If you’ve ever wondered about the mystical powers of Gorilla Wood Glue, particularly how long it takes to work its magic, then you’re in for a treat. Today, we’re diving headfirst into the captivating world of Gorilla wood glue’s curing time, covering everything from casual projects to professional endeavors.

Gorilla Wood Glue has earned its reputation as the go-to adhesive for craftsmen and craftswomen everywhere. But let’s get down to business – just how long does this mighty glue take to fulfill its destiny? Well, my friends, patience is key when dealing with this powerful adhesive.

When you first apply Gorilla Wood Glue, it grabs hold with lightning speed thanks to its quick-grab formula. You’ll feel that initial bond forming in no time. However, if you want maximum strength and durability, be prepared to wait up to 24 hours under ideal conditions. Keep in mind that factors like temperature, humidity, and even the type of wood can influence the curing time.

Now, why does it take so darn long? Let me break it down for you. Gorilla Wood Glue is water-based and works by seeping into the very pores of your wooden masterpiece. As it dries gradually over time, it forms an unbreakable bond that will withstand whatever challenges come its way.

If you’re itching for a quicker cure, listen up. The pros recommend applying the glue on both surfaces that need bonding, clamping them tightly together (no slacking off here.), and giving it plenty of time to set. And hey, if you really want to make sure your wood is ready for action, consider using a moisture meter to check if it’s dry enough for bonding.

Whether you’re fixing up a little something or tackling an ambitious woodworking project, understanding Gorilla Wood Glue’s curing process is crucial. Don’t rush the magic; let this extraordinary adhesive work its wonders.

So, my fellow glue enthusiasts, remember these two things: Gorilla Wood Glue is a bonding superstar, and patience is the name of the game during the curing process. And while you eagerly await your glue to work its magic, stay tuned for more captivating insights into the world of exceptional woodworking adhesives in our upcoming blog posts. Get ready to stick around for more incredible discoveries

What is Gorilla Wood Glue?

Contents

- 1 What is Gorilla Wood Glue?

- 2 How Long Does it Take for Gorilla Wood Glue to Work?

- 3 Factors Affecting the Curing Time of Gorilla Wood Glue

- 4 Tips for Optimal Results

- 5 Temperature and Humidity Considerations

- 6 Types of Woods and their Impact on Bond Strength

- 7 Preparing the Surfaces Before Applying Glue

- 8 Initial Bond Strength vs Maximum Strength

- 9 Conclusion

In the world of woodworking, finding an adhesive that can deliver strong and seamless bonds is essential. Enter Gorilla Wood Glue. This exceptional adhesive has become a favorite among professionals and DIY enthusiasts alike, thanks to its outstanding strength, versatility, and user-friendly nature. Let’s take a closer look at what makes Gorilla Wood Glue the go-to choice for all your woodworking endeavors.

Unmatched Bonding Power:

Gorilla Wood Glue is renowned for its exceptional bonding power. It creates a durable bond that can withstand even the harshest indoor and outdoor conditions, ensuring your wood projects remain intact for years to come. Whether you’re working with hardwood, softwood, or composite wood materials, Gorilla Wood Glue provides a reliable and long-lasting bond that won’t let you down.

Versatility at Its Finest:

No matter the type of wood surface you’re working with, Gorilla Wood Glue has got you covered. From natural woods to plywood, MDF, and particleboard, this versatile adhesive can handle it all. Whether you’re constructing furniture or repairing broken pieces, Gorilla Wood Glue guarantees seamless results every time.

Ease of Application:

Gorilla Wood Glue is designed with ease of use in mind. Its liquid form is ready to go straight out of the bottle, saving you precious time and effort. Additionally, the glue boasts a fast tack time, allowing it to start gripping surfaces within minutes of application. This ensures quick and efficient assembly of wood pieces, making your woodworking experience a breeze.

Waterproof and Safe:

One standout feature of Gorilla Wood Glue is its impressive water resistance. Once dried, the glue becomes fully waterproof, adding an extra layer of durability and reliability to your woodworking projects. Moreover, Gorilla Wood Glue is non-toxic and solvent-free, making it safe to use for professionals and hobbyists alike. In fact, it has even received approval from the FDA for indirect food contact, giving you peace of mind when using it for kitchen projects.

How Long Does it Take for Gorilla Wood Glue to Work?

One such adhesive that has gained immense popularity in the woodworking community is Gorilla Wood Glue. But just how long does it take for this powerful glue to work its magic? In this article, we will dive into the science behind Gorilla Wood Glue and explore the factors that influence its drying and curing time.

Factors Affecting Drying and Curing Time:

When it comes to Gorilla Wood Glue, several factors come into play when determining its drying and curing time. These factors include:

- Wood Type: Different woods have varying levels of porosity, which affects how quickly they absorb glue. For example, hardwoods like oak or mahogany may absorb glue more slowly than softer woods, leading to a longer drying time.

- Temperature and Humidity: The environment in which you apply Gorilla Wood Glue plays a crucial role in its drying and curing process. This adhesive performs best when used at temperatures around 70°F (21°C) and humidity levels between 45-55%. Higher humidity levels or colder temperatures can extend the drying and curing time significantly.

- Amount of Glue Applied: Applying the right amount of glue is essential for a strong bond. While using too little glue may result in a weak bond, using too much can lengthen the drying time as excess moisture needs to evaporate.

Drying Time:

To achieve an initial bond, Gorilla Wood Glue requires clamping for at least 20-30 minutes. During this time, the glue sets and begins to harden. However, for optimal results, it is recommended to leave the clamps in place for a longer period, allowing the glue to fully cure.

Curing Time:

In ideal conditions, where the temperature and humidity are within the recommended range, Gorilla Wood Glue typically fully cures within 24 hours. This curing process involves a chemical reaction between the glue components, resulting in a strong and durable bond. However, it is important to note that colder temperatures and higher humidity levels can significantly extend the curing time, sometimes up to 72 hours or more.

Tips for Successful Bonding:

To ensure a successful bond when using Gorilla Wood Glue, consider the following tips:

- Follow Instructions: Carefully follow the instructions provided by Gorilla Glue. This includes applying a sufficient amount of glue evenly on both surfaces and using proper clamping pressure.

- Surface Preparation: Ensure that the wood surfaces being glued are clean, dry, and free from any contaminants or finishes. Proper surface preparation promotes better adhesion and reduces drying time.

Factors Affecting the Curing Time of Gorilla Wood Glue

That’s where Gorilla Wood Glue comes in, offering exceptional adhesive capabilities. To maximize its potential, it’s crucial to understand the factors that influence its curing time. This article will explore the impact of temperature, humidity, wood type, bond thickness, and application method on the drying and curing process of Gorilla Wood Glue.

Temperature:

The curing time of Gorilla Wood Glue is greatly influenced by temperature. Warmer temperatures accelerate the glue’s chemical reactions, resulting in faster curing. Conversely, colder temperatures slow down these reactions, prolonging the curing process. For optimal results, it is recommended to use the glue within a temperature range of 55°F to 75°F.

Humidity:

Humidity levels also play a significant role in the curing time of Gorilla Wood Glue. Higher humidity slows down the process, while lower humidity speeds it up. Since wood glue relies on moisture to cure properly, high humidity impedes water evaporation from the glue, prolonging the curing time. On the other hand, low humidity conditions may cause the glue to dry too quickly, affecting its bonding capabilities. Finding a balance between humidity levels is essential for achieving optimal results.

Wood Type:

The type of wood being bonded affects curing time due to variations in porosity and moisture content. More porous woods like pine or cedar absorb more moisture from the glue, resulting in longer curing times. In contrast, less porous woods like oak or maple require less time for the glue to cure. Oily or resinous woods may also interfere with bond strength and curing time due to their natural oils or resins.

Bond Thickness:

The thickness of the bond line directly impacts curing time. Thicker bond lines take longer to cure due to increased moisture retention. Conversely, thinner bond lines allow for quicker moisture evaporation, resulting in faster curing. Applying a thin and even layer of glue ensures efficient and reliable bonding.

Application Method:

The way Gorilla Wood Glue is applied can affect curing time. Applying the glue in small dots or beads instead of a continuous line can speed up the process, as smaller amounts of glue allow for quicker moisture evaporation. Additionally, applying pressure during clamping helps distribute the glue evenly and expel excess moisture, leading to faster curing.

Tips for Optimal Results

When it comes to woodworking projects, achieving a strong and reliable bond is crucial. Gorilla wood glue is known for its exceptional adhesive properties, but to ensure optimal results, it’s important to follow these tips. In this guide, we will walk you through the steps to maximize the bonding strength of Gorilla wood glue.

Prepare the Surfaces:

Before applying Gorilla wood glue, ensure that the surfaces to be bonded are clean, dry, and free from any dust, debris, or grease. Use a clean cloth or brush to remove any loose particles. This step ensures proper adhesion and creates a stronger bond.

Apply the Right Amount of Glue:

Using the appropriate amount of Gorilla wood glue is crucial for optimal bonding strength. Follow the manufacturer’s instructions to determine the correct amount to apply. Remember, a little goes a long way, so spread the glue evenly for maximum coverage.

Spread the Glue Evenly:

Once you’ve applied the glue, use a brush or spreader to distribute it evenly over the surface. This ensures that every inch of the bonded area is covered with an even layer of glue. A smooth and uniform application helps create a solid bond between the wood pieces.

Clamp for Success:

To achieve optimal results, clamp the bonded surfaces together using appropriate clamps or weights. This provides consistent pressure and allows the glue to cure properly. Follow the manufacturer’s instructions for recommended clamping times, as they can vary depending on the project and materials.

Allow Sufficient Curing Time:

Patience is key when working with Gorilla wood glue. Allow sufficient curing time for the glue to reach its maximum strength. While initial bonding may occur within 20-30 minutes, wait a full 24 hours before subjecting the bonded pieces to stress or load-bearing activities. This gives the glue ample time to fully cure and ensures a durable bond.

Temperature and Humidity Considerations

Today, let’s delve into the fascinating world of Gorilla wood glue and explore how temperature and humidity can have a profound impact on its performance. Paying attention to these factors can make all the difference when it comes to achieving rock-solid bonds that will stand the test of time.

Let’s start with temperature. When using Gorilla wood glue, it is essential to work within the recommended temperature range of 55°F to 75°F (13°C to 24°C). Why is this crucial? Well, if it’s too cold, the glue will take an eternity to dry, and no one wants to wait around forever for their project to be ready. Conversely, excessive heat can cause the glue to cure too quickly, compromising its strength. So, finding that sweet spot and striking a balance is key.

Now, let’s talk about humidity – the silent player in the glue game. Aim for a humidity level between 45% and 55% for optimal results. If it’s too dry, your glue might dry out before you even finish applying it, resulting in a weaker bond. But beware of high humidity too. Excess moisture in the air can slow down drying and curing times, leaving you twiddling your thumbs for longer than necessary.

Here’s an important tidbit: Gorilla wood glue is water-based, which means it can be affected by changes in environmental conditions. High humidity can cause the wood to absorb more moisture, potentially weakening the bond. To combat this, consider using a moisture barrier or ensuring proper ventilation in humid conditions.

One more thing to keep in mind – avoid extreme fluctuations in temperature and humidity during the curing process. Rapid changes can stress the bond and lead to a weaker connection between your glued surfaces. So, be patient and give your adhesive ample time to cure under stable conditions.

When you’re not using Gorilla wood glue, make sure to store it in a cool, dry place. Extreme temperatures or high humidity can mess with its consistency and shelf life, and nobody wants that.

So, my fellow woodworkers, by paying attention to temperature and humidity considerations, you can unlock the full potential of Gorilla wood glue. Follow the recommended temperature range, maintain the right humidity levels, avoid extreme variations, and store it properly. By doing so, you’ll create bonds that are as strong as Hercules himself and projects that will withstand the test of time.

Types of Woods and their Impact on Bond Strength

Woodworking is a beautiful craft that requires patience, skill, and the right adhesive to create strong and durable bonds. When it comes to bonding wood surfaces together, Gorilla wood glue is a popular choice known for its strength and versatility. However, did you know that the type of wood you use can actually impact the bond strength? In this blog post, we will explore the secrets behind strong wood glue bonds and how different woods can affect bond strength when using Gorilla wood glue.

Density Matters:

The density of the wood plays a crucial role in determining bond strength. Dense woods like oak or maple provide more surface area for the glue to adhere to, resulting in a stronger bond. Softer woods like pine or cedar, on the other hand, may not offer as much surface area, leading to weaker bonds. When choosing wood for your project, consider opting for denser woods if you desire a stronger bond with Gorilla wood glue.

Moisture Content:

Wood with high moisture content can hinder the effectiveness of the glue by preventing proper adhesion. It is important to ensure that the wood has been properly dried before applying Gorilla wood glue. This can be done by allowing the wood to acclimate in a controlled environment for a certain period of time, depending on its thickness and species. By using properly dried wood, you can achieve a stronger bond with Gorilla wood glue.

Porosity and Preparation:

The porosity of the wood also impacts bond strength. Woods with open grain structures may require additional steps to achieve a strong bond. Using a wood conditioner or sanding the surface can create a smoother and more even surface for the glue to adhere to, enhancing bond strength. So, if you’re working with woods like oak or mahogany, make sure to prepare the surface properly for optimal bonding with Gorilla wood glue.

Natural Oils and Resins:

Certain woods contain natural oils or resins that can interfere with the bonding process. Woods like teak or rosewood have higher oil content, which may require special surface preparation techniques or the use of specific adhesives designed for oily woods. By addressing the presence of natural oils or resins, you can ensure a strong bond with Gorilla wood glue, even with these challenging woods.

Surface Treatments:

Consider any treatments or finishes applied to the wood. Some finishes, such as varnishes or polyurethane coatings, can create a barrier between the glue and the wood surface, reducing its effectiveness. In such cases, it may be necessary to remove or sand down the finish before applying Gorilla wood glue for optimal bond strength. Remember, a clean and bare wood surface is ideal for achieving strong bonds.

Preparing the Surfaces Before Applying Glue

In the world of woodworking, a strong and durable bond is the holy grail. To unlock this secret, it all starts with proper surface preparation before applying glue. In this article, we will delve into the crucial steps required to prepare surfaces before using Gorilla wood glue, as well as share some expert tips and tricks to achieve the ultimate bonding results.

Step 1: The Clean Freak’s Guide

Before even thinking about the glue, cleanliness reigns supreme. Banish dirt, dust, and debris from the surfaces to be bonded. Grab a clean cloth or whip up a mild detergent and water solution to give those surfaces a thorough wipe down. A clean slate ensures that your glue can work its magic without any pesky interference.

Step 2: The Dry Dance

Moisture is the arch-enemy of bonding. Make sure your surfaces are bone-dry before unleashing the glue. Give them a gentle pat-down with a dry cloth, or let nature take its course and allow them to air dry completely. This step prevents any moisture-related bond weakening and guarantees optimal strength.

Step 3: Rough and Ready

If you want to take your bond from good to great, embrace a little roughness. Grab some fine-grit sandpaper or unleash a wire brush on those surfaces. The aim here is not to strip away material, but rather create a slightly rough texture that gives your glue more surface area to cling onto. It’s like giving your bond an iron grip.

Step 4: Fit Like a Glove

Before committing to the glue, play matchmaker and test-fit those pieces together. This allows you to ensure perfect alignment and make any necessary adjustments before sealing the deal. It’s better to address any issues or misalignments at this stage rather than after you’ve applied the glue. Trust us, your bond will thank you.

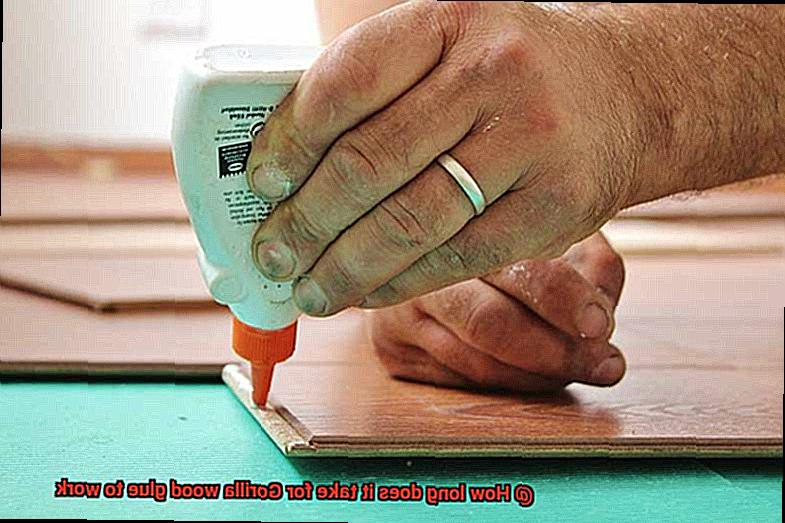

Step 5: Gorilla Wood Glue Application 101

When it’s time to unleash the Gorilla, remember that less is not always more. Applying too little glue results in a weak bond, while drowning your project in glue creates a messy nightmare. Follow the manufacturer’s instructions to determine the perfect amount of glue to use and achieve bonding nirvana.

Step 6: The Power of Pressure

Once the glue is in place, it’s time to get hands-on. Firmly press those surfaces together like an expert matchmaker bringing two soulmates together. Applying pressure ensures even distribution of the glue and creates optimal contact between the surfaces. Depending on the size and shape of your project, clamps or other pressure-inducing methods can be your secret weapons here.

Initial Bond Strength vs Maximum Strength

When it comes to woodworking projects, Gorilla wood glue is a go-to choice for its exceptional strength and durability. But what exactly is the difference between initial bond strength and maximum strength? Today, we’ll take a deep dive into the science behind Gorilla wood glue to uncover the secrets of achieving a strong and long-lasting bond.

Initial Bond Strength:

After applying Gorilla wood glue and joining two wood surfaces together, the initial bond strength refers to the strength of the bond immediately. Within just 20 to 30 minutes, this remarkable adhesive starts penetrating deep into the wood fibers, creating a robust and secure connection. Its adhesive properties allow it to seep into the pores of the wood, ensuring a reliable bond.

However, it’s important to note that while the initial bond strength is relatively quick to achieve, it may not be sufficient for applications involving heavy loads or stress. In such cases, allowing more time for the glue to cure and reach maximum strength is essential.

Maximum Strength:

Maximum strength is reached when Gorilla wood glue has fully cured and achieved its optimal bonding capacity. This process typically takes around 24 hours or longer, depending on factors such as temperature, humidity, and the thickness of the glue line.

During this curing period, a chemical reaction called cross-linking occurs. It’s like magic happening at a molecular level. Cross-linking involves the formation of bonds between the molecules of the adhesive, resulting in a stronger and more durable bond. To ensure maximum bond strength, it is recommended to clamp or apply pressure on the glued surfaces during the curing period. This promotes intimate contact between the wood fibers and the glue, enhancing the overall strength of the final bond.

s2EH3C-jzIM” >

Also Read: Will Gorilla Glue damage rubber?

Conclusion

The effectiveness of Gorilla wood glue can be seen in its quick action and strong bond.

In just a matter of minutes, this powerful adhesive begins to work its magic, securely joining wood surfaces together. With each passing second, the bond grows stronger, ensuring a reliable and durable hold.

Whether you’re working on a small DIY project or tackling a larger woodworking endeavor, you can trust that Gorilla wood glue will deliver results in no time.