melt glue, exploring the effects of this sizzling interaction and providing tips on how to handle it like a pro.

The Softening Effect:

When petrol meets hot melt glue, sparks fly as if fuel is added to a blazing fire. Petrol contains solvents that break down the molecular structure of the adhesive, causing it to soften or even liquefy. Picture your solid bond turning into a sticky mess—it’s not what you had in mind.

Weakened Bonding Power:

Under petrol’s influence, hot melt glue loses its adhesive strength. The once unbreakable bond can become weaker or completely fail. So, if you’re relying on hot melt glue in a petrol-rich environment, think twice before trusting it to hold things together.

Alteration of Properties:

Petrol does more than weaken the bond—it also messes with the overall performance of hot melt glue. It alters the adhesive’s viscosity (thickness), tackiness (stickiness), and drying time. It’s as if petrol plays a twisted game of chemical makeovers with our trusty hot glue.

Resistance Varies:

Not all hot melt glues are created equal when it comes to facing off against petrol. Different formulations have varying levels of resistance to this feisty fuel. Some glues are specially designed to withstand exposure to chemicals like petrol. To find out if your hot melt glue is up for the challenge, check the manufacturer’s specifications or conduct a compatibility test.

Consider Alternatives:

If your project involves materials exposed to petrol or other solvents, it may be wise to explore alternative adhesive options. Epoxy adhesives, known for their resistance to a wide range of chemicals, including petrol, could be your new best friend.

Storage and Handling:

Don’t forget that proper storage and handling play a key role in preserving the integrity of your hot melt glue. Keep it in a cool, dry place and tightly seal it when not in use. This will help prevent deterioration and contamination from external substances.

Factors that Determine the Petrol Resistance of Hot Melt Glue

Hot melt glue, with its fast bonding capabilities and ease of use, is a versatile adhesive widely used in various industries. However, when it comes to resisting petrol, not all hot melt glues are created equal. To understand the factors that determine petrol resistance in hot melt glues, we must delve into their composition, application temperature, curing time, substrate compatibility, and exposure conditions.

The composition of hot melt glue is crucial in determining its petrol resistance. Different formulations and combinations of polymers, resins, and additives can affect the overall resistance of the glue to substances such as petrol. Certain types of polymers and resins, like polyethylene and polypropylene-based hot melt glues, are naturally hydrophobic and exhibit better petrol resistance. Additionally, additives like fillers, antioxidants, and plasticizers enhance the performance and durability of the glue, making it more resistant to petrol and other chemicals.

Application temperature plays a significant role in petrol resistance. Higher temperatures during application result in stronger bonds and improved resistance to substances including petrol. Conversely, applying hot melt glue at lower temperatures may lead to weak bonds that are vulnerable to chemical degradation caused by petrol exposure.

Curing time is another factor affecting petrol resistance. Longer curing times result in stronger bonds and improved resistance to petrol. Inadequate curing time leads to weaker bonds prone to chemical attack from petrol.

The type of material being bonded also influences petrol resistance. Some materials are inherently resistant to petrol while others are more susceptible to chemical attack. Hot melt glues formulated for specific substrates, such as plastics or metals, exhibit better petrol resistance when used on those materials.

Lastly, environmental conditions impact glue’s resistance to petrol. Temperature, humidity, and duration of exposure all influence the extent to which glue withstands the effects of petrol. Hot melt glues designed for outdoor applications or environments with high petrol exposure possess enhanced resistance properties for long-term durability.

Is Hot Melt Glue Specifically Designed to be Petrol Resistant?

In the world of adhesives, hot melt glue stands out as a versatile and fast-bonding superhero. However, when it comes to its ability to resist the villainous petrol, hot melt glue’s powers can vary. In this article, we will delve into the factors that influence hot melt glue’s resistance to petrol and explore how each factor contributes to its performance. So, gear up and get ready for an epic battle between hot melt glue and petrol.

The Composition:

Hot melt glue is primarily composed of thermoplastic polymers that are solid at room temperature and melt when heated. While these polymers provide excellent bonding capabilities, they may not possess the same resistance as adhesives specifically designed to withstand harsh chemicals like petrol.

Application Temperature:

Just like superheroes need their armor, hot melt glue requires the right temperature during application. Higher temperatures create bonds that can withstand petrol’s attacks, while lower temperatures leave the glue vulnerable to chemical degradation caused by petrol exposure.

Curing Time:

Time is of the essence. Allowing hot melt glue enough time to cure enables it to build strong defenses against petrol. Rushing through this process can result in weak bonds that are susceptible to attack.

Substrate Compatibility:

Choosing the right material for bonding is crucial. Some materials have inherent resistance to petrol, while others are more prone to its destructive nature. Hot melt glues specially formulated for specific substrates know exactly how to protect them from petrol’s harm.

Environmental Conditions:

Temperature swings, humidity levels, and prolonged exposure all play a significant role in hot melt glue’s resistance to petrol over time. These conditions can impact the glue’s durability and performance.

Enhancing Performance:

Although hot melt glue may not be specifically designed to be petrol resistant, there are steps you can take to enhance its performance in such environments. Additives or modifiers can be used to improve the glue’s resistance to chemicals like petrol, providing an extra layer of protection.

Choosing the Right Glue:

For projects involving frequent or prolonged exposure to petrol, alternative adhesive options specifically designed for chemical resistance should be considered. These adhesives offer superior performance and durability in harsh environments.

Types of Polymers Used in Hot Melt Glue Composition

When it comes to finding the perfect adhesive for your project, it’s crucial to consider its resilience against petrol or gasoline. In this comprehensive analysis, we will delve into the world of hot melt glue composition and explore the different types of polymers used. By understanding how these polymers vary in terms of petrol resistance, you can make an informed decision and choose the ideal glue for your needs.

The Power of Ethylene-Vinyl Acetate (EVA):

Hot melt glues formulated with ethylene-vinyl acetate (EVA), a remarkable copolymer of ethylene and vinyl acetate, offer an excellent level of petrol resistance. This versatile polymer not only provides flexibility and adhesion but also exhibits remarkable resistance to low temperatures. Whether you’re working on a delicate craft project or repairing household items, EVA-based hot melt glue stands as a reliable choice that can withstand exposure to petrol.

Polyolefin: The Chemical-Resistant Champion:

Polyolefin-based hot melt glues, comprising robust polymers like polyethylene or polypropylene, stand as true champions in terms of petrol resistance and chemical resilience. These glues are renowned for their exceptional resistance to a wide range of chemicals, including petrol. If you’re in need of an adhesive that can handle even the harshest environments and provide unmatched durability, polyolefin-based hot melt glue should be at the top of your list.

Polyamide: Strength and Chemical Resistance Combined:

Polyamide-based hot melt glues are known for their superior strength, flexibility, and impressive temperature resistance. Although they may not match the same level of petrol resistance as EVA or polyolefin-based glues, they still offer commendable adhesion properties while withstanding certain levels of chemical exposure. If you require a strong bond with moderate petrol resistance, polyamide-based hot melt glue emerges as a promising option.

Specialty Polymers for Specific Applications:

Certain specialty polymers, such as polyurethane (PU), bring exceptional flexibility and impact resistance to hot melt glues. These unique polymers also exhibit commendable resistance to petrol and various solvents, making them the perfect choice for demanding applications in the automotive or industrial sectors where exposure to petrol or chemicals is common.

Testing and Compatibility:

While hot melt glues composed of these polymers generally showcase good petrol resistance, it’s essential to consider the specific formulation and additives within the glue composition. Factors such as temperature, duration of exposure, and concentration of petrol can all influence the glue’s performance. To ensure optimal compatibility with fuel exposure, it is highly recommended to conduct thorough testing of the specific glue formulation in your intended application.

Temperature and Duration of Exposure to Petrol

When it comes to the effects of temperature and duration of exposure to petrol on hot melt glue, there’s more than meets the eye. Hot melt glue, composed of thermoplastic polymers that can be melted for application, can lose its strength when faced with petrol. But fear not, because we’re here to shed light on this sticky situation.

Let’s dive into the nitty-gritty. Petrol, a volatile substance containing hydrocarbons, can potentially interact with and degrade hot melt glue. However, here’s the kicker – temperature matters. Hot melt glue exhibits better resistance to petrol at lower temperatures. But crank up the heat, and you might find yourself dealing with a softened adhesive that’s more vulnerable to damage from petrol’s chemical onslaught. So, if you’re working in a sweltering environment, it’s crucial to select a glue with high-temperature resistance.

Duration of exposure also plays a pivotal role. Short-term contact with petrol may not pose significant harm to hot melt glue. However, prolonged or repeated exposure can spell trouble, as the glue gradually deteriorates over time. So, if your glue is constantly exposed to petrol in your automotive or industrial projects, opt for a highly resistant adhesive that can withstand the test of time.

Now let’s talk about other influencing factors. The specific formulation of hot melt glue and the composition of the petrol itself can affect resistance levels too. Different polymers and additives can either enhance or reduce resistance, so it’s imperative to consider these variables when choosing your adhesive.

Applications Where Hot Melt Glue Should Not Be Used

Hot melt glue is a versatile adhesive that finds its place in a wide range of applications. However, it is essential to recognize the areas where hot melt glue may not be the best choice due to its limitations and potential risks. In this blog post, we will explore these applications and discuss why hot melt glue should be avoided in these cases.

High-Temperature Environments:

Hot melt glue has a relatively low melting point, typically ranging from 120 to 180 degrees Celsius. In applications involving high temperatures, such as automotive engines or industrial ovens, hot melt glue may not withstand the heat and can lose its adhesive properties. To tackle extreme temperatures, adhesives like silicone or epoxy-based glues with heat-resistant properties are more suitable.

Outdoor Applications:

While hot melt glue can endure moderate temperature variations, it is not designed to withstand prolonged exposure to outdoor elements. The glue can degrade when subjected to sunlight, moisture, and extreme weather conditions. For outdoor applications like construction projects or outdoor signage, weather-resistant adhesives such as polyurethane or acrylic adhesives should be used instead.

Structural Bonding:

Hot melt glue is primarily used for temporary bonding or non-structural applications. It lacks the high bond strength and long-term durability required for structural bonding tasks. When dealing with projects that demand a strong and permanent bond, structural adhesives like epoxy or cyanoacrylate (super glue) should be considered.

Porous Surfaces:

Hot melt glue works best on non-porous surfaces like plastic, metal, or glass. However, it may not effectively bond porous surfaces such as wood, fabric, or paper since the adhesive can be absorbed into the material and fail to create a strong bond. For bonding porous materials, specific adhesives designed for those materials, like wood glue for woodworking projects or fabric glue for textile applications, should be utilized.

High-Stress Applications:

Hot melt glue is unsuitable for applications involving high stress or pressure. It has limited flexibility and can become brittle under certain conditions, leading to bond failure. In situations where the bonded parts will experience constant movement, vibration, or heavy loads, flexible adhesives like polyurethane or rubber-based adhesives are more appropriate choices.

Food Contact Surfaces:

Hot melt glue should never be used on surfaces that come into direct contact with food or beverages. The adhesive may contain harmful chemicals that can leach into the food, posing a significant health risk. For food-related applications, it is essential to use food-grade adhesives specifically formulated to be safe for contact with edible items.

71IzSTV_S20″ >

Conclusion

Hot melt glue, commonly used in various applications, is often praised for its strong bonding properties and versatility. However, when it comes to its resistance to petrol, the results are not as promising. Despite its impressive performance in many other aspects, hot melt glue falls short in withstanding the harsh effects of petrol exposure.

Petrol, a highly flammable liquid commonly used as fuel for engines and machinery, can pose a significant challenge for hot melt glue. When exposed to petrol, the glue’s adhesive properties weaken, leading to potential bond failure. This can be problematic in situations where the glued materials are subjected to petrol or gasoline spills or leaks.

The chemical composition of hot melt glue plays a crucial role in determining its resistance to different substances. While it may excel in adhering to various surfaces such as wood, plastic, or fabric, petrol can penetrate the glue’s structure and cause it to break down over time. This breakdown weakens the bond between materials and compromises their overall integrity.

It is important to note that not all hot melt glues are created equal when it comes to resisting petrol. Some manufacturers offer specialized formulations that claim improved resistance against specific chemicals or solvents. These products may be worth considering if you anticipate regular exposure to petrol or other similar substances.

In conclusion, while hot melt glue exhibits remarkable bonding capabilities in a wide range of applications, its resistance to petrol is generally lacking. The chemical nature of petrol can compromise the adhesive properties of hot melt glue over time, potentially leading to bond failure.