Woodworking is a craft that demands the perfect blend of creativity and practicality. And when it comes to joining materials, finding the right adhesive can make or break your project. But what about Medium Density Fiberboard (MDF)? This versatile wonder material has become a go-to for its affordability and smooth finish. Yet, the burning question remains: can glue alone hold MDF together? In this blog post, we’ll embark on an adventure through the world of woodworking to uncover the truth behind MDF joints. So, whether you’re a seasoned pro or just starting out on your DIY journey, get ready to dive deep into the sticky world of glue and MDF connections.

What is MDF?

Contents

In the realm of woodworking, the choice of material is paramount to the success of any project. Medium-Density Fiberboard, or MDF for short, has emerged as a popular option in recent years. In this comprehensive guide, we will embark on a journey through the world of MDF, exploring its composition, advantages, limitations, and the best glue options to achieve flawless bonds.

What is MDF?

MDF is an engineered wood product forged through the fusion of wood fibers and adhesive resin under intense pressure and temperature. This meticulous process yields a dense and uniform board with a velvety-smooth surface, making it an ideal canvas for painting, laminating, and perfecting finishing techniques.

Advantages of MDF:

- Versatility: MDF is a maestro in the hands of craftsmen. With conventional woodworking tools, it can be effortlessly cut, routed, and shaped into intricate designs and custom-made furniture that transcend imagination.

- Cost-effective: Embracing elegance doesn’t have to come at exorbitant prices. MDF’s affordability sets it apart from solid wood or plywood, making it a budget-friendly choice for various projects without sacrificing quality.

- Sustainability: Mother Earth smiles upon those who choose MDF. Often crafted from recycled wood fibers and by-products from the lumber industry, MDF minimizes waste and champions environmental sustainability.

Limitations of MDF:

- Moisture susceptibility: MDF’s Achilles’ heel lies in its vulnerability to moisture and humidity. Excessive water or moisture exposure can cause swelling, warping, or even disintegration. To preserve its integrity, sealing and finishing techniques are crucial fortifications against unwanted moisture penetration.

- Structural strength: While MDF boasts strength and stability, it falls short in comparison to solid wood or plywood when it comes to structural applications. Load-bearing ventures may require alternative materials.

Choosing the Right Glue for Bonding MDF:

- Carpenter’s glue (PVA glue): A celebrated choice in the woodworking realm, carpenter’s glue delivers formidable bonds when applied with precision and allowed ample drying time. However, its performance may falter in high-moisture environments.

- Polyurethane glue: Embracing challenges head-on, polyurethane glue triumphs in demanding conditions such as high humidity or fluctuating temperatures. It expands during the curing process, filling gaps and adding strength to the bond.

- Epoxy resin: Renowned for its unwavering might and durability, epoxy resin excels in bonding MDF to other materials or when a waterproof union is essential. Its meticulous mixing process and longer curing time ensure a bond that withstands the test of time.

Advantages and Disadvantages of MDF

Today, we’ll dive deep into the world of glue, uncovering the advantages and disadvantages of this versatile material. So grab your tools and let’s get started.

Advantages of MDF:

- Affordability: MDF takes center stage when it comes to cost-effectiveness. With its pocket-friendly price tag, it’s the go-to choice for those looking to save some bucks without compromising quality.

- Versatility: MDF is like a chameleon, effortlessly adapting to any project you throw its way. Whether you’re crafting furniture or adding decorative touches, this material can be cut, shaped, and molded to perfection.

- Smooth Surface: Say goodbye to pesky knots and grain patterns. MDF flaunts a flawlessly smooth surface, perfect for achieving that professional finish. Painting or applying veneers becomes a breeze, ensuring your masterpiece shines.

- Stability: No more worries about warping or twisting. MDF boasts good dimensional stability, making it a reliable choice for long-lasting projects. It’ll keep its shape even when faced with temperature or humidity changes.

- Consistency: Predictability is key. The manufacturing process of MDF ensures consistency across the entire board. From density to strength, you can rely on its performance every single time.

Disadvantages of MDF:

- Susceptibility to Moisture: Beware the water beast. MDF has a weakness for moisture, which can cause swelling or even disintegration. To avoid such mishaps, keep it away from high-moisture areas unless properly sealed.

- Lack of Durability: While strong and stable, MDF falls short in durability compared to solid wood. Scratches, dents, and chipping are its kryptonite. Handle with care to keep your MDF creations looking their best.

- Weighty Matters: Brace yourself for a hefty lift. MDF is denser and heavier than natural wood. Moving larger items can be a challenge, so plan accordingly when assembling your furniture or structures.

- Environmental Concerns: Let’s talk about the elephant in the room – formaldehyde emissions. MDF’s manufacturing process involves resins that may contain formaldehyde, a VOC. Poor ventilation can lead to indoor air pollution and health risks. Look for low-emission or formaldehyde-free options to address these concerns.

- Limited Screw-Holding Capacity: MDF’s fibers don’t quite match the structural integrity of solid wood, so screws may become loose or stripped over time. Proper techniques and hardware selection are crucial to ensure secure fastening.

Different Types of Glue for Bonding MDF

When it comes to bonding Medium-Density Fiberboard (MDF), choosing the right glue is crucial. MDF is a versatile material used in various projects due to its affordability and smooth surface. In this article, we will explore different types of glue suitable for bonding MDF, each with its own strengths and weaknesses.

Carpenter’s Glue: The Reliable Workhorse

Carpenter’s glue, also known as yellow or PVA glue, is a popular choice for MDF projects. It offers a strong bond and dries clear, making it ideal for applications where aesthetics matter. However, it may not perform well in high moisture environments.

Polyurethane Glue: Tackling Challenging Conditions

Polyurethane glue is ideal for MDF bonding, especially in high humidity or temperature-varied environments. It expands while curing, filling gaps and providing extra strength to joints. Be cautious during application as it tends to foam up.

Epoxy Resin: Unbeatable Strength and Durability

For ultimate strength and durability, epoxy resin is the go-to glue. This two-part adhesive forms a chemical bond with MDF and works wonders when bonding MDF to other materials. However, it requires careful mixing and longer curing time.

Cyanoacrylate (Super Glue): Quick Fixes and Small-Scale Projects

For fast adhesion or small-scale repairs, cyanoacrylate glue, commonly known as super glue, is your go-to option. It sets instantly upon contact with moisture, making it perfect for quick fixes. However, it may not be suitable for larger or load-bearing applications due to its lower shear strength.

Specialized Adhesives: Tailored to Perfection

Some specialized adhesives are designed explicitly for bonding MDF. These adhesives contain resins specially formulated for MDF, offering a strong and durable bond without compromising the surface finish. Look for low odor or fast-curing options to enhance your MDF projects.

Carpenter’s Glue

Carpenter’s glue, also known as woodworking glue or yellow glue, is a versatile adhesive that is specifically formulated to bond wood materials together. Made from a combination of water, resin, and various additives, this adhesive has been a go-to choice for carpentry and woodworking projects for many years.

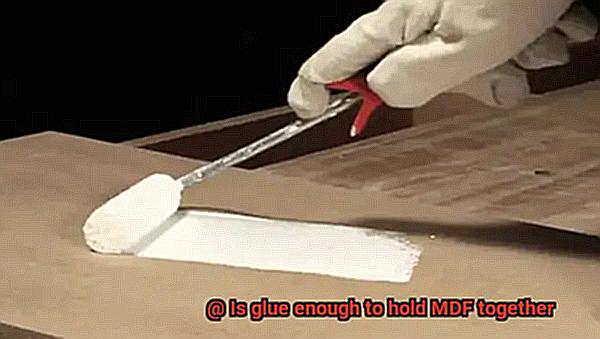

When it comes to MDF (medium-density fiberboard), carpenter’s glue can be an effective option for creating strong and durable bonds. MDF is a popular choice for furniture and cabinetry due to its smooth and consistent surface. To ensure a successful bond, proper surface preparation is crucial. Both surfaces should be thoroughly cleaned, dried, and free from any dust or debris. Additionally, lightly sanding the surfaces will create some texture, allowing the glue to penetrate and bond more effectively.

Applying carpenter’s glue on MDF requires an even layer on both surfaces. This can be achieved using a notched trowel or a brush to spread the glue evenly. It’s important to avoid using excessive amounts of glue as it can lead to weak bonds and longer drying times.

Once the glue is applied, firmly press the two pieces of MDF together. To ensure even pressure across the entire joint, use clamps or weights. It’s essential to allow sufficient drying time as specified by the manufacturer before removing the clamps or weights.

Carpenter’s glue typically dries clear and forms a strong bond on MDF. However, keep in mind that MDF can absorb moisture from the adhesive over time, potentially weakening the bond if exposed to excessive moisture.

For added reinforcement, some carpenters choose to use additional fasteners such as screws or nails. This provides extra support and prevents any potential movement or separation of the glued joint.

Polyurethane Glue

Polyurethane glue is a versatile and strong adhesive that is commonly used in woodworking projects, particularly when working with medium-density fiberboard (MDF). It offers several advantages that make it an excellent choice for joining different materials together.

First and foremost, polyurethane glue excels at creating a strong and durable bond. When applied to surfaces, it reacts with moisture in the air or on the materials, causing it to expand and foam up. This reaction fills in any gaps or irregularities in the surfaces, resulting in a tight and secure bond. This bond is not only strong but also resistant to water and heat, making it ideal for projects that may be exposed to moisture or high temperatures.

When it comes to MDF, polyurethane glue is particularly beneficial. MDF is made from wood fibers compressed together with a resin adhesive. While it is generally a stable material, it can be vulnerable to swelling and warping when exposed to moisture. Polyurethane glue’s water-resistant properties help prevent moisture from penetrating the MDF and causing damage, ensuring the longevity of your project.

Furthermore, polyurethane glue offers excellent adhesion to various other materials commonly used with MDF, such as solid wood or veneer. This means you can seamlessly integrate different components in your project, creating a cohesive and sturdy final product.

To achieve optimal results with polyurethane glue, proper preparation and application are essential. Ensure that the surfaces you are gluing are clean, dry, and free from any debris that could interfere with adhesion. Applying even pressure during clamping is also crucial to ensure a tight bond.

Epoxy Resin

In the world of adhesives, epoxy resin reigns supreme. Its exceptional strength, versatility, and durability make it a go-to choice for a wide range of applications. Whether you’re a professional woodworker or a DIY enthusiast, understanding what epoxy resin is and how it works can elevate your projects to new heights. In this comprehensive guide, we will delve into the depths of epoxy resin, uncovering its properties, benefits, and best practices for application.

The Chemistry Behind Epoxy Resin

Epoxy resin is a two-part adhesive composed of a resin and a hardener. When these components are mixed together, a chemical reaction occurs, creating a strong and durable bond. This unique chemistry gives epoxy resin its exceptional bonding strength and resistance to various environmental factors.

Advantages and Benefits of Epoxy Resin

- Unmatched Bonding Strength: Epoxy resin forms a chemical bond with the materials it is applied to, resulting in an incredibly strong and reliable connection that can withstand heavy loads and stress.

- Versatile Application: Epoxy resin can be used on a wide range of materials, including wood, metal, glass, and plastic, making it suitable for diverse projects.

- Gap-Filling Properties: Epoxy resin has excellent gap-filling capabilities, ensuring maximum stability and strength even in imperfect surfaces or joints.

- Resistance to Moisture and Chemicals: Epoxy resin creates a protective barrier against moisture and chemicals, preventing damage caused by swelling, warping, or chemical corrosion.

- Temperature Resistance: Epoxy resin maintains its bonding strength in extreme temperature conditions, making it suitable for projects exposed to heat or cold.

Best Practices for Using Epoxy Resin

- Surface Preparation: Proper surface preparation is crucial for achieving optimal bonding results. Surfaces should be clean, dry, and free from any contaminants or debris.

- Mixing Ratios and Curing Time: Following the manufacturer’s instructions regarding the correct mixing ratios and curing time is essential for achieving a strong bond.

- Application Techniques: Applying epoxy resin evenly and using the appropriate tools, such as brushes or rollers, ensures consistent coverage and a reliable bond.

- Clamping and Pressure: Applying even pressure during clamping helps create a tight bond and eliminates any gaps or air pockets.

Cyanoacrylate (Super Glue)

Cyanoacrylate, commonly known as super glue, is a remarkable adhesive that can work wonders when it comes to bonding materials together. This fast-acting adhesive is like a superhero for your projects, especially when it comes to Medium-Density Fiberboard (MDF). So, let’s take a closer look at what makes super glue so special.

First and foremost, cleanliness is key. Before applying the super glue, make sure your surfaces are clean and free of any dust or debris. This will pave the way for better adhesion and a stronger bond. Think of it as creating a pristine canvas for your masterpiece.

Now, let’s talk technique. When using super glue on MDF, less is more. Apply the adhesive sparingly and evenly on both surfaces. Remember, a little goes a long way. Too much glue can lead to a messy situation and might not contribute to a stronger bond.

But here’s the real magic: super glue dries in mere seconds. So, before you dive in with the adhesive, take a moment to align and position your MDF pieces correctly. Precision is key when it comes to creating seamless joints.

While super glue can provide an impressive initial bond, it may not be enough to withstand heavy loads or constant stress. MDF is a dense and weighty material, after all. So, consider reinforcing your project with additional measures like other types of adhesives or mechanical fasteners such as screws or nails. It’s like giving your creation an extra layer of armor.

Of course, safety should always be a priority when working with super glue. Protect your precious digits by wearing gloves to prevent any skin contact. And don’t forget about proper ventilation in your workspace. We want you to breathe easy while you bring your projects to life.

uaNckEMncQE” >

Conclusion

In conclusion, glue alone can indeed be sufficient to hold MDF together. However, it is crucial to select the appropriate glue for the task at hand. Medium Density Fiberboard (MDF) boasts numerous advantages, including its affordability and smooth finish. Nonetheless, it does have its limitations – namely, vulnerability to moisture and a lack of structural strength.

When it comes to choosing a glue for bonding MDF, there are several options worth considering. Carpenter’s glue (also known as PVA glue) is a popular choice due to its formidable bond and transparent drying properties. For environments with high levels of moisture, polyurethane glue reigns supreme with its exceptional adhesion capabilities. Meanwhile, epoxy resin offers unparalleled strength and durability, making it ideal for bonding MDF to other materials or when a waterproof bond is required. On the other hand, cyanoacrylate (commonly referred to as super glue) works wonders for quick fixes or smaller-scale projects but may not be suitable for larger or load-bearing applications.

To ensure strong and durable bonds in your woodworking endeavors, proper surface preparation before applying the glue is key. Additionally, maintaining even pressure during clamping is essential. For added support, reinforcing the joint with screws or nails can prove beneficial.