Tired of messy repairs and subpar fixes for your leather and suede items? Look no further than Aleene’s Leather and Suede Glue, the adhesive that guarantees a flawless union for all your beloved leather and suede creations. But before you dive into your next project, there’s one crucial question that needs answering – how long does this glue take to dry?

Today, we’re delving into the nitty-gritty details of Aleene’s Leather and Suede Glue’s drying process. By understanding this essential aspect, we can achieve impeccable results and ensure a long-lasting bond that preserves the integrity of our cherished leather and suede possessions.

Drying Time Unveiled:

Contents

- 1 Factors Affecting Drying Time

- 2 Recommended Drying Time

- 3 Additional Tips for Optimal Results

- 4 Full Strength Achieved After 72 Hours

- 5 Proper Ventilation is Essential

- 6 Variety of Applications for Aleenes Leather and Suede Glue

- 7 Test on a Small Area Before Applying to Entire Project

- 8 Storage Tips to Prolong Shelf Life of Glue

- 9 Conclusion

Aleene’s Leather and Suede Glue stands out with its impressively quick drying time. No more waiting around endlessly like a kid on Christmas morning. This expert adhesive strikes the perfect balance between speed and durability.

On average, Aleene’s Leather and Suede Glue takes about 12 to 24 hours to fully dry. However, keep in mind that various factors can influence drying time, such as ambient temperature, humidity levels, and how thickly you apply the glue. So be sure to consider these variables when planning your project.

Tips for Success:

To ensure top-notch results with Aleene’s Leather and Suede Glue, here are some handy tips:

- Prep Like a Pro: Before applying the adhesive, make sure your surface is clean, dry, and free from any dust or grease. This step is crucial for achieving a strong and enduring bond.

- Apply with Finesse: Spread a thin, even layer of glue on one or both surfaces to be bonded. Avoid going overboard with the glue – too much can compromise both looks and durability.

- Clamp It Down: Once the glue is applied, press the surfaces together firmly and secure them with clamps or a heavy object. Let the glue dry undisturbed for the recommended 12 to 24 hours.

- Test and Age: After the suggested drying time has passed, give your bond a test run to ensure it’s fully cured and sturdy. Keep in mind that the strength of the bond will continue to improve over time, reaching its full potential after a few days.

Factors Affecting Drying Time

When working on a project using Aleenes leather and suede glue, it’s essential to consider the factors that can affect its drying time. From temperature to material type, understanding these variables will help you achieve optimal results and a strong bond.

- Temperature: The temperature in your workspace can make or break the drying process. Warmer temperatures speed up drying, while colder temperatures slow it down. Aim for a room temperature of around 70°F (21°C) to ensure efficient drying. Avoid extreme temperatures as they can compromise both the drying time and bond strength.

- Humidity: The level of humidity in your workspace has a direct impact on drying time. High humidity means more moisture in the air, slowing down evaporation and prolonging drying. Conversely, low humidity accelerates drying as there is less moisture to be evaporated. To have better control over drying time, work in a well-ventilated area with moderate humidity levels.

- Thickness of application: How thick you apply the glue affects how long it takes to dry. Thin layers dry faster than thick ones. For quicker and more efficient drying, apply a thin and even layer of Aleenes leather and suede glue. If your project requires a thicker layer, allow for additional drying time or use clamping or pressure techniques to ensure proper bonding.

- Material type: Different materials have varying levels of porosity, which affects how quickly the glue penetrates and dries. Fabrics or suede, being more porous, will require longer drying times compared to non-porous materials like leather. Consider the characteristics of the material you are bonding and adjust your expectations accordingly.

- Quality and age of the glue: The quality and age of the glue also play a role in its drying time. Fresh glue tends to dry faster than older glue that has been exposed to air for a prolonged period. To ensure optimal performance and drying time, always use a fresh and properly sealed bottle of Aleenes leather and suede glue.

Recommended Drying Time

Recommended Drying Time for Aleene’s Leather and Suede Glue: Achieving the Perfect Balance

Crafting and DIY projects involving leather and suede can be both exciting and challenging. But there’s nothing more frustrating than waiting for glue to dry before moving on to the next step. The clock seems to tick slower, as we anxiously tap our fingers, wondering if we can proceed or risk ruining our masterpiece. Fear not. I’m here to guide you through the recommended drying time for Aleene’s leather and suede glue, so you can achieve the perfect balance.

Several factors influence the drying time of Aleene’s leather and suede glue. First, consider the material type and thickness. Thicker or more porous materials may require longer drying times compared to thinner or less absorbent ones. So, take into account the characteristics of your leather or suede before setting your expectations.

Another crucial factor is the environmental conditions in which you are working. High humidity levels or colder temperatures can significantly affect the drying time of the glue. Adjust accordingly. Remember, patience is key in achieving a strong bond.

Additionally, the amount of glue applied plays a role in drying time. A little goes a long way with Aleene’s leather and suede glue. Applying too much can extend the drying time, so be mindful of how much adhesive you use.

In general, Aleene’s leather and suede glue typically dries within 2 to 4 hours. However, it is important to allow the glued materials to dry for at least 24 hours before handling or applying any stress to the bond. This extended drying time allows the glue to fully cure and reach its maximum strength.

While it may be tempting to handle your project after a few hours, resist that urge. Premature handling or stressing of the bond can lead to weakened adhesion and compromised durability. Give it ample time to cure completely, and you’ll be rewarded with a strong and long-lasting bond.

To optimize bonding, consider the environmental conditions during the drying process. Adjust drying time accordingly if you’re working in high humidity or colder temperatures. If necessary, apply light pressure or use clamps to ensure proper bonding.

It’s worth noting that different types of leather and suede can have variations in absorption rates, which can affect drying times. Thicker or more porous materials may require longer drying times compared to thinner or less absorbent ones. Take this into account when planning your project timeline.

Lastly, always remember that the recommended drying time provided by the manufacturer is a general guideline. Actual drying times may still vary based on individual circumstances. It is always best to experiment on a small, inconspicuous area or conduct a test bond to determine the ideal drying time for your specific project.

Additional Tips for Optimal Results

To ensure you achieve the best results and a strong, durable bond, it’s important to follow some additional tips. In this article, we will explore six essential tips for optimal results when using Aleene’s Leather and Suede Glue.

Apply the glue evenly:

One of the key factors in creating a strong and durable bond is applying Aleene’s Leather and Suede Glue evenly on both surfaces. Using a brush or applicator, spread a thin layer of glue over the entire area that needs bonding. This ensures maximum contact between the surfaces, enhancing the adhesive strength. By applying the glue evenly, you reduce the risk of weak spots or gaps in the bond.

Use proper bonding techniques:

Each project may require different bonding techniques. It’s important to read the manufacturer’s instructions and follow them carefully. Whether you’re repairing a shoe or creating a new accessory, following the recommended techniques will help you achieve optimal results. These techniques may include applying pressure, using specific application methods, or allowing for a specific drying time. By following these instructions, you can ensure that you are using the glue in the way it was intended, maximizing its effectiveness.

Allow sufficient drying time:

The drying time of Aleene’s Leather and Suede Glue can vary depending on factors like temperature, humidity, and how thickly the glue is applied. To ensure a strong bond, it’s essential to allow sufficient drying time as specified by the manufacturer. Patience is key. Rushing the drying process can lead to a weak bond or even failure. By allowing the glue to dry fully before handling or applying any stress to the bonded surfaces, you give it the time it needs to cure properly and create a strong bond.

Clamp or press the surfaces together:

After applying the glue, it’s recommended to clamp or press the surfaces together. This technique helps create maximum contact between the glued surfaces, resulting in a stronger bond. You can use clamps, weights, or even your hands to hold the surfaces firmly together until the glue dries completely. Applying pressure ensures that the adhesive bonds securely and reduces the chances of any gaps or weak spots in the bond.

Avoid excessive moisture exposure:

While Aleene’s Leather and Suede Glue is water-resistant, excessive exposure to moisture can affect the bond strength. It’s important to avoid exposing bonded surfaces to water or excessive moisture for at least 24 hours after gluing. This allows the glue to cure properly and ensures a long-lasting bond. By protecting the glued surfaces from moisture during the curing process, you can maintain the integrity of the bond and prevent any weakening of the adhesive.

Full Strength Achieved After 72 Hours

When it comes to leather and suede repair or crafting, the right adhesive is paramount. Enter Aleene’s Leather and Suede Glue, a mighty glue that requires patience to achieve its full strength. In this blog post, we will delve into the reasons why waiting for a full 72 hours is crucial for this remarkable adhesive. So grab your favorite beverage, sit back, and let’s explore the captivating world of glue.

The Science Behind It:

Aleene’s Leather and Suede Glue is meticulously formulated to create a robust bond between leather or suede surfaces. During the drying process, the glue permeates and intertwines with fibers, forging a connection that can withstand even the toughest wear and tear.

Time is of the Essence:

Although the glue may feel dry to the touch before the 72-hour mark, it is vital not to rush the process. Allowing the adhesive to cure fully within this timeframe ensures optimal results. Premature use or manipulation of bonded surfaces can compromise adhesion and weaken the bond, potentially leading to damage or failure.

Factors That Influence Drying Time:

Humidity, temperature, and application thickness all influence how long it takes for Aleene’s Leather and Suede Glue to dry. To facilitate proper drying, it is advisable to place glued items in a well-ventilated area with moderate temperature and humidity levels.

Patience Pays Off:

Exercising patience and waiting for 72 hours grants your repaired or crafted leather and suede items their best chance at long-lasting strength. Now you can confidently use them without concerns of potential failures.

Tips for Optimal Bonding:

To achieve optimal results, apply the glue evenly like an artist, utilize proper bonding techniques like a master craftsman, and press or clamp the surfaces together for maximum contact. Furthermore, avoid excessive moisture or exposure to extreme heat during the drying period to maintain the bond’s integrity.

Proper Ventilation is Essential

Aleene’s Leather and Suede Glue is your trusted companion for repairing cherished leather jackets and crafting dazzling suede accessories. But before you embark on your adhesive adventure, it is imperative to understand why proper ventilation is essential in ensuring a safe and successful experience with this remarkable glue.

Why Proper Ventilation Matters:

- Harmful Fumes: As Aleene’s Leather and Suede Glue dries, it releases fumes that, when excessively inhaled, can pose serious health risks. These fumes may result in respiratory irritation, dizziness, and debilitating headaches. To protect your well-being and stay comfortable throughout your creative journey, adequate ventilation within your workspace is paramount.

- Fresh Air Flow: Working in a well-ventilated area means inviting the exhilarating embrace of fresh air. By opening windows or doors, you allow the circulation of air to disperse the potentially harmful fumes, preventing their accumulation in your workspace. Beyond health benefits, fresh air enhances the quality of your work and fosters heightened focus and productivity.

Tips for Effective Ventilation:

- Open Spaces: Whenever possible, select a room with open windows or doors as your workspace. This simple step allows invigorating gusts of fresh air to enter while propelling the fumes outwards. Embracing natural airflow ensures a clean and healthy environment for your creative endeavors.

- Fans and Exhaust Systems: For confined spaces like workshops or basements, consider employing fans or exhaust systems to swiftly expel fumes from the area. Strategically positioning a fan near an open window facilitates the influx of crisp air while effectively eliminating any lingering fumes.

- Adjacent Room Ventilation: Mindful of the fumes’ propensity to permeate adjacent spaces, it is essential to extend your ventilation efforts beyond your immediate workspace. By keeping doors open or utilizing fans to promote airflow throughout the entire area, you safeguard the health of both yourself and those nearby.

- Personal Protective Equipment (PPE): While proper ventilation greatly minimizes fume exposure, donning a mask or respirator provides an additional layer of protection. Individuals with respiratory conditions or sensitivities should particularly prioritize the use of PPE when working with any glue.

Variety of Applications for Aleenes Leather and Suede Glue

Step into a world of limitless possibilities with Aleene’s Leather and Suede Glue. This extraordinary adhesive has been tailor-made for all your leather and suede needs, whether you’re a seasoned crafter or just looking to repair your favorite leather jacket. So, grab hold of your glue gun and let’s embark on a journey through the diverse range of applications for this exceptional adhesive.

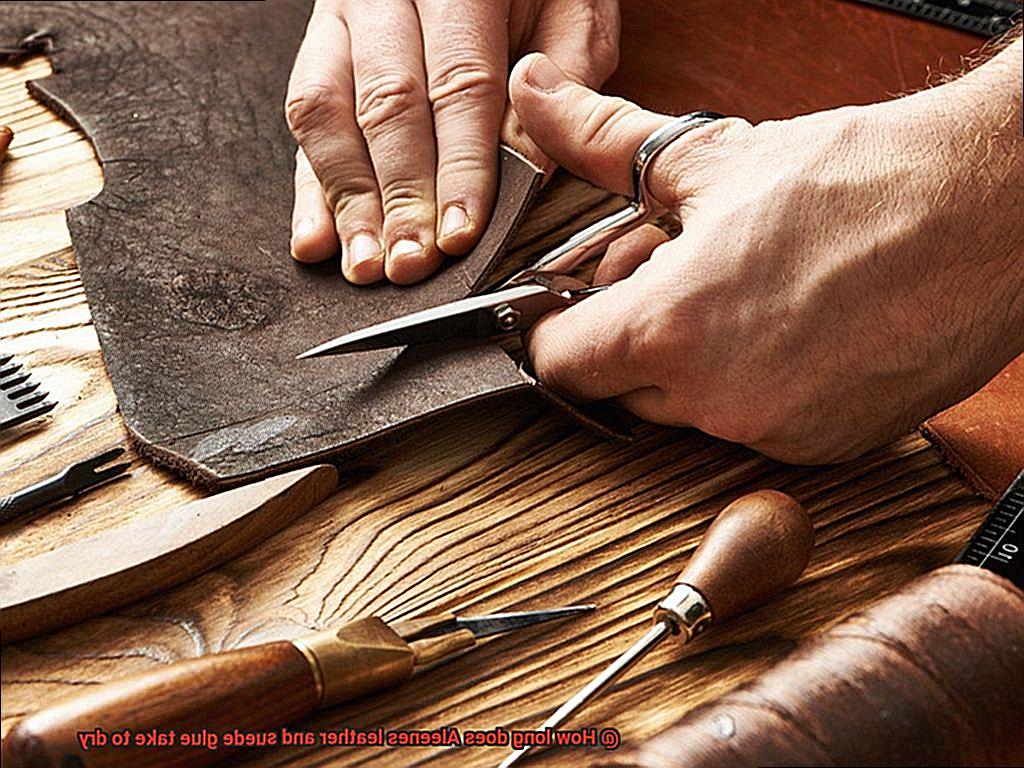

Repairing Leather and Suede:

From a tear in your beloved handbag to a loose sole on your favorite pair of shoes, Aleene’s Leather and Suede Glue is here to save the day. With its quick and secure bonding capabilities, this glue ensures that your repairs are not only strong but also visually seamless. Its clear and flexible drying formula guarantees both durability and aesthetics, giving your beloved items a new lease on life.

Crafting with Leather and Suede:

Unleash your inner artist. Aleene’s Leather and Suede Glue is an absolute must-have for all your leather and suede crafting projects. Whether you’re designing exquisite jewelry, creating stylish accessories, or adding a touch of elegance to home decor items, this versatile adhesive will flawlessly bond your pieces together. So go ahead, let your imagination run wild as you fashion stunning leather necklaces or trendy suede clutches.

Upholstery Projects:

Revitalize your furniture with Aleene’s Leather and Suede Glue. Embarking on a reupholstering adventure? Adding decorative trim to your sofa? This adhesive ensures a professional finish that withstands the test of time. Its robust bond keeps fabric securely in place, even with regular use, giving your furniture a touch of elegance and sophistication.

DIY Fashion Projects:

Be a trendsetter with Aleene’s Leather and Suede Glue. Elevate your fashion game by embellishing a leather jacket or customizing suede boots. This adhesive adheres effortlessly to various materials, allowing you to express your creativity and make a bold statement with your fashion choices.

Other Creative Projects:

The versatility of Aleene’s Leather and Suede Glue knows no bounds. It can be used in a myriad of creative projects such as bookbinding, creating leather or suede journals, albums, and even in jewelry-making when working with leather or suede components. Let your imagination soar as you explore the endless possibilities.

Test on a Small Area Before Applying to Entire Project

Imagine stumbling upon the perfect vintage leather jacket – the price is right, the style is impeccable, and you can already feel the envy of everyone around you. But before you hit the streets, there’s one crucial step you must not overlook: testing Aleenes leather and suede glue on a small area. This simple precautionary measure can save you from heartbreak and disaster. In this article, we will explore why testing on a small area is vital and how it can make or break your creative endeavors.

Why Test on a Small Area?

- Compatibility Check: Different leathers and suedes may react differently to glues. By testing on a small, inconspicuous area, you can ensure that Aleenes glue works harmoniously with your chosen material.

- Damage Prevention: No one wants their beloved leather or suede item ruined by a subpar adhesive. Testing allows you to identify potential discoloration, damage, or undesirable effects before they become irreversible problems.

- Adhesion Assurance: The last thing you want is for your carefully crafted project to fall apart at the seams. Testing ensures that Aleenes glue bonds firmly and securely to your material, providing peace of mind in the longevity of your creation.

How to Perform the Test:

- Choose a discreet spot and thoroughly clean it to remove any dirt or debris.

- Apply a small amount of Aleenes glue evenly across the test area using a brush or applicator.

- Allow the glue to dry completely according to the manufacturer’s instructions.

- Inspect the test area for any negative effects or signs of poor adhesion, such as discoloration or peeling.

Factors to Consider:

Drying Time: Aleenes glue may dry differently depending on factors such as temperature, humidity, and the thickness of the application. Testing allows you to gauge the drying time under your specific conditions, ensuring you plan your project accordingly.

Storage Tips to Prolong Shelf Life of Glue

In this article, we will delve into specific storage tips for Aleenes leather and suede glue, ensuring that it remains effective and ready to tackle your projects whenever inspiration strikes.

Keep it Cool and Dry:

Maintaining the consistency and performance of the glue is crucial. To achieve this, store it in a cool and dry place. Extreme temperatures can wreak havoc on its adhesive properties, so make sure to keep it away from direct sunlight and opt for a temperature-controlled environment.

Seal it Tight to Preserve Freshness:

When not in use, tightly seal the glue container. Exposure to air can cause the glue to dry out and become unusable. Before closing the cap, wipe off any excess glue from the nozzle to ensure a tight seal that keeps the glue fresh and ready for action.

Upright Storage Prevents Mishaps:

Avoid leakage or drying out of the glue by storing it upright with the nozzle facing upwards. This simple yet effective tip ensures that the glue remains contained within the bottle, always prepared for your next project without any messy surprises.

Shield it From Sunlight’s Harmful Rays:

UV rays can degrade the adhesive properties of glue over time. Therefore, protect Aleenes leather and suede glue by storing it away from direct sunlight. By doing so, you safeguard its integrity and ensure long-lasting performance that won’t let you down.

Stick With the Original Container:

Whenever possible, store the glue in its original container. These containers are specifically designed to preserve the integrity of the adhesive, providing an ideal storage environment for prolonged shelf life. By sticking with the original packaging, you give your glue the best chance at remaining effective and reliable.

A Clean Haven for Optimal Performance:

Maintain the quality of your glue by storing it in a clean and dust-free area. Dust or debris can contaminate the glue and compromise its performance. By keeping the storage environment pristine, you ensure that your glue is always ready to go when creativity calls.

ilDcLDjOZ0M” >

Conclusion

Aleene’s leather and suede glue is a popular choice for those looking to repair or create projects involving these materials.

One of the most common questions asked about this adhesive is how long it takes to dry. Well, the good news is that Aleene’s leather and suede glue dries relatively quickly.

In fact, you can expect it to be fully dry within 24 hours. This means that you won’t have to wait around for days on end for your project to be completed.

Whether you’re fixing a torn leather jacket or embellishing a suede handbag, Aleene’s glue will get the job done efficiently.