One of the easiest ways to glue metal to glass is through the use of epoxy.

Due to its strong nature, epoxy can be used to attach metal ornaments to glass bowls in Bohemian plaster sculptures. So, how do you glue metal to glass?

So, how do you glue metal to glass? There are two main ways to glue metal to glass.

First, you can solder the two together, creating a bond that will last for a long time. However, this method is not ideal because it takes time and skill to solder properly.

Second, you can weld the metal and glass together. This will create a bond that is stronger than soldering, but it takes much more skill and equipment than a soldering job.

Therefore, if time and equipment are a concern, welding is the best option. However, if quality is not an issue, soldering is the better option.

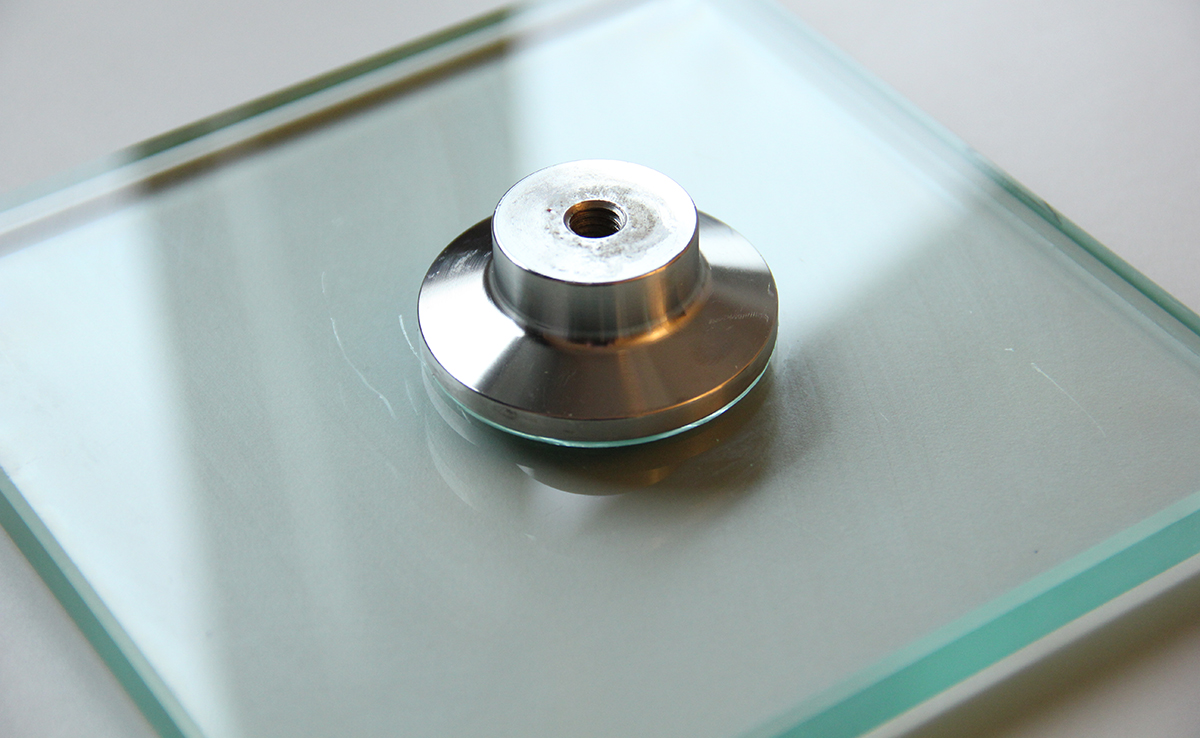

How to Glue Metal to Glass

Contents

Metal really sticks to glass.

However, this process requires special glues. One type of glues is epoxy glues.

Epoxy glues work by creating a strong chemical bond between the metal and the glass. However, epoxy glues take a long time to cure.

Another type of glues is sealant glues. Sealant glues are super strong.

They create a mechanical bond between the metal and the glass. However, sealant glues take some time to cure.

Both types of glues can be used effectively to glue metal to glass.

Does Gorilla Glue Work on Glass and Metal?

Gorilla Glue has been around since the 1960s, but many people remain skeptical about whether it really does work on glass and metal.

This is because many people claim that Gorilla Glue doesn’t bond as well as advertised. However, this isn’t true.

Gorilla Glue works on glass and metal, but its strength isn’t as strong on these materials as it is on wood. For example, Gorilla Glue won’t hold up to high temperatures like epoxy would.

Gorilla Glue is also unsuitable for items that will be submerged in water. However, for woodworking around the home or in the garage, Gorilla Glue works just as well as advertised.

What Glue for Metal and Glass?

UV Light Curable Adhesive

UV light is used to cure the glue during the bonding process. An ultraviolet light source is installed underneath the bonding surface during assembly to ensure the curing process is complete.

The UV light does not harm the components being bonded together but does make them very hot to the touch.

This forms an extremely strong bond as the glue cures under intense heat and moisture, rendering it virtually indestructible.

This sort of adhesive works well with glass, metal, wood, ceramic and stone surfaces.

Silicone Polyurethane Hybrid

The combination of the advantages of silicone and polyurethane makes this sort of adhesive suitable for bonding a variety of materials including plastics and metal.

This is ideal for applications where one part needs to be waterproof and the other needs to be flexible. This hybrid works well for fixing leaks in shower enclosures and other bathroom fixtures.

Structural Acrylic

Permabond specialists characterize structural acrylics as two part liquids that are mixed together before being applied to the surface of the materials to be bonded.

After the liquid has been spread evenly across the surfaces to be bonded, they are pressed together and allowed to dry to form a permanent bond that can withstand extremely high pressure and temperature differences without failing.

Clear Epoxy

Heavy-duty glue that has to be mixed to within 10 seconds of application and then applied directly to the surfaces to be bonded using brush, roller or spray gun.

Once the mixture has been applied to the surfaces to be bonded, the two parts must be joined immediately as the epoxy resin begins to harden rapidly once exposed to air.

A strong adhesive with incredible bonding strength that is able to adhere to a wide variety of materials including wood, metal and plastic.

Cyanoacrylate (Super Glue)

When set, it forms a strong and permanent bond to most metals, glass, ceramics and plastics.

Cyanoacrylate gels are better suited to outdoor applications as they are unaffected by moisture when cured.

Can you Bond Metal to Glass?

The answer is yes!

Using special adhesives, you can bond metal to glass. For example, you can bond a copper pipe to a window pane to form an air conditioner unit or to a glass sheet to form a picture frame.

The adhesives contain a substance called acetoxysilane. When exposed to air, acetoxysilane bonds with glass and metal molecules to form strong chemical bonds.

These bonds are so strong that the glass can’t be broken with a sledgehammer! However, the bonds aren’t permanent.

If they’re exposed to too much heat or air, the bonds will weaken and eventually break. So, avoid using adhesives in extreme temperatures.

Will JB Weld Bond Metal with Glass?

JB Weld is a two-part adhesive that’s often used to bond metal to metal.

For example, you can use JB Weld to fix a leaking pipe or fix a cracked pan. However, can you use JB Weld to bond metal to glass?

The answer depends on what type of glass you’re working with. JB Weld is notorious for bonding poorly to glass.

However, JB Weld does bond well to tempered glass, which is much stronger than regular glass. Tempered glass often has grooves on its surface that prevent glass from shattering into sharp pieces when broken.

The combination of grooves and glass’ thinness makes it virtually impossible to bond to with regular glues.

However, JB Weld bonds well to tempered glass because the grooves create a strong surface for the glue to bond to.

JB Weld also bonds well to glass that’s coated with wax or grease because the wax or grease act as a sealant that seals off the glass’ pores and allows the JB Weld to bond to the glass’ surface.

Also Read: Does Krazy Glue Work on Glass?

Things to Consider When Gluing Glass to Metal

Cheap adhesives will not adhere to both glass and metal because both surfaces have different chemical properties.

The second thing to remember is to make sure your adhesive is applied properly.

Any filth or oil on the surfaces of the components being glued can interfere with the adhesion of the glue to the surfaces. Surfaces must be thoroughly cleaned and dried before gluing to ensure maximum adhesion of the glue to the surfaces.

Finally, secure the glass and metal together with clamps or other fasteners until your JB Weld dries.

This will assist to establish maximum contact between the parts being glued so they’ll form a strong and permanent bond between themselves.