Ever found yourself wondering just how long it takes for grab adhesive to dry? Well, you’ve stumbled upon the perfect place for answers. Imagine this: you’re all set to tackle that home improvement project armed with your trusty grab adhesive, ready to conquer any challenge. But before you dive in headfirst, it’s crucial to understand just how long this magical bonding agent needs to set.

Grab adhesive is like a superhero solution for those tricky projects that demand a strong and speedy bond. Whether you’re dealing with stubborn tiles or securing that wobbly cabinet once and for all, knowing the drying time of grab adhesive can save you from costly mistakes and ensure your project’s success.

In this blog post, we’ll take a deep dive into the world of grab adhesive and uncover what affects its drying time. We’ll explore different types of grab adhesives and their unique properties. So buckle up because we’re about to drill down into this fascinating topic.

But first, let’s quickly understand what exactly grab adhesive is and why it has become a favorite among DIY enthusiasts and professionals alike.

Grab adhesive, also known as construction adhesive, is a versatile powerhouse that can bond materials ranging from wood and metal to plastic and even stone. Unlike regular adhesives, grab adhesive doesn’t rely on evaporation to cure. Instead, it uses chemical reactions to form an unbreakable bond. No need for clamps or mechanical help – it’s super convenient for quick fixes or projects where time is of the essence.

Stay tuned as we unveil the secrets behind grab adhesive drying time – how to make it work faster and what factors might affect it. Get ready to unleash the full potential of this incredible adhesive and say goodbye to waiting around for glue to dry.

So, let’s get started and discover the amazing power of grab adhesive.

What is Grab Adhesive?

Contents

- 1 What is Grab Adhesive?

- 2 Factors Affecting the Drying Time of Grab Adhesive

- 3 Temperature and Humidity Conditions

- 4 Types of Materials Being Bonded

- 5 Allowing Sufficient Drying Time for Optimal Results

- 6 Appearances Can Be Deceiving

- 7 Quick-Drying Formulas

- 8 Exercising Caution After Application

- 9 Conclusion

In this comprehensive guide, we will explore the fascinating features, wide-ranging applications, and undeniable benefits of grab adhesive. Let’s get started on this adhesive adventure.

What is Grab Adhesive?

Grab adhesive, also known as construction adhesive or construction glue, is a game-changing adhesive used in construction and DIY projects. It possesses an incredible ability to bond different materials together, such as wood, metal, glass, and plastic. What sets grab adhesive apart from the rest? Its instant grab feature. Upon application, it immediately provides tackiness, eliminating the need for additional support or clamping.

Key Features of Grab Adhesive:

- Instant Grab: Say goodbye to waiting around for adhesives to dry. Grab adhesive’s immediate tackiness ensures that you can start working on vertical applications or heavy materials with ease.

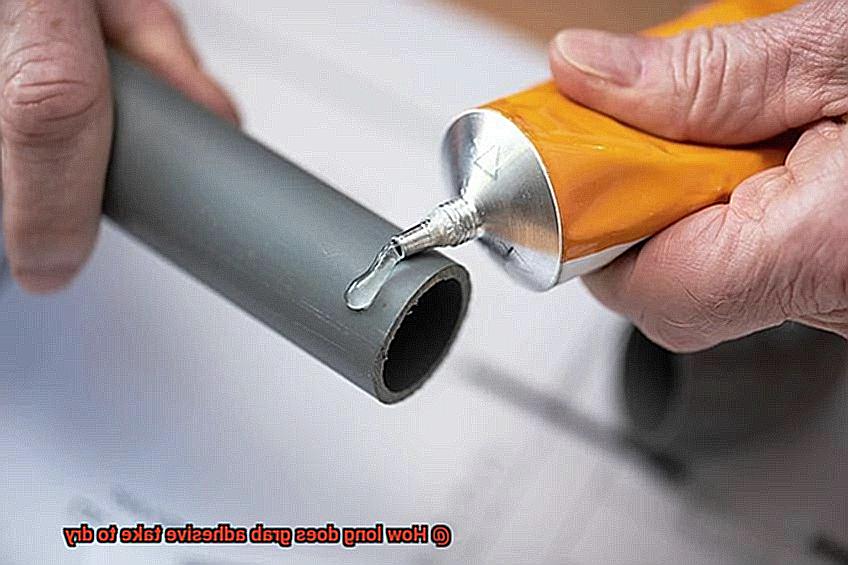

- Easy Application: Designed for convenience, grab adhesive is typically available in tubes or cartridges. Applying it is a breeze with a caulking gun or by simply squeezing it out of the tube. Its thick and viscous consistency enables smooth extrusion onto surfaces.

- Strong Bond: When you use grab adhesive, there’s no compromise on strength. Formulated with high-performance polymer resins like polyurethane or acrylic, it creates a durable and long-lasting bond between surfaces while maintaining flexibility.

- Resistance to Environmental Factors: Mother Nature doesn’t stand a chance against grab adhesive. It is water-resistant, impervious to temperature changes, and even UV radiation won’t break its bond. This makes it ideal for both indoor and outdoor applications.

Benefits of Using Grab Adhesive:

- Versatility at Its Finest: Grab adhesive is a true magician when it comes to bonding different materials. From constructing furniture to repairing household items, its versatility knows no bounds.

- Time-saving Wonder: With its instant grab feature, grab adhesive saves you precious time and effort. No need to wait for the adhesive to dry or use additional support during the bonding process.

- Unyielding Durability: When you choose grab adhesive, you’re choosing strength. Even under stress or movement, your project remains intact for the long haul.

- Seamless Integration: Once dry, grab adhesive becomes a canvas for your creativity. It can be painted over, allowing for flawless integration with surrounding surfaces.

Factors Affecting the Drying Time of Grab Adhesive

Factors Affecting the Drying Time of Grab Adhesive

Understanding the factors that affect the drying time of grab adhesive is crucial for achieving optimal results in any project. Whether you’re a DIY enthusiast or a professional contractor, knowing how temperature, humidity, substrate, thickness of application, type of adhesive, and ventilation can impact the drying process will help you make informed decisions and ensure successful bonding.

Let’s start with temperature, the ultimate player in the adhesive game. Higher temperatures speed up the drying time by turbocharging the evaporation of the adhesive’s solvent. Picture yourself basking in the warm sun on a scorching summer’s day – your grab adhesive would dry in a flash. On the flip side, lower temperatures put the brakes on the drying process as the evaporation rate takes a nosedive. So, if you find yourself working in frigid conditions, be prepared for a longer waiting game.

Now let’s talk about humidity, the pesky moisture content in the air. High humidity levels can throw a wrench in the drying process by mingling with the adhesive and stretching out its drying time. In contrast, low humidity cranks up the speedometer, as there is less moisture in the air to interfere with evaporation. So, if you’re toiling away in a muggy environment, consider using a dehumidifier or patiently await drier conditions before applying grab adhesive.

Next up is substrate – the material that plays host to your adhesive. Porous surfaces like wood or concrete have an insatiable thirst for moisture, which they happily slurp from the adhesive, leading to slower drying times. Non-porous surfaces like metal or glass, on the other hand, are water-repellent and allow for faster drying. Additionally, grimy or oily substrates create a formidable barrier between the adhesive and surface, causing drying time to drag on. Make sure to give your substrate a good scrub and prep job before applying the adhesive.

The thickness of application is another influential factor. Thicker layers take their sweet time to dry compared to thin coats because there is more material that needs to evaporate. Follow the manufacturer’s guidelines regarding recommended thicknesses to ensure proper drying and bonding. Remember, patience is key.

The type of adhesive you choose also wields power over drying time. Different grab adhesives have unique formulations; some are engineered for rapid bonding with lightning-fast drying times, while others are designed for slower drying to allow for repositioning or adjustment of bonded materials. Select the adhesive that best aligns with your project requirements and timeline.

Temperature and Humidity Conditions

Temperature and humidity conditions have a profound impact on our environment, affecting various aspects of our daily lives. Let’s dive deeper into the significance of these factors and explore their effects on our surroundings.

First, let’s discuss temperature. Whether it’s a scorching summer day or a freezing winter night, temperature plays a crucial role in shaping our environment. Extreme temperatures can have detrimental effects, causing discomfort, health issues, and even damage to infrastructure. Heatwaves, for instance, can lead to heat exhaustion and heatstroke, especially in vulnerable populations. On the flip side, extreme cold can result in frostbite and hypothermia.

Moreover, temperature variations influence the behavior of plants and animals. They affect the growth patterns of vegetation, altering ecosystems and impacting biodiversity. Rising temperatures can also contribute to the melting of glaciers and ice sheets, leading to rising sea levels and coastal erosion.

Now let’s shift our focus to humidity. Humidity refers to the amount of moisture present in the air. High humidity can create a muggy and uncomfortable atmosphere, making it harder for our bodies to cool down through sweat evaporation. This can increase the risk of heat-related illnesses.

Humidity also affects the quality of indoor air. Excessive moisture can lead to mold growth, which poses health hazards such as respiratory issues and allergies. On the other hand, low humidity levels can cause dry skin, respiratory irritation, and static electricity.

Furthermore, humidity impacts agriculture and food production. Crops require specific levels of moisture in the air for optimal growth. Insufficient humidity can result in crop failure, while excess humidity can promote the spread of plant diseases.

Types of Materials Being Bonded

Prepare yourself for an exhilarating DIY adventure. Enter grab adhesive, your trusty sidekick capable of bonding an array of materials with ease. This versatile adhesive possesses the extraordinary ability to create robust and long-lasting connections. Let us embark on a journey through the enchanting realm of grab adhesive and unveil its magic with different material types.

Wood – A Match Made in Heaven:

Grab adhesive and wood form an inseparable duo, akin to peanut butter and jelly. Whether you’re constructing a wooden masterpiece or mending a broken chair leg, grab adhesive is your ultimate secret weapon. It forges bonds that withstand all the knocks and bumps life throws your way. However, remember that patience is key. Allow the adhesive to dry for at least 24 hours before subjecting your woodworking marvel to any stress.

Metal – The Mighty Bond:

While bonding metal may seem daunting, fear not. Grab adhesive is up to the challenge. From attaching metal trims to bonding lightweight metals like aluminum or stainless steel, grab adhesive has got your back. However, cleanliness is crucial when working with metal. Ensure that surfaces are free from grease or oil before applying the adhesive. And remember to provide ample drying time – at least 48 hours – for an unyielding bond.

Plastic – The Perfect Pair:

Plastics come in diverse shapes and sizes, but grab adhesive embraces them all. Whether it’s PVC, acrylic, or ABS, grab adhesive possesses the prowess to create powerful bonds. Select an adhesive specifically formulated for plastics, as different formulations cater to varying plastic types. Drying times may differ depending on the plastic used, so consult the manufacturer’s instructions for guidance.

Ceramic and Porcelain – Unbreakable Bonds:

Rejoice, devotees of ceramics. Grab adhesive is now your dearest ally for bonding stunning tiles or repairing beloved porcelain pieces. Ensure that surfaces are meticulously cleaned, devoid of any dust or debris. Exercise patience and allow the adhesive to dry for at least 24 hours before flaunting your handiwork to the world.

Stone, Concrete, and More – The Powerhouse Bond:

Do not underestimate the might of grab adhesive when it comes to heavy-duty materials like stone and concrete. Whether you’re constructing a stone pathway or repairing a concrete structure, grab adhesive stands as your unwavering sidekick. Provide ample drying time and witness its remarkable ability to bond these weighty materials with ease.

Allowing Sufficient Drying Time for Optimal Results

Today, we will explore the importance of allowing sufficient drying time to achieve optimal results. Grab adhesive is a superhero in the glue kingdom, renowned for its ability to create strong and long-lasting bonds. So, let’s equip ourselves with knowledge and dive into the details.

Factors Affecting Drying Time:

- Type of Adhesive: Different grab adhesives have varying drying times due to their unique chemical compositions. It is crucial to choose the right adhesive for your project and understand its specific drying requirements.

- Environmental Conditions: Temperature and humidity play significant roles in the drying process. Higher temperatures and lower humidity levels expedite drying, while colder temperatures and higher humidity levels prolong it. To create an optimal drying environment, aim for a well-ventilated area with a temperature range of 60°F to 80°F (15°C to 27°C).

- Thickness of Application: The thickness of the adhesive layer influences drying time. Thicker layers take longer to dry compared to thinner ones. To achieve desired results, it is essential to adhere to the manufacturer’s recommended thickness guidelines.

Achieving Optimal Results:

- Patience is Key: Rushing the drying process weakens the bond and compromises the adhesive’s effectiveness. Allow ample time for the grab adhesive to fully cure, ensuring a robust and durable bond between materials.

- Avoid Movement or Stress: During the drying process, it is crucial to avoid any movement or stress on the bonded materials. Such disruptions can weaken the bond and lead to failure. Wait until the adhesive has fully cured before subjecting it to any stress or load.

- Manufacturer’s Guidelines: When in doubt about specific drying times, refer to the manufacturer’s instructions. They provide detailed guidelines tailored to their grab adhesive products, ensuring optimal results.

Patience truly is a virtue in the world of adhesives. By allowing sufficient drying time for grab adhesive, you can achieve optimal results and forge unbreakable bonds between materials. So, dear readers, remember to give your adhesive the time it needs to work its magic, and watch as your DIY projects flourish with strength and durability.

Appearances Can Be Deceiving

Today, we’re going to dive deep into the captivating world of grab adhesive drying time. Prepare to have your preconceptions shattered as we uncover the hidden truths behind this often misunderstood process.

The Illusion of Quick Drying:

On first glance, grab adhesive may seem like a quick-drying solution due to its initial tackiness. However, appearances can be deceiving. Despite its name, grab adhesive actually requires proper curing time to reach its full strength and bonding potential.

Factors that Dictate Drying Time:

The drying time of grab adhesive is influenced by multiple factors, including adhesive type, temperature, humidity levels, and the materials being bonded. Each of these factors plays a significant role in determining how long it takes for the adhesive to fully cure.

The Journey to Solidity:

As grab adhesive dries, it undergoes various stages: from initial tackiness to a solid state as it cures and fully dries. Rushing this process can compromise the bond’s effectiveness and result in weaker or failed outcomes.

The Importance of Instructions:

To avoid falling victim to deceptive appearances, it is crucial to follow the manufacturer’s instructions regarding drying time for specific grab adhesives. These instructions provide valuable insights into the optimal drying time required for a strong and durable bond.

Environmental Factors: Temperature and Humidity:

Temperature and humidity exert a significant influence on the speed of grab adhesive drying. High temperatures and low humidity levels tend to expedite the process, while cooler temperatures and higher humidity can slow it down. It is vital to consider these environmental factors when anticipating drying times.

Material Considerations:

Different materials have varying absorption rates, affecting how much adhesive they soak up during bonding. Porous materials, such as wood or fabric, may require additional drying time to achieve complete curing. Taking material characteristics into account ensures that appearances don’t deceive us.

Quick-Drying Formulas

If you’ve ever found yourself impatiently waiting for glue to dry, then prepare to have your DIY dreams come true. These magical elixirs are specially crafted to accelerate the drying and curing process, transforming your projects from tedious to turbocharged.

The secret behind the wizardry of quick-drying formulas lies in their unique composition. These adhesives are formulated with solvents or accelerators that evaporate at lightning speed, propelling the adhesive towards rapid drying. It’s like strapping a turbocharger onto your glue bottle.

Of course, the drying time can vary depending on several factors. The specific brand and type of adhesive wield their own drying properties, with some boasting completion in mere minutes and others requiring a few hours. Always consult the manufacturer’s instructions for guidance.

But temperature and humidity also play starring roles in this drying drama. Higher temperatures and lower humidity levels create a stage primed for swifter drying, while cooler temperatures and higher humidity can slow things down. So if time is of the essence, crank up that thermostat and summon a fan for good measure.

The materials being bonded can also sway drying time. Porous materials, like wood or fabric, may necessitate extra drying time to forge a robust bond. So be patient and resist the temptation to rush things along.

Before you embark on your quick-drying glue frenzy, it’s crucial to note that while these formulas offer expeditious results, they may not yield as durable or strong bonds as their slower-drying counterparts. The rapid drying process may not allow sufficient time for the adhesive to fully penetrate and solidify its connection with the materials. Therefore, choose wisely based on your project’s needs.

Exercising Caution After Application

Ready to tackle your next DIY project with grab adhesive? Exercise caution after application to ensure a secure bond and avoid mishaps. In this article, we’ll explore why caution is crucial and provide essential tips for success. Let’s dive in.

Allow Sufficient Drying Time:

Patience is key. Grab adhesives have varying drying times based on temperature, humidity, and materials. Refer to the manufacturer’s instructions for recommended drying time. Rushing compromises strength and longevity.

Avoid Disturbing the Bond:

Resist the temptation to touch or move bonded materials until fully dried. Movement weakens or breaks the bond, leading to failures. Let that adhesive work its magic.

Provide Adequate Ventilation:

Safety first. Some grab adhesives emit harmful fumes during drying. Open windows or use fans for fresh air circulation. Protect your respiratory system and create a comfortable working environment.

Protect Surfaces:

Prevention is better than cure. Grab adhesives create strong bonds but leave residue that may be challenging to remove when dried. Protect surfaces with masking tape or plastic sheets before applying adhesive. Save time and effort during cleanup.

Test Bond Strength:

Essential for success. Test bond strength before using your project. Gently apply pressure or perform a small tug test to ensure full cure and ability to handle intended load. Prevent surprises down the road.

WSoaX4kgMeg” >

Conclusion

Grab adhesive is a popular choice for bonding materials together, but how long does it actually take to dry? The answer depends on several factors, including the type of grab adhesive used and the environmental conditions. Generally, grab adhesives require anywhere from 24 to 48 hours to fully dry and cure. However, it’s important to note that this is just an estimate and can vary based on the specific product and application method.

In ideal conditions, where the temperature is around room temperature (around 20-25 degrees Celsius) and humidity levels are moderate, grab adhesive can start to set within minutes. As time passes, it gradually becomes more solid and reaches its maximum strength after a day or two. This curing process allows the adhesive to form a strong bond between surfaces.

It’s worth mentioning that colder temperatures can significantly lengthen the drying time of grab adhesive. In colder environments, it may take up to 72 hours or even longer for the adhesive to fully dry. On the other hand, warmer temperatures can speed up the drying process, reducing the waiting time.

Additionally, factors such as humidity levels and air circulation also play a role in how long grab adhesive takes to dry. Higher humidity levels can slow down drying times, while good air circulation helps facilitate faster drying.

To ensure optimal results when using grab adhesive, it’s crucial to follow the manufacturer’s instructions carefully. This includes applying the correct amount of adhesive and allowing sufficient drying time before subjecting the bonded surfaces to any stress or load.

In conclusion, while there isn’t a definitive answer for how long grab adhesive takes to dry due to various factors at play, a general guideline is that it typically requires 24-48 hours under normal conditions.