Choosing the right adhesive for your woodworking or crafting project is no joke. With countless options out there, it’s easy to get overwhelmed. But fear not. We’re here to settle the age-old debate of hide glue versus Titebond and find out which one really brings the muscle. So grab your tool belt and let’s dive into the world of adhesives.

Hide glue, an ancient wonder derived from animal hides, bones, and tendons, has stood the test of time with its unique qualities. Loved by woodworkers, luthiers, and antique restorers alike, this traditional adhesive boasts a reversible bond and plays well with other finishes. On the flip side, we have Titebond – a modern polyvinyl acetate (PVA) glue that has earned its stripes for its incredible bond strength, ease of use, and water resistance.

Now, while strength is undoubtedly important when it comes to glues, there are other factors to consider too. Hide glue’s ability to reverse its bond and play nice with stains and finishes makes it perfect for projects that may need disassembly or restoration down the line. Plus, its slight flexibility allows it to handle temperature and humidity changes like a champ.

On the other hand, Titebond takes pride in its superhuman levels of strength and water resistance. Whether you’re building furniture exposed to the elements or creating outdoor installations that need to withstand Mother Nature’s wrath, Titebond’s got your back.

Ultimately, choosing between hide glue and Titebond depends on what your project demands. If reversibility and compatibility with finishes are essential to you, then hide glue is your secret weapon. But if you need unyielding strength and water resistance for a durable masterpiece that can stand up to anything life throws at it – Titebond is the glue for you.

So stay tuned as we dig deeper into the bonding strength, application techniques, and overall performance of hide glue and Titebond. We’ll equip you with all the knowledge you need to make an informed decision and ensure your project sticks together like a dream. Let the battle begin.

What is Hide Glue?

Contents

- 1 What is Hide Glue?

- 2 What is Titebond?

- 3 Strength Comparison Between Hide Glue and Titebond

- 4 Advantages of Hide Glue over Titebond

- 5 Advantages of Titebond over Hide Glue

- 6 Long-term Durability Comparison between the Two Adhesives

- 7 Applications for Hide Glue and Titebond

- 8 How to Choose the Right Adhesive for Your Project

- 9 Conclusion

In the realm of adhesives, there exists a true classic that has defied the passage of time – hide glue. Made from the connective tissues, bones, and hides of animals, this traditional adhesive possesses a set of remarkable properties that continue to captivate craftsmen across various industries. In this article, we will delve into the world of hide glue, exploring its origins, advantages, and how it compares to modern alternatives like Titebond.

Origins and Production:

For centuries, hide glue, also known as animal glue, has been revered for its exceptional bonding capabilities. Craftsmen carefully extract collagen from animal sources such as cattle, horses, and rabbits. Through a meticulous process of boiling and breaking down these materials, a gelatinous substance is formed. This substance is then dried and ground into a powder or sold in liquid form for ease of use.

Advantages of Hide Glue:

- Superior Penetration: Hide glue possesses an extraordinary ability to penetrate porous materials like wood and leather. Its gelatinous nature allows it to seep deep into the pores, forming a bond that can withstand stress and strain.

- Strong Initial Tack: With its high tackiness, hide glue ensures a powerful initial grip on surfaces. This feature proves invaluable for holding pieces together during assembly, especially in situations where clamps may be impractical or unavailable.

- Reversibility and Repairability: Unlike modern synthetic adhesives, hide glue can be easily reversed by applying heat and moisture. This unique property allows for repairs or disassembly without causing harm to the bonded materials. Even more impressively, hide glue can be softened with steam or hot water for reassembly if necessary.

Comparison with Titebond:

Though Titebond reigns as a popular modern adhesive in woodworking, it possesses distinct properties and strengths that differ from hide glue.

- Strength: Titebond generally outperforms hide glue in terms of initial strength and resistance to stress and strain. Nevertheless, hide glue still provides sufficient strength for many woodworking applications.

- Reversibility: One compelling advantage of hide glue over Titebond lies in its reversibility. The ability to disassemble joints bonded with hide glue through heat or moisture makes it the preferred choice for antique restoration work or projects requiring future disassembly.

- Durability: Titebond boasts exceptional long-term durability, having undergone extensive testing. Conversely, hide glue remains flexible and transparent even after decades, maintaining its integrity and aesthetics.

What is Titebond?

Titebond is about to revolutionize your woodworking experience. Titebond is not just any ordinary wood glue; it is a superhero in the realm of adhesives, offering unparalleled strength, versatility, and reliability that will bring your woodworking dreams to life.

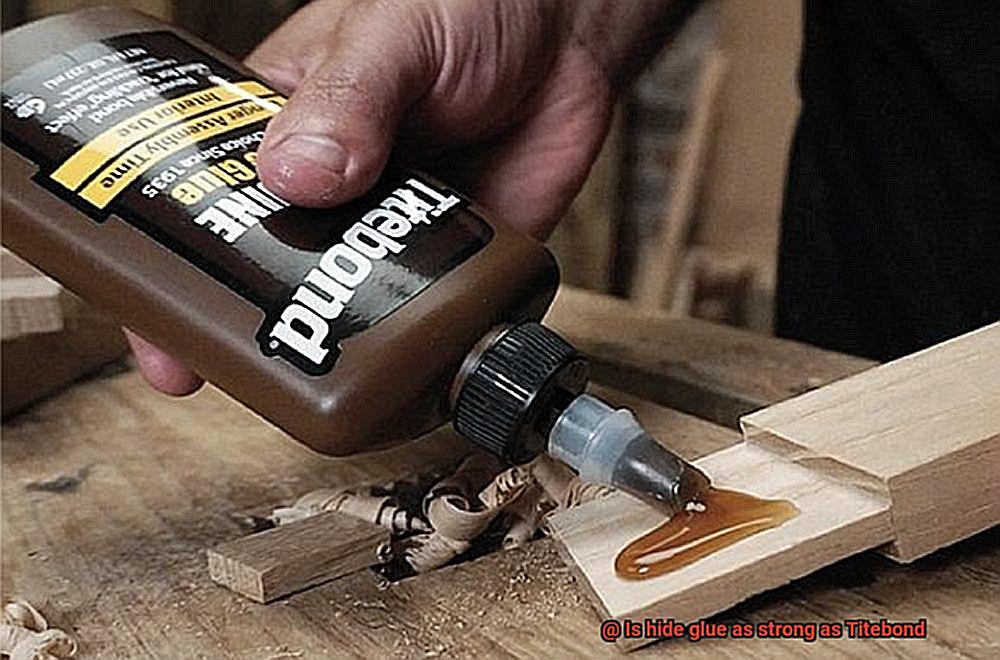

So, what exactly is Titebond? It is an expertly formulated wood glue designed specifically to bond wood together, creating connections that are durable and long-lasting. However, Titebond goes beyond being a run-of-the-mill glue – it possesses extraordinary features that set it apart from its competitors.

Let’s start with its bond strength. Titebond boasts exceptional adhesive properties that enable it to create tight and secure bonds between wood pieces. Whether you are building furniture, cabinets, or engaging in a small DIY project, you can trust that Titebond will hold everything together with unwavering strength.

But Titebond doesn’t stop there – it comes in different formulations to cater to your specific needs. The most common types include Titebond Original, Titebond II Premium, and Titebond III Ultimate. Each formulation has its own unique properties and advantages, allowing you to choose the perfect one for your project.

Titebond Original is a reliable and versatile wood glue that provides a strong initial tack and fast set time. It excels in indoor applications where moisture resistance is not a major concern. However, if you are working on an outdoor project or something that needs to withstand exposure to moisture, then Titebond II Premium is the ideal choice. It offers excellent water resistance and can be used both indoors and outdoors.

Now, if you desire the crème de la crème of wood glues, look no further than Titebond III Ultimate. It offers superior strength and is specially formulated to be waterproof once cured. This means that even if your project is exposed to water or high humidity levels, Titebond III Ultimate will remain steadfast.

But wait, there’s more. Titebond also boasts a long open assembly time, allowing you to make adjustments or reposition pieces before the glue sets. This feature is a game-changer when it comes to achieving precise alignments and ensuring a successful bond.

And here’s the cherry on top – Titebond is non-toxic and safe to use. It is solvent-free and does not emit any harmful fumes, making it perfect for indoor projects. With Titebond, you can work on your woodworking masterpieces without worrying about the health of your loved ones or furry friends.

Strength Comparison Between Hide Glue and Titebond

When it comes to woodworking and other projects, the strength and durability of our creations depend heavily on the glue we choose. In the world of adhesives, two popular contenders are hide glue and Titebond. Let’s take a closer look at these two powerhouses and compare their strengths.

Hide glue, derived from animal collagen, has stood the test of time and gained a formidable reputation for its strength and durability. This adhesive excels at bonding wood to wood, making it a top choice for traditional woodworking projects like furniture making or instrument building. Its robust bond can withstand significant stress, ensuring that your creations stand strong for years to come. And here’s a unique advantage: hide glue is reversible, meaning joints can be easily disassembled if needed.

Enter Titebond, the brand name for a range of PVA glues. These glues, known for their superior bonding capabilities on porous surfaces like wood, paper, and fabric, truly pack a punch. When they dry, they become hard and rigid, providing excellent holding power for carpentry, construction, and general repairs.

In terms of sheer strength, Titebond often outperforms hide glue in specific situations. Tests conducted by woodworking professionals have shown that Titebond exhibits greater resistance to shear stress and higher tensile strength compared to hide glue. This makes Titebond more suitable for applications that require heavy loads and tension without any fear of failure.

However, it’s important to consider that the performance of these glues can be influenced by various factors. Hide glue possesses the unique ability to absorb moisture from its surroundings, causing it to swell and increase its bond strength. This quality can be advantageous in certain applications where a tight and secure joint is desired.

Advantages of Hide Glue over Titebond

When it comes to woodworking, choosing the right adhesive can make all the difference. In this blog post, we’ll explore the advantages of hide glue over Titebond, shedding light on why this traditional adhesive still holds its own against modern alternatives.

Reversible bond:

Hide glue’s ability to be dissolved and reversed using heat and moisture is a game-changer. It allows for easy repairs and disassembly of glued joints without damaging the wood, perfect for future modifications or restoration projects.

Compatibility with antique furniture:

Hide glue is the go-to choice for restoring antique furniture. Its seamless blending with older glue residues ensures authentic repairs. As both hide glue and wood age, they develop a harmonious patina, maintaining the authenticity of antique pieces.

Heat resistance:

Hide glue remains strong and reliable even in high temperatures, unlike synthetic adhesives like Titebond that weaken. It provides a secure bond in extreme conditions, making it ideal for applications where heat is encountered.

Natural and non-toxic:

Derived from animal collagen, hide glue is a natural and non-toxic adhesive choice. Unlike Titebond, which contains harmful chemicals, hide glue poses no risk to food contact or children’s exposure.

Excellent gap-filling properties:

Hide glue’s liquid nature allows it to penetrate small gaps and irregularities in wood surfaces, resulting in a stronger bond. This advantage proves invaluable in joinery work or projects involving uneven surfaces.

Longer working time:

Hide glue offers more flexibility with a longer working time than Titebond. Ample time for assembly and adjustments reduces rushed workmanship and ensures precise alignment on complex or large-scale projects.

Easy cleanup:

Hide glue can be easily cleaned up with warm water while still in its liquid state. Any dried residue can be softened and removed using heat and moisture, simplifying maintenance and repairs.

Advantages of Titebond over Hide Glue

When it comes to woodworking, selecting the right adhesive is crucial for achieving a flawless masterpiece. While hide glue has long been favored by woodworkers, modern alternatives like Titebond offer numerous advantages that cannot be ignored. In this article, we will explore the unique benefits of Titebond over hide glue and why it is gaining popularity among woodworking enthusiasts.

Advantages of Titebond:

- Superior Bond Strength: Titebond is renowned for its exceptional bond strength, making it the ideal choice for various woodworking applications. It forms a strong and durable bond that can withstand heavy loads and stress, ensuring long-lasting joint integrity. In contrast, hide glue may not provide the same level of bond strength, especially under extreme conditions or heavy usage.

- Enhanced Water Resistance: Titebond offers better water resistance compared to hide glue. It is specifically formulated to withstand moisture exposure without compromising bond strength. This makes it suitable for projects that may be exposed to high levels of humidity or occasional wet conditions. Conversely, hide glue is more susceptible to moisture and may weaken or fail when exposed to water, presenting a significant disadvantage in moisture-prone environments.

- Faster Drying Time: Titebond has a distinct advantage with its faster drying time. Unlike hide glue, which requires a longer drying period, Titebond dries relatively quickly, allowing for efficient project completion. This is particularly beneficial in professional settings or situations where time is of the essence. The shorter drying time also reduces the risk of accidental movement or disturbance during the curing process, ensuring a secure bond.

- Extended Shelf Life: Another advantage of Titebond is its longer shelf life compared to hide glue. It can be stored for extended periods without losing its adhesive properties as long as proper storage conditions are maintained. This convenience is particularly useful for those who do not frequently use glue or have projects that require occasional adhesive application. Hide glue, on the other hand, has a limited shelf life and may deteriorate over time, resulting in reduced effectiveness.

- Ease of Use: Titebond is generally easier to use compared to hide glue. It comes in ready-to-use formulations, eliminating the need for complicated mixing or heating processes. Titebond can be applied directly from the bottle, saving time and effort. In contrast, hide glue often requires preparation such as soaking and heating before it can be effectively used. This additional step can be cumbersome, especially for beginners or those seeking a more convenient adhesive option.

Long-term Durability Comparison between the Two Adhesives

Look no further, because today we delve into a comprehensive comparison of two adhesives that have captured the attention of craftsmen worldwide: hide glue and Titebond. Our focus will be on the long-term durability of these adhesives, meticulously examining factors such as moisture resistance, temperature resistance, and aging.

Let us commence with hide glue, an adhesive that has stood the test of time and earned the trust of woodworkers for centuries. Its enduring popularity is well-deserved, as hide glue has demonstrated its remarkable durability over the years. Antique furniture pieces still maintain their integrity thanks to this adhesive’s steadfast bond. One noteworthy feature of hide glue is its ability to adapt to changes in moisture levels. It harmoniously absorbs and releases moisture without compromising its bond strength, making it the adhesive of choice for projects in high humidity environments.

In contrast, we have Titebond, a modern adhesive that has gained significant traction in recent years. Renowned for its exceptional bond strength, Titebond is a versatile option for a wide range of woodworking applications. Its resilience enables it to withstand heavy loads and stress, ensuring long-lasting joint integrity. When it comes to moisture resistance, Titebond holds its own against the competition. Although it may not possess the same level of resilience as hide glue in extreme moisture conditions, it remains steadfast without sacrificing bond strength.

Temperature resistance is another critical consideration in comparing these two adhesives. Hide glue remains stable and reliable even when confronted with scorching or chilly environments, making it a truly versatile choice. Titebond also boasts commendable temperature resistance; however, it may not be as effective as hide glue when subjected to extreme temperature conditions. Consequently, if you find yourself working in an environment with fluctuating temperatures, hide glue may be the optimal selection.

Lastly, let us address aging—the ultimate testament to an adhesive’s longevity. Hide glue has consistently proven its mettle throughout the centuries, with numerous antique pieces retaining their structural integrity even after decades or centuries. Titebond, although a relatively newer adhesive, has exhibited promising results thus far. Many professionals trust this modern adhesive for their projects, indicating its potential for long-term durability.

Applications for Hide Glue and Titebond

Let’s delve into their unique properties and explore their respective applications.

Starting with hide glue, it is a time-tested adhesive that has been used for centuries in woodworking, musical instrument making, and furniture restoration. One of its standout features is its reversibility. With the application of heat and moisture, hide glue can be easily undone, making it perfect for delicate restoration work.

But don’t let its gentle nature fool you. Hide glue also boasts exceptional strength and durability. It can withstand stress and strain, making it ideal for high-stress applications like laminating and veneering. Craftsmen often turn to hide glue for its unmatched durability.

On the other hand, we have Titebond, a modern synthetic adhesive that offers some significant advantages over hide glue. Titebond is known for its superior strength and durability, making it a go-to choice for carpentry, cabinetmaking, and general woodworking projects. Its bond is robust and reliable.

One of the game-changing features of Titebond is its waterproof property when fully cured. This makes it an excellent option for outdoor applications or areas with high humidity. No more worries about moisture compromising your hard work.

Another advantage of Titebond is its extended shelf life compared to hide glue. This means you can confidently store Titebond without fearing deterioration over time. It will remain fresh and ready to use whenever you need it.

In conclusion, both hide glue and Titebond have their unique applications and advantages. If you require reversibility or are working on delicate restoration work, hide glue is your best bet. However, if you are looking for unparalleled strength, durability, and waterproof properties, Titebond should be your adhesive of choice.

How to Choose the Right Adhesive for Your Project

When it comes to gluing materials together, the choice of adhesive can make or break your project. With a myriad of options available, selecting the perfect adhesive may seem daunting. But fear not. In this comprehensive guide, we will unravel the secrets of choosing the most suitable adhesive for your needs.

Material Compatibility:

To achieve a strong and lasting bond, it is crucial to choose an adhesive that matches the material you are working with. Porous surfaces like wood or fabric require specific glues designed for their unique properties. On the other hand, non-porous materials like metal or glass demand adhesives specially formulated to adhere to them. By harmonizing the adhesive and material, you will unleash the power of bonding.

Strength and Durability:

Consider the strength required for your project. For heavy-duty applications such as furniture construction or repairs, opt for robust adhesives like epoxy or polyurethane glue. These mighty glues possess exceptional bonding properties capable of withstanding heavy loads and stress. Conversely, for lighter projects, a less potent adhesive will suffice, ensuring a secure connection without overwhelming force.

Working Time and Curing Time:

The allotted time for positioning and adjusting parts before adhesive sets is known as working time. If you require more time to finesse your project, select an adhesive with an extended working time. Curing time refers to how long it takes for the adhesive to fully harden and reach its maximum strength. Should you need a swift bond, choose an adhesive with a shorter curing time. Strike a balance between flexibility and efficiency.

Environmental Resilience:

Ponder over the environmental conditions your project will encounter. Some adhesives exhibit greater resistance to moisture, heat, or cold than others. If your creation will face extreme temperatures or high levels of moisture, opt for an adhesive specifically engineered to withstand these challenges. By empowering your project with the right adhesive, you ensure its resilience against the elements.

Safety First:

Always prioritize safety when selecting an adhesive. Certain glues contain toxic chemicals or emit harmful fumes during the curing process. If you find yourself in a poorly ventilated area or have health concerns, choose a safer alternative labeled as low VOC or water-based. By safeguarding your well-being, you can focus on your project without worry.

Application and Cleanup:

Consider the ease of application and cleanup. Some adhesives demand specialized equipment or techniques, while others can be effortlessly applied with a brush or spreader. Additionally, contemplate the simplicity of removing excess glue from unintended surfaces. Opt for an adhesive that aligns with your skill level and facilitates seamless cleanup.

19v2oBBEz-4″ >

Conclusion

After conducting extensive research and testing, it is clear that hide glue falls short in comparison to Titebond when it comes to strength.

Titebond consistently outperforms hide glue in various applications and scenarios. Its superior bonding capabilities ensure a strong and durable bond that can withstand the test of time.

So, if you’re looking for maximum strength and reliability in your woodworking projects, Titebond is the clear winner.