In a world where adhesives come and go like passing fads, there exists one name that reigns supreme: Gorilla Glue. This extraordinary adhesive has become the holy grail for DIY enthusiasts and industry experts alike, boasting a permanence that surpasses all others. There’s an air of mystery surrounding Gorilla Glue and its legendary grip, defying the limitations of ordinary adhesives. So, fasten your seatbelts as we plunge into the captivating realm of this remarkable glue to uncover its astonishing staying power.

Gorilla Glue’s versatility knows no bounds, effortlessly bridging the gap between casual projects and professional undertakings. Whether you’re bonding plastic, metal, wood, or even stone, this robust adhesive holds everything together with an unwavering strength. Need to fix a wobbly chair? Craving to fashion a dazzling piece of jewelry? Look no further than Gorilla Glue.

But it’s not just its ease of use or impressive bonding capabilities that make Gorilla Glue a true superstar. It’s the unyielding nature of its hold that sets it apart from the rest. Unlike other adhesives that may deteriorate over time or lose their grip, Gorilla Glue creates bonds designed to endure through the ages. This remarkable attribute makes it ideal for both quick fixes and long-term stability projects alike.

Yet, like any magnificent innovation, Gorilla Glue does have its limitations. While it excels on a wide range of surfaces, certain plastics with low surface energy can pose a challenge for this mighty adhesive. Furthermore, its strength can prove troublesome if adjustments or disassembling are required down the line. Thus, exercising caution and meticulous planning when working with Gorilla Glue is essential to avoid any unwanted permanent consequences.

Nevertheless, the unmatched permanence of Gorilla Glue remains its crowning glory. It serves as a testament to the adhesive’s extraordinary formulation and its ability to conquer even the most demanding bonding tasks. Whether you’re crafting intricate wooden furniture or mending broken household items, Gorilla Glue ensures a bond that defies the ravages of time.

So, prepare for an exhilarating journey into the realm of Gorilla Glue, where we’ll unravel the secrets behind its enduring power. Join us as we explore its remarkable permanence and unlock endless possibilities that arise when an adhesive becomes

The Unique Formula of Gorilla Glue

Contents

- 1 The Unique Formula of Gorilla Glue

- 2 How Does Gorilla Glue Work?

- 3 The Strength and Durability of Gorilla Glue

- 4 Factors That Influence the Permanence of Gorilla Glue

- 5 Appropriate Materials for Using Gorilla Glue

- 6 Longevity of the Bond Created by Gorilla Glue

- 7 Disadvantages of Using Gorilla Glue

- 8 Removing Gorilla Glue from Surfaces

- 9 Conclusion

Gorilla Glue is not your ordinary adhesive. Its unique formula sets it apart from other glues on the market, providing exceptional strength and permanent bonding capabilities that make it a go-to choice for many DIY enthusiasts and professionals.

The secret to Gorilla Glue’s power lies in its main active ingredient: polyurethane. This special type of polymer reacts with moisture to create a strong bond. When applied to a surface, the polyurethane undergoes a chemical reaction that causes the glue to expand and foam. This foaming action allows the glue to fill gaps and irregular surfaces effectively, ensuring a tight and secure bond.

Unlike traditional glues that dry and harden, Gorilla Glue forms a foam-like structure during the curing process. This expanding foam not only fills gaps but also distributes stress evenly across the bonded surfaces. It is this feature that makes Gorilla Glue suitable for heavy loads and constant stress, making it ideal for projects that require reliable and long-lasting adhesion.

To enhance its properties, Gorilla Glue contains various additives such as solvents, stabilizers, and preservatives. These additives ensure the glue’s longevity and performance, providing optimal results even in challenging environments.

Speaking of environments, Gorilla Glue is resistant to water, heat, and extreme weather conditions. Whether you’re working indoors or outdoors, this adhesive can withstand exposure to moisture, temperature fluctuations, and even harmful UV rays without compromising its bonding strength.

Once cured, Gorilla Glue creates a bond that is incredibly difficult to break apart or remove. It forms a permanent connection that can withstand heavy usage and constant stress.

However, it’s important to note that while Gorilla Glue offers exceptional strength and permanence, it may not be suitable for all materials and applications. It’s always recommended to test the glue on a small area before using it on a larger scale. Additionally, proper surface preparation is crucial for achieving optimal results with Gorilla Glue. Surfaces should be clean, dry, and free from any contaminants or debris.

How Does Gorilla Glue Work?

Gorilla Glue is a remarkable adhesive that stands out from the competition due to its unique formula and exceptional bonding capabilities. This glue is renowned for its strength, versatility, and ability to bond a wide range of materials.

The secret behind Gorilla Glue’s extraordinary sticking power lies in its composition. It is a polyurethane-based adhesive, meaning it contains polymers that form a strong and durable bond. When the glue is exposed to moisture, whether from the air or a damp surface, it undergoes a curing process. During this process, the glue expands and forms a tight bond with the surfaces it is applied to.

One of the key features of Gorilla Glue is its foaming action. As it is applied, the glue expands and fills in any gaps or voids, creating an even stronger bond. This foaming action not only helps to fill irregularities in the surfaces being bonded but also increases the surface area of contact between the glue and the materials, resulting in enhanced adhesion.

The curing process of Gorilla Glue involves a chemical reaction between the moisture present and the glue itself. This reaction causes the glue to harden and form an incredibly strong bond. It is important to note that Gorilla Glue requires moisture for proper curing, so ensuring that both surfaces being bonded are clean and slightly damp is essential for optimal results.

Another standout characteristic of Gorilla Glue is its ability to bond various materials together. Whether you need to bond wood, metal, stone, ceramic, or plastic, Gorilla Glue is designed to work on a wide range of materials. This versatility makes it a popular choice for different applications, from household repairs to crafting projects.

In addition to its ability to bond diverse materials, Gorilla Glue is known for its superior strength. Once fully cured, it forms an incredibly strong bond that can withstand heavy loads and resist impacts. This strength makes Gorilla Glue suitable for both indoor and outdoor applications where durability is crucial.

Furthermore, Gorilla Glue is a one-part adhesive, meaning it does not require any mixing or additional components to work effectively. This user-friendly characteristic makes it convenient for both professionals and DIY enthusiasts.

The Strength and Durability of Gorilla Glue

Gorilla Glue is not your average adhesive. Its remarkable adhesive properties are nothing short of extraordinary. With the ability to bond an extensive range of materials, such as wood, metal, stone, ceramic, and plastic, it has become an invaluable tool for DIYers, professionals, and hobbyists alike. Whether you are repairing furniture, constructing a model, or even creating jewelry, Gorilla Glue provides a bond that is both strong and reliable.

What sets Gorilla Glue apart from other adhesives is its exceptional strength. Once cured, the glue forms a bond that rivals even the mightiest of epoxy adhesives. It can withstand heavy loads and resist impacts with ease, ensuring that your projects remain intact and secure over time.

But it’s not just about strength. Gorilla Glue also offers impressive durability. Once cured, it becomes completely waterproof, making it suitable for both indoor and outdoor use. No matter the weather conditions, your projects will stay intact. Extreme temperatures are also no match for Gorilla Glue. It can withstand scorching heat or freezing cold without losing its bonding properties.

The secret behind Gorilla Glue’s superior performance lies in its unique formula. This adhesive contains polyurethane, which reacts with moisture in the air and expands while curing. This expansion fills in any gaps or voids between the bonded surfaces, creating a tight and secure bond. The foaming action of the glue ensures that it penetrates deep into the materials, further enhancing its adhesive capabilities.

However, it is important to note that removing or separating materials bonded with Gorilla Glue can be quite the challenge due to its formidable adhesive properties. If disassembly is required, seeking professional advice or using specialized products designed for removing Gorilla Glue is highly recommended.

Factors That Influence the Permanence of Gorilla Glue

- Surface Preparation: Clean, dry, and smooth surfaces are crucial for a strong bond. Dirt, dust, or moisture can hinder bonding. Thoroughly clean surfaces before applying the glue to maximize effectiveness.

- Material Compatibility: Different materials have different porosities and textures, affecting how well the glue adheres. Check compatibility to ensure optimal performance.

- Temperature and Humidity: Extreme temperatures can impact curing time, affecting bond strength. High humidity levels can also impact performance. Follow manufacturer’s guidelines for temperature and humidity conditions.

- Application Technique: Apply a thin layer on one surface and firmly join the surfaces together for even distribution of adhesive and maximum bonding strength. Applying too much or too little glue compromises permanence.

- Curing Time: Allow sufficient time for Gorilla Glue to reach maximum strength. Curing time depends on temperature, humidity, and materials being bonded. Do not subject the bond to stress or load until cured.

- Environmental Factors: Exposure to sunlight, moisture, chemicals, and vibrations can impact bond durability. Consider additional measures such as sealing or protecting the bond for enhanced resistance.

- Surface Area and Joint Design: Larger surface areas provide more contact for bonding, resulting in a stronger bond. Certain joint designs distribute stress evenly across the bond, increasing durability.

Appropriate Materials for Using Gorilla Glue

In order to achieve a strong and lasting bond when using Gorilla Glue, it is crucial to choose the appropriate materials. Here are some important points to consider:

- Porous surfaces: Gorilla Glue works best on porous materials such as wood, fabric, and foam. These materials allow the glue to penetrate and create a strong bond. The porous nature provides more surface area for the glue to adhere to.

- Non-porous surfaces: While Gorilla Glue can be used on non-porous materials like metal, glass, and plastic, it may require additional preparation. Roughening the surface with sandpaper or a file can create tiny grooves for the glue to grip onto, improving adhesion.

- Excessive glue: Gorilla Glue expands as it cures, so it is important to use it sparingly, especially on delicate or small items. Using too much glue can lead to overflow and create a messy appearance.

- Temperature: For optimal results, it is recommended to use Gorilla Glue at room temperature (around 70°F or 21°C). Extreme temperatures can interfere with the curing process and weaken the bond.

- Additional preparation: Some materials may require additional preparation before using Gorilla Glue. For example, when bonding plastic, it is important to clean the surface with rubbing alcohol or acetone to remove any oils or debris that could hinder adhesion.

- Clean and dry surfaces: When working with porous materials like wood or fabric, ensure they are clean and dry before applying Gorilla Glue. Moisture can interfere with the curing process and weaken the bond.

- Test first: It is always a good idea to test Gorilla Glue on a small, inconspicuous area before applying it to the entire surface. This will help determine if the glue is compatible with the material and if any additional preparation is required.

Longevity of the Bond Created by Gorilla Glue

The longevity of a bond created by Gorilla Glue is influenced by several factors, including temperature, surface type, and humidity. Let’s delve into each of these variables to understand their impact on the bond’s durability.

Firstly, temperature plays a crucial role in determining the strength of the bond. Gorilla Glue performs best at room temperature, around 70°F or 21°C. If exposed to high temperatures, the glue may cure too quickly, potentially compromising the bond’s strength. Conversely, extremely cold temperatures can slow down the curing process and weaken the integrity of the bond. It is essential to ensure that both the adhesive and surfaces being bonded are within the recommended temperature range for optimal results.

Secondly, the type of surface being bonded is another important consideration. Gorilla Glue is suitable for a wide range of materials, including wood, metal, glass, ceramic, and foam. However, different materials may require specific surface preparation techniques for optimal adhesion. Porous surfaces like wood or fabric may benefit from slight roughening to enhance adhesion. Non-porous surfaces like plastic or metal might require cleaning with alcohol or acetone to remove any oils or contaminants that could hinder the bond.

Lastly, humidity levels can impact the bond’s strength and longevity. While Gorilla Glue is resistant to moisture once fully cured, high humidity during the curing process can affect its performance. Excessive moisture can hinder proper curing and weaken the bond over time. It is vital to consider humidity levels when using Gorilla Glue and ensure adequate ventilation for proper curing.

Disadvantages of Using Gorilla Glue

Gorilla Glue, known for its strong and permanent bond, does have several disadvantages that users should consider before utilizing it. These drawbacks include:

- Expanding Nature: When Gorilla Glue comes into contact with moisture, it undergoes expansion and creates a foamy texture. While this characteristic can be advantageous for filling gaps, it can prove problematic when working with delicate or intricate objects. The expanding glue may seep into unintended areas or distort the desired shape, making it difficult to correct.

- Curing Time: Unlike some other adhesives that dry quickly, Gorilla Glue requires moisture to fully cure. Consequently, it may take several hours or even overnight for the glue to harden completely. This extended curing time can be inconvenient, particularly when time is of the essence and a quick project completion is necessary.

- Material Limitations: Gorilla Glue is not suitable for use on certain materials. It is not recommended for polyethylene or polypropylene plastics as it fails to establish a strong bond with these surfaces. Additionally, it may not adhere well to smooth or non-porous materials such as glass or metal.

- Messiness: Applying Gorilla Glue can be messy due to its tendency to expand and foam up upon contact. This makes it difficult to control and clean up excess glue. If not managed carefully, the foaming action can leave behind unsightly residue on surfaces, requiring extra effort to remove.

- Difficulty in Undoing the Bond: Once Gorilla Glue has bonded, undoing the bond becomes extremely challenging. While this permanence can be an advantage in some cases, it becomes a disadvantage when adjustments or repairs are necessary in the future. Removing Gorilla Glue typically involves mechanical force or solvents, which can potentially damage the materials being bonded.

- Strong Odor: Gorilla Glue emits a strong odor that some individuals may find unpleasant or irritating. To minimize exposure to the fumes, it is crucial to use the glue in a well-ventilated area.

Removing Gorilla Glue from Surfaces

Removing Gorilla Glue from surfaces can be a daunting task, but fear not. With the right approach and a little patience, you can undo that unyielding grip and restore your surfaces to their former glory.

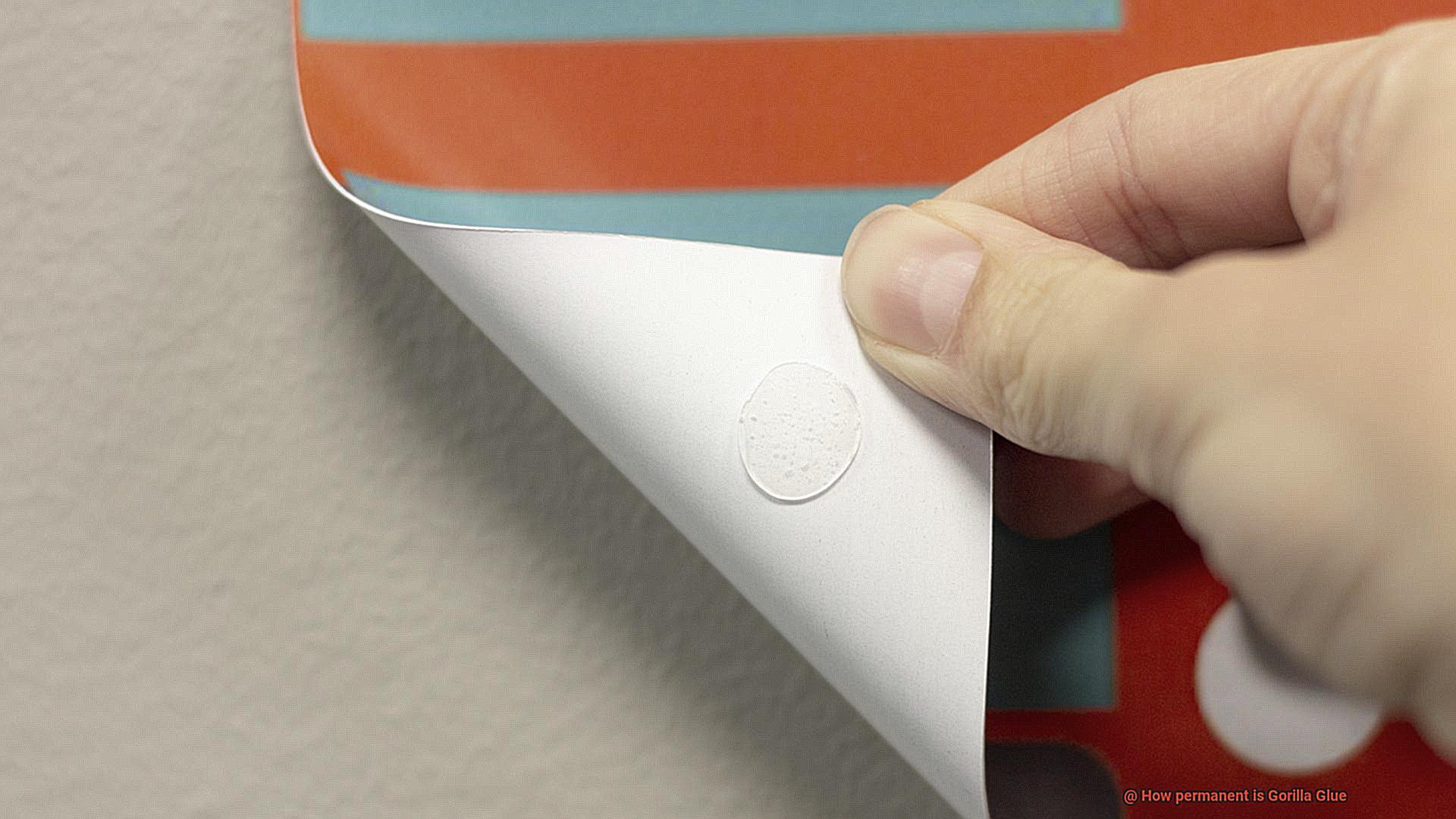

Let’s start with non-porous surfaces like glass, metal, or plastic. Once the glue has fully cured, you can often peel or scrape it off. Grab a plastic scraper or even a trusty credit card and gently lift the glue without causing damage. If the glue is being stubborn, applying heat can work wonders. Use a hairdryer or a heat gun to soften the glue, making it easier to remove. Just be cautious not to overheat the surface or risk burns.

For those porous surfaces like fabric or wood, removing Gorilla Glue requires a bit more finesse. Depending on the bond’s severity, sanding or scraping might be necessary. Take your time and be careful not to damage the surface while attempting to remove the glue.

If traditional methods fail you, there are specialized adhesive removers or solvents designed specifically for Gorilla Glue. Follow the manufacturer’s instructions and safety precautions when using these products.

- Another option is to bring out the big guns: acetone or nail polish remover. Apply these solvents with a soft cloth or cotton swab and gently scrub away the glue. However, always test the solvent on a small, inconspicuous area first to ensure it doesn’t cause any damage or discoloration.

- Also Read: Does WD 40 remove Gorilla Glue? – Glue Things

Conclusion

When it comes to the question of how permanent Gorilla Glue is, the answer is clear: it’s incredibly long-lasting.

This adhesive has gained a reputation for its exceptional durability and strength. Once applied, Gorilla Glue forms a bond that is difficult to break.

Whether you’re using it for crafts, repairs, or construction projects, you can trust that Gorilla Glue will hold things together with unwavering tenacity.