Are you tackling a project that involves using epoxy, but unsure of the number of layers needed for optimal results? Perhaps you’re concerned that one layer may not suffice, or you’re worried about overdoing it and wasting materials. Fret not. As an expert in this field, I’m here to answer the age-old question – how many layers of epoxy do you really need?

To begin with, it’s essential to understand that the number of coats required will depend on several factors such as the type of project, quality of epoxy used, thickness and size of the surface being coated. However, in most cases, at least two coats are necessary for a smooth finish that offers superior protection against wear and damage.

While two layers may suffice for simpler projects, more complex ones like boat hulls or garage floors may require additional layers for enhanced durability and waterproofing. Therefore, it’s crucial to identify your specific needs before embarking on any project involving epoxy.

So if you’re still uncertain about how many layers of epoxy you need for your project, don’t worry. In this blog post, I’ll cover everything you need to know to ensure your application is a success. From choosing the right type of epoxy to determining how many coats are necessary based on your unique requirements – I’ve got you covered.

How Many Layers of Epoxy Does My Project Require?

Contents

- 1 How Many Layers of Epoxy Does My Project Require?

- 2 Factors to Consider When Determining the Number of Layers

- 3 Primer: The First Layer of Epoxy

- 4 Second Layer: Added Strength and Durability

- 5 Additional Layers for Complex Projects

- 6 Following Manufacturer’s Instructions

- 7 Applying Too Many Layers Is Detrimental

- 8 Curing Between Coats

- 9 Conclusion

The answer depends on several factors, including the size and type of your project, the type of epoxy used, and the desired outcome.

For smaller DIY projects such as jewelry or small trinkets, a single layer of epoxy is typically sufficient. However, larger projects like countertops or tabletops may require multiple layers to achieve the desired thickness and durability.

It’s crucial to note that not all epoxies are created equal. Some are designed for thin applications and should not be layered too thickly. Others can handle thicker layers without any issue. So, it’s essential to consult with the manufacturer’s guidelines or seek professional advice before starting your project.

The final look you want to achieve is another factor to consider. For instance, some projects may require multiple layers to create a clear, glass-like finish for maximum gloss and clarity. Meanwhile, others may only need a single layer for a more rustic or matte appearance.

Temperature and humidity during application, the surface being coated, and the intended use of the finished product can also affect the number of layers needed. Applying too many layers can lead to cracking, bubbling or other defects in the finish. Therefore, make sure to apply each layer evenly and allow ample time for curing between coats.

Factors to Consider When Determining the Number of Layers

When it comes to using epoxy for a project, determining the number of layers needed can be a daunting task. However, there are several factors that you should consider to ensure that your project is a success. As an expert in this field, I have compiled a list of essential factors that you should keep in mind.

First and foremost, the type of epoxy that you choose is critical. Different types of epoxies have different properties, and their application requirements vary. To ensure that you use the correct number of layers, it’s vital to read the manufacturer’s instructions carefully and follow their recommended application guidelines.

The purpose of the project is another critical factor to consider. If your project needs to withstand heavy traffic or harsh weather conditions, more layers will be required to ensure its durability. On the other hand, if it’s a decorative or low-traffic project, fewer layers may be needed.

The surface on which you apply the epoxy is equally important. A porous surface will require more layers than a smooth surface as it will absorb more epoxy. Therefore, before applying epoxy, it’s essential to prepare the surface adequately to ensure that it is smooth and even.

The thickness of each layer also plays a crucial role in determining the number of layers required. If each layer is thicker, fewer layers will be needed compared to thinner layers. However, it’s essential to note that if the layers are too thick, they may take longer to cure or may not cure evenly.

Finally, time constraints may affect the number of layers required. If there is limited time available for the project, fewer layers may be required as each layer takes time to dry before another layer can be applied.

Primer: The First Layer of Epoxy

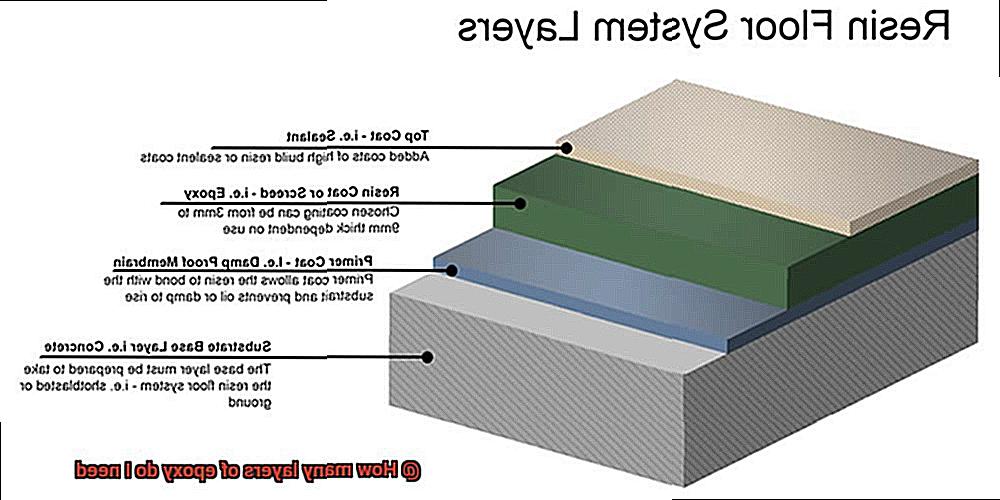

If you’re looking to apply an epoxy coating to a surface, you may be wondering where to start. The answer is simple: primer. As the first layer of epoxy, primer is crucial for creating a strong and durable bond between the surface and the coating. Think of it like the foundation of a house – without it, everything else will crumble.

But primer isn’t just important for bonding – it also helps to prevent air bubbles, cracks, and other defects from appearing in your final epoxy coating. This is why experts in this field cannot stress enough how important it is to use primer before applying the actual epoxy coating.

The number of layers of primer needed depends on various factors such as the type and condition of the surface being coated, as well as the type of primer being used. For example, if the surface is porous or uneven, multiple layers of primer may be necessary to achieve a smooth and even surface. On the other hand, if the surface is smooth and in good condition, then one layer of primer may suffice.

It’s important to note that not all primers are created equal. There are different types of primers available such as epoxy primers, acrylic primers, and zinc-rich primers – each with its own unique properties and benefits. The choice of primer will depend on the specific needs of your project.

In general, it is recommended to apply at least one layer of primer before applying the epoxy coating. However, some experts may suggest applying two or more layers of primer for added durability and to ensure a strong bond between the surface and the epoxy coating.

Second Layer: Added Strength and Durability

In our previous section, we discussed the significance of primer as the foundation for your epoxy project. Today, we’re delving into the second layer of epoxy and why it’s critical for adding strength and durability to your project.

Picture the second layer as the sturdy muscle that fortifies your project’s bones. While the first layer guards and secures your surface, the second layer provides added robustness and bonding agents required for a long-lasting finish.

Now you may wonder how many layers of epoxy you require for your project. The answer is simple: always apply a second layer. This guarantees that your project will have the necessary toughness to endure everyday wear and tear. Some experts even suggest applying a third or fourth layer for added protection – it’s like donning a suit of armor for your project.

The thickness of your second layer depends on what you’re creating and how frequently it will be used. If you’re constructing a tabletop or countertop that will receive daily use, apply a thicker second layer than if you were creating a decorative piece that won’t be handled as frequently.

Timing is also crucial when applying your second layer. Be sure to follow the manufacturer’s recommended timeframe – waiting too long between layers can result in poor adhesion, leading to breakage or cracking over time.

Additional Layers for Complex Projects

You may need to apply additional layers of epoxy. However, it’s crucial to understand that the number of layers required will depend on the specific project and level of protection needed.

Let’s take boats and watercraft, for example. These require protection against water damage and wear and tear. Typically, it’s recommended to apply at least three to four coats of epoxy. But, if the boat is exposed to harsh conditions or constant use, additional layers may be necessary.

Similarly, for flooring projects, extra layers are essential to safeguard against heavy foot traffic or equipment. Standard flooring projects will require two to three coats of epoxy, but high-traffic areas may need an additional layer or two.

In addition to added protection, multiple layers of epoxy can provide a smoother and more even finish. Each layer helps fill in any imperfections or inconsistencies in the previous layer, resulting in a polished final product.

However, it’s important to note that adding too many layers of epoxy can have adverse effects on the overall strength and durability of your project. Too much weight can cause stress on the underlying structure. Therefore, it’s best to consult with experts or follow manufacturer guidelines when determining the appropriate number of layers for your specific project.

Following Manufacturer’s Instructions

Whether it’s a boat or flooring project, following the manufacturer’s instructions is key to a successful application. As an expert, I can tell you that there are several reasons why this is crucial.

Firstly, the manufacturer’s instructions will provide guidance on the number of layers needed for your specific project. Applying too few layers can result in a weak and easily damaged surface while applying too many can lead to an uneven finish or excessive buildup. By following the recommended number of layers, you can ensure a strong and durable finished product.

Secondly, the type of epoxy being used and the intended use of the finished product will also impact the number of layers required. For instance, if you are using an epoxy for a decorative coating, the manufacturer may recommend a minimum of two coats for optimal coverage and durability. In contrast, if you are using an epoxy for a high-traffic area such as a garage floor, the manufacturer may recommend three or more coats for added protection and longevity.

Thirdly, the instructions may also provide guidance on other factors such as application temperature and curing time. These guidelines are essential to achieving the best results. By adhering to them closely, you can ensure that your finished product is strong, durable, and long-lasting.

Moreover, it is important to note that applying epoxy without following the manufacturer’s instructions can have dire consequences. It could result in damage to your project or even harm to yourself.

Applying Too Many Layers Is Detrimental

While it may seem like a logical step to add extra layers for added strength and durability, it can actually have the opposite effect.

To begin with, each layer of epoxy must fully cure before applying another one. If you rush the process and add another layer before the previous one has cured completely, it can result in weak spots forming in the bond. This can compromise the structural integrity of your project, leading to potential damage and safety hazards.

Moreover, over-application of epoxy can lead to excess weight and thickness, which may not be ideal for certain applications such as in aerospace or automotive industries. In these industries, every ounce and millimeter count, and adding unnecessary weight or thickness can negatively impact performance.

Thus, it is essential to adhere to the manufacturer’s recommended guidelines for the number of layers necessary for a particular application, as well as the appropriate curing time between each layer. Not all projects require the same number of layers, so finding the right balance is paramount.

But what about applying too few layers? While it is true that insufficient layers can result in a weaker bond, it’s crucial not to go overboard with additional layers. It’s imperative to stick to the recommended guidelines and avoid compromising quality over quantity.

Curing Between Coats

Curing between coats is an essential step in this process, ensuring that each layer fully cures before adding the next.

Why is it so important to cure between coats? Simply put, it allows each layer to set and become tack-free before adding another layer. This creates a solid foundation for the layers to bond together properly. Waiting at least 4-6 hours (depending on the epoxy type, temperature, and humidity levels) is recommended to ensure successful bonding.

However, waiting too long can also affect adhesion, which is why it’s crucial to follow the manufacturer’s instructions carefully. Failure to do so can lead to weak spots or bubbles in the finished product.

To ensure proper bonding between layers, it’s important to have a clean surface free from dust or debris. Even the smallest amount of contaminants can compromise the adhesive quality. Thus, thoroughly cleaning the surface before application is crucial.

Sanding between coats is another essential step in achieving a smooth surface and increasing adhesion between layers. A light sanding with fine-grit sandpaper (such as 220 grit) before applying the next coat will help create a strong bond.

EcFMlDh5_DM” >

Conclusion

To achieve a successful epoxy project, several factors come into play when determining how many layers of epoxy are needed. The type of project, quality of the epoxy used, thickness and size of the surface being coated, and intended use of the finished product all have an impact.

For smaller DIY projects, one layer may suffice. However, larger projects like countertops or boat hulls require multiple layers to ensure enhanced durability and waterproofing.

Before starting any project involving epoxy, it’s crucial to select the right type of epoxy and consult with manufacturer guidelines or seek professional advice. Adequately preparing the surface being coated is also essential to ensure it is smooth and even.

The first layer should always be a primer to create a strong and durable bond between the surface and coating while preventing air bubbles, cracks, and other defects. Applying at least one layer of primer before adding the epoxy coating is recommended.

Curing between coats is critical in ensuring each layer fully cures before adding another layer for proper bonding. Failure to follow manufacturer instructions can compromise adhesion and result in weak spots or bubbles in the finished product.

It’s important to find a balance by adhering to recommended guidelines without compromising quality over quantity. Applying too many layers can lead to excessive weight and thickness negatively impacting performance in some industries.

In summary, determining how many layers of epoxy are needed depends on various factors.