Picture this: you’re finally tackling that long-awaited DIY project, building a show-stopping PVC masterpiece that will leave everyone in awe. With eager anticipation, you reach for your trusty PVC glue, only to realize that time is not on your side.

The glue seems to take forever to dry, and frustration sets in. But fear not, my fellow DIY enthusiasts. We’ve got the inside scoop on how to speed up PVC glue and save the day.

In this captivating blog post, we’ll dive deep into the world of adhesive sorcery and unveil the secrets that will transform your PVC glue into a speedy superhero. Say goodbye to endless waiting and hello to turbocharged adhesive power.

Join us as we explore three game-changing strategies that will revolutionize your bonding experience. First up, we’ll delve into surface preparation – the key to lightning-fast adhesion. Get ready to learn why clean and dry surfaces are essential for expediting the bonding process.

Next on our agenda is the fascinating realm of PVC primers. These seemingly ordinary bottles hold extraordinary powers when it comes to enhancing adhesion and curing time. Prepare for a mind-blowing journey through the wonders of these magical elixirs.

But wait, there’s more. Brace yourself as we introduce you to the ultimate secret weapon – accelerator additives. Just a few drops of these enchanting substances can turn your PVC glue into a drying wizard, slashing drying time like never before.

Are you ready to become a master of PVC glue wizardry? Get ready for an adventure filled with expert knowledge that will help you conquer your DIY projects with lightning speed. Grab your safety goggles and join us on this thrilling quest to unlock the full potential of PVC glue.

What is PVC Glue?

Contents

- 1 What is PVC Glue?

- 2 Applying Heat to Speed up Drying Time

- 3 Using Primers to Accelerate the Process

- 4 Fast-Drying Glues for Quick Bonding

- 5 Exercise Caution When Using Heat

- 6 Follow Manufacturer’s Instructions for Proper Application and Curing Time

- 7 Benefits of Speeding Up PVC Glue Drying Time

- 8 Common Mistakes to Avoid when Speeding Up PVC Glue

In the realm of plumbing and construction, a reliable bond is of paramount importance. Step forward PVC glue, also known as PVC adhesive or PVC solvent cement. In this captivating guide, we will delve into the depths of what PVC glue truly is, uncovering its exceptional qualities and providing valuable tips to expedite its drying time.

Discovering PVC Glue:

PVC glue is an extraordinary solvent-based adhesive, skillfully formulated to forge unbreakable connections between PVC pipes and fittings. Its composition consists of a precise blend of solvents and resins that work in perfect harmony to create a bond that is both robust and enduring.

The Art of Chemical Fusion:

Unlike conventional glues, PVC glue does not dry through evaporation. Instead, it possesses the remarkable ability to chemically melt and fuse PVC surfaces together. The solvents within the glue gently soften the PVC, enabling a seamless fusion upon tight compression. Meanwhile, the resins initiate a chemical reaction that catapults the bond strength to astonishing heights.

Swift-Drying Marvel:

One of the most remarkable features of PVC glue is its rapid-drying prowess. Within seconds of application, the glue begins to set in motion, racing against time to achieve full curing within a mere 24 hours. This accelerated drying process renders it ideal for situations where immediate bond strength is essential.

Unleashing the Power of Speed:

To expedite the drying time of PVC glue, several ingenious techniques can be employed:

- Harnessing Heat’s Magic: By applying controlled heat to the glued area, the chemical reaction between the glue and PVC is amplified, resulting in a swifter drying process. Nonetheless, caution must be exercised to avoid causing harm to the PVC or igniting the glue.

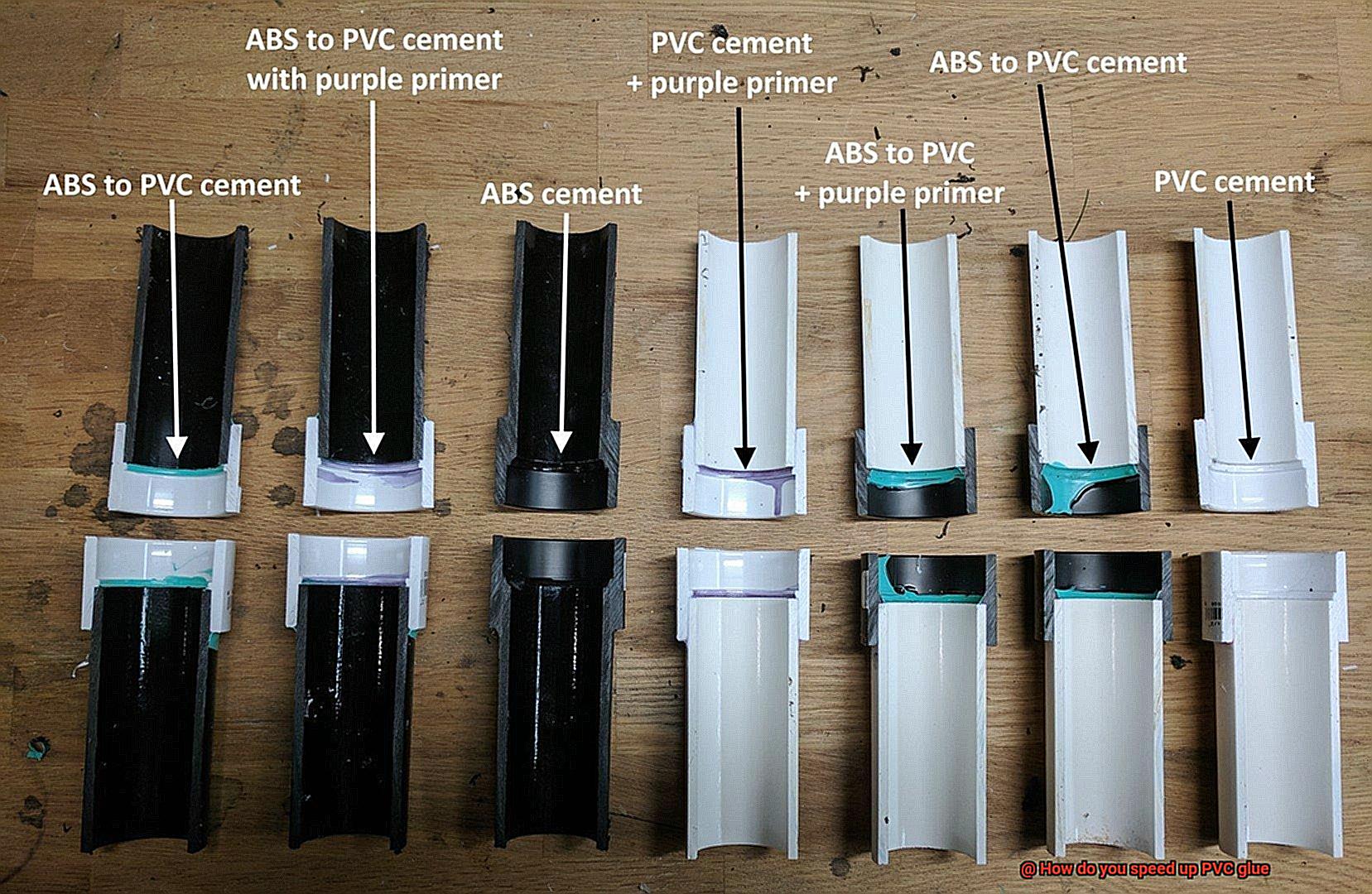

- Priming for Perfection: Prior to applying the glue, utilizing primers aids in preparing the surfaces by eliminating impurities and facilitating a superior bond between the PVC and the glue. Primers also play a pivotal role in reducing drying time.

- Selecting the Swiftest Glues: Not all PVC glues are created equal. Different brands offer varying drying times. Opting for a fast-drying glue can significantly expedite the bonding process, minimizing waiting time.

Applying Heat to Speed up Drying Time

In our relentless pursuit of swift bonds, we have delved into the wondrous realm of PVC glue and discovered remarkable methods to expedite its drying time. Today, we embark on an exhilarating journey into the captivating world of heat application, a turbocharged technique that will leave you in awe of its efficiency. Prepare to unleash the speed demon within your PVC glue.

The Mighty Heat Gun: A Superhero for Glue Drying

Picture a handheld tool that breathes fiery hot air onto your glued surfaces, propelling the evaporation process into overdrive. Behold, the heat gun. This trusty companion is the ultimate game-changer when it comes to accelerating PVC glue drying time. To harness its extraordinary power, hold the heat gun a few inches away from the glued area and glide it in a sweeping motion. The scorching air expelled by this superhero tool will work its enchantment, evaporating solvents faster than you can utter “speed demon.”

Remember, dear adventurers, caution is paramount when wielding the heat gun. Keep it in constant motion to prevent concentrated heat on one spot, which could potentially warp or melt your precious PVC material. Safety first, brave souls.

Hairdryer: Embrace the Breezy Velocity

Fear not, fellow enthusiasts, if a heat gun eludes your grasp. For within your humble abode lies a worthy substitute – the trusty hairdryer. Crank it up to its highest heat setting and direct its gusty airflow towards your glued surface. Glide the hairdryer ceaselessly, ensuring that every nook and cranny of your project basks in its balmy embrace. While it may not match the scorching intensity of a dedicated heat gun, your hairdryer will still serve as a formidable ally, hastening the drying time.

But beware, adventurers, do not grow too complacent in the company of your hairdryer. Holding it perilously close or for extended periods may result in overheating and potential harm to your PVC material. Speed is our ally, but safety is our steadfast companion.

Using Primers to Accelerate the Process

Look no further because primers are here to save the day. These solvents are like superheroes for your PVC glue, preparing the surfaces, improving adhesion, and speeding up the curing process.

But what exactly are primers? Think of them as the ultimate sidekick for your adhesive. Before applying the glue, primers are applied to the surfaces, removing contaminants and providing better adhesion. And that’s not all – they also work their magic by accelerating the curing process. Talk about efficiency.

Using primers is a breeze. First, ensure that the surfaces you’re gluing are clean and free from dirt, grease, or moisture. A quick wipe with a cloth or mild detergent will do the trick. Once your surfaces are squeaky clean, it’s time to bring out the primer.

Various types of primers are available, but it’s crucial to choose the right one for PVC glue. Most suitable primers for PVC gluing are solvent-based, containing volatile organic compounds (VOCs). These VOCs soften the PVC surface, allowing for better penetration and adhesion of the glue.

Applying the primer is a simple process. Use a brush or cloth to evenly spread it over the surfaces you’re gluing, ensuring complete coverage. Remember not to apply too much primer as it can weaken your joints – moderation is key.

Now comes the waiting game. Let the primer dry completely before applying the PVC glue. Drying time may vary depending on the type of primer, but on average, it takes around 10-15 minutes. Take this time to relax and let the primer work its magic.

Once the primer is dry, it’s showtime. Proceed with applying the PVC glue. Thanks to the primer, your surfaces will have enhanced adhesion properties, resulting in a stronger bond between the PVC pieces. Remember to apply the glue evenly on one surface and firmly press the two surfaces together.

While primers can significantly speed up the PVC glue process, they should be used with caution. The VOCs in primers can be harmful if inhaled or come in contact with the skin. It’s important to work in a well-ventilated area and wear protective gloves when handling primers.

Fast-Drying Glues for Quick Bonding

Look no further than fast-drying glues. These miraculous formulations are designed to dry in the blink of an eye, saving you precious time on your projects. Let’s dive into the world of fast-drying glues and discover their advantages and considerations. Get ready to be amazed.

First up, we have the superhero of fast-drying glues: cyanoacrylate adhesive, also known as super glue. This incredible glue can bond various materials together in mere seconds. Got a broken PVC pipe? Super glue will fix it in a jiffy. But beware, this powerful adhesive can stick skin and unintended surfaces together too. So, handle with care, my adhesive enthusiasts.

Next on our list is the dynamic duo known as epoxy adhesive. This tag team consists of a resin and a hardener that must be mixed before application. Once combined, this unstoppable duo forms a strong and durable bond that sets quickly. It’s perfect for those time-sensitive projects that demand fast results.

But before you start gluing like a mad scientist, prepare your surfaces for maximum adhesion. Cleanliness is key. Ensure that your PVC surfaces are free from dirt, debris, or oil that could hinder the bonding process. A little sanding or roughening can also enhance adhesion, giving you an even stronger bond.

But wait, there’s more. If you’re in a hurry to see your glue dry, we have some tricks up our sleeves. One method is to apply heat using a heat gun or low-heat hairdryer. The warmth speeds up the chemical reaction of the glue, causing it to dry faster. Just be cautious not to damage your precious PVC material with excessive heat.

For those who crave even greater speed, accelerators or activators designed specifically for fast-drying glues are here to save the day. These magical potions can be applied before or after the glue, hastening the curing process. Just remember to follow the manufacturer’s instructions, as each product may have its unique application method.

Now, before you embark on a fast-drying glue shopping spree, consider your project’s needs. While these speedy glues are fantastic for quick bonding, they may not be suitable for all applications. Some projects require a longer open time for adjustments and repositioning before the glue sets. In such cases, opting for a slower-drying adhesive may be more appropriate.

Exercise Caution When Using Heat

Before you embark on your adhesive adventures, let’s talk about a crucial topic: exercising caution when using heat to speed up the drying time of PVC glue.

To ensure a strong and reliable bond without compromising safety, here are some important points to remember:

- Proper Safety Guidelines: Follow proper safety guidelines when using heat with PVC glue. Protect yourself with gloves and goggles to prevent injuries or exposure to harmful fumes.

- Time for Proper Curing: PVC glue needs time to cure and bond properly. Heat can expedite this process by accelerating the evaporation of solvents. However, rushing it can weaken the bond.

- Even Application: Apply the glue evenly and in the correct amount before applying heat. This prevents issues or weaknesses in the bond and ensures structural integrity.

- Moderate Heat Settings: Use a heat gun or hairdryer on low to moderate heat settings. High temperatures can cause bubbling or burning of the glue, leading to a weakened bond.

- Safe Distance and Continuous Movement: Maintain a safe distance between the heat source and the PVC joint to avoid overheating and damaging surrounding materials. Keep the heat source moving continuously to distribute heat evenly.

- Temperature Monitoring: Monitor the temperature closely while heating the PVC glue. Excessive heat can make the glue less effective or even damage the PVC material itself.

- Cooling Time: Allow sufficient cooling time for the joint after using heat. Premature handling can weaken the bond, so be patient before subjecting it to stress or pressure.

Follow Manufacturer’s Instructions for Proper Application and Curing Time

In our previous discussion, we delved into the dangers of speeding up PVC glue drying time. Today, we embark on a new mission – understanding the vital role of following manufacturer’s instructions for proper application and curing time. Just like superheroes need a game plan, you need the right knowledge to achieve a sturdy bond between your PVC pipes or fittings. So, fasten your capes and prepare to unlock the secrets that will make your adhesive endeavors a resounding success.

Decoding Specificity:

Every brand and type of PVC glue has its own unique requirements. To ensure an impeccable bond, it is imperative to delve into the manufacturer’s instructions with utmost care. By doing so, you gain access to the specific application and curing techniques recommended for the glue you are using. Remember, even adhesive superheroes follow the rules.

Surface Preparation:

To conquer the world of PVC bonding, surface preparation is key. The manufacturer’s instructions will serve as your guiding light, providing step-by-step guidance on cleaning and roughening surfaces to maximize adhesion. So, before you embark on your gluing adventure, immerse yourself in these guidelines and lay a solid foundation for your adhesive triumph.

Mastering Application Technique:

Just as superheroes perfect their signature moves, applying PVC glue requires precision and finesse. The manufacturer’s instructions act as your personal mentor, revealing the secrets of how much glue to apply and how to achieve an even distribution on both surfaces. Adhering to these guidelines guarantees just the right amount of glue, preventing any excess or deficiency that could compromise the strength of your bond.

The Art of Patient Waiting:

In a world that thrives on speed, embracing patience may seem like a superpower all its own. However, when it comes to PVC glue, allowing ample curing time is the key to a durable bond. The manufacturer’s instructions will unveil the recommended duration for the glue to fully dry and create an unyielding connection. Attempting to hasten the process through excessive heat or pressure can result in weak bonds and potential leaks or failures in the future. So, dear adhesive superheroes, exercise patience and let the glue cure naturally.

Benefits of Speeding Up PVC Glue Drying Time

Today, we embark on an exhilarating journey into the world of PVC glue, where time-saving techniques and productivity-boosting methods reign supreme. Join us as we explore the mind-blowing benefits of speeding up PVC glue drying time – a game-changer for efficiency, strength, and project success.

Time-saving:

Imagine being in the midst of a project, racing against the clock, only to be held back by the sluggishness of traditional PVC glue. Frustration sets in as precious hours slip away. But fear not. By utilizing accelerators or applying heat, you can transform hours into mere minutes. Bid farewell to tedious waiting and embrace the thrill of completing tasks at lightning speed.

Increased productivity:

In the fast-paced realms of construction sites and manufacturing facilities, time equates to money. With faster drying times, workers can conquer projects with unrivaled efficiency. Imagine meeting tight deadlines without the stress of glue taking forever to dry. By becoming a productivity powerhouse, you’ll leave colleagues and clients astounded by your ability to deliver exceptional results in record time.

Improved bonding strength:

Speeding up drying time doesn’t mean compromising on bond quality; it means elevating it to new heights. Some methods used to accelerate drying actually enhance bonding strength. Through the use of accelerators, you can forge unbreakable connections between PVC surfaces. Weak joints become a thing of the past, replaced by durable and long-lasting bonds that withstand the test of time.

Reduced waiting time:

The agony of waiting for glue to dry is a universal frustration. It’s like watching paint dry, but with even less excitement. However, by expediting the drying process, you can minimize wait times and propel your project forward at warp speed. Say goodbye to idle moments spent watching glue dry and hello to the thrill of tackling multiple projects simultaneously or meeting tight deadlines head-on.

Common Mistakes to Avoid when Speeding Up PVC Glue

In our quest to conquer the sluggish drying time of PVC glue, we’ve already explored the wonders of speeding up this process. Now, let’s delve into the realm of common mistakes that can hinder your adhesive endeavors. Brace yourselves as we unveil the secrets to achieving lightning-fast results while avoiding these pitfalls.

Applying Excessive Pressure:

Imagine this scene: in your eagerness to expedite the bonding process, you force the pipes together with all your might. Hold on, hero. Excessive pressure causes the glue to squeeze out of the joint, resulting in weak connections and incomplete bonding. Remember, a steady and gentle touch is key to success.

Rushing the Drying Time:

Impatience can be our greatest foe when dealing with PVC glue. Trying to hasten the drying process by applying heat or force is a grave mistake. This impulsive act compromises the joint’s integrity, paving the way for potential leaks or breakages. Always adhere to the manufacturer’s instructions on drying time and resist the urge to rush – patience will be rewarded.

Using Expired or Old Glue:

Picture this scenario: you reach for that dusty bottle of PVC glue hidden at the back of your shelf, only to discover it expired ages ago. Oh dear. Employing expired or old glue severely hampers its effectiveness and speed. Over time, glue chemicals degrade, leading to weaker bonding strength. Always check the expiration date before using PVC glue and discard any ancient relics.

Neglecting Surface Preparation:

Just as a painter needs a pristine canvas, PVC glue requires meticulously prepared surfaces for optimal adhesion. Neglecting surface preparation by overlooking cleaning and drying can impede the glue’s effectiveness, resulting in feeble joints. Take the time to ensure your surfaces are free from dirt, dust, grease, or other contaminants – your adhesive prowess depends on it.

Not Applying Enough Glue:

Remember, PVC glue thrives on enthusiasm. When coating your joint, liberally apply an ample amount of glue for a robust bond. Insufficient glue leads to incomplete coverage and weak connections. Don’t hold back – let your glue flow freely.