Picture this: you’re in a pinch, and you need a quick fix. Enter super glue, the hero of all adhesives. We’ve all been there, relying on its incredible strength and versatility to save the day. But have you ever wondered just how long it takes for super glue to fully cure? Well, my friend, let’s dive into this sticky question together.

When you apply super glue to a surface, it starts a magical reaction with the moisture in the air. This reaction sets off a rapid polymerization process, transforming the glue from a liquid-like state to a solid, hardened material. It’s like watching an everyday miracle unfold before your eyes.

Now, let’s get down to business: how long does it take for super glue to fully cure? Brace yourself because it’s not as simple as slapping on some glue and calling it a day. The curing time can vary depending on factors like the brand of glue you’re using, the materials you’re bonding together, and even the environmental conditions.

On average, most super glues will reach their maximum bond strength within 24 hours. But here’s where things get interesting – the initial bond forms almost instantly. Yes, that’s right. Within minutes of applying the glue, you’ll see those surfaces coming together like they were meant to be.

But hold your horses. Don’t go putting any heavy stress or strain on that freshly glued object just yet. Patience is key here if you want a bond that can withstand the test of time. Rushing the process could result in a weaker connection that won’t hold up when things get tough. So do yourself a favor and give it the time it needs to cure properly.

To speed up this magical transformation, make sure you’re working in a well-ventilated area with temperatures between 65°F to 75°F (18°C to 24°C). Oh, and don’t forget to apply a thin layer of glue and ensure the surfaces are clean, dry, and fit together snugly. These little tricks will help you achieve a quicker and stronger bond.

So, my friend, next time you reach for that trusty super glue, remember this: patience is your secret weapon. Don’t be tempted to rush the process; give it the time it deserves. Trust me, a little patience goes a long way when it comes to creating a bond that can withstand anything life throws at it.

Factors Affecting the Curing Time of Super Glue

Contents

- 1 Factors Affecting the Curing Time of Super Glue

- 2 The Chemistry Behind the Curing Process

- 3 Temperature and Humidity Considerations

- 4 Thickness of the Glue Layer

- 5 Manufacturer Instructions and Recommendations

- 6 Surface Preparation and Priming

- 7 Initial Bond Strength vs Maximum Strength

- 8 Optimal Conditions for Faster Curing Times

- 9 Conclusion

Super glue, the superhero of adhesives, possesses the power to form unbeatable bonds in a flash. Yet, its curing time remains an enigma to many. In this captivating journey, we will unravel the mysteries behind this process.

Brace yourself as we explore the factors that influence the curing time of super glue: temperature, humidity, surface area and thickness, type of materials, and the quality and age of the adhesive.

Temperature:

Picture this: super glue molecules dancing in a heated frenzy. Temperature is the maestro controlling the tempo of their performance. When temperatures rise, these molecules shimmy with vigor, accelerating the chemical reaction responsible for curing. Conversely, colder environments put a damper on their dance moves, slowing down the reaction and extending the curing process.

Humidity:

In this watery waltz, humidity takes center stage. Moisture in the air acts as a catalyst for polymerization—the enchanting transformation that turns liquid super glue into a solid bond. Higher humidity levels bestow upon them an abundance of water molecules to tango with, expediting polymerization and reducing curing times. Meanwhile, low humidity leaves them parched and longing for moisture, resulting in a prolonged performance.

Surface Area and Thickness:

Behold. The grand stage awaits—a surface area yearning to be bound. A larger surface area provides ample room for moisture to join the act, fueling a faster cure. Thin layers of super glue are like nimble acrobats, leaping effortlessly into action as they bask in more exposure to moisture. Thick layers, however, are akin to sluggish giants, requiring more time to absorb moisture and complete their mesmerizing metamorphosis.

Type of Materials:

Materials possess unique qualities that influence super glue’s timing. Porous materials like wood or fabric absorb the adhesive’s moisture, slowing down the performance. These thirsty partners require patience for their bonding ballet. Non-porous materials, such as glass or metal, don’t absorb moisture and eagerly embrace the adhesive, leading to faster curing times and a breathtaking finale.

Quality and Age of Super Glue:

Enter the secret ingredient: quality and youth. High-quality super glue boasts accelerators that propel its curing prowess to new heights. Freshly brewed super glue, like a vibrant elixir, brims with vitality, offering swift cures as its adhesive properties remain at their peak. Aging glue, however, musters a gentle waltz, its potency fading over time, demanding more patience from its users.

The Chemistry Behind the Curing Process

The chemistry behind the curing process of super glue is a captivating dance of molecules and moisture. Super glue, also known as cyanoacrylate adhesive, relies on a chemical reaction called polymerization to form strong and durable bonds. At the heart of this adhesive lies a monomer called cyanoacrylate, which has a remarkable ability to polymerize when it comes into contact with moisture.

Polymerization is the process in which small molecules, or monomers, join together to form long chains called polymers. In the case of super glue, the cyanoacrylate monomers react with moisture to initiate the polymerization process. As soon as the monomers encounter moisture, they kickstart their reaction and start forming a solid polymer network. This transformation from liquid to solid is what allows super glue to bond materials together so quickly and effectively.

The presence of moisture is crucial for initiating the curing process of super glue. This moisture can come from the air or from the surfaces being bonded. As soon as the cyanoacrylate monomers come into contact with moisture, they begin to form strong bonds between the materials. This rapid curing time is one of the reasons why super glue is so popular for quick fixes and repairs.

During the curing process, super glue releases heat as an exothermic reaction takes place. This heat can cause the glue to become warm or even hot to the touch. It’s important to note that while super glue may appear to be fully cured within seconds, it may take longer for the bond to reach its maximum strength. The polymer chains continue to form and strengthen over time.

Various factors can influence the curing time of super glue. Temperature and humidity play a significant role, with higher temperatures and humidity levels accelerating the curing process. On the other hand, lower temperatures and humidity levels can slow it down. Additionally, factors such as surface area, thickness of the adhesive layer, types of materials being bonded, and even the quality and age of the adhesive can affect the curing time.

To ensure that your super glue bond reaches its maximum strength, it is recommended to allow the bonded materials to sit undisturbed for at least 24 hours. This gives the polymer chains ample time to form and strengthen, resulting in a strong and durable bond.

Temperature and Humidity Considerations

Today, we’ll explore how temperature and humidity affect the curing process of super glue. Get ready to witness the magic unfold as we unlock the secrets behind achieving strong and durable bonds.

The Heat is On:

- Warmer temperatures speed up the chemical reaction, resulting in a quicker bond.

- Extreme heat can cause weak bonds, so follow the manufacturer’s temperature guidelines.

- Check the ideal temperature range for your specific super glue brand.

The Cold Truth:

- Colder temperatures slow down curing, extending the time for the glue to set.

- Excessive cold can hinder proper curing, leading to less durable bonds.

- Remember, moderation is key.

The Humidity Factor:

- Higher humidity speeds up curing by reacting with certain components of super glue.

- Excessive moisture causes foaming or bubbling, affecting adhesive performance.

- Avoid using super glue in extremely dry environments.

Ventilation is Vital:

- Proper ventilation removes fumes and vapors emitted during curing, creating a safer working environment.

- Crack open a window or turn on a fan for better airflow.

Glue Storage Secrets:

- Store super glue in a cool, dry place to maintain effectiveness.

- Extreme temperature fluctuations and moisture exposure degrade adhesive properties.

Thickness of the Glue Layer

Today, we embark on a journey to unravel the enigmatic relationship between glue layer thickness and super glue curing time. Prepare yourself for a captivating exploration into the effects of thin and thick layers on the bonding process.

The Role of Glue Layer Thickness:

A thin layer of super glue acts as a conduit, promoting intimate contact between the adhesive and the surfaces being bonded. This close proximity allows the adhesive to work its magic, forming a strong bond more rapidly. Think of it as two friends holding hands tightly, ensuring a solid connection.

The Downside of Thick Layers:

On the other end of the spectrum, thick layers of glue can hinder the curing process. They create a considerable distance between the surfaces being bonded, undermining the adhesive’s ability to establish a robust bond quickly. It’s like trying to bridge a gap with an extended arm—it takes longer to connect.

Moreover, thick layers are prone to trapping air bubbles within them, creating obstacles that impede bonding and further delay the curing process. These pesky air bubbles act as tiny hurdles that need to be overcome before a strong bond can be formed.

Varying Curing Times:

Not all super glues are created equal when it comes to curing time. Different types and brands exhibit variations in their curing times, even when applied in similar thicknesses. Some super glues are specially formulated to cure rapidly, regardless of the thickness of the glue layer. Others may require more time to cure when thicker layers are applied.

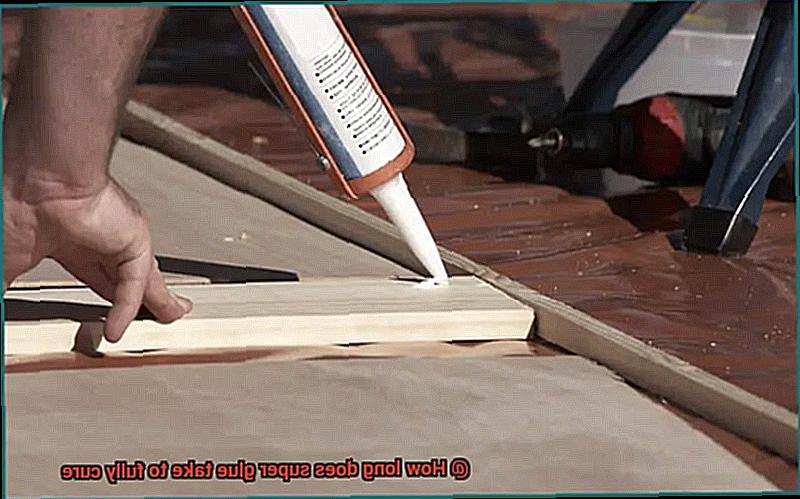

Optimal Application Techniques:

To achieve optimal bonding and faster curing times, it is crucial to follow manufacturer instructions and guidelines. Applying super glue in thin, even layers is generally recommended. This technique ensures that the adhesive can establish maximum contact with the surfaces being bonded, facilitating a quicker and stronger bond.

Manufacturer Instructions and Recommendations

Manufacturer Instructions and Recommendations are essential guidelines provided by the manufacturer of a product. When it comes to using super glue, these instructions and recommendations are particularly crucial for achieving the best results.

One important aspect covered in these guidelines is the curing time. Did you know that different brands and types of super glue can have varying curing times? It’s true. That’s why it’s essential to refer to the specific instructions provided by the manufacturer. They usually mention the recommended application thickness, temperature range, and other factors that can affect the curing time. By following these instructions, you’ll have a better understanding of how long you need to wait for the glue to fully set.

But why is waiting for glue to dry so important? Well, following the manufacturer’s instructions ensures optimal bonding and helps you avoid any potential issues down the road. Some super glues may even require additional time for maximum strength development after the initial curing period. So, be patient and don’t subject that bond to excessive stress too soon.

In addition to curing time, manufacturers often provide tips and recommendations on how to achieve the best results. They might suggest applying the glue in thin layers or clamping the bonded parts for a certain amount of time. These little nuggets of wisdom can make all the difference in achieving a strong and long-lasting bond.

So, whether you’re fixing broken ceramics or mending your favorite pair of shoes, always remember to read those manufacturer instructions and recommendations. They hold the key to achieving optimal bonding strength and ensuring that your bond stands the test of time.

Surface Preparation and Priming

Surface preparation and priming are essential steps in the process of using super glue. Properly preparing the surface ensures a strong bond and optimal curing time. Here are some key points to keep in mind:

Surface Preparation:

Before applying super glue, it is crucial to clean the surfaces thoroughly. Remove any dust, oil, grease, or moisture that may hinder bonding. Use a mild detergent or alcohol-based cleaner to clean the surfaces, then rinse and dry them completely.

Roughening the Surface:

For smooth surfaces like plastics or metals, consider roughening them up slightly. This can be done by lightly sanding with fine-grit sandpaper or using a specialized primer. Roughening the surface increases the contact area, allowing for a stronger bond.

Priming:

Priming is like a secret sauce for super glue bonding. Primers create a microscopically rough surface or chemically react with the substrate to enhance adhesion. Choose a primer that is compatible with both the material and the type of super glue being used. Follow the manufacturer’s instructions for application and curing time.

Curing Time:

Curing time varies depending on factors such as temperature and humidity. Higher temperatures and lower humidity levels speed up the curing process, while lower temperatures and higher humidity levels can slow it down. Follow the manufacturer’s recommendations for curing time to ensure a strong bond.

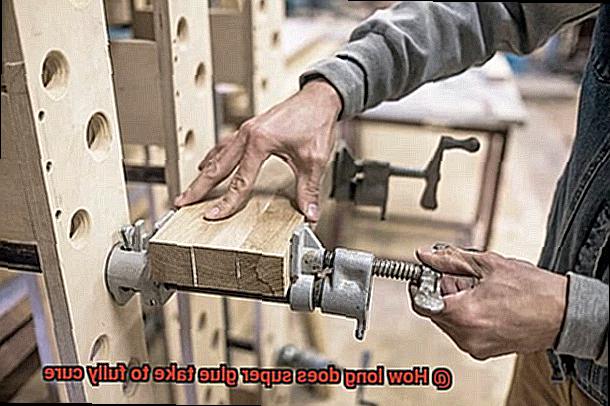

Applying Pressure:

Applying pressure or clamping the bonded surfaces together during the curing process can give your bond an extra boost. This is especially useful for larger or uneven surfaces where maintaining contact between the adhesive and substrate may be challenging.

Remember, patience is key when working with super glue. Allow the bonded item to sit undisturbed for at least 24 hours before subjecting it to any stress or load. This will allow the bond to strengthen over time, ensuring a durable connection.

Initial Bond Strength vs Maximum Strength

Today, we’re going to delve into the captivating realm of super glue and explore the intriguing contrast between its initial bond strength and maximum strength as it cures. Get ready for a sticky journey of knowledge.

When you apply super glue, it works its magic in an instant. This liquid adhesive, packed with cyanoacrylate, swiftly reacts with the moisture in the air and forms an initial bond that’s strong enough to hold lightweight objects together within seconds. It’s like having a superhero come to the rescue at warp speed.

The initial bond strength is just the beginning. As time passes, your super glue continues to cure and strengthen, building up to its maximum strength. During this curing process, the cyanoacrylate molecules link together, forming long chains of polymers. Each polymer chain adds another layer of strength, like constructing a fortress brick by brick.

Now, here’s the crucial part: patience is your best friend. While the initial bond may feel secure, it needs time to reach its maximum strength. Applying excessive stress too soon can jeopardize the bond’s integrity, leading to weakening or even breaking. Nobody wants their project to crumble like a house of cards.

So how long should you wait? Well, it depends on factors like temperature and humidity. As a general rule of thumb, it’s wise to let super glue cure for at least 24 hours before subjecting it to serious stress. Trust me, your project will thank you for the extra time to strengthen those polymer chains.

Oh, and did I mention that different types of super glue have varying curing times and strengths? Some formulas work faster than others, while specialized versions are designed for specific materials and offer enhanced bonding capabilities. Make sure to read the manufacturer’s instructions for accurate curing times and optimal strength.

To sum it all up, the initial bond strength of super glue is impressive, but it’s only the beginning. The maximum strength is achieved over time as the glue cures and those polymer chains solidify. So be patient, give it time to reach its full potential, and you’ll have a bond that’s unbreakable.

Optimal Conditions for Faster Curing Times

Let’s dive right in.

- Temperature: Super glue loves the heat. Work in a room with a temperature between 70-90 degrees Fahrenheit to speed up the curing process without compromising bond strength.

- Humidity: Super glue hates moisture. Low humidity environments are ideal for faster curing. Consider using a dehumidifier or finding a dry space to work in.

- Surface Preparation: Cleanliness is key. Ensure surfaces are clean, dry, and free from any grease, oil, or dirt. A quick wipe down with mild detergent or isopropyl alcohol should do the trick. Roughen up smooth surfaces with sandpaper for better bonding.

- Thin Layers: Apply thin layers of glue for faster curing. Too much glue or thick application can slow it down. Apply a thin layer evenly on one surface and firmly press the surfaces together.

- Pressure: Apply pressure to speed up curing. Use clamps, weights, or suitable methods to exert pressure on the bond for better contact between adhesive and surfaces. Avoid excessive pressure that squeezes out excess glue.

- Ventilation: Work in a well-ventilated area to dissipate fumes emitted by super glue. A fan or good air circulation can help speed up the curing time.

- Type of Super Glue: Different brands offer different curing times. Some have fast-drying formulas for quick bonding. Check product label or manufacturer’s instructions for the fastest curing glue.

SG4gOpHZTBM” >

Also Read: How Long Does Super Glue Take to Dry?

Conclusion

Super glue, a powerful adhesive that can bond almost anything together, is known for its quick-drying properties.

But have you ever wondered how long it actually takes to fully cure? Well, the answer might surprise you.

When you apply super glue to a surface, it starts to set within seconds. Yes, you read that right – mere seconds.

However, don’t be fooled by this initial drying time. While the glue may appear dry on the surface, it’s important to note that it hasn’t fully cured just yet.

In fact, it can take anywhere from a few hours to several days for super glue to reach its maximum strength and durability. So if you’re planning on using super glue for a project or repair job, make sure to exercise patience and give it ample time to cure completely.

Rushing the process could result in weaker bonds and potential disappointment down the line.