Ever found yourself faced with an enigmatic puzzle, only to realize the answer was right there all along? Well, that’s exactly how it feels when you’re trying to stick foam board to plywood. If you’ve experienced the frustration of finding the perfect adhesive bond, fear not. Today, we embark on a journey filled with wisdom and practical know-how, uncovering the secrets to effortlessly sticking foam board to plywood.

Imagine effortlessly mounting your stunning artwork, creating jaw-dropping DIY projects, or constructing functional displays with ease. Our mission is to equip you with essential tips and techniques for achieving a robust and long-lasting bond that defies gravity and stands the test of time.

In this captivating guide, we’ll dive into a range of adhesive options, unveiling their unique strengths and weaknesses. From trusty liquid nails to the hidden gem of contact cement, you’ll discover the perfect adhesive match for your specific project.

But that’s not all. We’ll also explore the prepping process – cleaning surfaces thoroughly, selecting the right foam board thickness, and providing ample support during bonding. As we delve deeper, we’ll address common challenges and troubleshoot potential pitfalls so your adhesive endeavor remains foolproof.

So whether you’re a seasoned DIY enthusiast or simply seeking a reliable solution for your latest project, join us as we unravel the mystery behind achieving a seamless bond between foam board and plywood. Say goodbye to peeling, warping, and detachment as we unlock the secrets of this perfect union between two remarkable materials. Get ready to stick ’em together like a pro.

What is Foam Board and Plywood?

Contents

In the world of construction and DIY projects, two materials reign supreme: foam board and plywood. These versatile components possess unique characteristics that make them indispensable to builders and craftsmen alike. Prepare to embark on a captivating journey as we unravel the mysteries of foam board and plywood, examining their properties, applications, and the art of effectively adhering foam board to plywood.

The Magic of Foam Board:

- Composition: Picture a foam core embraced by two layers of paper or plastic, creating the epitome of lightweight perfection.

- Featherweight Insulation: The foam core, crafted from polystyrene or polyurethane, gifts foam boards with unparalleled insulation capabilities while maintaining an ethereal weight.

- Limitless Applications: From vibrant signage to captivating display boards, intricate model making to superior insulation, foam boards are the chameleons of the construction world.

Plywood Unmasked:

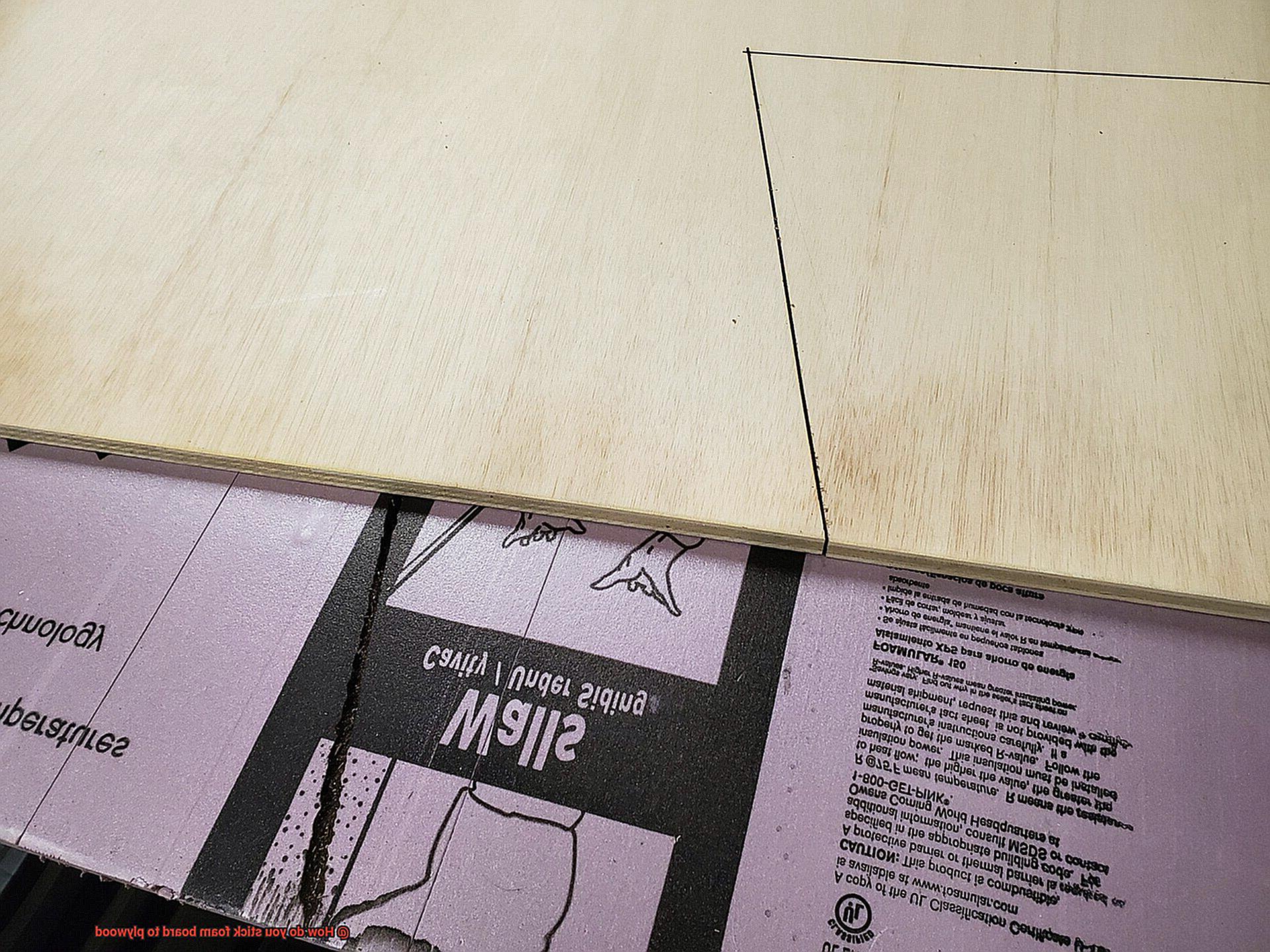

- An Engineering Marvel: Plywood emerges as an engineered wood product, where thin layers of wood veneer unite under immense pressure.

- Strength Unleashed: The secret lies in arranging plies with perpendicular grain directions, endowing plywood with resilience against warping and shrinking.

- A Universe of Usages: Construction marvels, furniture masterpieces, cabinetry wonders – plywood flexes its versatility in projects that demand load-bearing prowess.

The Artful Fusion: Adhering Foam Board to Plywood:

Method 1: Adhesive Glue

- The Dance Begins: Eliminate dust and debris through meticulous surface preparation.

- Brushstrokes of Perfection: Invoke an adhesive glue masterpiece by delicately applying a thin layer on both surfaces.

- Aligning the Stars: Every edge and corner must align harmoniously as the foam board embraces the plywood surface.

- The Power of Compression: Employ firm pressure to forge an unbreakable bond between the two materials.

Method 2: Construction Adhesive or Liquid Nails

- A Symphony of Strength: Douse both surfaces with a generous application of construction adhesive or liquid nails, fusing them together with a resolute grip.

- The Adhesive’s Anthem: Respect the manufacturer’s instructions, allowing ample drying and curing time for an impeccable outcome.

What Adhesive Glue Should You Use?

In our previous section, we uncovered the endless applications of foam board and plywood, marveling at their unique qualities. Now, let’s embark on an adhesive adventure to answer the burning question: What adhesive glue should you use to stick foam board to plywood? Buckle up and get ready for an exploration of the adhesive world.

Construction Adhesive: The Versatile Powerhouse

First up on our adhesive journey is the mighty construction adhesive. This versatile option is a top choice for bonding foam board to plywood. With its strong and durable bond, it ensures that your foam board stays firmly in place. Whether you opt for a polyurethane-based or solvent-based formulation, rest assured that construction adhesive boasts excellent bonding properties. Just remember to select a compatible adhesive that works well with both your foam board and plywood materials.

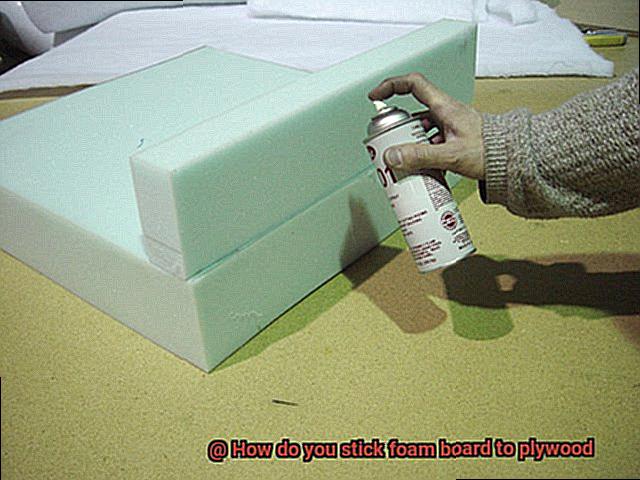

Foam Board Adhesive: The Spray of Perfection

Next on our list is the superhero of adhesives – foam board adhesive. Designed specifically for bonding foam boards to various surfaces, including plywood, this adhesive comes in a convenient spray form. Applying an even layer onto both surfaces is a breeze, resulting in an inseparable bond. The best part? Foam board adhesive provides a secure connection without damaging the foam board or leaving any unsightly traces of glue.

Contact Cement: Stick It Like a Pro

Enter contact cement, another popular choice for bonding foam board to plywood. This adhesive offers a strong and permanent connection, making it perfect for applications where durability is key. Applying contact cement to both surfaces, allowing it to dry until tacky, and then pressing them together firmly ensures a lasting bond. One advantage of contact cement is its repositioning capability before the bond becomes permanent. So, if you need a little wiggle room before committing, contact cement has got your back.

Epoxy: The Indestructible Bond

If you’re seeking an adhesive with unparalleled strength and durability, look no further than epoxy. Ideal for heavy-duty construction or structural projects, epoxy adhesives create bonds that can withstand the test of time. These adhesives usually come in two parts that need to be mixed together before application. Follow the manufacturer’s instructions carefully to achieve the ultimate bond, considering proper mixing and curing times.

Hot Glue: Quick and Easy, But Temporary

Preparing the Surfaces for Bonding

Preparing the surfaces for bonding is a critical step in the process of sticking foam board to plywood. It sets the foundation for a strong and durable bond, ensuring that you won’t have to deal with any pesky issues like peeling or detachment down the line.

First things first, let’s talk cleanliness. Before you even think about bonding, make sure both the foam board and plywood are squeaky clean. Get rid of any dust, dirt, grease, or other contaminants that could ruin your bonding party. Use a clean cloth or, if things are really messy, a mild detergent solution to wipe them down.

Now that your surfaces are sparkly clean, it’s time to give them a little texture. Grab some fine-grit sandpaper and lightly sand both the foam board and plywood. This will create a slightly rough surface that gives your adhesive something to grip onto. It’s like giving your surfaces a makeover before they become best friends forever.

But wait, we’re not done yet. After all that sanding action, make sure to clean up any leftover dust. Use a tack cloth or a damp cloth to wipe down the surfaces and get rid of any loose particles. We don’t want anything getting in the way of our perfect bond.

Now, here’s where things get interesting. You have the option to take it up a notch by applying a primer or sealant to your surfaces. This superhero-like substance can enhance the adhesion between the foam board and plywood, especially if they have different surface properties. Just make sure you choose a primer that works well with both materials and follow the manufacturer’s instructions for application. It’s like giving your surfaces an extra boost of bonding power.

Now it’s time for the main event – adhesive application extravaganza. There are different types of adhesives available for this job, such as construction adhesive or foam board adhesive. The key here is to choose an adhesive that is suitable for both materials and provides a strong bond. Don’t forget to read those labels.

Once you’ve got your adhesive of choice, follow the manufacturer’s instructions carefully. Apply an even layer of adhesive on both the foam board and plywood surfaces, making sure to cover every nook and cranny. Use a notched trowel or a spreader tool to achieve an even distribution of adhesive. This ensures that your bond will be as strong as can be.

Applying the Adhesive Glue

Today, we’re going to explore the art of applying adhesive glue when sticking foam board to plywood. Get ready for a bonding experience like no other.

When it comes to creating a strong and durable bond between foam board and plywood, choosing the right adhesive glue is crucial. There are several options available, each with its own unique properties and recommended applications. The two most commonly used glues for this purpose are construction adhesive and polyurethane-based adhesive.

Construction adhesive is specially designed for bonding porous surfaces, making it perfect for foam board and plywood. It provides a reliable bond that can withstand various environmental conditions. On the other hand, polyurethane-based adhesives offer excellent flexibility and can handle the expansion and contraction that may occur due to temperature changes between the two materials.

But before we dive into the gluing process, let’s talk about prepping your surfaces. Just like getting ready for a special occasion, your foam board and plywood need a clean slate. Take a clean cloth or mild detergent solution and wipe away any dust or debris that may hinder the bond. If necessary, give them a gentle scrub to ensure they’re squeaky clean. Remember, a clean surface is essential for optimal adhesion.

Now it’s time for the main event – applying the adhesive glue. Start by applying a thin layer evenly onto one of the surfaces. To ensure complete coverage, try using a zigzag pattern. But be careful not to go overboard with the glue; too much can cause it to squeeze out when pressure is applied. We want a strong bond, not a glue explosion.

With the glue perfectly laid down, let’s bring our foam board and plywood together. Gently press the foam board onto the plywood surface, applying even pressure across the entire area. To provide extra support during the drying process, consider using clamps or weights to hold everything in place. This way, you can be confident that your bond will withstand even the strongest forces.

Now, let’s talk about drying time. Different adhesive glues have different drying times, so it’s essential to follow the manufacturer’s instructions. Some may require additional steps like applying pressure or allowing for curing time. As a general rule, give your bond at least 24 hours to fully dry and cure before subjecting it to any stress or load. Patience is key when it comes to creating a long-lasting bond.

Aligning the Foam Board with the Plywood Surface

Step into the world of DIY perfection as we uncover the secrets to aligning foam board with a plywood surface. Like poetry in motion, these two materials can come together harmoniously with a few simple steps. So let’s roll up our sleeves and embark on this captivating journey.

Step 1: The Power of Cleanliness

Prepare for the ultimate bonding adventure by giving both the foam board and plywood a pristine makeover. Bid farewell to any lurking dust or debris that could sabotage our flawless connection. Trust us, a little extra effort now will reap rewards later.

Step 2: Measure Twice, Mark Once

Now that we’ve achieved cleanliness nirvana, it’s time to chart the course for our foam board’s perfect placement on the plywood surface. Grab your trusty pencil or marker and measure and mark the desired position. Don’t worry about perfection just yet; we can finesse those marks later.

Step 3: Unleashing Adhesive Magic

Ah, adhesive—the enchanting glue that binds our dreams together. Choose an adhesive that dances harmoniously with both foam board and plywood, ensuring a bond that defies time itself. Construction adhesive or foam adhesive are the stars of this show.

Apply a tantalizingly thin layer of adhesive onto the plywood surface using either a notched trowel or a paintbrush. Remember, we’re painting a masterpiece here, aiming for an even distribution that tantalizes the senses. Caution: too much adhesive can spoil our symphony, creating unsightly bumps and dissonance.

Step 4: Placing the Puzzle Pieces

With adhesive at the ready, delicately place our foam board onto the plywood surface like a master artist unveiling their latest creation. Align it meticulously with our earlier markings, paying homage to precision and craftsmanship. Gently press down, ensuring each corner finds solace in perfect adhesion. Bid farewell to those pesky air bubbles that dared to disrupt our masterpiece.

To intensify the bond’s strength, add a touch of weight or apply gentle pressure atop the foam board. Heavy objects come alive as anchors of stability, or perhaps clamps will be our guiding light. Let them safeguard our creation as the adhesive sets, following the manufacturer’s instructions for drying time and the alchemical process of curing.

Securing a Strong Bond

Today, we embark on an exciting journey to achieve an unbreakable connection between foam board and plywood. Whether you’re crafting or renovating, a reliable bond is the foundation of success. Prepare to delve into the art of securing a strong bond that will withstand the test of time.

Step 1: Pristine Surfaces for Perfection

Before we begin our bonding adventure, let’s set the stage for greatness. Cleanse both the foam board and plywood surfaces, banishing any lurking dust or debris that could sabotage our flawless connection. Remember, a little extra effort now guarantees long-lasting results later.

Step 2: Measure Twice, Mark Once: Precision is Key

Now that our surfaces are spotless, it’s time to plan our masterpiece. Use a pencil or marker to measure and mark the desired position for the foam board on the plywood surface. Don’t fret about perfection just yet; we’ll finesse those marks later.

Step 3: Choosing the Perfect Adhesive: The Glue that Unites

Ah, adhesive—the enchanting elixir that binds our dreams together. Selecting the right adhesive is paramount for creating a strong bond between foam board and plywood. Construction adhesive takes center stage, renowned for flawlessly uniting different materials. But remember, not all adhesives are created equal, so ensure compatibility with both foam board and plywood.

Apply a whisper-thin layer of adhesive onto the plywood surface using either a notched trowel or a paintbrush. We’re painting a masterpiece here, aiming for an even distribution that tantalizes the senses. Caution: too much adhesive can mar our symphony, resulting in unsightly bumps and dissonance.

Step 4: Placing the Puzzle Pieces: A Flawless Fit

With adhesive in hand, it’s time for the grand unveiling. Gently place our foam board onto the plywood surface, aligning it meticulously with our earlier markings. This is where precision and craftsmanship shine. Press down firmly, ensuring each corner finds solace in perfect adhesion. Bid farewell to those pesky air bubbles that dared to disrupt our masterpiece.

Using Construction Adhesives or Liquid Nails

Embarking on a creative project where foam board and plywood join forces is like embarking on a thrilling adventure. The secret to a masterpiece that defies time lies in the precision and craftsmanship of using the right adhesive. In this comprehensive guide, we will explore the proper preparation and application techniques for using construction adhesives or Liquid Nails to bind foam board to plywood. So, grab your tools, buckle up, and let’s dive into the realm of adhesive magic.

Cleanliness is Key:

Before we embark on our adhesive journey, cleanliness takes center stage. The success of our bond depends on it. Ensure that both the foam board and plywood surfaces are flawlessly clean, free from even the tiniest speck of dust, dirt, or grease. A thorough wipe-down with a clean cloth will suffice, but for those stubborn stains, a mild detergent solution can work wonders.

Zigzag Your Way to Unbreakable Bonds:

Now that our surfaces are pristine, it’s time to unleash the power of construction adhesives like Liquid Nails. With their exceptional bonding capabilities and versatility, they are our secret weapon. Apply the adhesive in a mesmerizing zigzag pattern on the back of the foam board. This technique not only ensures an even distribution of adhesive but also creates an unbreakable bond between these two materials.

Secure with Precision:

With adhesive artfully applied, it’s time for the grand finale – joining our foam board and plywood in perfect harmony. Embrace your inner craftsman as you firmly press the foam board onto the waiting plywood surface. Leave no room for imperfections; every inch must connect flawlessly. To hold your masterpiece in place while the adhesive cures, employ weights or clamps – they’ll be your loyal assistants in this adhesive symphony.

Patience is a Virtue:

Now, my friends, we must demonstrate our unwavering patience. Like a fine wine, adhesive needs time to mature. The curing time for construction adhesives can vary depending on factors such as temperature and humidity. To achieve optimal results, follow the manufacturer’s instructions regarding curing time. Remember, in the realm of adhesive artistry, patience is not just a virtue; it’s a necessity.

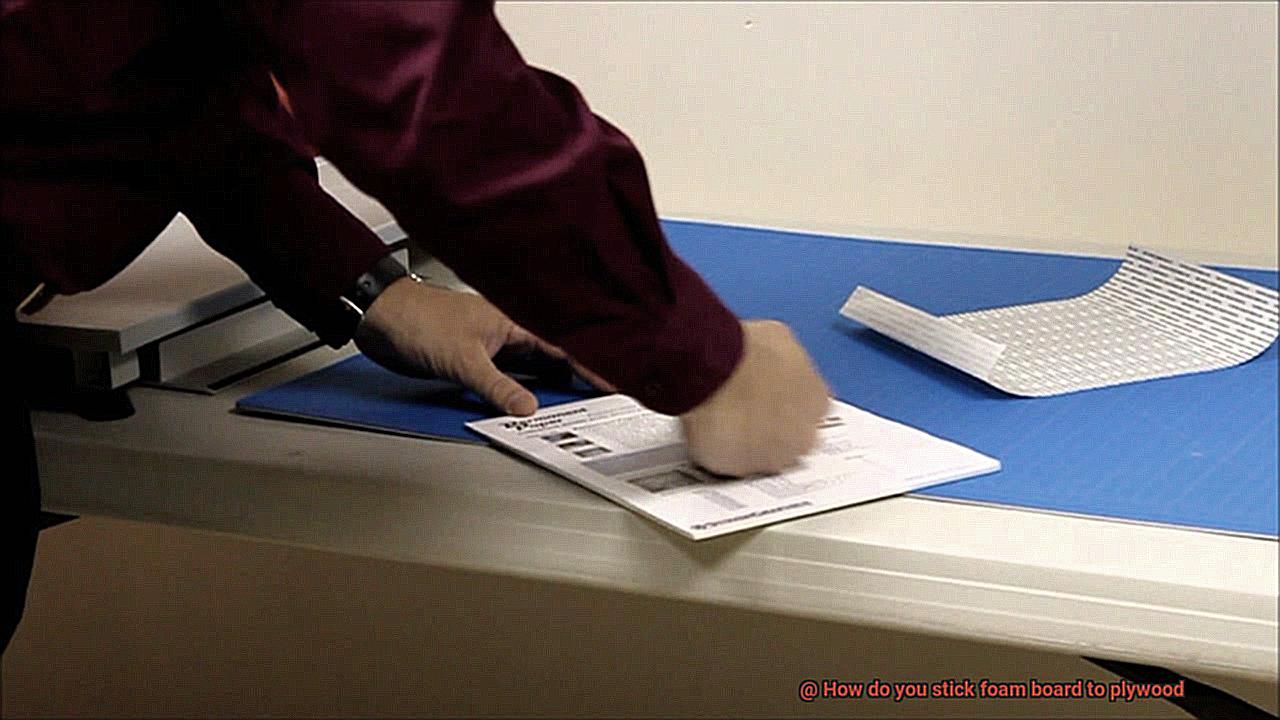

Using Double-Sided Tape

Prepare to be amazed as we delve into the extraordinary world of double-sided tape and its unparalleled ability to create seamless connections between foam board and plywood. Get ready to revolutionize your projects with this magical adhesive.

The Versatility of Double-Sided Tape:

Double-sided tape, the chameleon of adhesives, offers a range of widths and thicknesses to suit any project’s requirements. Whether you’re working on delicate crafts or heavy-duty constructions, this tape has got you covered.

Cleanliness is Next to Stickiness:

Before unleashing the power of double-sided tape, cleanliness is paramount. Ensure your foam board and plywood surfaces are pristine, free from dust, dirt, and moisture. A clean canvas guarantees an unshakeable bond that won’t let you down.

Applying Double-Sided Tape Like a Pro:

Using double-sided tape is a breeze. With one side’s protective backing removed, press the tape firmly onto the foam board, avoiding any accidental finger adhesion (we’ve all been there.). Once in place, remove the backing from the other side.

Precision Alignment for Perfect Bonding:

Achieving precision alignment is the secret to creating an unbreakable bond. Carefully position the foam board on the plywood, ensuring it’s exactly where you want it. Then, press it down firmly to forge an inseparable connection.

Pressure is All You Need:

To guarantee proper adhesion, apply even pressure across the entire surface of the foam board. Utilize your hands or employ a roller/flat object for that extra oomph. Remember, even pressure equals an even stronger bond.

Not All Projects Are Created Equal:

While double-sided tape is a convenient solution, project and environmental factors must be considered. Temperature, humidity, and weight-bearing capacity should influence your decision. Sometimes, a more traditional adhesive might be the way to go.

Conclusion

When it comes to sticking foam board to plywood, there are a few methods you can try.

One option is using adhesive, such as construction adhesive or spray adhesive. Apply the adhesive evenly on both surfaces and press them together firmly.

Another method is using double-sided tape, which provides a strong bond between the foam board and plywood. Simply apply the tape to both surfaces and press them together firmly.

Additionally, you can use screws or nails to secure the foam board to the plywood, but this may not be as aesthetically pleasing if you want a seamless finish.