When it comes to sticking plexiglass together, you need an adhesive that’s up to the task. Enter E6000 – a glue that’s got the goods. But before you dive headfirst into your project, let’s take a closer look at the pros and cons of using E6000 for plexiglass.

E6000 is like the superhero of adhesives – versatile, strong, and ready to save the day. It forms an unbreakable bond between plexiglass and other materials like wood, metal, and plastic. No matter what wild combo your project demands, E6000 can handle it with ease. Plus, its flexibility means it won’t crack under pressure or wiggle loose when things get shaky.

But hold on a sec – there are a few caveats to consider before you go all-in on E6000. One downside is its longer drying time compared to other glues. Patience is key here because rushing could ruin your masterpiece. And fair warning: this stuff has a bit of a funky smell. So make sure you crack open a window or two while you work.

Now let’s talk prep work – because even superheroes need some groundwork. Before applying E6000 to plexiglass, give those surfaces a good scrub down. Any dirt or grime will hinder the adhesive’s grip and weaken the bond. A quick sanding or roughing up will do wonders for improving its stickiness.

In conclusion, E6000 is one heck of an adhesive for bonding plexiglass to different materials. Its strength and versatility make it a top choice for many projects. Just remember to factor in the longer drying time and funky odor as potential downsides. With proper surface prep and some know-how about its quirks, E6000 can be your trusty sidekick in creating sturdy and long-lasting plexiglass masterpieces. So go forth, glue warriors, and conquer.

What is E6000?

Contents

If you’re a crafting enthusiast or a DIY lover, chances are you’ve heard of E6000. This popular adhesive has gained a strong reputation for its versatility and exceptional bonding capabilities. But what exactly is E6000, and why is it favored by so many?

E6000 is an industrial-strength adhesive that comes in the form of a clear glue. It is known as a multi-purpose adhesive because it can bond various materials together effectively. Whether you’re working with plastic, metal, glass, fabric, or more, E6000 can get the job done.

What sets E6000 apart from other adhesives is its flexibility once it has cured. Unlike some glues that become brittle or hard over time, E6000 remains flexible. This makes it perfect for applications that require movement or flexibility. It can withstand changes in temperature and vibrations without losing its bond strength.

This solvent-based adhesive does have a distinct smell, so it’s important to work in a well-ventilated area. Additionally, ensure that you don’t come into direct contact with the adhesive or ingest it. Safety first.

Now let’s talk about what makes E6000 truly shine – its excellent adhesion properties. This glue forms a strong bond between surfaces, creating a durable and long-lasting connection. However, it’s crucial to prepare the surfaces properly by cleaning them and removing any grease or debris before applying the adhesive.

Using E6000 is a breeze. It comes in a tube or bottle with a nozzle for easy dispensing. You can apply it directly onto the surface or use brushes or applicators for more precision. Once applied, give it some time to cure fully – around 24 to 72 hours – to reach its maximum bond strength.

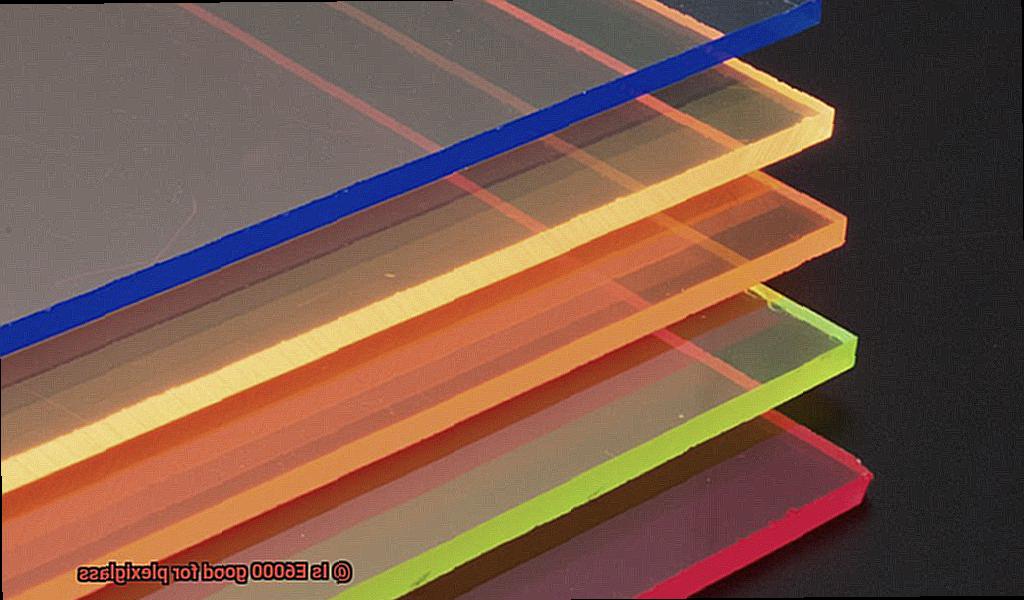

But what about using E6000 on plexiglass? Plexiglass, also known as acrylic glass, is a lightweight and shatter-resistant alternative to traditional glass. While E6000 is generally considered safe for plexiglass, it’s always a good idea to test a small area first to ensure compatibility and prevent any potential damage.

When using E6000 on plexiglass, remember to follow the manufacturer’s instructions and apply the adhesive in a thin, even layer. Allow sufficient curing time before subjecting the plexiglass to stress or pressure. Cleaning the surfaces beforehand is also important for optimal bonding.

However, keep in mind that E6000 may not be the best option for all plexiglass applications. Depending on your specific project requirements, there might be other adhesives that provide better results. It’s always wise to consult professionals or experts in the field for specific recommendations and advice.

What is Plexiglass?

It’s like the Clark Kent of glass alternatives – lightweight, shatter-resistant, and ready to save the day in a variety of applications.

Let’s talk about why plexiglass is a fan favorite. First off, it’s got killer optical clarity. Think about all those windows, display cases, and signage that need to be crystal clear. Plexiglass lets the light shine through like nobody’s business. And unlike traditional glass, it’s less likely to break and can handle impact like a champ.

But wait, there’s more. Plexiglass is a multitasking maven. It’s lighter than glass, making it a breeze to handle and install. Imagine how handy that is for things like aircraft windows or automotive windshields. And when it comes to design, plexiglass is as flexible as an Olympic gymnast. It can be shaped, molded, or cut into any form you desire, making it perfect for architectural projects or artistic installations.

Now, let’s talk durability. Plexiglass laughs in the face of harsh weather conditions. It retains its clarity and color even when Mother Nature tries her best to mess with it. And don’t get me started on its chemical resistance – it can handle solvents and corrosive substances like a boss.

But you know what they say – every superhero needs a sidekick. And when it comes to bonding plexiglass, E6000 adhesive is the Robin to its Batman. This glue can handle anything from plastic to metal and, yes, even plexiglass. Just remember to test a small area first and clean those surfaces before applying the adhesive.

Properties and Characteristics of E6000 and Plexiglass

Today, we embark on an exciting journey into the world of E6000 and plexiglass, uncovering their unique properties and characteristics to determine if E6000 is the glue for you. So, fasten your seat belts, because we’re about to explore the superpowers of these materials.

The Mighty E6000:

Prepare to be amazed by the versatility and strength of E6000. This adhesive is a true hero, capable of bonding various materials, including our beloved plexiglass. With its strong bond and exceptional resistance to water, chemicals, and temperature variations, E6000 is a force to be reckoned with. However, it’s important to note that it may not be suitable for materials submerged in water or exposed to extreme heat.

Plexiglass: The Transparent Hero:

Let’s now turn our attention to plexiglass, the transparent thermoplastic hero that brings a touch of elegance and durability to any project. With its superior optical clarity, plexiglass allows maximum light transmission, making it perfect for signage, display cases, windows, and artistic installations. But beware – plexiglass can be vulnerable to scratches, so handle it with care during installation and maintenance.

The Perfect Bond:

Now that we’ve acquainted ourselves with our heroes’ strengths, let’s explore if E6000 is the right adhesive for bonding plexiglass. First things first – ensure the plexiglass surface is pristine by removing any contaminants like dust or oils. A gentle cleanser or alcohol wipes will do the trick. Next, apply the adhesive evenly and sparingly to avoid unsightly residue or excessive squeeze-out.

Consider the Project:

While E6000 can bond plexiglass admirably, it may not be the best choice for every application. Its flexibility might not meet the requirements of projects that demand a rigid bond. Additionally, prolonged exposure to UV rays can cause yellowing over time, so consider this factor before committing to E6000.

Conclusion:

In the realm of bonding plexiglass, E6000 and plexiglass form a dynamic duo that can conquer many challenges. However, always remember to test the adhesive on a small, inconspicuous area before proceeding with the full application. And if a stronger or more rigid bond is needed, explore specialized adhesives designed specifically for plastic bonding.

Is E6000 Suitable for Plexiglass?

Renowned for its incredible adhesive power, this versatile glue is a top choice for many. But does it have what it takes to bond plexiglass? Let’s dive into the world of glue and plastic to uncover the truth.

E6000, a flexible and high-strength adhesive, has garnered praise from experts for its ability to bond various materials together. When it comes to plexiglass, also known as acrylic or PMMA (polymethyl methacrylate), choosing the right adhesive is crucial. You want a bond that’s not only strong but also won’t damage the material.

Fortunately, E6000 has earned its stripes in the world of plexiglass bonding. However, not all types of plexiglass are compatible with this adhesive. Some varieties may have special coatings or treatments that affect adhesion. To ensure compatibility, always check the manufacturer’s recommendations or consult with experts before diving in. Don’t forget about proper surface preparation either. Thoroughly clean both surfaces, banishing any pesky dirt, grease, or debris.

To achieve optimal results when using E6000 on plexiglass, spread a thin layer evenly over the surface and firmly press the two pieces together. Exercise patience and allow sufficient curing time for the adhesive to set before subjecting your masterpiece to stress or load.

While E6000 offers a robust bond for various materials, including plexiglass, it may not suit all applications. Consider factors like temperature, UV exposure, and specific load requirements when choosing an adhesive for your project.

Dear readers, if you’re uncertain about whether E6000 is compatible with your specific plexiglass endeavor, take a small leap of faith. Test the adhesive on a discreet area before proceeding with the full application.

How to Use E6000 on Plexiglass

When it comes to bonding plexiglass, finding the right adhesive can make all the difference. E6000 is a popular choice known for its strength and versatility. In this guide, we will walk you through the process of using E6000 on plexiglass, from surface preparation to curing time, while providing safety precautions and tips for successful bonding.

Surface Preparation: A Clean Canvas

Before applying E6000, ensure that the plexiglass surface is free from dirt, dust, and oils. Cleanse the surface with a mild detergent and water solution, then dry it thoroughly. This step ensures optimal adhesion.

To create a better bond, lightly roughen the surface of the plexiglass using sandpaper or steel wool. This provides microscopic grooves for the adhesive to grip onto. Be gentle during this process to avoid scratching or damaging the plexiglass.

Apply with Precision:

Apply a small amount of E6000 to one of the surfaces you wish to bond. Avoid using too much adhesive as it can create a messy finish when pressure is applied. Use a brush, toothpick, or small applicator for precise application. Spread the adhesive evenly across the surface, ensuring complete coverage.

Press and Hold:

Press the two surfaces firmly together, ensuring they align properly. Apply even pressure for a few minutes to allow the adhesive to bond effectively. Consider using clamps or weights to hold the pieces in place while the adhesive cures.

Curing Time:

Patience is key. Let the adhesive cure for at least 24 hours before subjecting the bonded plexiglass to any stress or pressure. This ensures a strong and durable bond. Keep in mind that curing time may vary depending on factors such as temperature and humidity.

Safety Precautions:

Tips for Success:

- Test the adhesive on a small, inconspicuous area of the plexiglass before applying it to the entire surface. This will help ensure compatibility and satisfactory results.

- Store E6000 in a cool and dry place, tightly sealed, to maintain its effectiveness and prolong its shelf life.

- Consider using clamps or weights to hold the bonded pieces in place while the adhesive cures. This will prevent any movement that could compromise the bond.

Potential Alternatives to E6000 for Bonding Plexiglass

Are you tired of the same old E6000 adhesive for bonding plexiglass? Looking for alternatives that can provide a strong and reliable bond? Look no further. In this blog post, we’ll dive into some exciting options that can give your plexiglass projects a fresh new twist. From super glue to epoxy adhesives, we’ll explore a range of alternatives that are sure to meet your bonding needs.

Cyanoacrylate Glue – Super Glue:

Need speed? Cyanoacrylate glue, also known as super glue, is your go-to option. This fast-drying adhesive forms an incredibly strong bond on smooth surfaces like plexiglass. Choose a formulation specifically designed for plexiglass bonding to ensure optimal results.

Two-Part Epoxy:

For durability and versatility, two-part epoxy adhesives take the crown. These adhesives consist of a resin and a hardener, which need to be mixed before application. Once cured, epoxy offers exceptional strength and can withstand heavy loads and extreme temperatures.

Acrylic Cement:

Specifically designed for acrylic materials like plexiglass, acrylic cement chemically melts the surfaces of the material, creating a strong bond upon solidification. Exercise caution and use acrylic cement in a well-ventilated area due to its toxic nature.

Structural Adhesive Tapes:

Simplicity and convenience? Structural adhesive tapes are your answer. These high-strength tapes are easy to use and require no mixing or curing time. Just ensure you select a tape specifically designed for bonding plexiglass.

Mechanical Fasteners:

In certain load-bearing applications, mechanical fasteners like screws or bolts can be used in combination with adhesives to enhance strength and stability. Ideal for projects requiring an extra-strong bond.

Tips When Using E6000 on Plexiglass

When working on craft or DIY projects involving plexiglass, achieving a strong and reliable bond is crucial. E6000 adhesive is a popular choice for its versatility and strength. However, there are important tips to keep in mind to ensure successful results. Let’s delve into these tips together.

Cleanliness is Key:

Before applying E6000 on plexiglass, cleanliness is paramount. Ensure the surface is free from dust, dirt, or grease by using a mild detergent solution. Thoroughly dry the plexiglass to optimize adhesion for a solid bond.

Test, Test, Test:

E6000 is a solvent-based adhesive that may potentially damage or discolor plexiglass if not used correctly. Avoid mishaps by testing the adhesive on a small, inconspicuous area before applying it to the entire surface. This precautionary step ensures compatibility and prevents any unwanted surprises.

Apply with Precision:

When using E6000 on plexiglass, remember that less is more. Apply a small amount of adhesive and evenly spread it in thin layers across the surface. This careful application prevents excess seepage and guarantees a neat and professional finish.

Support for Strength:

Due to E6000’s extended curing time, providing proper support or clamping for the plexiglass while the adhesive sets is crucial. This support ensures a secure bond and eliminates any potential movement or shifting of the pieces being glued together.

Ventilation Matters:

E6000 may emit a strong odor during application. To prioritize safety, work in a well-ventilated area or wear a mask for personal protection. Creating an environment with fresh air circulation ensures comfort and safeguards against any respiratory discomfort.

b2Dd2_BjEWY” >

Conclusion

In conclusion, E6000 is a highly effective adhesive for bonding plexiglass. Its strong and durable formula ensures a secure and long-lasting bond between the two materials. Whether you’re working on DIY projects or professional installations, E6000 provides reliable adhesion that can withstand various conditions.

Not only does E6000 excel in its bonding capabilities, but it also offers versatility. It can be used on different types of plexiglass, including acrylics and polycarbonates. This makes it a convenient choice for a wide range of applications, from crafting to construction.

One of the standout features of E6000 is its flexibility. It allows for some movement and expansion without compromising the bond between the adhesive and plexiglass. This is especially important as plexiglass can be prone to slight shifts or vibrations over time.

Furthermore, E6000 dries clear, ensuring that your projects maintain a clean and professional appearance. The adhesive’s transparent finish seamlessly blends with the plexiglass surface, leaving no visible traces of glue behind.

When using E6000 on plexiglass, it is essential to follow the manufacturer’s instructions carefully. Proper surface preparation and application techniques will enhance the adhesive’s performance and ensure optimal results.

In summary, if you’re looking for a reliable adhesive for bonding plexiglass, E6000 is an excellent choice. Its strong bond, versatility, flexibility, and transparent finish make it a go-to option for both DIY enthusiasts and professionals alike.