Welcome to our deep dive into the world of Weldbond, the adhesive superstar that’s changing the game. Whether you’re fixing up ceramics, creating stunning mosaics, or tackling woodworking projects, chances are you’ve heard of Weldbond. But here’s the question on everyone’s lips: “How long does it take for this magical glue to cure?”

Well, my friends, get ready for a wild ride because Weldbond’s curing time is a fascinating blend of science and artistry. Unlike those other glues that leave you twiddling your thumbs while you wait for something to happen, Weldbond strikes the perfect balance between efficiency and durability. It’s like watching an action-packed movie with just enough romance sprinkled in.

This adhesive has been crafted with precision and modern know-how to ensure maximum strength in minimal time. It cures faster than a cheetah on roller skates, allowing you to keep your project moving forward at lightning speed. But hold onto your hats – the exact curing time isn’t one-size-fits-all. We’re about to dive into the nitty-gritty details.

Join us as we embark on an epic journey through the ever-evolving timeline of Weldbond’s cure. We’ll peel back the layers and reveal the secrets behind its mind-blowing versatility and performance. Prepare yourself for a rollercoaster ride of knowledge as we uncover optimal strategies for harnessing this adhesive’s full potential. Get ready to level up your DIY game and experience that sweet satisfaction when everything sticks together perfectly.

So buckle up, folks. We’re about to unravel the mesmerizing curing process of Weldbond and discover how it can transform your crafting adventures into something truly extraordinary. Trust me, once you’ve experienced the power of this glue, there’ll be no turning back. Let’s dive in and get ready to bond just about anything with confidence and ease.

Factors Affecting Weldbond Curing Time

Contents

- 1 Factors Affecting Weldbond Curing Time

- 2 Average Curing Time of Weldbond

- 3 Optimal Conditions for Quicker Curing Times

- 4 Maximum Strength After 72 Hours

- 5 Lower Temperatures and Higher Humidity Slowing the Curing Process

- 6 Different Materials Requiring Different Curing Times

- 7 Manufacturer’s Instructions for Optimal Bonding with Weldbond

- 8 Test a Scrap Piece of Material Before Proceeding with Your Project

- 9 Conclusion

When it comes to bonding materials, Weldbond is the ultimate adhesive powerhouse. But did you know that understanding the factors that affect its curing time is essential for achieving a solid and long-lasting bond?

In this article, we will dive deep into the science behind Weldbond and explore the various factors that can make or break its curing time. Get ready to unlock the secrets of Weldbond and revolutionize your bonding projects.

Temperature:

Temperature holds the key to unlocking the full potential of Weldbond. Higher temperatures can ignite a blazing fast curing process, while lower temperatures slow things down to a snail’s pace. To harness the power of Weldbond, apply and cure it at temperatures between 70°F and 85°F (21°C – 29°C).

Humidity:

Humidity levels are like the secret sauce that can either make or break your Weldbond bond. High humidity levels dampen the drying party, inhibiting evaporation and prolonging curing time. On the other hand, low humidity levels turn up the heat on drying times, making your bond rock-solid in no time. Aim for a sweet spot of 50-70% humidity for optimal results.

Substrate Porosity:

Think of substrate porosity as the silent player in your bonding game. Porous materials like wood or fabric have an insatiable thirst for adhesive, resulting in longer curing times as they soak up every drop. Non-porous materials like metal or glass, however, have zero patience for waiting around and cure at lightning speed.

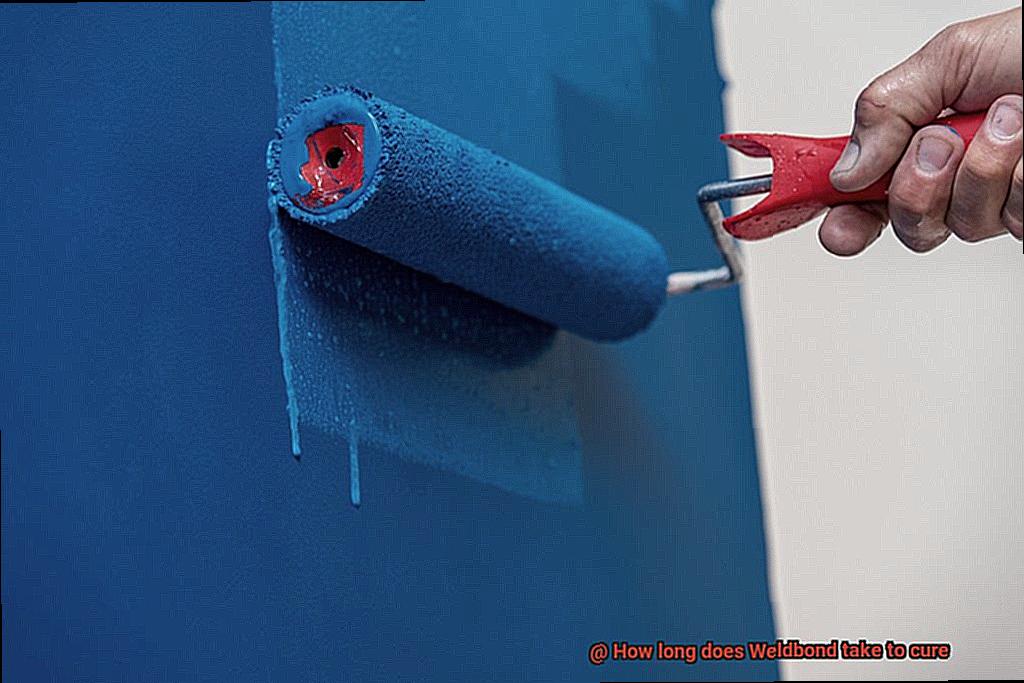

Thickness of Application:

The thickness of your adhesive layer is like a magician’s trick that can either make your bond appear instantly or keep you waiting in suspense. Thick layers hold more moisture and take their sweet time to evaporate, while thin and even coats ensure a speedy and efficient curing process. It’s time to cast your magic spell with thin layers.

Ventilation:

Ventilation is the breath of fresh air that your Weldbond bond needs. Good airflow not only expedites the curing process but also clears out any fumes, making your workspace a safe haven. Take a deep breath and work in a well-ventilated area or let fans do the air dance for you.

Mixing with Other Substances:

Mixing substances with Weldbond can be a thrilling experiment, but beware the effect on curing time. Adding water-based pigments or dyes may extend the party by introducing additional moisture. Follow the manufacturer’s instructions to avoid any unexpected twists and turns in your bonding journey.

Average Curing Time of Weldbond

The average curing time of Weldbond, a renowned adhesive known for its strength and versatility, is approximately 24 hours. However, it is important to note that this estimate may vary depending on several factors.

Temperature is one of the key influencers of curing time. Higher temperatures can expedite the process, while lower temperatures can slow it down. So, if you find yourself working in a warm environment, be prepared for a quicker drying time. Conversely, if you’re in a colder climate, exercise patience as it may take a little longer for the glue to fully cure.

Humidity also plays a role in the curing process. Higher humidity levels can prolong the drying time, while lower humidity levels can hasten it. If you’re in a humid area, it’s advisable to allow for additional drying time.

Additionally, the thickness of the adhesive layer can affect curing time. Thicker layers of Weldbond generally require more time to cure compared to thinner layers. Therefore, if you’re applying a substantial amount of glue, it’s wise to allocate additional curing time.

It’s worth noting that the type of materials being bonded also impacts curing time. Different materials possess varying levels of porosity, which affects the absorption rate of Weldbond. Porous materials like wood or fabric may necessitate more time for the adhesive to fully penetrate and cure.

Lastly, proper ventilation is crucial for an effective bond. Adequate airflow aids in the evaporation of water from the adhesive, allowing it to form a strong bond. Thus, ensuring your workspace is well-ventilated promotes optimal curing.

Optimal Conditions for Quicker Curing Times

Today, we delve into the optimal conditions for quicker curing times of Weldbond glue. Get ready to unleash the full potential of this adhesive powerhouse.

Let’s start with temperature – the master conductor of the curing symphony. Higher temperatures speed up the process, while lower temperatures slow it down. So, aim for a cozy temperature range of 60°F (15°C) to 80°F (27°C) to achieve optimal results. In colder temperatures, toss in some extra heat to keep things moving along.

Now, let’s talk humidity – the sneaky partner in crime. High humidity levels prolong drying time, while low humidity expedites it. Maintain a humidity level between 40% and 60% for smooth sailing. If you’re in a humid environment, bring out the dehumidifier or find a well-ventilated area to speed up the process.

Ah, surface preparation – the crucial step that sets the stage for success. Before applying Weldbond glue, ensure your surfaces are clean, dry, and free from dirt or grease. Give them a good wipe-down and banish any loose or flaky material. For an extra boost, roughen smooth surfaces with sandpaper to enhance adhesion and shorten curing time.

Next up is pressure – the secret ingredient for quicker drying. Apply pressure while the glue cures to expedite the process. Use clamps or heavy objects to hold bonded parts together firmly. Just follow manufacturer guidelines for the right amount of pressure based on the materials you’re bonding.

Ventilation takes center stage as our next performer. Good airflow is vital for whisking away evaporating solvents from the glue, speeding up the curing process. So, work in a well-ventilated area to ensure quicker drying and prevent any potentially harmful fumes from lurking around.

Last but not least, let’s discuss the thickness of application. Thin layers of Weldbond dry faster than thick ones. So, if you’re in a hurry, go for a thin, even layer. But if you need a thicker bond, be ready to allow for additional curing time.

By following these optimal conditions for quicker curing times, you’ll be able to witness the full magic of Weldbond glue in no time. Just remember to give it enough time to fully cure before subjecting your bonded materials to stress or load-bearing activities.

Maximum Strength After 72 Hours

Have you ever wondered how long it takes for glue to reach its maximum strength? If you’re a craft enthusiast or a DIY enthusiast, this question might have crossed your mind at some point. Well, wonder no more. In this article, we will dive into the fascinating world of Weldbond adhesive and explore why it takes a full 72 hours for this magical glue to achieve its maximum strength.

The curing process of Weldbond is a masterpiece in itself. Let’s break it down into three stages to better understand the journey that leads to maximum strength after 72 hours.

Setting the Stage (First 24 hours):

During the first 24 hours, Weldbond begins its performance by setting and bonding the materials together. However, it is not yet at its full strength. It’s like the glue is warming up for the grand performance that is about to unfold.

Building Up (Next 48 hours):

Over the next 48 hours, something incredible happens. The glue continues to cure and strengthen, gradually reaching its maximum bonding capacity after the 72-hour mark. It’s like watching a symphony orchestra building up to a crescendo – every hour that passes brings us closer to witnessing the true power of Weldbond.

Factors Influencing the Curing Time:

Now, let’s talk about the factors that can influence the curing time. Temperature and humidity play significant roles in this process. Higher temperatures and lower humidity levels can accelerate the curing process, while colder temperatures and higher humidity can slow it down. It’s like a delicate dance between these two factors, ensuring that the glue cures at just the right pace.

Additionally, the type of materials being bonded also affects the curing time. Porous materials tend to absorb more moisture from the glue, which can extend the curing period. So, if you’re working with porous materials, be patient and give Weldbond the time it needs to work its magic.

Once fully cured, Weldbond forms a strong and durable bond that can withstand various environmental conditions and common stresses. It’s like having a superhero by your side, ready to tackle any challenge that comes its way. But remember, patience is key. It’s important to follow the manufacturer’s instructions and avoid subjecting the glued materials to any stress or load until the full 72-hour curing period has passed.

So, what are the benefits of knowing about the maximum strength after 72 hours? By understanding this crucial aspect of Weldbond adhesive, you can plan your projects accordingly. You can ensure that you allow enough time for the glue to reach its full strength before subjecting your creations to any stress or load. This knowledge empowers you to create long-lasting and durable bonds that will stand the test of time.

Lower Temperatures and Higher Humidity Slowing the Curing Process

The curing process of Weldbond glue can be significantly influenced by lower temperatures and higher humidity, impeding the hardening and bonding of the adhesive. To attain optimal results, it is crucial to comprehend how temperature and humidity affect the curing process.

Temperature plays a vital role in the chemical reactions during curing. When the temperature falls below the recommended range, these reactions occur at a lethargic pace. Consequently, the glue takes twice as long to dry and harden, demanding patience. Maintaining a controlled temperature between 50°F to 90°F (10°C to 32°C) is essential for efficient curing.

In addition to temperature, higher humidity levels also disrupt the process. Excessive moisture obstructs water evaporation, crucial for proper drying and setting of the glue. If humidity exceeds 50% to 70%, curing time for Weldbond significantly prolongs.

To conquer these challenges, an optimal environment for curing Weldbond must be created. Here are some tips:

- Control the temperature: Use heaters or other warmth sources in colder environments to sustain recommended temperatures. Accelerated curing will be the result.

- Manage humidity: In humid conditions, employ dehumidifiers or other methods to reduce moisture levels, enabling faster evaporation and drying of the glue.

- Ensure proper air circulation: Unhindered airflow expedites drying. Adequate ventilation is vital for optimal results.

By adhering to these recommendations and considering Weldbond’s formulation and materials used, optimal curing results can be achieved. Always consult the manufacturer’s instructions regarding temperature and humidity requirements for superior outcomes.

Different Materials Requiring Different Curing Times

Glue is a magical substance that helps us bring our creative ideas to life. Whether you’re a DIY enthusiast or a professional crafter, understanding the factors that affect the curing time of glue when bonding different materials is crucial for achieving strong and long-lasting bonds. In this article, we’ll dive into the fascinating world of Weldbond glue and explore how various materials interact with it, affecting the time it takes to cure.

Porosity Matters:

Imagine trying to quench your thirst with a dry sponge versus a glass of water. The same principle applies when bonding materials with Weldbond glue. Porous materials like wood and fabric tend to absorb more moisture from the glue, resulting in a longer curing time. In contrast, non-porous materials such as metal or glass do not absorb moisture as readily, leading to shorter curing times.

The Climate Connection:

Temperature and humidity are two key environmental factors that can make or break your bonding experience. Higher temperatures and lower humidity levels speed up the curing process, while colder temperatures and higher humidity levels can slow it down. Therefore, it’s wise to work in an environment with moderate temperature and humidity to achieve optimal curing times.

The Thickness Factor:

Just like Goldilocks searching for the perfect porridge, finding the right consistency when applying Weldbond glue is essential. Thick layers take longer to dry compared to thin layers. To ensure efficient and consistent curing, apply an even layer of glue on both surfaces being bonded.

Extra Factors for Extra Strength:

Sometimes, a little extra effort goes a long way in achieving stronger bonds. Applying gentle pressure or weight to the glued materials during the curing process can expedite bonding and reduce overall curing time. However, do keep in mind that certain materials may have specific handling instructions or precautions during curing to prevent damage or misalignment.

Manufacturer’s Instructions for Optimal Bonding with Weldbond

Let’s dive into the manufacturer’s instructions and discover how to achieve that perfect bond. So, grab your safety goggles, because we’re about to embark on a glue adventure.

First things first – cleanliness is key. To ensure a bond that’s as strong as a superhero, make sure your surfaces are squeaky clean. Grab some soap and water or a suitable cleaning agent and give those surfaces a thorough scrub. Say goodbye to dirt, dust, grease, and other pesky contaminants that could sabotage your bonding magic.

Once your surfaces are pristine and dry, it’s time to apply the Weldbond adhesive. Remember, less is more. Apply a thin and even layer of glue to both surfaces. This ensures proper bonding without any excess gooey mess threatening to ruin your masterpiece.

Now comes the moment of truth – pressing those surfaces together firmly. It’s like giving them a bonding hug. This simple act helps distribute the adhesive evenly and creates a bond that’s as solid as a rock. If you really want to level up your game, use clamps or weights to hold everything in place while the glue works its magic.

But hold on just a second. Like a patient baker awaiting a perfectly risen cake, you’ll need some patience too. The curing time for Weldbond can vary depending on factors like material and environmental conditions. Generally, it takes around 24 hours for Weldbond to fully cure. But don’t worry. The adhesive develops initial strength within minutes of application, so you can handle your project with care after a short period of time. Just resist the urge to go all Hulk on it until it’s fully cured.

To achieve optimal bonding and maximum strength, let Weldbond cure at room temperature with moderate humidity. Think around 20-25 degrees Celsius and about 50% humidity. Avoid extreme temperatures or moisture during the curing process, as they can weaken the bond. We don’t want any glue mishaps, do we?

Oh, and one more thing. If you spot any excess glue oozing out during the bonding process, don’t panic. Grab a damp cloth or sponge and wipe it off immediately. Trust me, it’s much easier to clean up when it’s fresh rather than trying to remove it once it’s fully cured.

Test a Scrap Piece of Material Before Proceeding with Your Project

Before you dive in headfirst, there’s one crucial step that can save you time, effort, and materials – testing a scrap piece of material. In this article, we’ll explore why this step is essential and how it can ensure the success of your project.

Assessing Compatibility:

Different materials have unique properties and characteristics. Testing a scrap piece of material allows you to determine if the material is compatible with your project requirements. By applying the desired treatment or technique to the scrap material, you can evaluate its response and suitability. This step helps you avoid potential issues or failures when working with your main materials.

Evaluating Durability:

Testing a scrap piece of material enables you to assess its durability. Apply stress, pressure, or other forces that the material may encounter during your project. Observe how well the material holds up and whether it meets your expectations in terms of strength and resilience. This evaluation ensures that your chosen material will withstand the demands of your project.

Exploring Aesthetic Considerations:

For projects where aesthetics are important, testing a scrap piece of material allows you to experiment and explore different finishes, coatings, or treatments. This step gives you the opportunity to assess how these aesthetic enhancements will look and feel on your chosen material. It also helps you make informed decisions about the final appearance of your project.

Troubleshooting Potential Issues:

During the testing phase, if you encounter any issues or unexpected outcomes, don’t panic. Use this opportunity to troubleshoot and address any problems before proceeding with your main materials. Consult experts or reference guides to find solutions or alternative approaches that may better suit your project needs. By troubleshooting beforehand, you can avoid costly mistakes and ensure a smoother workflow.

U0hhFjjW5EU” >

Conclusion

Weldbond, a popular adhesive used in various industries, is known for its quick curing time. But just how long does it take for Weldbond to fully cure? Well, the answer depends on a few factors.

Firstly, the temperature and humidity of the environment play a significant role in the curing process. In ideal conditions, where the temperature ranges from 70°F to 85°F (21°C to 29°C) and the humidity is around 50%, Weldbond can cure within 24 hours.

However, if you’re working in colder temperatures or high humidity levels, you’ll need to exercise some patience. In these conditions, the curing time may extend up to 48 hours or even longer.

It’s important to note that while Weldbond may appear dry and ready for use within a few hours, it’s best to give it ample time to fully cure before subjecting it to any stress or pressure. This ensures maximum bond strength and durability.

So, whether you’re tackling a DIY project at home or working on an industrial application, allowing Weldbond sufficient time to cure will guarantee optimal results. Remember, patience is key when it comes to achieving strong and lasting bonds with this versatile adhesive.

In conclusion, the curing time for Weldbond can range from 24 hours under ideal conditions to potentially longer periods in colder temperatures or high humidity environments. By giving this adhesive adequate time to cure, you’ll ensure reliable and durable bonds for your projects.