Are you a DIY enthusiast or a professional contractor in search of an adhesive that dries quickly and securely?

Well, look no further. Today, we’re delving into the fascinating world of adhesive drying times, with a specific focus on Power Grab and Bond.

Whether you’re tackling a small home repair or embarking on a massive construction project, knowing how long it takes for your adhesive to dry is crucial. In this blog post, we’ll explore all the nitty-gritty details about Power Grab and Bond’s drying times, equipping you with the knowledge you need to ensure your projects are a resounding success.

So sit back, relax, and let’s dive right in.

Factors That Can Affect Drying Time

Contents

In this blog post, we will delve into the science behind drying time and explore the key factors that influence how quickly power grab and bond glue dries.

Temperature:

Temperature plays a crucial role in the drying time of adhesive. Higher temperatures accelerate molecular activity, allowing the glue to cure faster. Conversely, colder temperatures slow down the chemical reactions required for drying. So, if you’re working in a chilly environment, consider using a heat source like a hairdryer to speed up the drying process.

Humidity:

Humidity levels in the air can affect the evaporation of moisture from the adhesive. High humidity hinders evaporation, leading to longer drying times. On the other hand, low humidity promotes faster drying by facilitating moisture evaporation. To optimize drying time, choose a day with lower humidity or use dehumidifiers in enclosed spaces.

Substrate Type:

The material or surface to which the adhesive is applied can also impact drying time. Porous materials like wood or fabric tend to absorb glue more readily, slowing down drying time. In contrast, non-porous surfaces like metal or glass allow for quicker drying as they do not absorb moisture from the glue. Adjust your expectations accordingly based on the type of material you are working with.

Application Thickness:

The thickness of the adhesive layer significantly affects drying time. Thicker layers take longer to dry as there is more material that needs to evaporate or cure. Following the manufacturer’s guidelines regarding proper application thickness is crucial to ensure optimal drying time.

Ventilation:

Proper ventilation is essential for efficient drying. Adequate airflow helps remove moisture from the glue and aids in the curing process. Insufficient ventilation, particularly in enclosed spaces, can extend drying times. Ensure proper air circulation by opening windows or using fans to speed up the drying process.

Environmental Conditions:

Factors such as air pressure and altitude can also influence drying time. Higher altitudes or lower air pressures may lead to longer drying times due to differences in atmospheric conditions. While these factors may not be easily controlled, it’s important to be aware of their potential impact on drying time.

Material Type

Well, fear not. In this blog post, we will unravel the mysteries behind the drying times of power grab and bond adhesive. Join us as we explore the fascinating factors that influence drying times for different materials. From wood to metal, concrete to plastic, we’ll cover it all.

Wood Bonding:

Wood bonding with power grab and bond adhesive is a reliable choice. On average, it takes around 20 minutes for the adhesive to dry. However, the drying time can vary based on factors such as humidity levels and wood density. Porous woods, such as pine or cedar, may require a bit more patience, as they take longer to dry compared to denser woods like oak or maple.

Metal Bonding:

Power grab and bond adhesive is your trusty companion when working with metal surfaces. In most cases, it takes approximately 30 minutes for the adhesive to fully dry. However, larger or heavier pieces of metal may need a bit more time to ensure a secure bond. Rest assured, once dry, the adhesive creates a strong and lasting connection that can withstand the test of time.

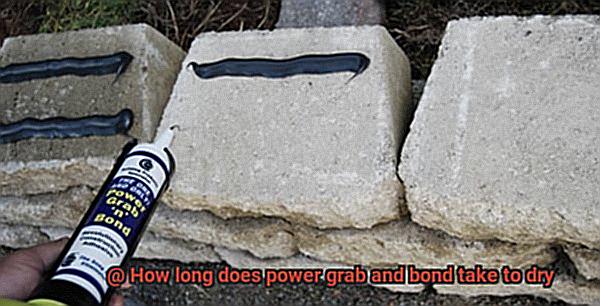

Concrete Bonding:

Concrete is a porous material that demands more time for the adhesive to penetrate and form a solid bond. When using power grab and bond adhesive, plan for an overnight wait as it generally takes around 24 hours to dry completely. It’s essential to exercise caution before subjecting your bonded concrete to any stress or load during this curing period.

Plastic Bonding:

Plastics come in various forms, each with its unique drying time requirements when using power grab and bond adhesive. Depending on the type of plastic being bonded, you can expect a drying time ranging from 30 minutes to 2 hours.

Some plastics boast porous surfaces that facilitate faster drying, while others might need extra patience. It’s crucial to choose the right adhesive for the specific type of plastic to ensure a strong and durable bond.

Temperature and Humidity

Temperature and humidity are two key factors that greatly influence the drying time of power grab and bond adhesive. The relationship between these variables is crucial in understanding how to achieve optimal drying performance. Let’s take a closer look at the fascinating interplay of temperature and humidity and how they affect the adhesive’s drying process.

When it comes to temperature, power grab and bond adhesive have a fondness for warmth. Picture this: warmer temperatures act as a catalyst, accelerating the evaporation of solvents in the adhesive. This speedy evaporation translates into a faster drying time. So, if you find yourself working in a cozy environment, expect your glue to dry up in a jiffy. However, don’t let things get too hot. Excessive heat can throw your glue game off balance, drying the adhesive too quickly and potentially compromising its bonding strength. On the flip side, bone-chilling temperatures put a freeze on the drying process, leaving you with subpar adhesion.

Now, let’s shift our attention to humidity. Humidity levels hold sway over how swiftly your adhesive sets. Imagine this: higher humidity means more moisture in the air, which hampers solvent evaporation and extends drying time. On the contrary, lower humidity creates an environment conducive to speedy evaporation, expediting the drying process.

To hit the sweet spot for optimal drying performance with power grab and bond adhesive, aim for a temperature range that Goldilocks would approve of – not too hot, not too cold – somewhere between 60°F (15°C) and 80°F (27°C). Pair this with a relative humidity level of around 50%, and you’ll have the winning formula.

However, in environments where humidity runs high or temperatures dip low, you may need to take additional measures. Consider employing fans or heaters to control temperature and airflow. Alternatively, introduce dehumidifiers to reduce moisture levels in the air. These efforts ensure that your adhesive doesn’t get thrown off balance by extreme conditions.

One crucial reminder: exercise patience. While the adhesive may feel dry to the touch within a specific timeframe, allowing ample curing time is imperative. Curing time refers to the period required for the adhesive to reach its maximum strength and durability. So, resist the urge to subject the bonded surfaces to stress or load-bearing activities until the adhesive has fully cured.

Thickness of the Adhesive Layer

The thickness of the adhesive layer is a critical factor when using power grab and bond glue. Understanding this concept will help you achieve optimal drying times and ensure successful bonding.

When it comes to drying time, the thickness of the adhesive layer directly affects how long it takes for the glue to dry completely. Simply put, the thicker the layer, the longer it takes for the solvent in the adhesive to evaporate. Therefore, it’s crucial to apply the adhesive in thin layers, typically between 1/8 inch to 1/4 inch. Applying a thicker layer than recommended can lead to extended drying times and potential performance issues.

To determine the recommended thickness, check the product packaging or manufacturer’s instructions. These guidelines provide essential information for achieving proper adhesion and efficient drying. However, if your project requires a thicker layer, consider using adhesive products specifically designed for thicker applications with faster drying times.

In addition to thickness, several external factors can influence drying time. Temperature, humidity, and airflow all play significant roles in this sticky equation. Higher temperatures and lower humidity levels accelerate drying, while colder temperatures and higher humidity levels slow it down. Aim for a temperature range of 60°F to 80°F and a relative humidity of around 50% for optimal drying performance.

If extreme conditions make it challenging to achieve ideal drying conditions, you can use fans or heaters to control temperature and airflow. Introducing dehumidifiers can help combat excessive moisture. However, be patient. Allow ample curing time before subjecting bonded surfaces to stress or load.

Estimated Drying Time

Imagine yourself in the midst of a project, eagerly bonding materials together using the renowned Power Grab and Bond adhesive. With anticipation, you wonder: how long will it take for the glue to dry and achieve its full strength? In this article, we’ll unravel the secrets behind the estimated drying time of Power Grab and Bond, exploring the factors that can influence it. So, let’s embark on this journey to become masters of timing.

Understanding the Thickness:

To unveil the key to quick-drying Power Grab and Bond adhesive, let us first grasp the concept of thickness. The solvent within the glue takes longer to evaporate as the layer becomes thicker. To avoid any sticky predicaments, it is crucial to apply thin layers ranging from 1/8 inch to 1/4 inch.

Applying a thick layer may result in extended drying times and potential performance issues. For precise guidance, refer to the product packaging or manufacturer’s instructions for recommended thickness guidelines.

Factors Affecting Drying Time:

Temperature, humidity, and airflow play mischievous roles in determining drying time. Higher temperatures and lower humidity levels accelerate drying, while colder temperatures and higher humidity levels slow it down. To achieve optimal drying performance, aim for a temperature range between 60°F to 80°F, accompanied by approximately 50% relative humidity. In the face of extreme conditions, bring forth fans or heaters to control temperature and airflow. Alternatively, deploy dehumidifiers to combat excess moisture.

Estimated Drying Time:

Power Grab and Bond typically dries to the touch within an enticing timeframe of 30 minutes to an hour. However, bear in mind that this initial drying time does not signify complete curing. To attain maximum bond strength, it is essential to allow Power Grab and Bond to cure for at least 24 hours before subjecting the bonded materials to any stress or load. The curing process continues over time, and it may take up to 7 days for the adhesive to reach its peak strength.

Tips for Faster Drying:

If you yearn for swifter drying times, fret not. Several tricks lie within your grasp. Utilizing fans or applying gentle heat can expedite the process. However, exercise caution to avoid applying excessive heat that could potentially damage the materials or compromise the adhesive’s performance. Always adhere to the manufacturer’s instructions for optimal results.

Additional Curing Processes

Join us on this journey as we explore the fascinating world of temperature, humidity, ventilation, surface type, and adhesive thickness to help you achieve faster and more efficient results.

Temperature: The Heat of the Matter

Temperature plays a pivotal role in the curing process of adhesives. Optimal drying for Power Grab and Bond is typically achieved between 50°F and 90°F. Lower temperatures prolong drying, weakening the bond, while higher temperatures lead to rapid curing that compromises strength.

Humidity: The Dampening Effect

Humidity levels have a direct impact on drying time. Excessive moisture in the air slows solvent evaporation, extending drying time. Conversely, low humidity accelerates drying but may result in shrinkage and reduced bond strength. Maintaining ideal humidity levels is essential for your specific adhesive.

Ventilation: A Breath of Fresh Air

Adequate ventilation is crucial for efficient drying. Good airflow facilitates solvent and moisture removal, promoting faster drying. Inadequate ventilation prolongs drying time and may cause incomplete curing, resulting in a weaker bond. Work in well-ventilated areas or use fans to enhance air circulation during curing.

Surface Type: The Perfect Match

The type of surface being bonded affects drying time. Porous surfaces absorb more adhesive, lengthening drying time as solvents take longer to evaporate. Non-porous surfaces allow for faster evaporation and quicker drying. Consider surface properties when estimating overall drying time.

Adhesive Thickness: Thin is In

The thickness of the adhesive layer influences drying time. Thicker layers require more time for solvents to fully evaporate, resulting in longer drying times. Applying thinner layers ensures quicker and more efficient drying. Strike a balance between adhesive thickness and bond strength.

Full Strength Achieved Over Time

Today, we embark on a captivating journey to explore the mysteries surrounding the drying time and duration required for Power Grab and Bond adhesives to achieve their full strength. So, prepare to be enthralled as we delve into the realm of curing and discover the key factors that influence this process.

Understanding the Curing Process:

Before we dive into the specifics, it’s crucial to grasp the concept of curing. Picture it as a magical transformation where adhesives transition from a liquid state to a solid bond. For Power Grab and Bond adhesives, this entails the evaporation of solvents or water content, resulting in a hardened adhesive that forms a robust connection.

Factors Affecting Drying Time:

Now, let’s uncover the elements that influence the drying time of Power Grab and Bond adhesives. Surface type, temperature, humidity levels, and adhesive thickness all play a role in determining how quickly our adhesive reaches its full strength.

- Surface Type: Different surfaces have varying levels of porosity and texture, affecting how well the adhesive adheres and cures. Rough or porous surfaces may require more drying time for optimal bonding.

- Temperature: Like a brewing storm, temperature can either speed up or slow down the curing process. Higher temperatures accelerate evaporation, while lower temperatures prolong drying time.

- Humidity Levels: Humidity acts as an invisible dance partner in the curing tango. High humidity can impede evaporation, extending drying time, while low humidity encourages faster curing.

- Adhesive Thickness: The thickness of the adhesive layer also contributes to drying time. Thicker layers take longer to dry and cure compared to thinner applications.

The Waiting Game Begins:

Imagine this scenario: you’ve applied your Power Grab and Bond adhesive for that perfect project. After a few hours, it appears dry to the touch. But hold your horses. Though it may seem dry, it hasn’t reached its full strength just yet. Brace yourself for a bit of waiting.

Patience is a Virtue:

The timeframe for Power Grab and Bond adhesives to achieve their full strength can vary. Typically, it can take anywhere from 24 hours to several days. Remember, Rome wasn’t built in a day, and neither are strong bonds.

Following Manufacturer’s Instructions:

To ensure optimal results, always consult the manufacturer’s instructions provided with your specific Power Grab and Bond adhesive variant. These guidelines contain valuable insights on recommended drying times and curing periods tailored to the adhesive’s unique composition.

Environmental Influences:

Let’s not forget about the external factors that can affect drying time. High humidity or low temperatures can extend the curing process, demanding a little extra patience from us. In such cases, it’s crucial to allow the adhesive ample time to cure properly before subjecting it to significant pressure or loads.

Recommendations for Proper Bonding Results

I have gathered some expert recommendations that will help you achieve proper bonding results when using Power Grab and Bond Adhesive. So grab your glue and let’s dive in.

First and foremost, proper surface preparation is paramount. Before bonding, ensure that the surfaces are clean, dry, and free from any dust, oil, or grease. Take a moment to imagine a pristine canvas awaiting your adhesive masterpiece. Achieving this clean canvas can be accomplished by using a suitable cleaning agent or solvent to remove any contaminants. Trust me, this step acts as the foundation for optimal bonding.

Next, pay heed to the manufacturer’s instructions. They know their product inside out and will provide invaluable guidelines on temperature and humidity conditions for application, as well as the appropriate amount of adhesive to use. Don’t dismiss their wisdom; it can make all the difference between a strong bond and a weak one.

When applying the adhesive, remember that evenness is key. Spread it smoothly on both surfaces that need to be bonded. Depending on the consistency of the adhesive, you can utilize tools such as a trowel, brush, or dispenser to achieve this even spread. And remember, less is more. Overdoing it with the adhesive can lead to excessive squeeze-out and jeopardize the bond strength. Conversely, too little adhesive may result in an insecure bond.

Once the adhesive is applied, join the surfaces together immediately. This prompt union ensures proper contact and maximizes the bonding strength. Picture two puzzle pieces interlocking flawlessly; that’s what we’re aiming for here. Avoid any sliding or shifting of the materials once they are joined — firmness is key.

To further enhance bond strength, consider applying some pressure on the bonded surfaces. Think of it as a warm hug for your project. This pressure can be achieved through clamps, weights, or any suitable method. By doing so, you’re helping the adhesive distribute evenly and solidify the bond strength.

Now, we play the waiting game. The drying time of Power Grab and Bond adhesives can fluctuate depending on factors such as temperature, humidity, and the materials being bonded. Patience is key; allow sufficient drying time before subjecting the bonded materials to any stress or load. This will ensure that the bond has fully cured and reached its maximum strength. Think of it as allowing a fine wine to age to perfection.

Before putting your project into action or subjecting it to heavy loads, it’s always wise to test the bond strength. Picture a gentle tug-of-war between your project and your expectations. Apply gradual pressure or perform a pull test on a small area of the bond. Better to be safe than sorry, right?

AJpV_Ewnes0″ >

Conclusion

Power Grab and Bond, two popular adhesive products, are commonly used for various DIY projects and professional applications. One of the most important factors to consider when using these adhesives is their drying time. So, how long does Power Grab and Bond take to dry?

The drying time of Power Grab and Bond can vary depending on several factors such as temperature, humidity, and the materials being bonded. Generally, these adhesives require approximately 24 hours to fully cure and reach their maximum strength.

However, it’s important to note that this is just a general guideline, and the actual drying time may vary in different situations. In ideal conditions with optimal temperature (around 70°F or 21°C) and low humidity levels, the adhesive may dry faster than in colder or more humid environments.

To ensure proper bonding and optimal results, it’s recommended to allow sufficient drying time before subjecting the bonded materials to stress or load-bearing activities. Rushing the process may compromise the bond strength and durability.

In addition to considering the drying time, it’s also crucial to follow the manufacturer’s instructions regarding application techniques and surface preparation. Properly cleaning and preparing the surfaces before applying Power Grab and Bond can significantly enhance its effectiveness.

In conclusion, while Power Grab and Bond typically require around 24 hours to dry completely, it’s essential to consider external factors such as temperature and humidity that may affect the drying process.