Are you a DIY enthusiast eagerly looking to explore the world of 2 part epoxy? Are you wondering how long it takes for this adhesive to dry and bond your project together? Whether you’re into crafts, jewellery-making, or home repair, 2 part epoxy is a popular choice for its versatile bonding capabilities. But before diving in, it’s crucial to know how long it takes to dry.

So, how long does 2 part epoxy take to dry? Unfortunately, there’s no simple answer. Several factors come into play that can affect the drying time of this adhesive. The brand of the epoxy and the surface type you’re gluing are significant factors that impact drying time. Additionally, temperature and humidity levels can also influence the process.

In this blog post, we’ll take a closer look at all these variables affecting the drying time of 2 part epoxy. We’ll also explore why using 2 part epoxy is an excellent choice for your projects and how you can speed up the drying process if needed. Whether you’re an experienced crafter or just starting with DIY projects, our guide will provide all the information you need to make sure your 2 part epoxy bonds perfectly. So buckle up and get ready to dive into the fascinating world of 2 part epoxy.

Factors Affecting the Drying Time of 2 Part Epoxy

Contents

- 1 Factors Affecting the Drying Time of 2 Part Epoxy

- 2 Temperature and Humidity Levels

- 3 Different Types of 2 Part Epoxy

- 4 Working With Large Surface Areas or Thick Layers

- 5 Poorly Ventilated Areas or High Moisture Levels

- 6 Reading Manufacturer’s Instructions Carefully

- 7 The Curing Process Involves a Chemical Reaction

- 8 Testing the Strength and Durability of the Bond

- 9 Conclusion

If you’re working with 2 part epoxy, it’s important to understand the various factors that can affect its drying time. While 2 part epoxy is known for its strength and durability, the curing process can be influenced by temperature, humidity, mixing ratio, thickness, and type of hardener.

Temperature is a critical factor that can significantly impact the drying time of 2 part epoxy. Higher temperatures can accelerate the curing process, while lower temperatures can slow it down. It’s important to consider both the ambient temperature and the temperature of the epoxy itself to ensure proper curing.

Humidity is another factor that can affect the drying time of 2 part epoxy. High humidity levels can cause the adhesive to take longer to cure, while low humidity levels can speed up the process. For optimal curing, aim for a humidity level between 40% and 60%.

The correct mixing ratio of the two components in 2 part epoxy is essential for proper curing. An inaccurate ratio can lead to uneven curing or even failure to cure at all. Always carefully follow the manufacturer’s instructions when mixing the two components.

The thickness of your epoxy layer can also impact drying time. Thicker layers will take longer to cure, while thinner layers will dry faster. To ensure even curing, apply a consistent layer of epoxy.

Lastly, consider the type of hardener used in your 2 part epoxy. Different hardeners are designed for varying curing times; some are intended for faster curing times while others are meant for slower curing times. Make sure you choose a hardener that fits your specific needs.

Temperature and Humidity Levels

Temperature and humidity levels can have a significant impact on the drying time and strength of the bond. As an expert in this field, let me share with you some fascinating insights on how temperature and humidity levels affect the curing process of 2 part epoxy.

Let’s start with temperature. The ideal range for curing 2 part epoxy is between 60-90°F (15-32°C). This range ensures that the epoxy will dry at a consistent rate, leading to a strong and long-lasting bond. If the temperature is too low, it will take longer for the epoxy to dry, leading to frustration. On the other hand, if the temperature is too high, it may dry too quickly, resulting in a weaker bond.

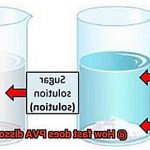

Now, let’s dive into humidity levels. The ideal range for curing 2 part epoxy is between 40-60%. High humidity levels can slow down the drying time, while low humidity levels can speed it up. Can you guess why? Moisture in the air reacts with the curing agent in the epoxy, which affects the drying time. Therefore, maintaining a stable humidity level is equally essential as temperature.

It’s crucial to keep in mind that temperature and humidity levels should remain consistent throughout the entire curing process. Fluctuations can cause inconsistencies in the drying time and weaken the bond of the epoxy. So, keep your environment stable by using a dehumidifier or fan to ensure a strong and long-lasting bond.

Different Types of 2 Part Epoxy

2 part epoxy is a highly versatile and strong adhesive that can be used for a wide range of applications. However, not all 2 part epoxies are created equal. There are several different types available on the market, each with its own unique properties and drying/curing times. Let’s explore these different types and how they vary in their drying and curing.

Standard Epoxy Resin and Hardener Combination

The most common type of 2 part epoxy is the standard epoxy resin and hardener combination. This clear adhesive can be used for bonding, coating, and filling. The drying time for this type of epoxy varies from 24 to 72 hours, depending on the specific brand and formula. It is important to note that the curing time can also be affected by temperature and humidity levels.

Fast-Setting Epoxy

If you need a quick fix, fast-setting epoxy is the way to go. This type of epoxy dries much faster than standard epoxy, typically within just a few hours. It is ideal for quick repairs or bonding materials that need to be used or handled shortly after application. However, it is important to work quickly with this type of epoxy as it can set rapidly.

Specialized Epoxy

There are also specialized types of 2 part epoxy available for specific applications. High-temperature epoxy is designed to withstand extreme heat, making it ideal for use in automotive or industrial applications. Marine-grade epoxy is specifically engineered for use in saltwater environments, making it perfect for boat repairs or other water-related projects. These specialized epoxies may have longer drying times than standard or fast-setting epoxies due to their specialized properties.

Slow-Setting Epoxy

For larger projects that require a longer working time, slow-setting epoxy is the way to go. This type of adhesive typically takes anywhere from 8-24 hours to dry and cure completely. This allows for more time to work with the adhesive and make adjustments as needed.

Factors That Affect Drying and Curing Time

It is important to remember that the drying and curing time of 2 part epoxy can be affected by several factors, including temperature, humidity, and the thickness of the adhesive layer. Higher temperatures and lower humidity levels can speed up drying and curing times, while thicker layers may require longer curing times. It is important to refer to the manufacturer’s instructions for specific drying and curing times for the type of epoxy you are using.

Working With Large Surface Areas or Thick Layers

One crucial factor to keep in mind is that the drying time for these types of applications will be significantly longer than for smaller or thinner ones. This is because the curing process relies on the chemical reaction between the two parts of the epoxy, which can be slowed down by the increased amount of material.

To ensure a proper cure, it’s essential to carefully follow the manufacturer’s instructions for mixing and applying the epoxy. Here are some additional tips to help you achieve optimal results:

- Use a spreader or roller to evenly distribute the material and prevent air bubbles from forming.

- Ensure proper ventilation and temperature control in your workspace, as these factors can affect the curing process.

- Avoid any contact or movement of the material during the drying time, which can compromise the strength of the bond.

Keep in mind that large surface areas or thick layers of 2 part epoxy can take anywhere from 24 to 72 hours to fully dry and cure. However, if you need to speed up the process, there are a few techniques that you can use:

- Gently warm up the surface area using a heat gun or hair dryer to accelerate the chemical reaction.

- Add a specialized epoxy accelerator to the mixture before application to speed up the curing process.

Poorly Ventilated Areas or High Moisture Levels

Well, poorly ventilated areas and high moisture levels could be the culprits. As a seasoned expert on this topic, let me tell you more about it.

Firstly, poor ventilation is a significant factor that can hinder the drying time of 2 part epoxy. When working in an area with poor ventilation, the fumes released during the curing process can accumulate and pose health hazards. Furthermore, these fumes can interfere with the chemical reaction that causes the epoxy to harden, resulting in a longer drying time than anticipated.

In addition, high moisture levels can also have a negative impact on the curing process of 2 part epoxy. Excess moisture in the air can interfere with the chemical reaction, leading to incomplete curing or a weaker bond. This is not what you want after investing your time and effort.

The good news is that there are ways to prevent these issues from occurring. Proper ventilation and humidity control are essential when working with 2 part epoxy. You can use fans or ventilation systems to circulate air and remove fumes, as well as dehumidifiers or air conditioning units to reduce moisture levels effectively.

Following the manufacturer’s instructions for mixing and application is also crucial in ensuring optimal results. Improper ratios or inconsistent mixing can affect the drying time and strength of the bond.

Reading Manufacturer’s Instructions Carefully

It’s an exciting and versatile adhesive that can be used for a variety of projects. But before you dive in, let’s talk about the importance of reading the manufacturer’s instructions carefully.

First off, not all 2 part epoxy is created equal. Different types have varying drying times, which can be influenced by factors like temperature and humidity levels. By carefully reading the instructions, you can get specific information on how long it will take for the epoxy to dry under your particular conditions. This knowledge is crucial for planning and ensuring that you allow enough time for the epoxy to cure properly.

But wait, there’s more. Mixing ratio is another critical detail that can be found in the instructions. If you don’t get this right, it can result in an incomplete or uneven curing process, which will significantly weaken the bond and affect durability. So, take your time and ensure you get this step right.

The manufacturer’s instructions may also provide tips on surface preparation, application techniques, and safety precautions. For example, some types of 2 part epoxy require specific surface preparation to ensure proper adhesion. Additionally, some epoxies can emit harmful fumes during application, so understanding the necessary safety precautions is crucial for your health and well-being.

The Curing Process Involves a Chemical Reaction

Today, we’re going to explore how the curing process of this adhesive involves a chemical reaction, and what factors can impact its curing time. So, hoist the anchor and let’s begin our journey.

When you mix the resin and hardener components together, they trigger a chemical reaction that causes the mixture to harden and cure over time. This chemical reaction is known as an exothermic reaction, which means it releases heat. This heat provides energy for the reaction to occur and speeds up the curing process.

However, several factors can affect the curing time of 2 part epoxy. For instance, temperature plays a significant role in determining how long it takes for your epoxy to cure. Higher temperatures generally lead to faster curing times, while lower temperatures can drastically slow down the curing process. So, if you’re working in a chilly workshop or on a cold day, be prepared to wait longer for your epoxy to dry.

The humidity level is another critical factor that affects the curing process of 2 part epoxy. High humidity levels can slow down the curing process by preventing moisture from evaporating from the surface of the epoxy. This can cause your project to remain tacky for longer periods, which can be frustrating when you’re trying to complete a project quickly.

In addition to temperature and humidity, the thickness of your application can also impact how long it takes for your epoxy to cure. The thicker your application, the longer it will take for the chemical reaction to penetrate through and completely cure your epoxy.

To ensure optimal results when using 2 part epoxy, it’s crucial to read and follow the manufacturer’s instructions carefully. This will help you navigate the curing process smoothly and avoid any hiccups along the way.

Testing the Strength and Durability of the Bond

In our last section, we dove into the fascinating world of epoxy curing. But what happens once your epoxy has hardened? How do you ensure its strength and durability for your intended use? Fear not, as I’m here to guide you through the methods used to test the strength and durability of a two-part epoxy bond.

Let’s start with the pull test. This method involves applying force to both ends of the bonded materials until the bond breaks. Using a force gauge, we can measure the amount of force required to break the bond and determine its strength. This test is particularly useful for assessing how well an adhesive will hold up under tensile stress, making it ideal for applications such as bonding metals or composites.

Next, let’s talk about the shear test. This method involves applying a sideways force to the bond, which is perfect for testing adhesives used in structural applications. By measuring a bond’s ability to withstand forces that push or pull in opposite directions, we can determine its strength under more complex stress conditions.

But strength isn’t everything; durability is equally important. Environmental factors such as heat, moisture, and UV light can all impact the longevity of an adhesive bond. That’s where accelerated aging tests come in handy. By subjecting samples to high temperatures, humidity, or UV light, we can simulate these environmental conditions and predict how well an adhesive will hold up over time.

In summary, testing the strength and durability of a 2 part epoxy bond is essential for ensuring its performance in various environments. Combining pull tests, shear tests, and accelerated aging tests provides us with a comprehensive understanding of an adhesive’s performance characteristics. So don’t hesitate to put your bonds to the test with confidence.

Conclusion

In summary, the drying time of 2 part epoxy is influenced by a variety of factors that must be taken into account to ensure a robust and durable bond. The temperature, humidity, mixing ratio, thickness, and type of hardener all play significant roles in the curing process.

To achieve optimal results, it’s imperative to carefully follow the manufacturer’s instructions while keeping the temperature and humidity levels consistent throughout the entire curing process. Large surface areas or thick layers of 2 part epoxy may require specialized accelerators or gentle warming with a heat gun or hairdryer to speed up the curing process.

Ventilation and humidity control are also critical when working with 2 part epoxy. Poorly ventilated areas and high moisture levels can interfere with the chemical reaction that causes the epoxy to harden.

Finally, testing the strength and durability of your bond through pull tests, shear tests, and accelerated aging tests is necessary for ensuring its performance under various environmental conditions.