Finding the perfect adhesive can be a real head-scratcher when you’re trying to stick things together. With so many options out there, it’s easy to get overwhelmed. But fear not, because one adhesive that truly stands tall in terms of strength is good ol’ hot glue. When used right, this stuff can work magic, securely bonding materials together like nobody’s business.

So what makes hot glue so special? Well, it’s all in the ingredients. Hot glue adhesive is made up of thermoplastic polymers that go from solid to liquid when heated. This nifty little feature allows it to seep into surfaces and create a bond that’s as strong as an ox on steroids.

But here’s the kicker – hot glue isn’t just for your run-of-the-mill projects. Nope, this bad boy can handle anything you throw at it. Need to fix something around the house? Hot glue’s got your back. Want to jazz up your crafts with some serious sticking power? Hot glue is your new BFF. Even those heavy-duty industries like manufacturing and construction rely on hot glue for its rock-solid adhesion.

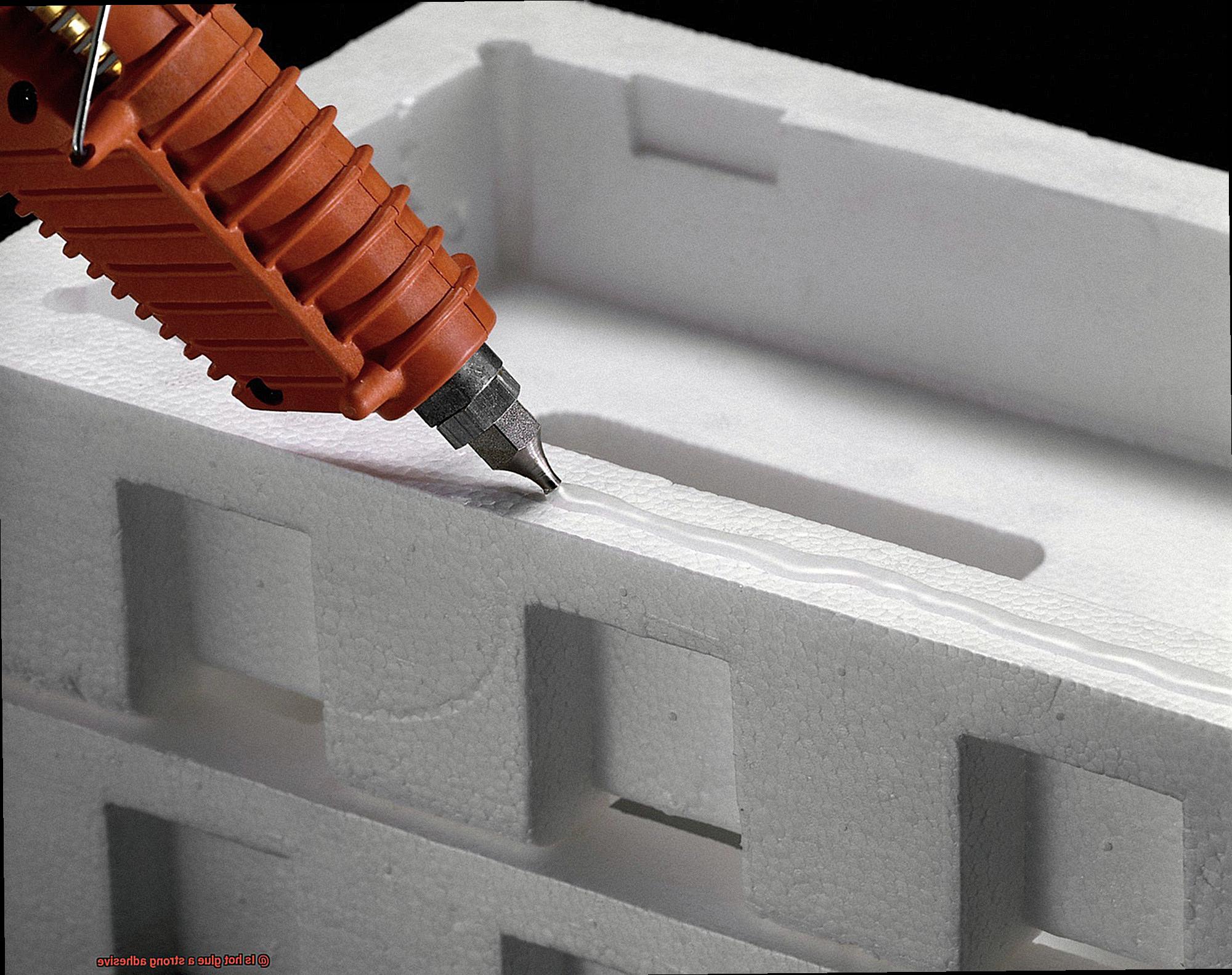

And let me tell you, using hot glue is a breeze. You can squirt it out of a gun (yes, like a cowboy) and get precise application even in those hard-to-reach nooks and crannies. No more struggling with other adhesives that just don’t cut it in tricky situations.

Now, I know what you’re thinking – what about extreme temperatures? Well, guess what? Hot glue laughs in the face of temperature fluctuations. It can handle scorching heat and freezing cold without breaking a sweat (or losing its grip). So whether you’re sticking stuff indoors or braving the great outdoors, hot glue won’t let you down.

Sure, there are a few things hot glue isn’t a fan of, like super smooth or oily surfaces. But hey, nobody’s perfect, right? Despite its quirks, hot glue is still a reliable and mighty adhesive for all sorts of tasks. So whether you’re a crafty genius, a DIY fanatic, or just someone who needs stuff to stay put, hot glue might just become your new best friend.

In our upcoming blog series, we’ll dive deeper into the world of hot glue adhesive. We’ll explore its best uses, share expert tips and tricks, and unlock the full potential of this

Advantages of Hot Glue

Contents

- 1 Advantages of Hot Glue

- 2 Limitations of Hot Glue

- 3 Factors that Affect the Strength of Hot Glue

- 4 Strength Comparison with Other Adhesives

- 5 How to Increase the Strength of Hot Glue

- 6 Applications for Stronger Adhesives

- 7 Tips for Choosing the Right Adhesive

- 7.1 Match the Materials:

- 7.2 Strength Matters:

- 7.3 Application Ease:

- 7.4 Time is Ticking:

- 7.5 Environmental Factors:

- 7.6 For outdoor projects or applications exposed to water or extreme temperatures, choose adhesives that are water-resistant, weatherproof, or heat-resistant. These specialized adhesives will ensure a strong bond even in challenging environments.

- 7.7 Seek Advice:

- 8 Conclusion

When it comes to adhesive applications, hot glue stands out as a popular choice for both professionals and hobbyists alike. Its versatility, lightning-fast drying time, robust bonding strength, heat resistance, user-friendly application, reversibility, and wide availability make it a reliable and convenient option for a wide range of projects.

In this article, we will delve into these advantages in detail, shedding light on why hot glue has become the go-to adhesive for countless crafting and DIY enthusiasts looking to unleash their creativity.

Versatility:

Hot glue’s versatility is like a chameleon of adhesives. It can bond various materials together, including paper, fabric, wood, plastic, and even metal. Whether you’re working on scrapbooking projects, creating fabric crafts, repairing broken household items, or securing heavy decorations, hot glue effortlessly adapts to any task.

Quick Drying Time:

Unlike other adhesives that sluggishly cure over hours or days, hot glue doesn’t waste any time. Within seconds of application, it solidifies and forms an unwavering bond between the surfaces being joined. This rapid curing property allows for immediate handling and use of the bonded items. With hot glue, there’s no more waiting around – your projects come to life in the blink of an eye.

Strong Bonding Strength:

Hot glue’s bond is unyielding, like the grip of a tenacious handshake. When applied correctly, it creates a durable connection that can withstand the test of time. Fixing a broken chair leg? Attaching embellishments to a handmade card? Hot glue ensures that your creations stay intact during everyday use and handling.

Heat Resistance:

Hot glue is an adhesive made of steel – it fearlessly faces high temperatures without losing its grip or weakening the bond. Perfect for projects involving heat-generating elements like candles or light bulbs, hot glue keeps everything securely in place, even when faced with sizzling challenges.

Easy Application:

Applying hot glue is as effortless as a painter’s brushstroke. With a glue gun in hand, the solid glue sticks transform into a liquid state and flow onto the desired area using the gun’s trigger mechanism. This precise application method grants greater control, reducing the chances of messy or uneven gluing. Hot glue’s ease of use ensures that crafters of all skill levels can wield it with finesse.

Reversibility:

Hot glue is a magician, granting makers the power to undo their creations if needed. Unlike many adhesives that form permanent bonds, hot glue can be softened and undone by applying heat to the glued area. This enchanting feature allows for easy disassembly or repositioning of items, giving crafters greater flexibility and freedom to experiment with different design ideas.

Wide Availability:

Hot glue is like a faithful companion that can be found by your side whenever you need it. Glue sticks and glue guns are widely available in various sizes and formulations at affordable prices. Craft stores, hardware stores, and online retailers all stock this adhesive wonder, making it accessible to professionals, hobbyists, and DIY enthusiasts alike.

Limitations of Hot Glue

Today, we embark on a journey to uncover the fascinating realm of hot glue and its limitations. While this adhesive superhero may initially seem invincible, it possesses a few kryptonite-like weaknesses that demand our attention.

So, grab your trusty glue guns, and let’s plunge into the world of hot glue’s limitations.

Temperature Sensitivity:

Hot glue’s Achilles heel lies in its sensitivity to temperature. Designed to melt at high temperatures, it can soften or even liquefy in hot environments. Consequently, if you plan on using hot glue for outdoor projects or applications exposed to high temperatures, it may not be the most reliable choice.

Lack of Flexibility:

Another limitation of hot glue lies in its rigidity. Once dried, it hardens into a solid form that lacks the flexibility required for certain projects. If you need a bond capable of enduring bending or stretching, hot glue might not be up to the task.

Moisture Woes:

Hot glue is not fond of moisture. Exposure to water or high humidity can diminish its stickiness or render it soft and pliable. Thus, if you’re working on something that will brave the elements or come into contact with water, hot glue may disappoint.

Material Compatibility:

While hot glue works marvelously on porous surfaces like wood, fabric, or paper, it struggles with smooth or non-porous materials such as glass, metal, or plastic. In such cases, selecting an adhesive specifically designed for those materials would be more effective.

Strength Matters:

Although hot glue is suitable for lightweight projects or temporary fixes, it may falter under heavy loads or in situations demanding a stronger bond. If you require a more robust adhesive option, exploring alternatives that offer greater strength is advisable.

Application Quirks:

Lastly, let’s address the application process itself. While hot glue is relatively easy to use, it necessitates a heated glue gun, demanding caution to avoid accidental messes or damage to your project or surrounding surfaces.

Factors that Affect the Strength of Hot Glue

Prepare to embark on a journey that will unravel the secrets behind hot glue’s adhesive power. So, grab your trusty glue guns and let’s dive in.

- Temperature Control: Hot glue has a temperature preference that can make or break its strength. If the temperature is too low, the glue won’t melt adequately, resulting in weak adhesion. Conversely, if it’s too hot, the glue becomes overly runny and loses its bonding prowess. To achieve optimal strength, adhere strictly to the manufacturer’s recommended temperature range.

- Pristine Surfaces: Just like your mother always said, cleanliness is key. Before applying hot glue, ensure that the surfaces are clean and dry. Dirt, grease, or moisture can hinder the glue’s ability to form a robust bond. So, take a moment to wipe those surfaces thoroughly with a cloth before you start gluing away.

- Material Compatibility: Not all materials are equal when it comes to bonding with hot glue. While hot glue works wonders on porous materials like wood, fabric, and paper, it may not adhere as strongly to non-porous substances such as metal or glass. For these challenging materials, special formulations or primers might be necessary to enhance adhesion and maximize strength.

- Masterful Technique: It’s not just about squeezing that trigger. The technique used to apply hot glue plays a critical role in its strength. To achieve maximum bonding potential, ensure an even layer of hot glue with full coverage on the surface. Uneven application can create weak spots and diminish bonding strength. And remember, less is often more – excessive amounts of glue can lead to shrinkage and reduced overall strength.

- Patience Rewarded: We understand your excitement about your project, but remember not to rush the curing process. Hot glue sets quickly, but it needs time to fully develop its strength. Allow it to cool and cure completely before subjecting the bond to any stress or load. Trust us, patience pays off with a stronger adhesive bond.

Strength Comparison with Other Adhesives

Step into the realm of adhesives, where a mighty warrior reigns supreme – hot glue. Celebrated for its exceptional bonding abilities, hot glue stands as a formidable contender in the adhesive kingdom.

Whether you’re a crafting enthusiast or an industrial professional, hot glue’s strength and versatility make it an unrivaled force. Join us on this thrilling adventure as we delve into a strength comparison between hot glue and other adhesives, shedding light on its unique qualities and limitations.

Versatility:

Hot glue’s greatest strength lies in its ability to form bonds effortlessly between a diverse range of materials. From wood to fabric, plastic to metal, hot glue holds its ground, forging powerful alliances between different surfaces. Crafters and professionals alike rely on its versatility to tackle any project with confidence.

Fast-Drying Time:

One of hot glue’s secret weapons is its lightning-fast drying time. Unlike liquid adhesives that demand hours or even days to cure, hot glue sets almost instantly upon application. This rapid bonding ensures swift project completion, eliminating the agony of waiting, and reducing the risk of accidental detachment during crucial moments of creation.

Durability:

Hot glue is no stranger to endurance. Once cured, it forms an unyielding bond capable of withstanding substantial stress and tension. Whether it’s securing delicate embellishments on a craft or reinforcing heavy-duty industrial components, hot glue’s unparalleled durability makes it the weapon of choice for tasks that demand long-lasting adhesive solutions.

Heat Resistance:

In the face of scorching temperatures, hot glue remains unflinching. With excellent heat resistance, it retains its adhesive properties even under extreme conditions. This quality makes it invaluable for applications where heat plays a significant role, ensuring that bonds stay strong and projects remain intact.

Cost-Effectiveness:

Hot glue’s strength doesn’t come at a hefty price. It stands as an affordable adhesive option compared to some other contenders in the market. Available in various forms such as glue sticks and cartridges for glue guns, hot glue ensures your budget remains intact while still delivering exceptional bonding performance.

Limitations:

While hot glue possesses many strengths, it does have its limitations. It may not be the ideal choice for bonding heavy or load-bearing objects, which require the brute force of other adhesives like epoxy or construction adhesive. Additionally, hot glue’s vulnerability to moisture and water exposure should be considered. While it offers resistance to heat, prolonged exposure to moisture can weaken its bond over time.

How to Increase the Strength of Hot Glue

Hot glue is a versatile adhesive that is widely used in crafting, DIY projects, and professional applications. While it may not be the strongest adhesive out there, there are several techniques you can employ to increase its strength. In this article, we will explore some tried and tested methods to help you maximize the bonding power of hot glue and create unbreakable bonds.

Harness the Heat:

Increasing the temperature setting on your glue gun is a simple yet effective way to enhance the strength of hot glue. By using hotter glue, you lower its viscosity, allowing it to penetrate and bond more effectively. This results in a stronger hold that can withstand greater stress and strain.

Prime for Power:

Certain materials, like plastics or metals, have smooth or non-porous surfaces that don’t adhere well to hot glue. To overcome this challenge, apply a bonding aid or primer specifically designed for hot glue adhesion. These products create a strong foundation for the hot glue to bond to, ensuring a durable and long-lasting connection.

Prep for Success:

Preparing the surface before applying hot glue is crucial for maximizing its strength. Roughen or sand the surface, especially on materials like wood or fabric, to create better grip and enhance adhesion. Cleaning the surface from dust, dirt, or grease is also essential as it removes any barriers that could weaken the bond.

Combine Adhesive and Mechanical Power:

For added strength and durability, consider reinforcing the hot glue joint with mechanical support. In addition to the adhesive bond, use staples, screws, or other fasteners to secure the materials together. This combination of mechanical and adhesive bonding provides extra reinforcement and ensures a strong connection that can withstand heavy loads.

Add a Touch of Magic:

In certain cases, adding additives or fillers to hot glue can significantly boost its strength. For example, incorporating powdered fiberglass into the hot glue mixture can improve its tensile strength and resistance to pulling forces. However, it is important to carefully follow instructions and guidelines when using additives, as they may alter the properties of the hot glue and require specific handling.

Patience is Key:

To achieve maximum strength, allow the hot glue to cure and cool fully before subjecting it to stress or load. Rushing can result in weaker bonds, so be patient and follow the manufacturer’s instructions for curing time and temperature. This will ensure that the adhesive has reached its full bonding potential, resulting in a stronger connection.

Applications for Stronger Adhesives

Stronger adhesives have revolutionized numerous industries, offering reliable and durable bonding solutions. From construction to aerospace, manufacturing to medicine, and even the arts and crafts industry, these powerful glues have become indispensable. Here are some of the fascinating applications of stronger adhesives:

- Construction Industry: Stronger adhesives play a vital role in bonding materials like concrete, metal, wood, and plastic. They are used in various applications such as installing flooring, attaching wall panels, and securing fixtures.

- Automotive Industry: Strong adhesives are the unsung heroes of car assembly, holding components together. They are used for attaching trim pieces, bonding glass to the vehicle frame, and even joining structural components. These adhesives ensure your car stays intact during bumpy rides.

- Aerospace Industry: Adhesives used in aerospace face extreme temperatures and must provide strong bonds to hold critical components in place. They are used in aircraft assembly, bonding composite materials, and repairing structures.

- Manufacturing Industry: Strong adhesives are essential for bonding parts during assembly processes. They also help attach labels or packaging materials and secure electronic components in devices. Without them, our gadgets wouldn’t be as sturdy.

- Medical Field: Stronger adhesives find applications in wound closure, surgical procedures, and dental work. They ensure that everything stays in place when it matters the most.

- Arts and Crafts: Stronger adhesives are perfect for bonding materials like ceramics, glass, fabric, and metals. Whether creating a stunning mosaic or sculpting a masterpiece, these glues ensure your creation stands the test of time.

Tips for Choosing the Right Adhesive

With so many options available, it can be overwhelming to find the perfect glue for your project. But fear not. We’ve gathered some tips to help you make an informed decision and stick with confidence.

Match the Materials:

Different adhesives work better on certain materials. Consider the surfaces you’re bonding – paper, fabric, wood, plastic, or metal – and choose an adhesive that is compatible with those materials. For example, hot glue is great for porous materials like fabric and wood, while epoxy is better for metals and plastics.

When working with delicate materials like paper or fabric, opt for a glue that dries clear and doesn’t leave any residue or stains. For heavy-duty projects involving metal or plastic, choose adhesives specifically formulated for those materials to ensure a strong bond.

Strength Matters:

Think about the strength required for your project. If you need a strong bond that can withstand heavy loads or extreme conditions, opt for adhesives like epoxy or construction adhesive. These adhesives provide exceptional strength and durability.

On the other hand, if you are working on lightweight crafts or need a temporary bond that can be easily removed without damaging the surface, consider using hot glue or double-sided tape. These adhesives offer versatility and ease of use.

Application Ease:

Consider the application method that suits your project best. Liquid adhesives with precision applicators are ideal for hard-to-reach areas or intricate details. They allow for precise control and ensure even distribution of the adhesive.

For quick and easy bonding, hot glue guns or double-sided tape are excellent choices. Hot glue guns provide instant bonding and are perfect for larger projects, while double-sided tape offers convenience and simplicity.

Time is Ticking:

Drying time matters. Some adhesives dry quickly, which is advantageous for time-sensitive projects or when you need to move on to the next step quickly. Others take longer to dry, providing more time for adjustments and repositioning.

If you’re working on a project that requires immediate bonding, consider using instant adhesives like cyanoacrylate (super glue) or hot glue. These adhesives bond quickly and securely. If you need more flexibility and time to make adjustments, opt for adhesives with longer drying times.

Environmental Factors:

Don’t forget to consider the environment in which your adhesive will be used. Factors such as temperature, humidity, and exposure to chemicals or UV light can affect bond strength. Select an adhesive that can withstand these conditions.

For outdoor projects or applications exposed to water or extreme temperatures, choose adhesives that are water-resistant, weatherproof, or heat-resistant. These specialized adhesives will ensure a strong bond even in challenging environments.

Seek Advice:

When in doubt, seek advice from professionals or read customer reviews. They can provide valuable insights into the effectiveness and reliability of different adhesives, helping you make an informed decision.

5mNAkxqhXiI” >

Also Read: How Much Weight Can Hot Glue Hold?

Conclusion

Hot glue is indeed a formidable adhesive. Its strength and versatility make it a go-to choice for many crafting and DIY projects. Whether you’re bonding materials like wood, plastic, fabric, or even metal, hot glue can hold them together with remarkable tenacity. It forms a strong bond quickly, allowing you to move on to the next step of your project without delay.

But what makes hot glue truly exceptional is its ability to withstand various conditions. It can endure extreme temperatures, making it ideal for both indoor and outdoor applications. Whether it’s scorching heat or freezing cold, hot glue remains steadfast in its grip. This resilience ensures that your creations will stand the test of time.

Not only is hot glue strong, but it’s also incredibly versatile. Its adhesive properties work well on a wide range of surfaces, including porous and non-porous materials. From delicate fabrics to rough surfaces, hot glue adapts effortlessly to different textures and substrates.

Furthermore, hot glue offers convenience and ease of use. With just a simple squeeze of the trigger on a hot glue gun, you have a molten adhesive ready to be applied precisely where you need it. The quick drying time means less waiting around for the bond to set – perfect for those who value efficiency in their projects.

In conclusion, hot glue unquestionably earns its reputation as a strong adhesive. Its strength, durability, versatility, and user-friendliness make it an indispensable tool in any crafter’s arsenal.