Welcome to our latest blog post, where we dive into the fascinating world of wood glue drying time. Whether you’re a DIY enthusiast or a seasoned woodworker, understanding how long it takes for that sticky goodness to fully dry is crucial for project success.

Wood glue drying time isn’t just a simple waiting game. It’s influenced by a multitude of factors, like the type of glue you use, the moisture content lurking in your wood, and even the environmental conditions surrounding your workshop. By mastering these variables, you’ll be able to plan your projects with confidence and achieve flawless results.

In this article, we’ll unravel the mysteries behind wood glue drying time and equip you with handy tips to speed up the process. We’ll also explore why knowing this magical timeframe is vital for avoiding mishaps, ensuring sturdy structures, and achieving that oh-so-satisfying finish.

So stick around (pun intended) as we uncover all there is to know about how long it takes for wood glue to fully dry. Get ready to level up your woodworking skills and unleash your creative genius.

What is Wood Glue?

Contents

- 1 What is Wood Glue?

- 2 Types of Wood Glue

- 3 Drying Time of PVA Glue

- 4 Drying Time of Aliphatic Resin Glue

- 5 Drying Time of Epoxy Glue

- 6 Role of Temperature and Humidity in Drying Times

- 7 Factors Affecting the Drying Time

- 8 Following Manufacturer Instructions for Optimal Results

- 9 Conclusion

Wood glue is a versatile adhesive that plays a crucial role in woodworking projects, providing a strong and durable bond between wood surfaces. Understanding the different types of wood glue, their specific drying times, and tips for optimal results is essential for successful and efficient woodworking. In this comprehensive guide, we will explore the various types of wood glue, delve into the factors that affect their drying time, and provide practical advice for achieving the best results.

Types of Wood Glue:

Yellow Wood Glue:

- Widely used and trusted by woodworkers.

- Boasts a strong bond strength.

- Dries to a distinctive yellowish color, making it easily visible on light-colored woods.

- Ideal for general woodworking projects.

White Wood Glue:

- Also known as aliphatic resin glue.

- Similar to yellow wood glue but dries transparent.

- Suitable for projects where glue lines need to be invisible.

- Commonly used in furniture making and interior woodworking applications.

Polyurethane Glue:

- Waterproof adhesive that expands as it cures.

- Fills gaps and provides excellent strength.

- Ideal for outdoor projects or areas exposed to moisture.

Epoxy Resin:

- Two-part adhesive consisting of a resin and a hardener.

- Provides an incredibly strong bond.

- Suitable for bonding large surfaces, filling gaps, and repairing damaged wood.

Drying Time Factors:

Type of Glue:

- Different types of wood glues have varying drying times.

- PVA glue typically dries within 30 minutes to 1 hour, while epoxy glue may take several hours to several days.

Environmental Conditions:

- Temperature and humidity affect drying time.

- Warmer temperatures and lower humidity levels generally result in faster drying times.

Application Thickness and Wood Porosity:

Thick layers of glue or highly porous wood may require additional drying time.

Tips for Optimal Results:

- Follow the manufacturer’s instructions for the specific type of wood glue being used.

- Allow at least 24 hours for the glue to fully cure before subjecting the bonded wood joints to stress or pressure.

- Ensure clean, dry, and debris-free wood surfaces before applying the glue.

- Apply even pressure to the glued pieces during the drying process.

Types of Wood Glue

Wood glue is like magic for woodworking projects. It helps to bond pieces of wood together, creating sturdy and reliable joints. But did you know that there are different types of wood glue? Each type has its own unique characteristics and drying times. Let’s dive into the fascinating world of wood glue and discover what makes each type special.

PVA Glue (Polyvinyl Acetate):

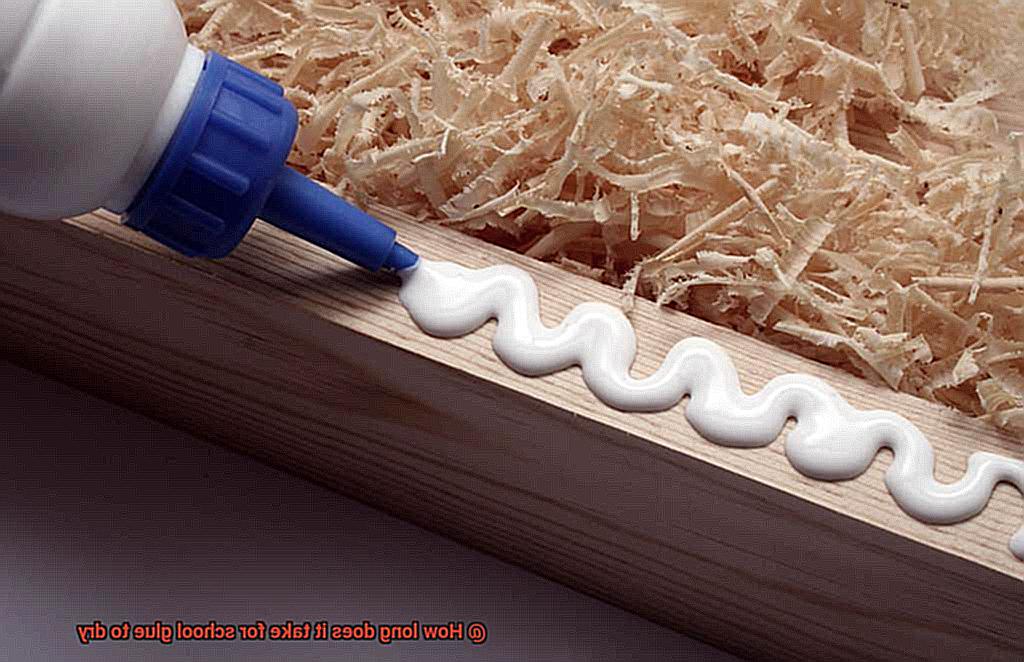

PVA glue is the superhero of wood glues. It’s easy to use and dries clear, making it perfect for all kinds of projects. PVA glue is known for its strong bond and fast drying time. You don’t have to wait forever for your project to dry – it usually takes around 30 minutes to 1 hour for PVA glue to partially dry. However, be patient because it can take up to 24 hours or more to fully cure, depending on the weather.

PVA glue is water-based, which means it’s non-toxic and easy to clean up with water when wet. This makes it a popular choice for both professional woodworkers and DIY enthusiasts. Its versatility also extends to various types of wood, allowing for strong bonds on different surfaces.

Polyurethane Glue:

Polyurethane glue is like a superhero with waterproof powers. It forms a strong bond between wood surfaces and can even be used on damp or oily surfaces. The best part? You have more time to position your pieces before the glue sets. Polyurethane glue takes around 4 to 6 hours to fully dry and cure, giving you plenty of time to perfect your project.

Polyurethane glue is known for its expanding properties, which allows it to fill gaps and create strong bonds even in challenging situations. It can handle high levels of stress and is resistant to water, making it suitable for outdoor applications or where moisture resistance is required.

Epoxy:

Epoxy is the super-strong glue you need for heavy-duty projects. It consists of a resin and hardener that you mix together before use. Epoxy creates an incredibly durable bond and is resistant to water, chemicals, and heat. The drying time for epoxy varies, but it can take anywhere from 5 minutes to 24 hours to fully cure. So, make sure you follow the instructions carefully.

Epoxy is known for its exceptional bonding strength, making it ideal for applications that require maximum durability. It can be used on a wide range of materials, including wood, metal, and plastic. Epoxy also allows for gap filling and has excellent adhesive properties, ensuring a strong bond between surfaces.

Drying Time of PVA Glue

Embarking on a woodworking project is an exhilarating journey of creativity and craftsmanship. And what’s the secret ingredient that holds it all together? PVA glue. But have you ever found yourself anxiously waiting for your glue to dry? In this blog post, we’ll delve into the factors influencing the drying time of PVA glue and uncover some effective tips and tricks to expedite the process. So grab your glue gun, because we’re about to unlock the secrets to efficient drying.

Factor 1: Temperature – The Hot or Cold Truth:

Temperature plays a pivotal role in the drying time of PVA glue. Higher temperatures create a sense of urgency, accelerating the drying process. Conversely, colder temperatures put the brakes on drying, testing our patience. To strike the perfect balance, aim for an ambient temperature between 60-80°F (15-27°C) to create an ideal environment for your glue to dry efficiently.

Factor 2: Humidity – The Moisture Maze:

Humidity levels can be sneaky little devils when it comes to drying time. High humidity slows down evaporation, leaving you waiting longer for that rock-solid bond. On the other hand, low humidity can give your glue a turbo boost, expediting the drying process. Aim for a humidity level of around 50-60% to strike the perfect equilibrium.

Factor 3: Thickness – Thin is In:

Let’s talk about thickness, baby. Thicker layers of glue take longer to dry compared to thin layers. To accelerate the process, apply a thin and even layer of PVA glue. Your project will thank you for it.

Patience is a Virtue:

Remember, Rome wasn’t built in a day, and neither is your woodworking masterpiece. Allow sufficient drying time before subjecting your glued pieces to any stress or load. Premature handling or clamping could lead to weakened bonds or complete failure. So sit back, relax, and let your glue work its magic for at least 24 hours or more, depending on the size and complexity of your project.

Drying Time of Aliphatic Resin Glue

Today, we’ll explore the concept of the drying time of aliphatic resin glue and uncover the secrets behind its strong bond. Get ready to dive into the fascinating details.

Factors Influencing Drying Time:

- Wood Type: Different woods have unique characteristics that affect how they absorb glue. Keep this in mind as you embark on your woodworking journey.

- Temperature and Humidity: These elements play a significant role in the drying time. Higher temperatures and lower humidity levels speed up the process, while lower temperatures and higher humidity levels slow it down.

The Numbers Game:

- Aliphatic resin glue is known for its relatively quick drying time compared to other wood glues.

- Within 30 minutes to 1 hour, you’ll likely see the surface dry. But don’t be fooled. It can take up to 24 hours or longer for the glue to fully cure and reach its maximum strength.

The Power of Pressure:

To ensure a strong bond, apply sufficient pressure during clamping. This helps squeeze out excess glue and ensures proper contact between the wood surfaces being bonded.

Manufacturer’s Instructions:

Different brands of aliphatic resin glue may have slight variations in their drying characteristics. Always consult the experts and follow the manufacturer’s instructions regarding drying and curing times.

Drying Time of Epoxy Glue

Well, the drying time of epoxy glue is a crucial aspect to consider when planning your project. Let’s dive into the factors that influence drying time and explore some tips and tricks to expedite the process.

The specific brand and type of epoxy glue you use can significantly impact drying time. Different formulas have varying curing times, so it’s important to follow the manufacturer’s instructions for optimal results.

Temperature and humidity play a pivotal role in drying time as well. Higher temperatures accelerate drying, while lower temperatures slow it down. Working in a well-ventilated area with a temperature range recommended by the manufacturer is ideal for optimal curing. Similarly, humidity levels can affect drying time. Higher humidity prolongs the process, while lower humidity speeds it up. Aim for moderate humidity levels for consistent results.

The thickness of the glue application is another crucial factor. Thicker layers take longer to dry compared to thinner ones. If time is of the essence, try applying thinner layers or opt for a faster-curing epoxy glue.

To expedite drying time, ensure proper clamping or holding of glued surfaces during the process. This prevents movement that could disrupt drying and creates a strong bond. Leave clamps or holding devices in place until the epoxy glue has fully cured.

Consider using a heat gun or hairdryer on low heat to gently warm the glued surfaces. Be cautious not to overheat or burn the epoxy glue, as this compromises its strength. The gentle heat accelerates the curing process.

However, patience is key. While epoxy glue may appear dry on the surface within a few hours, full curing takes longer. It’s best to wait at least 24 hours before subjecting glued surfaces to stress or load. This allows the glue ample time to fully harden and develop maximum strength.

Role of Temperature and Humidity in Drying Times

Fear not, for we are about to embark on a fascinating journey into the world of wood glue drying times. In this blog post, we will explore the role that temperature and humidity play in this process. Get ready for a sticky adventure.

The Heat is On: Temperature’s Influence:

Imagine stepping into a warm, sun-drenched room. Ah, the comforting embrace of the heat. Well, guess what? Wood glue feels the same way. Temperature plays a vital role in the drying time of wood glue.

When exposed to higher temperatures, the water content in the glue evaporates rapidly, leading to faster drying. In contrast, colder temperatures slow down evaporation, resulting in longer wait times. So, if you’re in a hurry, turn up the heat and watch that glue dry like lightning.

Humidity: The Moisture Monster:

Now let’s shift our focus to humidity. Picture yourself on a hot, humid day – the air feels thick and heavy. Well, guess what? That same humidity can make it difficult for wood glue to dry properly.

In high humidity environments, where the air is already saturated with moisture, evaporation becomes sluggish. This means your wood glue will take longer to dry. On the flip side, low humidity environments provide optimal conditions for fast drying since there is less moisture in the air hindering evaporation.

The Perfect Pair: Temperature and Humidity’s Dance:

Temperature and humidity are like dance partners – they influence each other’s moves. High humidity can counteract the effects of elevated temperatures. Even if it’s scorching hot outside, excess moisture in humid air may hinder evaporation and prolong drying times. On the other hand, low humidity can offset the impact of lower temperatures by promoting faster evaporation, despite a chill in the air. It’s a delicate balance, and finding that sweet spot is crucial for optimal drying times.

The Goldilocks Zone: Ideal Conditions:

Now that we understand the role of temperature and humidity, let’s talk about the perfect conditions for wood glue drying. Most wood glues perform best at temperatures between 70°F (21°C) and 80°F (27°C), with humidity levels between 45% and 55%. These conditions strike a balance between facilitating efficient evaporation and preventing the glue from drying too quickly or too slowly. So, aim for that Goldilocks zone to achieve glue-drying perfection.

Factors Affecting the Drying Time

Wood glue is an incredibly versatile adhesive that is essential in woodworking projects. Whether you’re building furniture, creating intricate designs, or repairing broken items, wood glue is a crucial tool in your arsenal. However, understanding the factors that affect drying time is paramount to planning your projects effectively.

Firstly, the type of glue used plays a significant role in drying time. Different types, such as PVA (polyvinyl acetate) glue, epoxy glue, and cyanoacrylate glue, have varying characteristics and drying times. PVA glue, like the popular Titebond, typically dries within 24 hours, while epoxy glue can take 24 to 48 hours to fully dry. Choosing the right type of glue for your project and considering its drying time is essential for proper planning.

Temperature and humidity are additional factors that impact drying time. Higher temperatures accelerate drying, while lower temperatures slow it down. Low humidity levels expedite water evaporation from the glue, resulting in faster drying times. Conversely, high humidity hinders evaporation and prolongs drying time. Therefore, working in a well-ventilated area with moderate temperature and humidity levels provides optimal conditions for drying.

The thickness and application method of wood glue also influence drying time. Thicker layers take longer to dry compared to thin layers. Applying a uniform and thin layer of glue promotes faster drying. Additionally, the method of application affects drying time. Applying glue to one surface only allows for faster drying compared to applying it to both surfaces being bonded together.

Wood type and condition also impact drying time. Different woods have varying levels of absorbency, affecting how quickly the glue dries. Hardwoods like oak or maple absorb glue slower than softwoods like pine or cedar. Rough or porous wood surfaces absorb more moisture from the glue, leading to longer drying times. Properly preparing wood surfaces by smoothing them with sandpaper and removing debris ensures optimal drying.

Lastly, clamping pressure during the drying process affects both strength and drying time. Appropriate clamping pressure ensures proper contact between glued surfaces, resulting in a strong bond. However, excessive pressure can squeeze out excess glue and prolong drying time. Striking the right balance is crucial when applying clamping pressure.

Following Manufacturer Instructions for Optimal Results

Wood glue is the unsung hero of woodworking projects, creating invisible bonds that hold everything together. To ensure your projects stand the test of time, it is crucial to follow the manufacturer’s instructions for optimal results. In this blog post, we delve into the importance of adhering to these guidelines and explore specific factors that influence wood glue drying time.

Understanding Drying Time Factors:

Type of Glue:

Different glues have varying drying times. PVA glue, polyurethane adhesive, and epoxy each have unique properties that affect drying speed. By carefully reading and following the manufacturer’s instructions, you can ensure the right drying time for your specific glue.

Environmental Conditions:

Temperature and humidity play a significant role in wood glue drying. Colder or humid conditions extend drying time, while warmer and drier environments speed it up. Consider these factors as you plan your projects and allow sufficient time for complete drying.

Thickness and Application Method:

The thickness of the glue layer and application method impact drying time. Applying too much or too little glue results in longer drying times or weaker bonds. Follow the manufacturer’s guidelines for an even layer of glue that promotes a strong bond between surfaces.

Wood Type and Condition:

Different woods absorb moisture differently, affecting drying time. High moisture content requires longer drying times for optimal results. Consider wood characteristics when determining how long to wait before handling or moving glued surfaces.

Clamping Pressure:

Applying appropriate clamping pressure during drying is crucial for a strong bond. Manufacturer instructions often provide specific guidelines on pressure. Proper clamping ensures glued surfaces remain in close contact, allowing effective curing.

gnG0FNxisvk” >

Conclusion

Wood glue typically takes anywhere from 30 minutes to 24 hours to fully dry. The exact drying time depends on various factors such as the type of wood glue used, the temperature and humidity of the environment, and the thickness of the glue application. It’s important to follow the instructions provided by the manufacturer for optimal results.

When it comes to wood glue, patience is key as it undergoes a remarkable metamorphosis from a runny state to a solid bond. This captivating process typically takes anywhere between half an hour and an entire day.

The duration of drying hinges upon several intriguing factors: the specific formulation of the adhesive being utilized, the prevailing temperature and humidity levels in your surroundings, as well as how generously or sparingly you apply the glue onto your wooden masterpiece.

You may also like: