Wood glue is a staple in any woodworking project, ensuring the strength and durability of our creations. But have you ever found yourself anxiously waiting for the glue to dry, unsure of how long it will take?

Well, fret no more. In this blog post, we will delve into the captivating world of wood glue drying time.

We will explore the different types of wood glue and uncover the various factors that influence drying time. Whether you are a novice or a seasoned pro, this knowledge will empower you to achieve flawless drying results every single time.

So, let’s embark on this enlightening journey together.

Different Types of Wood Glue

Contents

When it comes to woodworking projects, choosing the right wood glue is crucial for creating strong and durable bonds. With a wide variety of options available, it can be overwhelming to select the best glue for your project. In this article, we will explore the different types of wood glue on the market and shed light on their properties, drying times, and specific uses.

PVA Glue – The Trusty Sidekick:

Polyvinyl acetate (PVA) glue steals the spotlight as the most commonly used wood glue. This water-based adhesive dries transparently and provides excellent bonding strength. With its fast-drying nature, PVA glue typically sets within 30 minutes to an hour, making it a go-to choice for quick projects. Its versatility makes it suitable for a wide range of woodworking applications.

Epoxy Glue – The Mighty Bond:

When it comes to heavy or load-bearing woodworking projects, epoxy glue emerges as a powerful contender. Comprised of two components, resin and hardener, this two-part adhesive forms an incredibly strong bond. However, it requires more patience as epoxy glue may take up to 24 hours or more to fully cure. Its durability and resistance to moisture and heat make it ideal for demanding woodworking applications.

Polyurethane Glue – The Weather Warrior:

If you’re working on outdoor woodworking projects or need resistance against extreme temperatures, polyurethane glue is your knight in shining armor. Known for its waterproof properties, this adhesive can withstand the elements. Be prepared for a longer drying time of several hours as polyurethane glue takes its time to cure. Its flexibility and ability to bond dissimilar materials also make it a versatile choice.

Cyanoacrylate Glue – The Quick Fix:

Cyanoacrylate (CA) glue, commonly known as super glue or instant adhesive, offers quick bonding for small repairs or delicate wooden pieces. With its fast-drying capabilities, cyanoacrylate glue sets within seconds to a few minutes, ensuring a swift fix. Its strong bond and ability to bond non-porous surfaces make it suitable for intricate woodworking projects.

Hide Glue – The Time-Tested Classic:

For those who appreciate tradition and seek a reversible bond, hide glue delivers. Made from animal collagen, this ancient adhesive requires heating before use. Hide glue has a longer drying time ranging from 12 to 24 hours, but it offers exceptional strength and the ability to undo or repair joints. Its compatibility with antique furniture restoration and musical instrument construction makes it a favorite among artisans.

Conclusion:

Wood glue is an indispensable tool in any woodworker’s arsenal. With PVA glue’s fast-drying nature, epoxy glue’s incredible strength, polyurethane glue’s weather resistance, cyanoacrylate glue’s quick fixes, and hide glue’s timeless charm, there is a wood glue for every project. Remember to consider drying times, specific uses, and manufacturer instructions for optimal results.

Factors Affecting the Drying Time of Wood Glue

Factors Affecting the Drying Time of Wood Glue

Waiting for wood glue to dry can be an agonizing experience, especially when you’re eager to move forward with your woodworking project. However, the drying time of wood glue is influenced by several factors that deserve our attention. So, let’s delve into the intricate details and explore what really affects how quickly that glue sets.

First and foremost, the type of wood glue being used plays a significant role. There are different types available, each with its own specific drying time. Allow me to introduce you to them:

- White Glue (PVA): This popular choice for general woodworking projects typically dries within 30 minutes to an hour.

- Yellow Glue (PVA with added resins): Offering increased strength, it takes a bit longer to set, usually around one to two hours.

- Epoxy Glue: Forming an incredibly strong bond, this glue requires more patience as it can take several hours or even overnight to fully cure.

Moving on, environmental conditions come into play. The temperature and humidity of the environment significantly impact drying time. Wood glue tends to dry faster in warmer temperatures and lower humidity levels. So, if you find yourself working in a cold or humid space, prepare yourself for longer drying times.

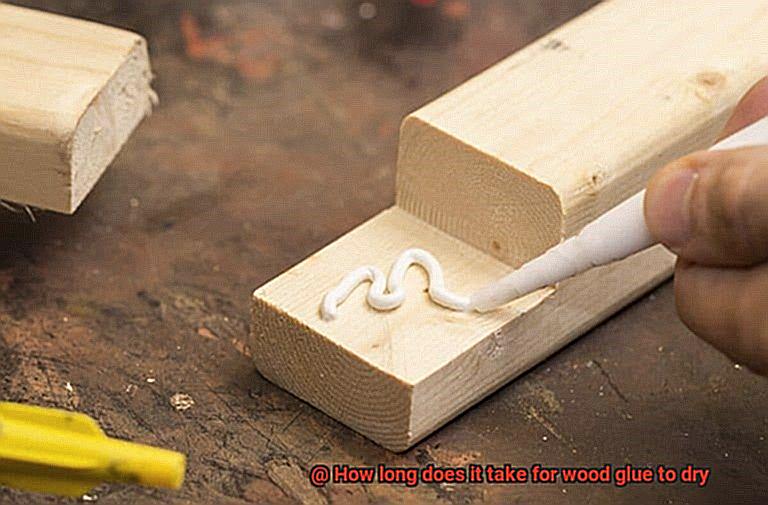

Now let’s talk about the thickness of the glue application. Thicker layers take longer to dry compared to thin, even layers. It’s important to spread the glue evenly and avoid excessive amounts for optimal drying time.

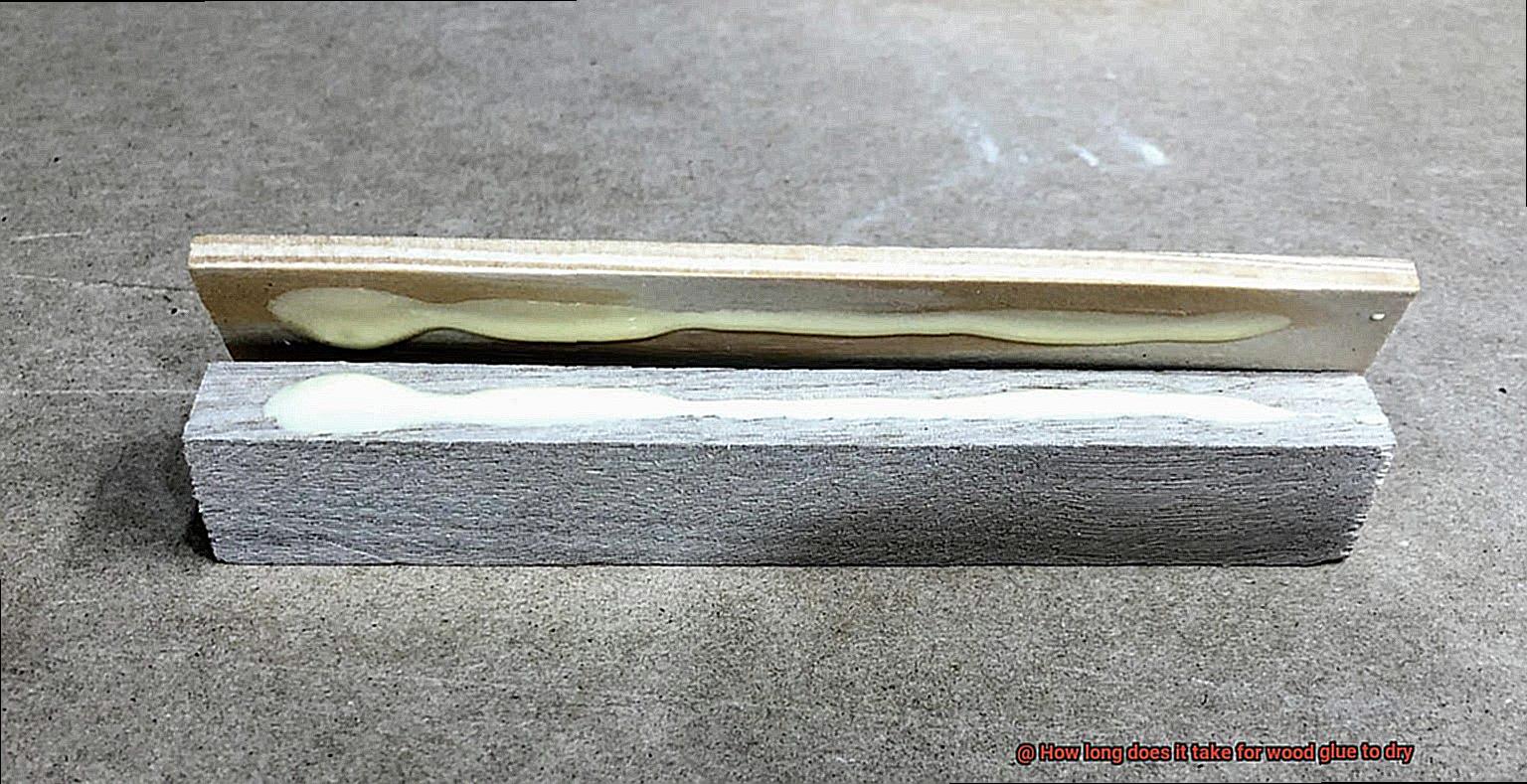

Consider also the type and moisture content of the wood being glued. Drier woods tend to absorb moisture from the glue more quickly, resulting in faster drying times. However, if the wood has a high moisture content or is coated with finishes or contaminants, it can interfere with the drying process and prolong drying time.

Lastly, your application technique plays a crucial role. Applying the glue evenly and pressing the pieces firmly together can help speed up the drying process. Remember, a tight bond requires proper clamping and sufficient pressure.

It’s worth mentioning that different brands or manufacturers may have slight variations in their drying times, so always refer to the specific instructions provided by the manufacturer for accurate drying time information.

PVA Glue

PVA glue, also known as Polyvinyl Acetate glue, is a versatile and popular adhesive used in woodworking and various other applications. It is renowned for its strong bonding properties and ease of use. When it comes to the drying time of PVA glue, several factors come into play.

Firstly, it’s important to note that different brands and formulations of PVA glue can have slight variations that impact drying time. Therefore, it’s always wise to consult the manufacturer’s instructions for the recommended drying time.

In general, PVA glue dries relatively quickly compared to other adhesives. It forms a strong initial bond within 15-30 minutes of application. However, this initial drying time doesn’t mean the glue is fully cured or at its maximum strength.

To achieve optimal bonding strength, it’s necessary to allow the PVA glue ample time to cure. The curing time can range from several hours to overnight, depending on factors such as humidity, temperature, and the thickness of the glue layer.

PVA glue thrives in warm environments with low humidity levels. Higher temperatures accelerate water evaporation in the glue, resulting in faster drying times. On the other hand, colder temperatures and high humidity can significantly slow down the drying process.

The thickness of the glue layer also affects drying time. Thicker layers take longer to dry compared to thin applications. It’s crucial to spread the PVA glue evenly and avoid excessive amounts to prevent extended waiting times.

Additionally, porous materials like wood can absorb moisture from the glue, affecting drying time. Ensuring that the wood is dry and free from moisture or contaminants before applying PVA glue will yield optimal results.

Epoxy Glue

Prepare to be amazed as we explore the incredible strength and versatility of this adhesive. Get ready, glue enthusiasts, because we’re about to dive into the process of curing epoxy glue and uncover some tips and tricks along the way.

Epoxy glue is no ordinary adhesive. It’s a superhero in the world of bonding, capable of joining a wide range of materials together with its mighty strength. But here’s the twist – it takes a little longer to dry compared to your run-of-the-mill wood glue. Why? Brace yourself, because we’re about to unveil the secret behind epoxy glue’s superpowers. During the curing process, this magical adhesive undergoes a chemical reaction, transforming from a liquid state to a solid-state.

Now, I know you’re itching to know how long it takes for epoxy glue to cure. Well, my friend, that depends on a few factors. Temperature, humidity levels, and the materials you’re bonding all play a role in this epic transformation. Generally, you can expect a complete cure within 24 to 72 hours. But here’s a pro tip – don’t be deceived by appearances. Even if the surface seems dry after a few hours, the internal curing process may still be underway. Patience is key here, my fellow glue enthusiasts.

But what if time is not on your side? Fear not. We’ve got some tricks up our sleeves to speed up the drying process. First up, let’s turn up the heat. Increasing the surrounding temperature can give epoxy glue a boost in its quest for speedy curing. Just remember, my friends, moderation is key – too much heat can lead to premature curing or weaken the bond.

Another trick in our arsenal is controlling humidity levels. Low humidity can put a damper on epoxy glue’s curing journey, so if you find yourself in a dry environment, consider using a humidifier or misting the air around your project. Watch as the humidity breathes life into your adhesive, accelerating its curing time.

Now, my fellow glue enthusiasts, let’s not forget the importance of following the manufacturer’s instructions. They hold the key to unlocking epoxy glue’s true potential. These instructions provide invaluable guidance on ideal temperature and humidity conditions for optimal curing. And that’s not all – they might even suggest applying pressure or clamping the materials together during the curing process to ensure a bond that stands the test of time.

Polyurethane Glue

Brace yourself for a journey into the realm of adhesive enlightenment.

Polyurethane glue, the superhero of adhesives, possesses unparalleled strength and versatility. It can conquer any bonding challenge, effortlessly adhering to wood, metal, plastic, and even stone. But here’s the twist – unlike other glues, this magical adhesive requires a touch of moisture to activate its superpowers.

So, how long does it take for this extraordinary glue to dry? Prepare for surprises because the answer is far from simple. On average, polyurethane glue takes anywhere from 6 to 24 hours to fully cure. But don’t be fooled by appearances; just because the surface seems dry doesn’t mean it’s entirely cured. Patience is key in unlocking its true potential.

Now, let’s dive deeper into the factors that influence drying time. First up is temperature. Imagine a slow-motion movie scene – lower temperatures and higher humidity levels can extend the curing process, leaving you waiting in suspense. Conversely, like a turbocharged race car, higher temperatures and lower humidity levels can speed things up, granting you swift results.

But hold on tight because there’s more. The thickness of the glue line also plays a role. The more adhesive you apply, the longer it will take to dry. So, if you find yourself working with thicker glue lines, embrace patience for a little while longer.

Ah, but let us not forget about the unique quirks of different polyurethane glue brands. Each brand may have its own peculiarities when it comes to drying time. Always consult the manufacturer’s instructions for optimal results that align with your adhesive choice.

Now that we’ve armed you with this invaluable knowledge, how about some tips and tricks? If you desire speedier drying times, seize control over the environment. Crank up the heat or employ a dehumidifier to reduce moisture levels. Just remember to stay within the manufacturer’s recommended temperature range, ensuring a perfect balance.

In conclusion, polyurethane glue stands as the true adhesive superhero, but it does require slightly more time to fully dry compared to other glues. By understanding the influencing factors such as temperature, humidity, and glue thickness, you can harness its extraordinary power and achieve flawless bonds.

Temperature and Humidity Considerations

Wood glue is a versatile adhesive that forms strong bonds in woodworking projects. However, its drying time can be influenced by various factors, including temperature and humidity. In this blog post, we will explore how these considerations affect the drying process of wood glue and provide tips for achieving optimal results.

The Impact of Temperature:

Temperature plays a crucial role in the drying time of wood glue. When the temperature is too low, the glue becomes thicker and more viscous, which hampers the evaporation of moisture. As a result, it takes longer for the glue to dry completely. On the other hand, excessively high temperatures can cause the glue to dry too quickly, resulting in a weak bond.

To ensure proper drying, it is recommended to work in an environment with a temperature between 70 to 75 degrees Fahrenheit. This range allows for optimal evaporation without compromising bond strength. Using climate-controlled workshops or adjusting the room temperature can help maintain these ideal conditions.

The Influence of Humidity:

Humidity levels also impact the drying time of wood glue. In areas with high humidity, excess moisture in the air inhibits evaporation, leading to longer drying times or incomplete curing. Conversely, low humidity levels facilitate faster evaporation, resulting in quicker dry times.

A relative humidity level of around 50% is considered ideal for proper drying. To achieve this, you can use dehumidifiers or humidifiers as needed. Additionally, acclimating both the wood surfaces and the wood glue to the desired working environment before application minimizes moisture transfer and ensures predictable drying times.

Variations among Glue Types:

Different types of wood glues have varying drying times under different temperature and humidity conditions. Some glues are formulated for faster drying, while others offer longer open times to allow for adjustments during assembly. Reading the manufacturer’s instructions and understanding the specific characteristics of your chosen wood glue will help you achieve the desired results.

Conclusion:

Temperature and humidity considerations are crucial in determining how long wood glue takes to dry. Maintaining a controlled environment with stable temperature and humidity levels is key to promoting proper evaporation and curing. By understanding these factors and taking appropriate measures, you can ensure strong and durable bonds in your woodworking projects. So, remember to embrace patience, control your environment, and unleash the full potential of wood glue.

Type of Wood Considerations

Wood glue is an indispensable tool for woodworking projects, but the drying time can vary depending on the type of wood being used. Understanding the factors that influence wood glue drying time is crucial for achieving strong and durable bonds. In this article, we will explore the key considerations when it comes to the type of wood used in woodworking projects.

Wood Absorption Rates:

Different types of wood have varying absorption rates, which directly impact drying time. Softwoods like pine have a more porous structure and tend to absorb glue more quickly, resulting in faster drying times. In contrast, hardwoods like oak or mahogany have a denser structure, making them less porous and thus taking longer to dry.

Moisture Content:

Moisture content plays a critical role in wood glue drying time. Wood with high moisture content requires more time for the water to evaporate before the glue can fully cure. It is advisable to use a moisture meter to ensure that the wood has an appropriate moisture level before applying glue.

Thickness of Wood Pieces:

The thickness of the wood pieces being glued together also affects drying time. Thicker pieces have a larger surface area for the glue to penetrate and cure, increasing the overall drying time compared to thinner pieces. It is important to account for this when planning your project timeline.

Environmental Conditions:

Environmental conditions, such as temperature and humidity, significantly influence the drying process. Higher temperatures and lower humidity levels generally accelerate drying, while cooler temperatures and higher humidity can slow it down. Working in a well-ventilated area with proper air circulation enhances the drying process and ensures optimal results.

Type of Wood Glue Used:

Different types of wood glues have specific drying characteristics. White glue, yellow glue, and polyurethane glue each have their own recommended drying times. It is crucial to read the manufacturer’s instructions for the specific glue being used to ensure optimal results. Additionally, some wood glues have faster drying variants available, which can be useful when working on time-sensitive projects.

Following Manufacturer’s Instructions

Wood glue is a transformative tool in the world of woodworking, enabling craftsmen to create sturdy and exquisite projects. However, to achieve optimal results, it is crucial to meticulously read and adhere to the manufacturer’s instructions when using wood glue. In this comprehensive guide, we will explore the significance of following these instructions and provide expert tips to ensure the best outcomes.

The Crucial Role of Drying Time:

The manufacturer’s instructions often specify the recommended drying time for the specific type of wood glue you are using. This critical step ensures a robust bond between the glued surfaces. Remember, patience is not just a virtue but a necessity. Hastening the drying process can weaken the bond and compromise the durability of your project.

Unraveling Variations in Drying Time:

Different types of wood glue have varying drying times. Some glues dry rapidly within minutes, while others require several hours or even overnight to fully cure. By diligently following the instructions, you will know precisely how long to wait before applying pressure or stress to your project.

Factors Influencing Drying Time:

Humidity and temperature significantly impact the drying time of wood glue. The manufacturer’s instructions may offer guidance on adjusting these factors to achieve optimal results. By heeding these recommendations, you will ensure that your wood glue dries properly and forms an unyielding bond.

Clamping for Success:

Occasionally, the manufacturer may recommend clamping or securing the glued pieces together during the drying process. This technique prevents any movement or shifting that could compromise the joint’s integrity, resulting in a stronger bond and a more reliable end product.

Harnessing the Power of Curing:

Do not be deceived by surface dryness; curing is equally as vital as drying for maximum strength and durability. Curing refers to the process in which the glue reaches its full potential. Depending on the glue type, curing can take hours or even days. Embrace patience and allow your project ample time to cure for the best possible results.

gnG0FNxisvk” >

Also Read: How to Make Glue Dry Faster

Conclusion

Wood glue typically takes anywhere from 30 minutes to 24 hours to dry completely. The exact drying time depends on various factors such as the type of wood glue used, temperature, humidity levels, and the size and thickness of the glued surfaces. It’s important to follow the manufacturer’s instructions for the specific wood glue you’re using to ensure optimal drying time.

When it comes to shorter drying times, some fast-drying wood glues can set in as little as 15 minutes. These glues are perfect for quick projects or when you’re in a hurry to finish your woodworking masterpiece. On the other hand, if you have more time on your hands and want a stronger bond, opt for a slower-drying wood glue that may take several hours or even overnight to fully dry.

Imagine this: You’ve meticulously crafted a beautiful wooden table, carefully joining each piece together with precision. Now comes the crucial step of applying wood glue to hold everything in place. As you wait anxiously for the glue to dry, it’s like watching paint dry – but with an added sense of anticipation and excitement.

The clock ticks away as the magical transformation occurs – from a sticky liquid substance that holds no shape to a solid bond that unifies your creation. The air around fills with a slight scent of freshly cut wood mixed with hints of chemical magic. You can almost feel the molecules locking into place, creating an unbreakable connection between the wooden fibers.

Patience is key during this waiting game. While it may be tempting to rush ahead and start sanding or applying finishes prematurely, resist the urge. Allow ample time for the wood glue to cure fully before moving forward with your project. Remember, haste makes waste – rushing through this crucial step could compromise all your hard work.

So whether you’re building furniture or repairing broken wooden pieces, understanding how long it takes for wood glue to dry is essential for achieving sturdy and reliable results. Take the time to choose the right glue for your needs, consider the environmental conditions, and be patient as you witness the transformation from liquid to solid.