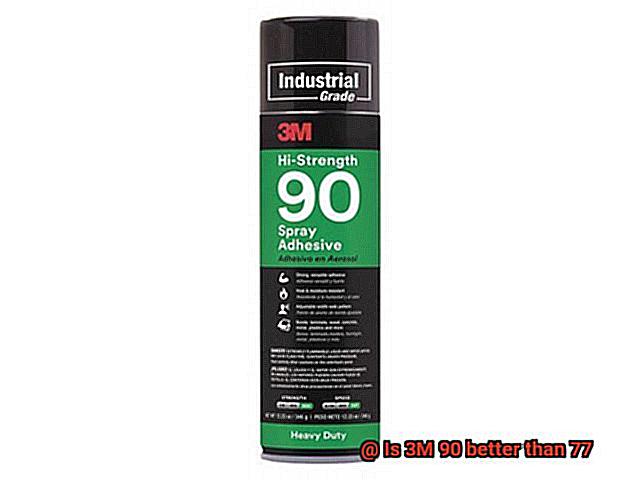

Looking for the perfect adhesive? You’ve got options. Let’s talk about two popular choices: 3M 90 and 3M 7They both have their strengths, but which one is better? Well, it all depends on what you’re working on.

First up, we have 3M 90. This bad boy is a heavy-duty spray adhesive that means business. It’s all about strength and durability. Need something to hold tight? Look no further. With its quick and strong bond, it’s perfect for those projects that need a secure and permanent hold. Plus, it can handle extreme conditions with its high heat resistance. Just keep in mind that it might be too strong for lightweight materials or delicate surfaces.

Now, let’s talk about 3M 7This multipurpose adhesive is all about versatility. It’s fast-drying and repositionable, making it great for lightweight materials like paper, fabric, and foam. The best part? You can make adjustments and move things around before the bond becomes permanent. However, if you’re looking for long-term durability, you might want to consider something stronger.

So which one should you choose? It really comes down to your project’s needs. If you’re working with heavy-duty materials that need an unshakeable bond, go for 3M 90. But if you’re dealing with lighter stuff and want some flexibility during the bonding process, opt for 3M 77.

Remember, both adhesives have their pros and cons. Take a moment to think about what you need before making your decision. Happy bonding.

Bonding Strength

Contents

Look no further. In this comprehensive guide, we will compare two widely-used adhesives, 3M 90 and 3M 77, and delve into their remarkable bonding strength. Whether you’re working with heavy-duty materials or delicate fabrics, we’ve got you covered.

3M 90: The Hercules of Adhesives

- Tailored for heavy materials like metals, plastics, and wood.

- Boasts exceptional bonding strength and withstands extreme conditions.

- Forms a permanent bond that resists heat, moisture, and most chemicals.

- Ideal for demanding applications in the automotive and construction industries.

- Example: Picture yourself constructing a robust wooden shelf capable of supporting heavy objects. By choosing 3M 90 adhesive, you ensure a resilient and long-lasting bond between the wooden pieces.

3M 77: The Jack-of-all-Trades

- A versatile adhesive suitable for lightweight materials such as fabric, foam, and paper.

- Provides a strong initial bond but may not match the long-term strength of 3M 90.

- Allows for repositioning of materials before complete setting.

- Popular choice for craft projects or applications requiring flexibility.

Example: Let’s say you’re creating an artistic collage using assorted fabrics. Opting for 3M 77 adhesive allows you to adjust the position of the fabric pieces until you achieve the perfect arrangement.

Factors Influencing Bonding Strength:

- Surface preparation: Thorough cleaning and roughening enhance adhesion.

- Application technique: Adhering to manufacturer’s instructions maximizes bonding strength.

- Curing time: Longer drying time (3M 90) permits adjustments, while quicker drying (3M 77) is advantageous for rapid assembly.

Material Compatibility:

- Both adhesives bond various materials, but slight variations may exist.

- Consult product labels or technical data sheets for specific compatibility information.

Cost Considerations:

- 3M 90 comes at a higher price due to its superior strength and performance.

- Evaluate the cost against the benefits and long-term durability required for your project.

Drying Time

Drying time is a critical factor to consider when comparing adhesives like 3M 90 and 3M 7It refers to the amount of time it takes for the adhesive to fully dry and achieve its maximum strength. Several factors can influence drying time, including adhesive type, bonded materials, and environmental conditions such as temperature and humidity.

Let’s delve into the specifics of these two popular adhesives. First up, 3M 90. This adhesive boasts a speedy drying time, thanks to its formulation containing a higher concentration of solvents. This makes it ideal for quick bonding needs or when working with moisture-sensitive materials. Need something to stick together in a flash? 3M 90 has got you covered.

On the other hand, we have 3M 7While it may take longer to dry compared to its counterpart, it offers some unique advantages. The slower drying time of 3M 77 allows for repositioning of bonded materials before the adhesive fully sets. This feature comes in handy when you need precise alignment or adjustments during your project. With 3M 77, you have the freedom to fine-tune your work without compromising the bond.

It’s important to note that drying time alone doesn’t determine the strength of the bond. Factors like surface preparation, application technique, and material compatibility also play significant roles in achieving a strong bond. Remember to follow the manufacturer’s instructions regarding drying time for both adhesives to ensure optimal performance.

Temperature and humidity can also impact drying time. Higher temperatures and lower humidity levels generally speed up the process, while lower temperatures and higher humidity can slow it down. So keep these environmental factors in mind when planning your adhesive projects.

Whether you’re working on heavy-duty projects with metals and plastics or tackling lightweight materials like fabric and foam, there’s a glue out there for you. Consider your specific project requirements and material compatibility when choosing between 3M 90 and 3M 77.

Application Method

The world of adhesive sprays is a sticky, yet fascinating one. Today, we will delve into the application method and safety precautions for using 3M 90 and 3M 77 adhesive sprays. So get ready to learn the ins and outs of this adhesive adventure.

To begin, it is crucial to emphasize the importance of following the manufacturer’s instructions when using these adhesive sprays. The instructions are there for a reason – they provide valuable guidance and expertise.

Before spraying that glue, take a moment to prepare the surface. Just as you wouldn’t paint a dirty canvas, a clean surface is essential for a strong bond. Remove any dust, dirt, or grease that could hinder the adhesion process.

Ventilation is key when working with adhesive sprays. No one wants to inhale those fumes. So make sure you’re in a well-ventilated area. Open those windows, turn on a fan, and let fresh air circulate.

Now, let’s talk about distance. When spraying the glue onto the surface, keep the nozzle at the recommended distance. This ensures an even and adequate application. Trust me, you don’t want uneven globs of glue ruining your project.

After applying the glue, exercise patience. Allow the adhesive to dry for the specified amount of time mentioned in the instructions before bonding the surfaces together. And remember to apply pressure. Give those materials a good squeeze to ensure a strong bond.

Safety should always be a priority. Wear protective gloves to avoid direct contact with the adhesive. Nobody wants sticky fingers.

Material Compatibility

Material compatibility is a crucial factor to consider when choosing an adhesive for your project. Adhesives like 3M 90 and 3M 77 may have different capabilities when it comes to bonding various materials. Let’s delve deeper into their material compatibility to better understand which adhesive is best suited for your needs.

First up, we have the mighty 3M 90. This high-strength adhesive is a true all-rounder, capable of tackling heavyweight materials like wood, metal, and plastics with ease. Whether you’re building a sturdy wooden masterpiece or assembling metal components, 3M 90 has got your back. Its excellent compatibility with a wide range of surfaces makes it a reliable choice for various applications.

Now, let’s meet its versatile counterpart – 3M 7This multipurpose adhesive is designed for lightweight materials such as fabric, foam, and lightweight plastics. Need to attach fabric to foam or bond lightweight plastics? Look no further than 3M 7It forms a strong and durable bond, making it the go-to choice for projects involving these types of materials.

But here’s the interesting part – there’s some overlap in their capabilities. While 3M 90 is primarily intended for heavyweight materials and 3M 77 for lightweight ones, they can still provide satisfactory results when used interchangeably. So don’t be surprised if you find success using 3M 90 on lighter materials or vice versa. Just ensure that you properly prepare the surface for optimal bonding.

To make an informed decision about which adhesive is best for your project, consult the product data sheets provided by our friends at 3M. These sheets contain detailed information about material compatibility, allowing you to choose the right adhesive based on your specific requirements.

So there you have it – the lowdown on the material compatibility of these two adhesives. Whether you’re dealing with heavyweight or lightweight materials, 3M has got you covered. Just remember to follow instructions, prepare your surfaces diligently, allow for proper drying time, and prioritize safety with protective gloves.

Cost Comparison

When it comes to selecting the perfect adhesive for your project, cost is undeniably a crucial factor to consider. In this epic glue showdown, we have two mighty contenders: 3M 90 and 3M 7These adhesives may have different price tags, but let’s dive deeper into their characteristics before we embark on our cost comparison journey.

Imagine yourself tackling a project that demands the bonding of tough materials like wood, metal, or plastics. Enter 3M 90, the heavyweight champion of adhesives. With muscles of steel, this adhesive can effortlessly handle even the most challenging materials. It’s like having a superhero by your side, guaranteeing a robust and enduring bond that will withstand the test of time.

But what if your project involves lighter materials such as fabric, foam, or lightweight plastics? Fear not, my friend, because 3M 77 is here to save the day. Although it may lack the sheer strength of its counterpart, this adhesive is nimble and quick when it comes to bonding lightweight materials. It’s like having a trusty sidekick that knows precisely how to handle delicate fabrics or foamy components.

Now, let’s get down to business – the cost comparison. Generally speaking, 3M 90 tends to be slightly pricier than 3M 7However, here’s where things start to get intriguing – value for money. While 3M 90 may carry a higher price tag, its exceptional performance and durability make it an investment that pays off in the long run. Thus, if your project demands a stronger bond or involves materials that are notoriously difficult to adhere, splurging on 3M 90 might be worth every hard-earned penny.

On the flip side, if you’re working on less demanding projects or only require occasional use of the adhesive, 3M 77 could be a more budget-friendly option without compromising on quality. It’s akin to scoring a fantastic deal on a reliable sidekick that still gets the job done.

Before making your final decision, it’s crucial to compare prices from various retailers or suppliers. Prices can fluctuate, so it’s wise to shop around and find the best possible deal.

Advantages of 3M 90

When it comes to adhesive choices, 3M 90 is a heavyweight contender that packs a punch. This popular glue offers a range of advantages that make it a top choice for various applications. Let’s take a closer look at what sets 3M 90 apart from the competition.

First and foremost, one of the standout advantages of 3M 90 is its superior bonding strength. Unlike its counterpart, 3M 77, 3M 90 provides a stronger and more durable bond, making it ideal for heavy-duty projects. Whether you’re working with wood, metal, plastic, or other materials, this adhesive offers a reliable and long-lasting bond that won’t let you down.

In addition to its strong bonding capabilities, 3M 90 also boasts a quick drying time. Unlike some other adhesives that require extended drying times, 3M 90 dries quickly, allowing you to continue with your project without unnecessary delays. This is particularly beneficial when working on time-sensitive projects or large-scale applications that require efficiency and speed.

Versatility is another key advantage of 3M 90. This adhesive works well on a wide range of materials, including fabrics, foam, rubber, and more. Whether you’re a DIY enthusiast or a professional craftsman, this versatility makes it a go-to adhesive for various projects. No matter what material you’re working with, you can trust that 3M 90 will provide a strong and reliable bond.

When it comes to temperature and moisture resistance, 3M 90 outperforms its competition. It can withstand higher temperatures without losing its adhesive properties or weakening the bond. Additionally, it offers excellent moisture resistance, making it suitable for projects that may encounter water or require durability in challenging environments.

The convenience of spray application is another advantage of 3M 90. Its aerosol spray format allows for easy and precise application, ensuring an even coat of adhesive on the desired surface. This user-friendly feature reduces the risk of excessive or uneven glue application, giving you more control over your project.

Furthermore, 3M 90 has a relatively long shelf life compared to some other adhesives. It can be stored for extended periods without losing its effectiveness, making it a cost-effective option for those who may not use it frequently or need to keep it in stock for future projects. You can trust that 3M 90 will be ready and reliable whenever you need it.

Advantages of 3M 77

This powerful adhesive offers a range of advantages that make it a top choice for various bonding applications.

First and foremost, 3M 77 boasts exceptional bonding strength. No matter if you’re working with fabric, foam, plastic, or metal, this adhesive will securely hold your materials together. Say goodbye to flimsy bonds and hello to a strong and reliable hold.

But what sets 3M 77 apart from other adhesives is its versatility. It can be used on a wide range of surfaces, making it suitable for all sorts of applications. Whether you’re working on lightweight crafts or heavy-duty repairs, this adhesive can handle the task effectively. It’s like having a superhero in a can.

Time is of the essence when it comes to adhesive applications, and that’s where 3M 77 shines. It has a quick drying time, allowing you to move on with your project without much delay. No more waiting around for your glue to dry – with 3M 77, you’ll be able to achieve fast and efficient results.

Using 3M 77 is a breeze thanks to its easy-to-use aerosol can. The spray formula ensures an even distribution of adhesive, reducing the chances of uneven bonding or messy application. Plus, the spray nozzle allows for controlled dispensing, so you can apply the adhesive exactly where you need it without any hassle.

But that’s not all – 3M 77 is also resistant to high temperatures. So whether you’re using it indoors or outdoors, this adhesive can withstand a wide range of temperatures without compromising its bonding strength. It’s like having an adhesive that can handle any heat wave or cold snap.

And once 3M 77 is fully cured, it forms a durable and long-lasting bond. So whether you’re working on a short-term project or a long-term application, you can rely on 3M 77 to keep your materials securely attached. It’s like having a trustworthy sidekick that never lets you down.

e4lJW418bwQ” >

Conclusion

In conclusion, both 3M 90 and 3M 77 have their own unique strengths and advantages. It all boils down to what your project demands.

Need an unbreakable bond that can withstand the toughest conditions? Look no further than 3M 90. With its exceptional bonding strength, it’s the go-to adhesive for heavy-duty materials in industries like automotive and construction. Plus, it dries quickly and works wonders on a variety of surfaces.

But if you’re working with lightweight materials or require some flexibility during the bonding process, 3M 77 is your secret weapon. Its multipurpose nature allows for adjustments before the bond becomes permanent, making it perfect for craft projects or any situation where precision matters.

Now, let’s talk cost. While 3M 90 may come with a higher price tag due to its superior strength, it’s an investment that pays off in performance and durability. On the other hand, if you’re working on less demanding projects or only need occasional use of adhesive, 3M 77 delivers quality results without breaking the bank.

Ultimately, choosing between these two powerhouses depends on your project’s specific requirements. Consider factors like bonding strength, drying time, material compatibility, application method, and cost when making your decision. Both adhesives have their pros and cons – so take a moment to ponder what you truly need before settling on your final choice.