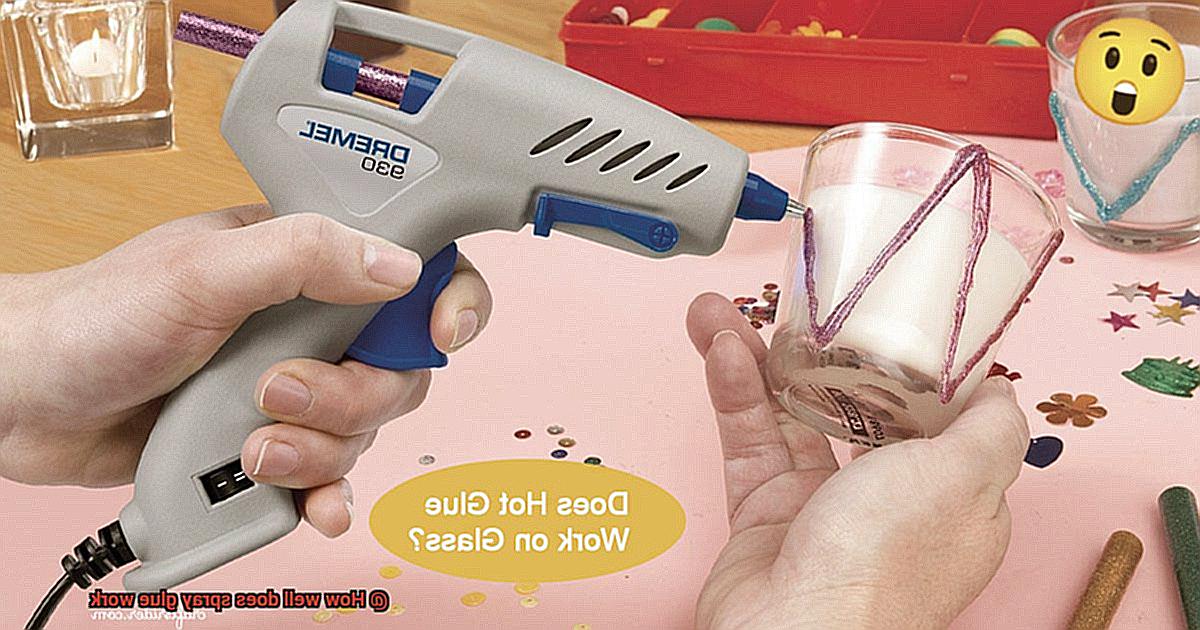

Spray glue, that nifty adhesive in a can, has become the ultimate DIY sidekick for craft lovers everywhere. But let’s get real – how well does this stuff actually work? Is it the superhero of bonding or just another flashy gimmick?

Well, fear not my fellow crafters, because we’re about to embark on an adventure to uncover the truth about spray glue. From artsy paper projects to fixing up your favorite old chair, this magical adhesive claims to do it all. So whether you’re a student with a killer school project or a creative genius crafting intricate cards, spray glue promises to be your trusty sidekick.

But let’s not forget the most important question – how strong is this stuff? We don’t want our masterpiece collages falling apart or our newly reupholstered chairs coming undone. That’s why we’re diving deep into the world of spray glue in this blog post. Stick around as we unveil its reliability and durability, and decide once and for all if it’s worth investing in.

So grab your glue guns and buckle up, because we’re about to find out just how well spray glue really works. Get ready for some serious bonding action.

Factors affecting the effectiveness of spray glue

Contents

- 1 Factors affecting the effectiveness of spray glue

- 2 Types of materials suitable for bonding with spray glue

- 3 Proper application techniques for spray glue

- 4 Drying time and curing process of spray glue

- 5 Strength and durability of spray glue bonds

- 6 Residue and cleanup after using spray glue

- 7 Comparing different brands and formulations of spray glue

- 8 Case studies and real-life examples showcasing the effectiveness of spray glue

- 9 Conclusion

Spray glue, the adhesive wizard of our time, offers an effortless and efficient solution for bonding materials together. Whether you’re an avid crafter, a master upholsterer, or a woodworking enthusiast, understanding the factors that influence the effectiveness of spray glue is crucial in your quest to achieve bonds that are robust and enduring. In this article, we embark on a captivating journey into these factors, equipping you with invaluable insights to conquer your adhesive applications.

Surface Preparation:

Before unleashing the magic of spray glue, you must lay the foundation for success through proper surface preparation. Cleanliness is key – rid your surfaces of all traces of dust, dirt, and grease. Free from these contaminants, your surfaces become receptive to the adhesive prowess of spray glue, ensuring an unyielding bond that defies the test of time.

Application Technique:

The artistry lies in how you wield your spray can. Hold it at just the right distance from your surface, allowing for an even distribution of glue. Engage in a sweeping dance, coating every inch with precision and grace. Beware the perils of overspray or underspray, for they can sow seeds of inefficiency and weak bonds.

Drying Time:

Patience, dear craftsmen and craftswomen, is a virtuous companion in the realm of spray glue. The drying time required for a bond triumphant depends on factors such as humidity, temperature, and the thickness of the applied layer. Allow your masterpiece to bask in its own glory – only then will you witness the birth of adhesion that stands firm against all odds.

Compatibility with Materials:

In this diverse world of materials, not all spray glues are created equal. Each formulation possesses its own secret recipe tailored to specific materials – paper, fabric, foam, wood, and more. Choose wisely, for an incompatible glue may lead to a deflated bond or worse, the destruction of your beloved materials. Let the label guide you and ensure harmony between glue and material for a marriage of strength and longevity.

Environmental Conditions:

Nature’s whims can influence the performance of spray glues. Temperature extremes can alter viscosity and drying time, while oppressive humidity levels may thwart the drying process altogether. Yield to the wisdom of the manufacturers, who beckon you to comply with their temperature and humidity requirements. Create an environment conducive to greatness, and witness the adhesive symphony that ensues.

Storage and Shelf Life:

Prolonged exposure to the elements or exceeding the recommended shelf life is a perilous path that leads to the demise of spray glue’s adhesive enchantment. Thus, safeguard its powers by storing it in a cool, dry sanctuary far from sunlight’s gaze and heat’s caress. Respect the expiration date, and let fresh glue be your ally in the pursuit of adhesive mastery.

Types of materials suitable for bonding with spray glue

It’s crucial to understand which materials are suitable for bonding with spray glue before starting your next project. In this article, we’ll explore five popular types of materials that can be effortlessly bonded using spray glue.

Paper and Cardboard:

Spray glue is a game-changer when it comes to working with paper and cardboard. Its ability to provide a strong and durable bond without distorting the delicate surface makes it perfect for scrapbooking, crafts, or repairing torn pages. Spray glue designed for paper bonding ensures a secure hold without wrinkling or warping the materials.

Fabrics:

Working with fabrics becomes a breeze with spray glue. Whether you’re attaching fabric to fabric or adhering it to other surfaces like wood or metal, spray glue formulated for fabric bonding is a must-have. Choose an adhesive that offers a temporary bond, allowing you to reposition the fabric before committing to a permanent hold. This feature is particularly useful when working on sewing projects or creating textile art.

Foam:

Spray glue is an essential tool for upholstery or cushioning applications involving foam. It expertly bonds foam to foam, foam to fabric, or foam to various materials like wood or plastic. Say goodbye to uncomfortable furniture and hello to perfectly bonded foam creations with the help of spray glue.

Wood:

Woodworking enthusiasts rejoice. Spray glues designed for wood bonding offer excellent adhesion, eliminating the need for clamps or mechanical fasteners. Choose a spray glue that suits your specific type of wood, and witness the magic of effortless bonding between wood pieces. Whether it’s a woodworking project or repairing furniture, spray glue provides a strong and long-lasting bond.

Plastics:

While not all spray glues are suitable for plastics, specialized adhesives are available that can effectively bond plastic surfaces. It’s crucial to test the compatibility of the spray glue on a small area before applying it to the entire surface. With the right adhesive, you can achieve a strong and durable bond that withstands everyday use.

Proper application techniques for spray glue

Mastering the Art of Spray Glue: Proper Application Techniques for Perfect Results

Introduction:

Prepare to unlock the transformative power of spray glue and revolutionize your crafting and woodworking projects. But hold on. Before you dive into the adhesive wonderland, it’s crucial to understand the proper application techniques for spray glue. This blog post will guide you through the process, ensuring that you can harness the adhesive’s full potential with ease and confidence.

Surface Preparation: The Foundation of Success

To set yourself up for success, take a moment to prepare the surfaces you plan to bond. Cleanliness is key. Wipe away any dust, dirt, or grease that could hinder the adhesive’s effectiveness. A quick sanding or wipe-down with a clean cloth can work wonders in creating a pristine bonding surface.

Test, Test, Test.

If spray glue is new to you or you’re working with an unfamiliar material, conduct a small test on an inconspicuous area. This mini-experiment will allow you to assess the compatibility of the adhesive with the material and make any necessary adjustments before diving headfirst into your project.

Distance and Angle: The Dance of Precision

When it comes to applying spray glue, distance and angle are your secret weapons. Maintain an appropriate distance between the can and the surface—consult the product label or manufacturer’s instructions for guidance. Hold the can at a consistent angle, usually perpendicular to the surface, for an even application that will leave you awe-struck.

Thin is In: The Art of Layering

Forget about slathering on one thick layer of spray glue—opt for multiple thin layers instead. This technique prevents oversaturation, evens out drying time, and guarantees superior adhesion. Allow each layer to dry before adding another, building up your masterpiece layer by layer.

Even Coverage: The Key to Perfection

Achieving even coverage is the holy grail of spray glue application. Avoid excessive spraying in one area, as it can lead to unsightly pooling or dripping. Instead, move your hand across the surface in a smooth and controlled manner. Maintain consistent speed and distance for a flawless finish that will make jaws drop.

Breathe Easy: Ventilation is Vital

Spray glue contains volatile chemicals that can be harmful if inhaled excessively. Don’t worry, you don’t need to hold your breath. Simply work in a well-ventilated area or protect yourself with a mask or respirator when using spray glue for extended periods. Your health is invaluable, after all.

Cleanup: The Final Touch

After completing your project, don’t forget to give your can of spray glue some love. Clean the nozzle to prevent clogging by turning the can upside down and spraying until only propellant flows. If any glue residue remains on surfaces or tools, consult the manufacturer’s recommendations for an appropriate solvent.

Drying time and curing process of spray glue

Unlocking these secrets is like discovering the holy grail of perfect bonding. Let’s embark on this journey together and unravel the mysteries that lie within.

First, let’s talk about drying time. This refers to the period it takes for the glue to become dry to the touch. The drying time varies depending on the type and brand of spray glue used, so it’s crucial to consult the manufacturer’s instructions. Brace yourself, because most spray glues dry like lightning, ranging from mere minutes to an hour. But don’t be fooled – just because it feels dry doesn’t mean it’s fully cured.

Ah, the curing process – where true magic happens. It’s a wondrous transformation akin to a butterfly emerging from its cocoon. The curing process involves complete hardening and bonding of the glue, ensuring a bond that can withstand the tests of time. However, be prepared for a variable journey as curing time depends on factors such as adhesive type, layer thickness, temperature, humidity, and materials being bonded. From a few hours to several days, patience is key for optimal results.

Here’s a vital tip: resist the urge to rush the curing process. Impatience can lead to weak adhesion and disappointment. Allow your glue sufficient time to work its enchantment before subjecting it to any stress or load. Trust me, you’ll be rewarded with unyielding strength.

It’s also important to note that different types of spray glues have unique curing processes. Some rely on solvent evaporation, while others require a chemical reaction with air moisture or heat for complete hardening. Understanding your chosen spray glue’s specific curing process will empower you to achieve superior results.

So my fellow glue enthusiasts, remember that drying time and the curing process of spray glue are pivotal elements in your bonding endeavors. By heeding the manufacturer’s instructions, ensuring proper ventilation, maintaining ideal temperature and humidity, and considering material compatibility, you’ll be well on your way to crafting and woodworking triumphs.

Strength and durability of spray glue bonds

Today, we embark on an exciting journey into the captivating realm of spray glue bonds. We will unlock the secrets behind their remarkable strength and unwavering durability. Whether you’re a master crafter or a woodworking wizard, understanding the key factors that influence these bonds is vital for achieving long-lasting and impeccable results. So, fasten your seatbelts as we dive deep into the world of adhesive mastery.

Factors Influencing Strength:

- Material Matters: The choice of materials being bonded is pivotal in determining the strength of spray glue bonds. This versatile adhesive excels at bonding lightweight materials like delicate paper or supple fabric. However, for more robust or load-bearing applications, it is prudent to explore alternative bonding methods or opt for stronger adhesives that can handle the demands.

- Application Method: The manner in which the spray glue is applied greatly impacts the bond’s strength. Achieving even coverage requires holding the can at a consistent distance from the surface. This meticulous approach ensures a robust bond capable of withstanding any pulling forces that may challenge its integrity.

- Adhesive Quality: Not all spray glues are created equal. To maximize bond strength, it is essential to choose high-quality adhesives that meet rigorous standards. Seek reputable brands renowned for their reliable performance, guaranteeing a bond that stands the test of time.

Factors Influencing Durability:

- Moisture Resistance: Moisture can be a formidable foe for any bond to face. Fortunately, some spray glues boast specialized formulations that bolster their resistance to moisture, making them ideal for humid environments or materials exposed to water. These resilient bonds stand strong against moisture’s relentless advances.

- Temperature Resistance: Bonds must endure extreme temperatures without succumbing to weakness. It is paramount to consult the manufacturer’s specifications to ascertain whether your chosen spray glue can withstand the desired temperature range while retaining its effectiveness. These bonds are forged to endure the harshest of thermal trials.

- Physical Stress Tolerance: Bonds that face frequent movement or handling require exceptional resilience. Selecting an adhesive that can withstand the rigors of physical stress without weakening or breaking apart is crucial for ensuring long-lasting durability. These bonds flex and adapt, unyielding in the face of relentless force.

The Limitations:

While spray glue bonds offer versatility and reliability for countless applications, they may not be suitable for critical or high-stress scenarios. In such cases, alternative bonding methods like screws, nails, or epoxy adhesives may provide the necessary strength and endurance. These robust alternatives guarantee unwavering stability where utmost reliability is paramount.

Residue and cleanup after using spray glue

Today, we embark on a thrilling journey into the world of spray glue residue and the mastery of cleanup. Whether you’re a DIY aficionado or an artistic virtuoso, understanding how to effectively remove residue will ensure your projects shine without a trace of stickiness. Get ready to conquer sticky situations with finesse.

Let it Dry, Patience is Key:

Before we dive into the battle against stubborn residue, give the spray glue ample time to dry completely. Depending on the brand and environmental conditions, this may require a few hours or even overnight. Trust us; patience will be rewarded.

Gentle Rubbing with Warm Water and Mild Soap:

Once the glue has dried, it’s time to commence our cleanup mission. Take a clean cloth or sponge, dampen it with warm water, and add a touch of mild soap. Gently rub the affected area in circular motions to loosen and dissolve the adhesive residue. Behold. The sticky situation starts losing its grip.

Adhesive Removers to the Rescue:

For those stubborn residues that refuse to budge, fret not. Adhesive removers come to the rescue. Head over to your nearest hardware or craft store and procure a remover specifically designed for tackling glue residues. Follow the instructions carefully and test it in an inconspicuous area first to avoid any unwanted surprises.

Scraping with Care:

Sometimes, a little scraping can go a long way in bidding farewell to tenacious residue. Utilize a plastic scraper or even an old credit card to gently lift away dried glue remnants. However, caution is paramount – we don’t want any scratches or damage on our surfaces.

Thorough Cleaning:

Once the residue has been successfully vanquished, it’s time to give your project a final cleansing. Use warm water and mild soap to wash away any remaining traces of glue or adhesive remover. This ensures a clean and polished finish that will make your creation shine.

Prevention is Key:

To minimize the headache of residue cleanup, let’s explore some preventative measures. Work in a well-ventilated area to avoid excessive fumes, apply the glue with controlled precision to minimize overspray, and protect surrounding surfaces with masking tape or newspapers. These simple precautions will save you time and effort down the road.

Comparing different brands and formulations of spray glue

Step into the captivating world of spray glue, where adhesive mastery awaits. Whether you’re a DIY aficionado, a craft connoisseur, or a professional seeking the perfect bond, comparing different brands and formulations of spray glue is an essential quest. Let us embark on this journey together as we explore the key factors that must be considered when evaluating these adhesive wonders.

First and foremost, let’s dive into the realm of adhesion strength. This mighty factor determines the glue’s ability to hold materials together with unwavering power. From delicate paper creations to robust wooden structures, finding a brand that offers a reliable and secure bond is paramount.

Now, let’s journey to the land of drying time. In this fast-paced world, time is of the essence for many projects. Finding a spray glue that dries quickly can be an absolute game-changer. However, if you prefer extra working time to adjust and position your materials with precision, a longer drying time might be more suitable for your creative escapades.

As we continue our expedition, versatility beckons us. Different spray glues are formulated for specific materials like fabric, foam, or wood. To unlock the full potential of your projects, choose a brand and formulation that aligns harmoniously with the materials you’ll be working with. By doing so, you’ll achieve optimal results that will leave you in awe of your own adhesive prowess.

Of course, ease of use reigns supreme in this adventure. No one desires to grapple with a messy or cumbersome adhesive application process. Seek out spray glues with precise nozzles or applicators that effortlessly bestow upon you the power to control the amount and direction of the adhesive with grace and ease.

While embarking on this odyssey, do not overlook the wisdom bestowed by customer reviews and real-world experiences. These valuable insights offer a glimpse into a brand’s durability and reliability in the face of sticky challenges.

Practicality calls us to consider price point and availability. Some brands may offer more affordable options or be more readily available in certain regions, making them the very key to unlocking adhesive success in your corner of the world.

Lastly, fear not the call to action. Engage in hands-on experimentation with different brands and formulations. By immersing yourself in the tactile realm of adhesive exploration, you shall gain firsthand understanding of their performance and usability. Through this personal voyage, you will emerge armed with the knowledge to confidently choose the spray glue that perfectly aligns with your projects.

Case studies and real-life examples showcasing the effectiveness of spray glue

Spray glue, a remarkable adhesive wonder, has revolutionized numerous industries and applications. Join me on an exhilarating journey as we delve into case studies and real-life examples that showcase the extraordinary effectiveness of this adhesive marvel.

Let’s start our adventure by zooming into the automotive industry, where spray glue has become a game-changer. Car manufacturers and repair shops have discovered the power of spray glue when it comes to bonding interior fabrics to the vehicle’s body. Unlike traditional glue that struggles to withstand constant vibrations and temperature changes experienced in vehicles, spray glue rises above and excels.

Imagine a car upholstery shop grappling with headliners that refuse to stay in place. Frustrated with traditional glue, they turned to a specialized automotive spray adhesive. The results were astounding. The spray glue provided an unmatched bond, ensuring the headliners stayed put even under extreme conditions. Customer satisfaction soared, and costly rework became a thing of the past.

Now let’s shift gears and explore the artistic side of spray glue. Brace yourself, artists and craft enthusiasts. Spray glue is your new best friend when it comes to creating awe-inspiring collages or mixed media projects. Its versatility knows no bounds as it effortlessly bonds different materials like paper, fabric, wood, and plastic.

Envision an artist meticulously crafting paper mosaics. With spray glue in hand, they effortlessly adhere small pieces of paper onto a canvas, creating intricate designs without any mess or residue. And the best part? The bond created by the spray glue ensures their artwork remains intact even when displayed or transported.

But wait, there’s more. Let’s dive into the construction industry, where spray glue has become an invaluable tool for contractors. When it comes to attaching insulation materials like foam boards or fiberglass batts to walls or ceilings, spray glue reigns supreme.

Imagine a construction company tackling a commercial building project. They utilize spray glue to attach foam insulation panels to the exterior walls, creating a seamless and airtight barrier. This not only saves time and money by eliminating the need for additional fasteners or messy adhesives but also enhances the building’s energy efficiency. Spray glue to the rescue.

These captivating case studies and real-life examples highlight the effectiveness of spray glue in various industries and applications. Whether it’s in automotive upholstery, arts and crafts, or construction, spray glue has proven time and time again to be a reliable and efficient bonding solution. Its versatility, strength, and ease of use make it the go-to choice for professionals and DIY enthusiasts alike.

IPd8vzIZpbE” >

Conclusion

Spray glue is a versatile adhesive that can be used for a variety of projects. It provides a strong bond and is easy to use, making it a popular choice among DIY enthusiasts and professionals alike. Whether you’re working on crafts, upholstery, or even home repairs, spray glue can help you achieve professional-looking results.

One of the key advantages of spray glue is its ease of application. Unlike traditional liquid adhesives, spray glue comes in an aerosol can, allowing for quick and even distribution. Simply point and spray onto the desired surface, and the adhesive will create a secure bond in seconds.

The strength of the bond created by spray glue is another standout feature. It works well on a wide range of materials, including paper, fabric, wood, metal, and plastic. This means you can use it for various projects without worrying about whether it will hold up over time.

In addition to its strong bond, spray glue also dries quickly. This means you don’t have to wait around for hours or even days for the adhesive to set. Once applied, it typically takes only a few minutes for the glue to dry completely.

Furthermore, spray glue offers versatility in terms of repositioning. If you make a mistake or need to adjust the position of your materials after applying the adhesive, you can do so easily before it fully sets. This flexibility allows for more precise work and reduces the chances of ruining your project due to errors.

When using spray glue, it’s important to consider proper ventilation as it emits fumes during application. Therefore, it’s best to use it in a well-ventilated area or wear a mask if necessary.

Overall, spray glue is an effective adhesive that delivers strong bonds quickly and effortlessly. Its ease of use and versatility make it an excellent choice for various projects.