Get ready to dive into the world of unbreakable bonds and extraordinary repairs. When it comes to adhesives and epoxy compounds, J-B Weld is the undisputed champion, renowned for its Herculean strength and unbeatable resilience. Whether you’re fixing a busted metal pipe or reinforcing a cracked engine block, J-B Weld has become the go-to solution for DIY enthusiasts and seasoned professionals alike. But here’s the million-dollar question: just how long can this super adhesive hold up against the test of time?

Knowing the answer to that question is crucial if you want a repair that lasts longer than your favorite pair of jeans. While the exact duration may vary depending on several factors, we’re here to spill all the beans on what influences J-B Weld’s durability. Get ready for some insider knowledge that’ll help you make informed decisions when it comes to choosing an adhesive that truly stands the test of time.

Surface Preparation:

Contents

- 0.1 Surface Preparation:

- 0.2 Material Compatibility:

- 0.3 Application Technique:

- 0.4 Environmental Factors:

- 0.5 Maintenance and Care:

- 1 What is J-B Weld?

- 2 What Factors Affect the Longevity of J-B Weld?

- 3 How Long Does it Take for J-B Weld to Cure?

- 4 What Applications are Ideal for J-B Weld?

- 5 How Strong is J-B Weld?

- 6 Is J-B Weld Suitable for Permanent Repairs?

- 7 How Can You Ensure Maximum Durability and Lifespan of J-B Weld?

- 8 Are There Any Maintenance or Inspection Tips to Consider When Using J-B Weld?

- 9 Conclusion

Get your surfaces squeaky clean and roughed up for maximum bonding power. Removing any loose debris or old adhesives will ensure that J-B Weld adheres like a champ, creating a seamless connection that won’t let you down.

Material Compatibility:

J-B Weld works wonders on metals, ceramics, wood—you name it. It forms an incredibly strong bond with almost any material out there. Just keep in mind that some plastics, like polyethylene or polypropylene, might put up more of a fight.

Application Technique:

You know what they say—technique is everything. Follow those manufacturer instructions religiously and make sure you mix those two components like there’s no tomorrow. A smooth application and sufficient curing time will give your bond an extra boost of strength.

Environmental Factors:

J-B Weld can handle extreme temperatures like a boss—from icy -67°F to scorching 500°F (-55°C to 260°C). But watch out for prolonged exposure to UV rays or other harsh conditions. If you’re expecting some serious heat or sunshine, consider using J-B Weld’s high-temperature formulas or protecting your repair with a suitable coating.

Maintenance and Care:

To keep your repaired surface in tip-top shape, show it some love. Avoid subjecting it to excessive stress, strain, or harsh chemicals that could weaken the bond. Regular inspections and maintenance will help nip any potential issues in the bud before they become full-blown disasters.

What is J-B Weld?

When it comes to bonding and repairing materials, one name stands out among the rest – J-B Weld. This epoxy adhesive has gained a reputation for its exceptional strength, versatility, and durability. Whether you’re a DIY enthusiast or a professional craftsman, J-B Weld is your go-to solution for creating long-lasting bonds. In this article, we’ll delve into the features and benefits of J-B Weld, providing you with all the information you need to know.

Versatility:

J-B Weld is not your average adhesive. It’s a superhero that can bond a wide range of materials with ease. Metal, wood, plastic, ceramic – you name it, J-B Weld can handle it. Whether you’re fixing a broken metal part or joining different materials together, J-B Weld is up to the task. Say goodbye to searching for separate adhesives for each material; with J-B Weld, you have one adhesive to rule them all.

Exceptional Strength:

J-B Weld isn’t just strong; it’s superhuman strong. With a tensile strength reaching up to 3960 PSI, it’s in a league of its own among epoxy adhesives. This incredible strength allows it to withstand heavy loads and resist pressure, making it suitable for both structural and non-structural applications. When you need a bond that can hold up under extreme circumstances, J-B Weld is the hero you can rely on.

Heat and Chemical Resistance:

J-B Weld doesn’t back down from extreme conditions. Once fully cured, it can handle scorching temperatures up to 550 degrees Fahrenheit (287 degrees Celsius), making it ideal for high-temperature environments. Additionally, it exhibits excellent resistance to chemicals like gasoline, oil, and common solvents. So even in the face of harsh conditions and chemical exposure, your bond remains unbreakable.

Ease of Use:

J-B Weld is a friend to both professionals and DIY enthusiasts alike. Its user-friendly nature makes it a breeze to use. The two-part epoxy system comes in separate containers, allowing you to mix only the amount you need for each application. Achieving the correct proportions is as easy as a 1:1 ratio of resin to hardener. Plus, with a comfortable working time of around 15-25 minutes, you have plenty of time to apply, position, and perfect your bond before it sets.

What Factors Affect the Longevity of J-B Weld?

J-B Weld, the ultimate adhesive solution, is known for its durability and strength. However, several key factors influence the longevity of this super adhesive. Let’s explore these factors and unlock the secrets to creating bonds that stand the test of time.

Surface preparation is the first step to ensuring a long-lasting bond. Just like a superhero needs a clean slate to save the day, J-B Weld requires a clean surface for optimal bonding. Removing dirt, grease, and rust is crucial. For an extra-strong bond, consider sanding or roughening the surfaces.

The mixing ratio is another critical factor. J-B Weld is a two-part epoxy adhesive that requires precise mixing of its resin and hardener components. Don’t be tempted to eyeball it. Stick to the recommended mixing ratio to ensure a bond that can withstand anything life throws at it.

Patience is key when it comes to curing time. J-B Weld needs sufficient time to cure and reach its maximum strength. The curing time varies based on temperature, humidity, and adhesive layer thickness. Follow the manufacturer’s instructions closely for that unbreakable bond.

Temperature resistance is also important. While J-B Weld handles high temperatures well, extreme heat can still affect its longevity. Choose the right variant for your application and stay within the recommended temperature range.

Chemical exposure can also impact J-B Weld’s durability. While it has good resistance to many chemicals, prolonged exposure to certain solvents, acids, or alkalis can compromise its performance over time. Ensure compatibility before using J-B Weld in chemical environments.

Mechanical stress is another villain that can weaken adhesive bonds over time. Consider the anticipated mechanical stresses in your application and choose the appropriate variant of J-B Weld accordingly.

Lastly, UV exposure should not be overlooked. J-B Weld is not inherently UV resistant. If you’re using it outdoors or in environments with significant sunlight or ultraviolet radiation, consider applying a protective coating or using a UV-resistant variant for enhanced longevity.

How Long Does it Take for J-B Weld to Cure?

Well, get ready to have your mind blown as we delve into the secrets of J-B Weld’s curing process.

The curing time of J-B Weld refers to the duration it takes for the adhesive to fully harden and achieve its maximum strength. However, this time can vary based on several factors, each playing a crucial role in the ultimate strength of your bond.

Let’s start with temperature. Just like superheroes thrive in the heat of battle, higher temperatures can actually accelerate the curing process of J-B Weld. So, if you find yourself in a rush to save the day, consider turning up the heat a notch. On the other hand, colder temperatures can slow down the curing process. If you find yourself battling villains in freezing conditions, exercise patience and give J-B Weld some extra time to work its magic.

Humidity is another factor that can affect the curing time of J-B Weld. High humidity levels can speed up the process, while low humidity levels may slow it down. So, it’s important to keep an eye on the weather forecast and adjust your expectations accordingly.

Now, let’s talk numbers. In general, J-B Weld reaches its initial cure in 4-6 hours. But here’s the catch – it’s recommended to allow it to cure for a full 24 hours to achieve its maximum strength. That’s right, folks, patience is key when it comes to J-B Weld.

But here’s an interesting tidbit – even though J-B Weld may feel hard after the initial cure time, it may still take several days or even weeks for it to reach its ultimate strength. So don’t rush into battle just yet. Give your J-B Weld bond some extra time to develop its superpowers.

To ensure optimal curing, it is crucial to clean and prepare the surfaces to be bonded properly before applying J-B Weld. Even superheroes need a clean slate to work their magic. Additionally, if you want to take your bond to the next level, apply pressure or use clamps during the curing process. This will help improve the strength of the bond and make it virtually unbreakable.

Once fully cured, J-B Weld can withstand high temperatures, water exposure, and even various chemicals. It’s like having a superhero on your side for all your bonding needs.

What Applications are Ideal for J-B Weld?

Look no further than the incredible J-B Weld. This versatile epoxy adhesive is the ultimate sidekick for all your bonding needs, from automotive repairs to household fixes and everything in between.

Let’s dive deeper into the world of J-B Weld and explore the diverse applications where it shines:

- Automotive Repairs: When it comes to automotive repairs, J-B Weld is a true hero. It effortlessly tackles cracked radiators, leaky fuel tanks, and broken plastic parts. Its unrivaled strength and resistance to high temperatures and chemicals make it the perfect solution for those pesky automotive issues.

- Plumbing Fixes: Say goodbye to leaky pipes and faucets with J-B Weld by your side. This adhesive forms a robust bond that can withstand water pressure and temperature changes. Whether it’s a crack in a PVC pipe or a leaking joint, J-B Weld ensures your plumbing stays leak-free.

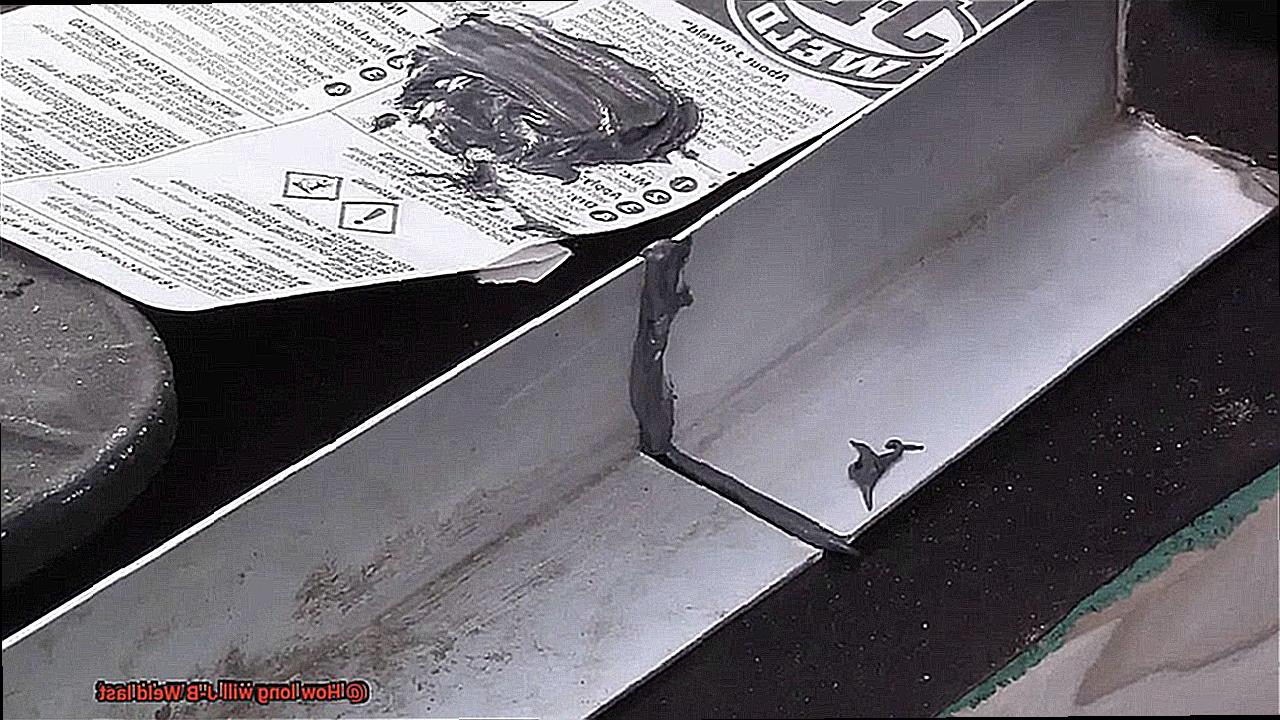

- Metal Bonding: Need to repair a broken tool or fix a piece of machinery? J-B Weld has the strength to keep those metal surfaces securely fastened. It’s like having a welding torch in a tube. From fixing outdoor furniture to repairing metal objects, J-B Weld is the go-to adhesive for any metal bonding project.

- Woodworking Projects: Woodworking enthusiasts rejoice. J-B Weld provides a durable bond that can handle the stress and strain of everyday use. Whether you’re fixing broken furniture joints or filling cracks in wooden surfaces, J-B Weld ensures your creations stand the test of time.

- Household Repairs: From broken ceramics to appliances on the fritz, J-B Weld is the glue that holds it all together. With this adhesive by your side, you’ll have a handyman in your pocket, ready to tackle any household repair job with ease.

- Marine Applications: If you’re a boat owner, J-B Weld is a must-have for marine repairs. Its resistance to water and harsh conditions makes it perfect for fixing leaks in hulls, repairing fiberglass cracks, or securing loose fittings. With J-B Weld, your boat will be shipshape in no time.

- DIY Projects: J-B Weld is a favorite among DIY enthusiasts. Whether you’re building a homemade sculpture, designing custom furniture, or embarking on a unique craft project, J-B Weld provides the bonding strength you need to bring your creations to life. With J-B Weld, there’s no limit to your creativity.

How Strong is J-B Weld?

When it comes to bonding materials together, J-B Weld reigns supreme. This two-part epoxy adhesive has earned a formidable reputation for its exceptional strength and durability, making it the go-to choice for professionals and DIY enthusiasts alike. In this article, we will delve into the factors that contribute to the unmatched strength of J-B Weld and why it stands head and shoulders above other adhesives in the market.

The Unique Formulation:

At the core of J-B Weld’s extraordinary strength lies its unique formulation. A perfect harmony of epoxy resins and hardeners is combined in equal proportions. When these components blend together, a chemical reaction occurs, giving birth to a bond that is unparalleled in its power. This ingenious combination creates a cross-linking structure that is not only incredibly robust but also remarkably long-lasting.

Testing the Strength:

J-B Weld’s strength has been tested rigorously to determine its capabilities. It has been proven to possess an astonishing tensile strength of up to 5020 PSI (pounds per square inch). This means that it can withstand tremendous pressure without breaking or separating. Whether you find yourself repairing a cracked engine block or fixing a broken metal railing, J-B Weld rises to the occasion, never faltering under pressure.

Versatility and Durability:

One key factor that contributes to J-B Weld’s unrivaled strength is its ability to bond an extensive range of materials. From the tough resilience of metal and wood to the delicate intricacies of plastic and ceramics, this adhesive forms an unbreakable connection on almost any surface. Furthermore, J-B Weld’s resistance to water, chemicals, and oil ensures its durability even in the harshest environments, guaranteeing a bond that will stand the test of time.

Surface Preparation:

To maximize the formidable strength of J-B Weld, proper surface preparation is of utmost importance. It is crucial to meticulously clean and roughen the surfaces that require bonding. This meticulous preparation allows for enhanced adhesion, resulting in a bond that is as strong as steel.

Curing Time:

J-B Weld typically sets within 4-6 hours and fully cures within 15-24 hours at room temperature. However, it is important to note that factors such as temperature and humidity can influence the curing time. Adhering strictly to the instructions provided ensures optimal results and a bond that will withstand any challenge.

Is J-B Weld Suitable for Permanent Repairs?

When it comes to permanent repairs, finding an adhesive that can truly stand the test of time is essential. Look no further than J-B Weld, the legendary epoxy adhesive that has captured the hearts of countless DIYers and professionals alike. But does it have what it takes for permanent repairs? Join us as we take a deep dive into the world of J-B Weld and discover its suitability for a wide range of repair scenarios.

Versatility:

J-B Weld truly shines when it comes to repairs on materials like metal, plastic, and fiberglass. From patching up cracked engine blocks to fixing broken pipes, this adhesive is known to provide a long-lasting solution. However, it’s worth noting that J-B Weld may not be compatible with certain materials such as polyethylene or polypropylene plastics. So always double-check compatibility before diving into your repair project.

Unyielding Durability:

J-B Weld’s claim to fame lies in its ability to withstand the harshest conditions. With a cured bond that can brave temperatures up to a scorching 550 degrees Fahrenheit and pressure up to a staggering 6000 pounds per square inch, J-B Weld proves its mettle in the most demanding situations. This makes it an ideal choice for repairs that require unmatched strength and unwavering stability.

Ease of Use:

What sets J-B Weld apart is its simplicity. With proper surface preparation and adherence to instructions, this adhesive sets within hours and fully cures within a day. Its user-friendly application process makes it accessible to both seasoned professionals and enthusiastic DIYers, ensuring that anyone can achieve professional-grade results.

The Limits:

While J-B Weld is undoubtedly a formidable adhesive, it may not be suitable for all permanent repairs. For critical or structural repairs, specialized adhesives or professional repair methods may be required. Additionally, if flexibility or resistance to extreme temperatures is needed, J-B Weld might fall short, as it can become brittle under certain conditions. It’s crucial to assess the specific requirements of your repair and consider alternative options if necessary.

How Can You Ensure Maximum Durability and Lifespan of J-B Weld?

J-B Weld is a powerful adhesive that can bond metal, plastic, and fiberglass. But how can you ensure that your J-B Weld bonds last a lifetime? Let’s dive in.

Surface Preparation:

Preparing your surfaces properly is vital for a strong bond. Clean all surfaces thoroughly, removing dirt, grease, and rust. Use a degreaser or solvent for a thorough cleaning. This ensures a solid bond between the adhesive and the materials.

Correct Mixing and Application:

Mixing J-B Weld correctly is an art in itself. Follow the instructions on the packaging meticulously, blending equal parts of epoxy resin and hardener until they become one harmonious mixture. Inadequate mixing can lead to incomplete curing and weaken the bond. Take your time and mix it up with love. Apply a thin and even layer of J-B Weld onto one of the surfaces to be bonded, then press the surfaces together firmly. Applying pressure during the curing process helps ensure a secure bond.

Appropriate Curing Time:

Patience is key when it comes to J-B Weld’s curing process. Allow sufficient time for the bond to strengthen before subjecting it to stress or load. The recommended curing time varies based on temperature and humidity, so consult the packaging for specific guidelines. Waiting at least 24 hours before stressing the bond will give it the time it needs to develop maximum strength.

Temperature and Humidity Considerations:

Extreme temperatures and high humidity can affect J-B Weld’s performance. Apply the adhesive within the recommended temperature range specified on the packaging to optimize results. Extreme temperatures impede curing and weaken the bond, while high humidity slows down curing time and impacts bond strength. Work in a well-ventilated area with moderate temperature and humidity for the best results.

Careful Maintenance:

To extend the lifespan of your J-B Weld bond, take care of it like a precious gem. Avoid exposing the bond to excessive heat, chemicals, or harsh environments that compromise its integrity. Regular maintenance and inspection of the bonded area will identify potential issues early on and prevent further damage.

Are There Any Maintenance or Inspection Tips to Consider When Using J-B Weld?

J-B Weld is renowned for its ability to create strong and durable bonds. However, to ensure the longevity of your repairs, proper maintenance and inspection procedures must be followed. This blog post will explore essential tips for using J-B Weld, focusing on surface cleaning, dry conditions, regular inspections, proper storage, and addressing damage promptly. By adhering to these guidelines, you can guarantee that your J-B Weld repairs remain robust and reliable for an extended period.

Thorough Surface Cleaning:

Before applying J-B Weld, it is crucial to clean the surfaces meticulously. Any dirt, grease, or oil can impede the adhesive’s ability to bond effectively. To achieve maximum adhesion and strength, use a solvent or degreaser to eliminate contaminants from the surfaces. This step sets the foundation for a successful repair.

Ensuring Dry Conditions:

Moisture can adversely affect the curing process of J-B Weld, compromising its adhesive properties. It is imperative to ensure that the surfaces being bonded are completely dry before applying the adhesive. If necessary, expedite the drying process by using a hairdryer. By doing so, you eliminate any potential hindrances to the adhesive’s performance.

Regular Inspections:

Once J-B Weld has cured, periodic inspections are vital to identify signs of damage or deterioration. Pay special attention to high-stress areas or applications exposed to constant vibrations or temperature changes. Thoroughly examine the bond for cracks, chips, or separation as these indicate weakening. Promptly reapply J-B Weld or repair the bond if any damage is detected. Regular inspections help maintain the integrity of your repairs.

Proper Storage:

To preserve J-B Weld’s effectiveness when not in use, proper storage is essential. Store it in a cool and dry place to prevent premature curing. Ensure the container is tightly sealed after each use to prevent air exposure and moisture absorption. By storing J-B Weld correctly, you extend its shelf life and maintain its adhesive properties.

Addressing Damage Promptly:

If J-B Weld repairs show signs of damage or failure, it is crucial to address the issue promptly. Depending on the severity of the damage, reapplying J-B Weld or seeking professional assistance may be necessary. By addressing issues promptly, you prevent further damage and maintain the strength of your repairs.

RCefQMkSMz4″ >

Conclusion

J-B Weld, known for its exceptional strength and durability, is a reliable solution for various repair projects. But how long can you expect it to last? Well, the answer depends on several factors.

Firstly, the longevity of J-B Weld largely depends on the proper application and preparation of the surfaces being bonded. It is crucial to ensure that the surfaces are clean, dry, and free from any contaminants. This allows for maximum adhesion and enhances the overall durability of the bond.

Secondly, environmental conditions play a significant role in determining how long J-B Weld will last. Extreme temperatures, moisture levels, and exposure to harsh chemicals can all impact its lifespan. If subjected to these conditions, it’s essential to monitor and maintain the bond regularly to prevent any potential deterioration.

Additionally, the type of materials being bonded also affects J-B Weld’s longevity. While it can effectively bond various materials such as metal, wood, plastic, ceramic, and more, some combinations may provide better results than others. It’s advisable to consult J-B Weld’s product recommendations or seek professional advice for optimal bonding outcomes.

Furthermore, proper storage and handling of J-B Weld can extend its shelf life. Keeping it in a cool and dry place away from direct sunlight ensures that its chemical composition remains stable over time.

Ultimately, while J-B Weld is renowned for its strength and reliability, it is important to remember that no adhesive lasts forever. However, with careful application and maintenance under suitable conditions, you can expect J-B Weld to provide a long-lasting bond that withstands the test of time.