Looking for a finish that’s both beautiful and tough as nails? Epoxy coating on wood might be just the ticket. But before you dive in, it’s important to ask: how long does epoxy on wood last?

The answer isn’t so simple. Epoxy is a resin that, when mixed with hardeners, creates an ultra-durable layer over your wood surface. It’s known for its scratch resistance, moisture protection, and ability to stand up against UV rays. But the longevity of your epoxy coating depends on a few things.

Firstly, the quality of your epoxy and how it’s applied will make all the difference. If you use a high-quality product and follow best practices during application, you could enjoy decades of protection from your epoxy.

But there are other factors at play too. The type of wood you’re working with matters – treated wood may hold up better than untreated or rotting wood. And don’t forget about maintenance. Regular cleaning and reapplication can help extend the life of your epoxy coating.

Ready to get started? Keep reading to learn more about how long epoxy lasts on wood and how to maximize its durability. Your wooden surfaces will thank you.

What is Epoxy?

Contents

Epoxy is a powerhouse adhesive that has become a go-to choice for woodworking and construction projects. A two-part adhesive, epoxy consists of a resin and a hardener, which when mixed together form an impressively strong and durable bond.

The resin component of epoxy is typically made from bisphenol-A (BPA) or bisphenol-F (BPF), while the hardener component is usually made from polyamine or polyamide. The two components are mixed together in a specific ratio, depending on the brand and type of epoxy being used.

Epoxy’s superior adhesion properties and high strength make it ideal for joining wood, metal, plastic, and other materials. It’s also perfect for filling gaps in wood joints, and even coating entire surfaces to protect them from environmental factors like moisture and heat.

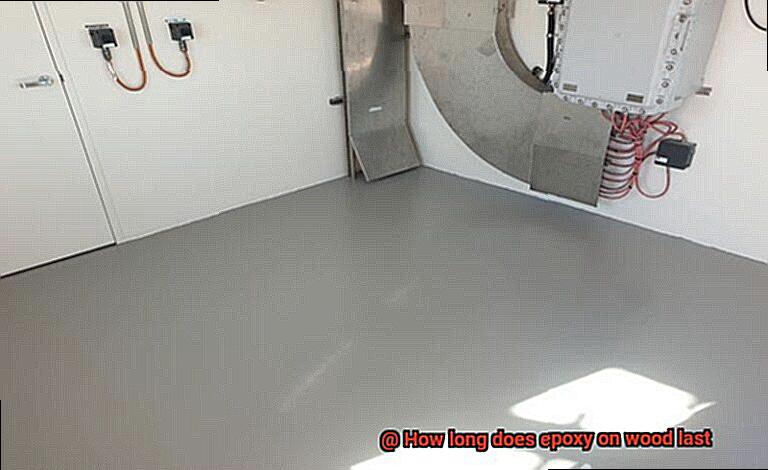

One of the most notable benefits of epoxy is its quick cure time, which produces a very hard, durable surface. This makes it perfect for high-traffic areas or areas where the wood will be exposed to harsh conditions.

However, not all epoxies are created equal; their longevity can vary depending on several factors. The quality of the epoxy used, the preparation of the wood surface before application, and the conditions under which the epoxy is exposed can all impact its lifespan.

To get optimal results from epoxy, it’s essential to choose a high-quality product that meets your specific project needs and follow proper application procedures. This includes adequately preparing the wood surface by sanding and cleaning it thoroughly before applying the epoxy.

Factors that Affect the Durability of Epoxy on Wood

To ensure a long-lasting, strong bond, it’s essential to take into account the following factors:

Moisture is a significant factor that can impact the durability of epoxy on wood. If the wood is not appropriately sealed before applying the epoxy, moisture can seep into the wood, causing it to expand and contract over time. This expansion and contraction can lead to cracks in the epoxy bond, compromising its strength and durability. To avoid this issue, it’s essential to seal the wood properly before applying the epoxy.

UV exposure is another critical factor that can affect the durability of epoxy on wood. Prolonged exposure to sunlight can cause epoxy to break down and lose its adhesive properties and result in a weaker bond over time. To prevent this from happening, it’s crucial to apply a UV-resistant topcoat over the epoxy to protect it from sunlight.

Temperature also plays a vital role in the durability of epoxy on wood. High temperatures can soften and weaken the bond, while low temperatures can make it brittle and prone to cracking. It’s important to select an epoxy rated for the temperature range in which it will be used.

The type of wood being bonded is another factor that impacts durability. Dense hardwoods like oak or teak require a stronger epoxy than softer woods like pine or cedar. It’s essential to select an appropriate epoxy for the specific type of wood being bonded for a durable bond.

Lastly, proper surface preparation is crucial for achieving a strong and long-lasting bond between the wood and epoxy. The surface should be thoroughly cleaned and sanded to create a rough texture that allows the epoxy to adhere correctly.

Quality of Epoxy Used

Then, you must pay attention to the quality of epoxy used.

As an expert in epoxy on wood, I can attest that the quality of epoxy used is paramount in determining its lifespan. So, let’s dive into some factors that you need to consider when choosing the right epoxy for your project.

Firstly, adhesive strength is a crucial factor. High-quality epoxies are formulated to withstand heavy loads and resist cracking or peeling. Therefore, it’s essential to choose an epoxy with a high PSI rating for maximum durability.

Secondly, curing time is another critical factor to consider. Low-quality epoxies take longer to cure, which can lead to uneven surfaces or even cracking and peeling. Hence, investing in an epoxy that cures quickly and effectively is essential.

Moreover, it’s vital to choose an epoxy specifically formulated for wood. Some types of epoxy are designed for use on metal or plastic surfaces and may not adhere well to wood or have a shorter lifespan. Using an epoxy formulated for wood will help ensure maximum adhesion and durability.

In summary, investing in high-quality epoxy will provide a longer-lasting finish for your wooden surfaces, saving both your time and money in the long run. So, take your time when selecting an epoxy for your project, and enjoy a beautiful and durable finish.

Preparing the Wood Surface

If you’re looking to add a protective layer of epoxy to your wooden surfaces, then it’s essential to prepare them properly. A well-prepared wood surface is the foundation for a long-lasting epoxy finish. Here are some tips for preparing the wood surface before applying epoxy.

First, gather all the necessary tools and materials, including sandpaper, a vacuum cleaner, a tack cloth, and a cleaning solution like denatured alcohol or acetone. Once you have everything ready, start by sanding the wood with coarse-grit sandpaper to remove any existing finish and create a rough surface. Use finer grits of sandpaper to achieve a smooth surface.

After sanding, it’s crucial to clean the wood surface thoroughly using a vacuum cleaner or tack cloth to remove any dust or debris. Any leftover debris can impact how well the epoxy adheres to the surface. Next, use a cleaning solution like denatured alcohol or acetone to wipe down the surface and remove any remaining contaminants.

Allowing the wood surface to dry completely is vital before applying epoxy. If there is any moisture left on the surface, it can affect how well the epoxy adheres to the wood and may cause it to peel or crack over time. Remember to give it enough time to dry fully.

Environmental Conditions

While epoxy is a robust adhesive that can withstand many environmental factors, it is still vulnerable to certain conditions that can impact its lifespan.

Temperature is one of the most critical factors affecting epoxy on wood. Extreme temperatures can cause the epoxy to expand or contract, leading to cracking and delamination of the bond. To ensure your epoxy bond remains intact, it is essential to apply the epoxy in a temperature-controlled environment.

Moisture is another significant environmental factor that affects epoxy on wood. Excessive moisture can cause the wood to swell, leading to separation of the bond. Conversely, low humidity levels can cause the epoxy to dry out and become brittle, leading to cracking and breaking. Therefore, it is crucial to ensure that the wood is dry before applying epoxy and that you’re working in a controlled humidity environment.

UV radiation can also weaken the strength of epoxy over time by breaking down its chemical bonds. To prevent damage from sunlight, it’s vital to use UV-resistant epoxy or apply a protective coating over the bond.

Additionally, exposure to chemicals, abrasion, and impact are other environmental factors that may affect epoxy on wood. It’s essential to be mindful of what chemicals may come into contact with your epoxy finish and take appropriate measures to protect it if necessary. Additionally, consider how much wear and tear your wood surface will be subjected to and take steps to protect it accordingly.

Tips for Using and Applying Epoxy on Wood

Epoxy is a versatile and powerful adhesive that can be used to bond wood together, but it’s important to use and apply it correctly to ensure a strong and long-lasting bond. Here are some tips for using and applying epoxy on wood:

Prep the Surface

Before applying epoxy, make sure the surface is clean and free of any dirt, dust, or debris. Sand the surface to remove any rough spots or unevenness, and wipe it down with denatured alcohol to ensure a clean surface that will allow the epoxy to adhere properly to the wood and create a strong bond.

Mix the Epoxy Thoroughly

Epoxy is a two-part adhesive that needs to be mixed correctly for it to work effectively. Follow the manufacturer’s instructions carefully and mix thoroughly to ensure an even consistency. A well-mixed epoxy will create a stronger bond that lasts longer.

Apply the Epoxy Evenly

Use a brush or spatula to apply the epoxy evenly over the surface you want to bond. Apply enough pressure to ensure that it penetrates into the wood’s pores. Avoid applying too much epoxy at once, as thicker layers can lead to cracking or bubbling over time.

Cure in Moderate Conditions

Avoid applying epoxy in direct sunlight or extreme temperatures, as this can affect the curing process and result in a weaker bond. Instead, apply epoxy in a well-ventilated area with moderate temperature and humidity levels. Allow ample time for the epoxy to cure before subjecting it to any stress or pressure.

Sand and Seal

After the epoxy has cured, sand down any rough spots and apply a sealant or finish to protect it from moisture and UV rays. This will help ensure that your epoxy bond lasts for a long time and remains strong and durable.

Common Mistakes to Avoid When Using Epoxy on Wood

However, there are some common mistakes that even the most experienced woodworkers make when using epoxy. Luckily, I am an expert in this field and have compiled a comprehensive list of mistakes you should avoid to ensure your wooden project stands the test of time.

Firstly, proper surface preparation is crucial when working with epoxy. Ensure that the wood is clean, dry, and free from any oils or contaminants before applying the adhesive. Skipping this step can lead to a weak bond that won’t stand up to the daily wear and tear your wooden project may encounter.

Secondly, mixing the epoxy correctly is also paramount. Epoxy is a two-part adhesive that must be mixed in the correct ratio to ensure a strong bond. If the mixture is off, it can result in a weaker bond that may not last as long.

Thirdly, many people believe that applying extra pressure when clamping the wood together with epoxy will create a stronger bond. However, this is a common mistake that can actually cause the adhesive to squeeze out of the joint resulting in a weaker bond. So, be mindful of how much pressure you apply during this process.

Lastly, not all epoxies are created equal. Some are specifically designed for use on metal or plastic applications only and may not provide a strong enough bond for wood applications. Therefore, it’s essential to choose the right type of epoxy for your wooden project to ensure a strong and long-lasting bond.

c6sidsJ_XmY” >

Conclusion

In conclusion, epoxy coating is an ideal solution for those seeking a durable and visually stunning finish on their wooden surfaces. However, the longevity of your epoxy coating hinges on various factors such as the quality of epoxy used, wood type, environmental conditions, and proper maintenance.

To guarantee maximum durability of your epoxy on wood, it’s crucial to use high-quality epoxy that meets your specific project needs and follow proper application procedures. This includes adequately preparing the wood surface by sanding and cleaning it thoroughly before applying the epoxy.

Environmental factors like moisture, UV exposure, and temperature can also impact the lifespan of your epoxy coating. Therefore, it’s essential to work in a controlled environment with moderate humidity levels and apply a UV-resistant topcoat over the bond.

Lastly, avoiding common mistakes like improper surface preparation or mixing ratios can help ensure a strong and long-lasting bond. By adhering to these tips and best practices, you can enjoy decades of protection from your epoxy coating on wood surfaces.