Are you tired of your craft and repair projects falling apart? Well, today we’re going to tackle the adhesive confusion and settle the debate between two popular types: contact cement and rubber cement.

You might be wondering if these two sticky substances are just cut from the same cloth. But let me tell you, they may seem similar at first glance, but they have distinct purposes and unique traits.

So, grab your tool belt, put on your safety goggles, and let’s dive into the world of adhesives to see how contact cement and rubber cement are alike, but definitely not like two peas in a pod.

What is Contact Cement?

Contents

When it comes to bonding materials together with precision and strength, contact cement is the adhesive of choice. This versatile glue has gained popularity among professionals and DIY enthusiasts in various industries, including construction and woodworking. In this blog post, we will explore the unique properties of contact cement, its wide range of applications, and the benefits it offers over other types of adhesives.

The Power of Instant Bonding:

Contact cement is renowned for its ability to create an instant bond. Unlike other glues that require pressure or clamping during drying, contact cement relies on a chemical reaction when the solvent evaporates. This distinctive characteristic allows for easy application and adjustment of the bonded materials before the bond becomes permanent. Once the solvent evaporates, the adhesive forms a robust and durable bond that can withstand movement and vibrations without deterioration.

Versatility at Its Best:

One of the standout features of contact cement is its versatility. This adhesive can bond to a wide range of materials, including wood, metal, plastic, leather, fabric, and many others. Whether you’re working on a woodworking project or repairing shoes, contact cement has got you covered. However, it’s important to note that not all materials are compatible with contact cement, so it’s always wise to conduct a small test before applying it extensively.

Advantages Over Other Adhesives:

Contact cement offers several advantages over other types of glues. Firstly, it provides an instant bond, allowing for immediate use or further processing of the bonded materials. This time-saving feature is especially beneficial for professionals who need to complete projects quickly. Secondly, contact cement creates a flexible bond that can withstand movement and vibrations without compromising its integrity. This makes it ideal for applications where flexibility is crucial, such as attaching laminate sheets to countertops or bonding shoe soles.

Safety Precautions:

While contact cement is a powerful adhesive, it’s essential to prioritize safety when working with it. The fumes from contact cement can be strong and potentially harmful if inhaled, so always work in a well-ventilated area. Additionally, wearing gloves and eye protection is crucial to protect yourself from any potential skin or eye irritation.

What is Rubber Cement?

Look no further than rubber cement, the game-changer in the world of glues. Made from latex or rubber particles mixed with a solvent, rubber cement is a liquid adhesive that provides a temporary bond that can be easily repositioned or removed.

The magic of rubber cement lies in its ability to remain tacky even after drying. This means you can easily adjust or move your materials around without any hassle. It’s perfect for projects like collages, scrapbooking, or mounting photos where you may want to change things up later.

But that’s not all – rubber cement is also versatile when it comes to the materials it works on. Whether you’re working with paper, fabric, leather, cardboard, or certain plastics, rubber cement has got you covered. Its strong adhesion to porous surfaces makes it an ideal choice for paper-based projects.

However, there are a few things to keep in mind when using rubber cement. The strong fumes emitted by the solvent can be irritating to some individuals, so make sure to use it in a well-ventilated area or wear a mask. Additionally, the solvent can cause damage to certain surfaces, so always test it on a small area before going all-in.

While rubber cement provides a temporary bond, it may not be suitable for long-term or heavy-duty applications. Over time, the bond may weaken or break down completely. So if you’re looking for something more permanent and durable, you might want to consider other types of glue.

Using rubber cement is a breeze. Simply apply it to both surfaces that need to be glued together, let it dry for a short while, and then press the two surfaces together. If you need to make adjustments or reposition your materials, no worries. The bond can be easily broken by peeling off the glued materials.

Difference in Composition

Glue, the unsung hero of the crafting world, comes in many forms and varieties. Two popular types of glue that often find themselves in the spotlight are contact cement and rubber cement. While they may seem similar at first glance, these glues have distinct compositions that greatly influence their properties and applications.

Let’s start with contact cement. This adhesive is a blend of natural or synthetic rubber, solvents, and resins. The rubber component gives contact cement its remarkable flexibility and elasticity, allowing it to withstand movement and stress without breaking or losing its bond. It’s like a gymnast performing graceful acrobatics, bending and stretching without ever faltering. The solvents in contact cement serve a double purpose – they dissolve the rubber and resins, making it easier to spread and apply onto surfaces, and once they evaporate, they leave behind a strong bond between the glued materials. It’s like a magical transformation – from liquid to solid, creating an unbreakable connection.

On the other hand, rubber cement marches to the beat of its own drum. It consists primarily of natural or synthetic rubber mixed with a thinner or solvent. The thinner in rubber cement not only helps with spreading and application but also aids in the drying process by evaporating quickly. When rubber cement dries, it forms a tacky layer that allows for easy repositioning or removal of bonded materials without causing damage. It’s like a gentle embrace – firm enough to hold things together, yet gentle enough to let go when needed.

So how do these differences in composition affect their properties and applications? Contact cement is your go-to for permanent bonding. It excels at creating strong and durable bonds between materials like wood, laminates, metals, and plastics. It can handle heavy loads and continuous stress without flinching. It’s like a rock-solid foundation – sturdy and unwavering amidst the chaos of everyday life. On the other hand, rubber cement is the master of temporary bonding. Its ability to create a bond that can be easily repositioned or removed makes it ideal for crafts, artwork, and design projects that require flexibility. It’s like a dance partner – always ready to move and adapt to the ever-changing rhythm of creativity.

Difference in Application Method

When it comes to gluing, there are two adhesive options that stand out: contact cement and rubber cement. While they may seem similar, their application methods set them apart.

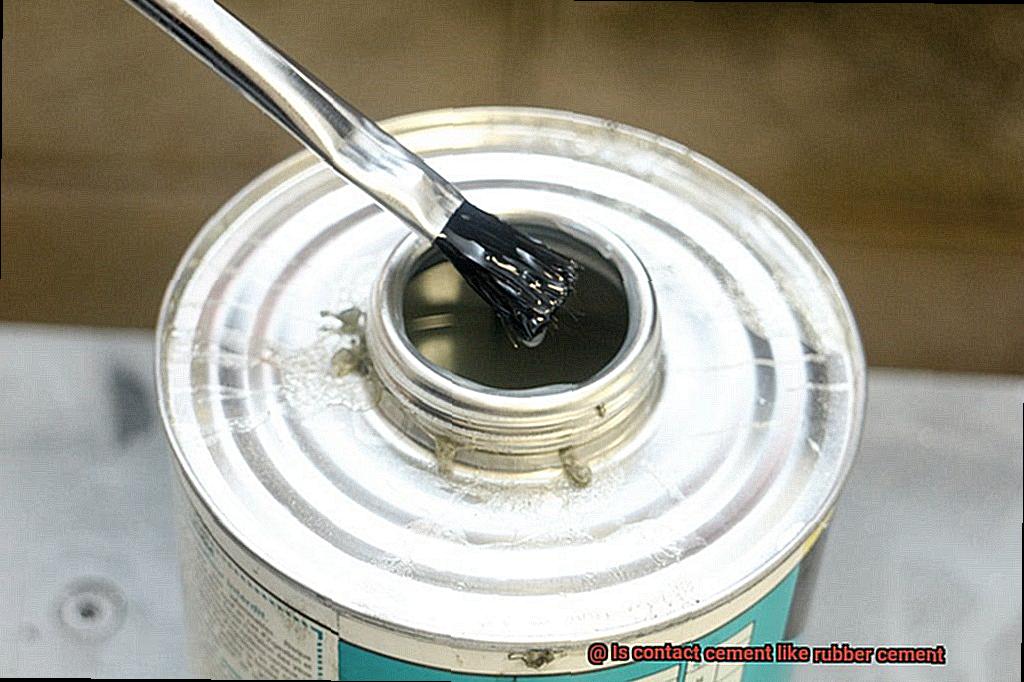

Let’s start with contact cement. This powerful adhesive requires precision during application. Using a brush or roller, it needs to be spread evenly on both surfaces that need to be bonded together. Once applied, the two surfaces must be pressed firmly together to activate the bonding process. It’s like a handshake between materials, creating an immediate and permanent bond. However, be cautious during application because any misalignment or mistakes can result in a bond that cannot be easily undone.

On the other hand, rubber cement offers more flexibility in its application. Also applied with a brush or built-in applicator bottle, it is usually applied to only one surface and allowed to dry before joining the two surfaces together. This adhesive forms a temporary bond that can be easily separated if needed. It’s perfect for those who want the option to reposition or make changes during the assembly process.

Another difference lies in drying time. Contact cement dries quickly, within minutes, allowing for immediate bonding. Rubber cement, however, requires more patience as it takes several minutes to an hour to fully dry, depending on environmental factors such as temperature and humidity.

Durability is another factor to consider. Contact cement provides a strong and permanent bond once fully cured. It can withstand moisture and heat without weakening the bond. On the other hand, rubber cement may not be as durable and is less likely to hold up under extreme conditions.

It’s important to consider the specific uses and applications of each adhesive. Contact cement is commonly used for materials like laminate, veneer, and leather where a strong and permanent bond is desired. Rubber cement is often used for paper crafts, collages, and temporary bonding where adjustability is key.

Drying Time Differences

In the world of gluing, two adhesives take center stage: contact cement and rubber cement. These mighty glues have their unique characteristics, but one notable difference lies in their drying times. In this blog post, we will delve into the details of this battle, discussing the differences between contact cement and rubber cement’s drying times and how it affects their applications.

Contact Cement: The Speedy Superhero

Contact cement is a lightning-fast adhesive. Once applied to both surfaces, it forms an instant and unbreakable bond within minutes. This superpower makes it ideal for projects that require immediate bonding and strong adhesion. Whether you’re working with laminate, veneer, or leather, contact cement ensures a reliable and durable connection that can withstand moisture and heat.

Rubber Cement: The Patient Partner

Rubber cement requires a bit more patience. After applying it to one surface, you must wait for it to dry before joining the materials together. This adhesive forms a temporary bond that allows for repositioning or adjustments during the assembly process. Rubber cement’s longer drying time gives you the flexibility to tweak your project until it’s just right. It’s perfect for paper crafts, collages, and temporary bonding scenarios.

Factors Influencing Drying Time:

The drying time of both adhesives can be influenced by various factors such as temperature, humidity, and the type of materials being bonded. Higher temperatures and lower humidity levels generally speed up the drying process for both contact cement and rubber cement. Conversely, colder temperatures and higher humidity may prolong their drying times.

Choosing the Right Adhesive:

When selecting between contact cement and rubber cement, consider your project’s specific requirements. If you need an unwavering bond that can withstand tough conditions, contact cement is the way to go. On the other hand, if you desire the ability to reposition or make changes during the assembly process, rubber cement is your ideal choice.

Intended Uses and Properties of Contact Cement

Contact cement and rubber cement are two powerful adhesives with distinct intended uses and properties. Contact cement is like the superhero of adhesives, designed for tough-to-stick materials such as leather, rubber, metal, plastic laminates, and wood. It is widely used in construction, woodworking, automotive, and footwear industries. Its strong bond can withstand heat, moisture, and chemicals, making it perfect for outdoor applications and high humidity environments.

The properties of contact cement contribute to its impressive performance. One standout feature is its fast-drying property, allowing for quick assembly and minimizing production time. It is a solvent-based adhesive typically containing neoprene or nitrile rubber as its main component. As the solvent evaporates during the drying process, it leaves behind a rock-solid bond between the surfaces being joined. This instant bond is typically permanent and difficult to break without damaging the materials.

Contact cement also excels in extreme conditions. It can handle temperature changes without losing its adhesive properties and is resistant to water and many chemicals. These properties make it a reliable choice for applications where durability and strength are crucial.

In contrast, rubber cement takes a more laid-back approach. It is typically made from natural rubber latex dissolved in a solvent like acetone or hexane. Unlike contact cement, rubber cement forms a temporary bond that allows for repositioning and adjustment of materials before fully drying. This flexibility makes it a favorite in crafts and artwork where precision is key.

Rubber cement is great for attaching paper or lightweight materials but is not suitable for heavy-duty applications or materials that require a strong and permanent bond.

Intended Uses and Properties of Rubber Cement

Looking to bring your creative projects to life? Need a reliable glue for office tasks? Look no further than rubber cement. This versatile adhesive has a range of intended uses and properties that make it highly effective in different contexts.

If you’re an arts and crafts enthusiast, rubber cement is your new best friend. It’s perfect for paper crafting, scrapbooking, and collage making. The adhesive nature of rubber cement allows for easy and temporary bonding, making it a breeze to experiment with different compositions until you achieve the perfect design. Plus, if you make a mistake or want to reposition something, no worries. Rubber cement allows for adjustments without causing damage or leaving behind residue.

Rubber cement also proves its worth in the office supplies realm. Whether you need to mount photographs, artwork, or other paper items onto various surfaces, rubber cement is up to the task. Its ability to reposition items without causing damage ensures that you can achieve the perfect placement every time. Say goodbye to crookedly mounted artwork or slightly off-center photographs.

But it doesn’t stop there. Rubber cement even finds its applications in bookbinding. Whether you need to attach book covers, repair torn pages, or strengthen bindings, rubber cement has got you covered. Its flexibility and durability make it an excellent choice for these purposes, providing a strong bond while allowing the book to open and close effortlessly.

What makes rubber cement so special? Its properties play a significant role in its usability and effectiveness. Firstly, it creates a temporary bond, allowing materials to be easily separated without damage or residue. This property is advantageous when adjustments or repositioning may be required.

Furthermore, rubber cement is solvent-based. It contains volatile solvents that evaporate upon application, leaving behind a dry and tacky surface that adheres to various materials. This quick-drying nature allows for efficient work processes, reducing waiting time and increasing productivity.

The formula of rubber cement is another key factor. It typically consists of a mixture of rubber latex, resins, and fillers. This combination provides the adhesive with flexibility, durability, and strong bonding capabilities. The rubber component ensures that the adhesive remains flexible even after drying, preventing cracking or peeling. Plus, the fillers contribute to its ability to adhere to different surfaces, making it a go-to adhesive for various materials.

LyF134qG_ys” >

Conclusion

In conclusion: contact cement and rubber cement may seem similar, but they have distinct purposes and unique traits that set them apart. Contact cement is the adhesive of choice for precision and strength in bonding materials together.

It creates an instant bond through a chemical reaction when the solvent evaporates, forming a robust and durable connection that can withstand movement and vibrations without deterioration. Its versatility allows it to bond to a wide range of materials, making it ideal for construction, woodworking, and other industries.

On the other hand: rubber cement is a liquid adhesive that provides a temporary bond which can be easily repositioned or removed.