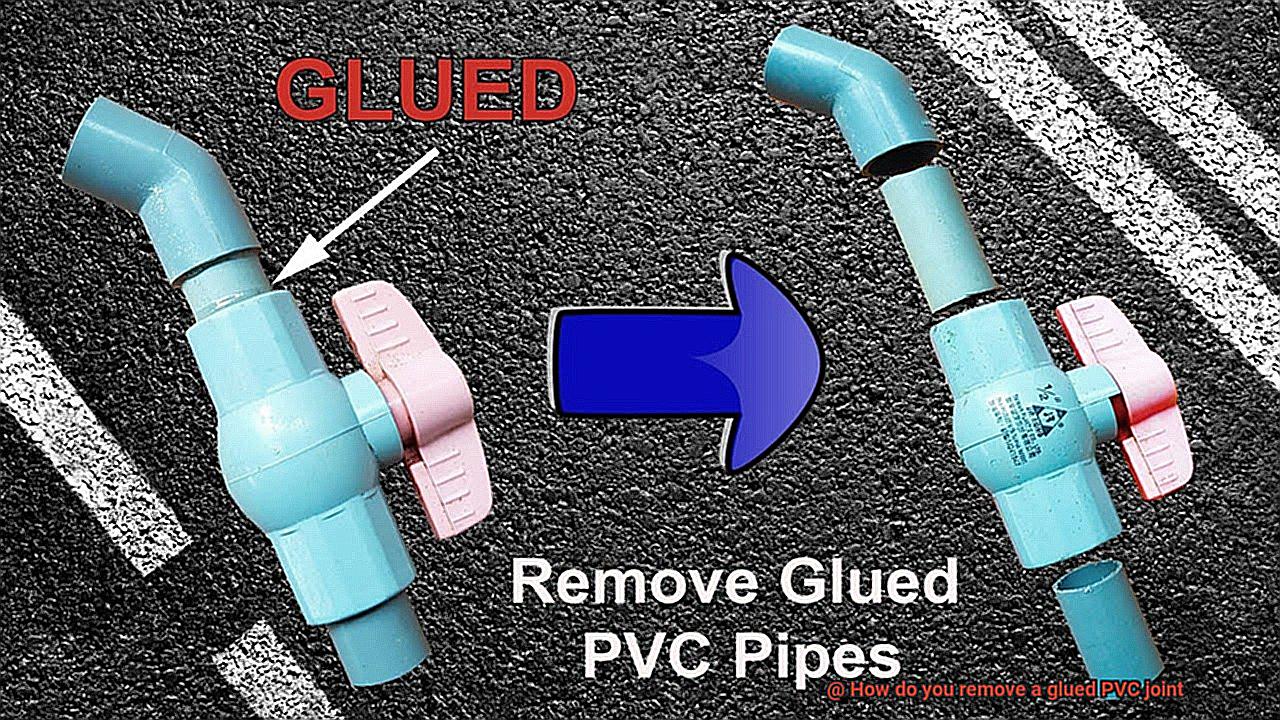

Ever found yourself knee-deep in a DIY project, patting yourself on the back for a job well done, only to realize you’ve made a sticky situation worse? Ah, the woes of PVC plumbing. Accidentally bonding the wrong pipes together with adhesive can feel like a major blunder. But fear not, my intrepid readers, for we are about to embark on a journey of liberation – learning how to remove those stubborn glued PVC joints and reclaim your DIY glory.

Imagine a seamless separation that doesn’t leave your pipes damaged or force you to start from scratch. Sounds like magic, right? Well, get ready to don your magician’s hat because we’re about to reveal the secret methods and techniques that will have you effortlessly unraveling glued PVC joints.

But before we dive into the nitty-gritty details, let’s cover the basics. We’ll explore the different types of PVC adhesives commonly used – from solvent cement to other options you may not have considered. We’ll also discuss potential challenges you might encounter along the way, like dealing with tricky pipe orientations or tight spaces. Don’t worry though; we’ve got your back.

Equipped with knowledge, it’s time to gather our tools and take protective measures before embarking on this daring mission. We’ll share some insider tips and tricks straight from seasoned professionals that will leave your fellow DIYers in awe. Who would have thought that heat, ice, or even a humble length of string could be your allies in liberating those stubbornly glued PVC joints?

And let’s not forget about being environmentally conscious. We’ll delve into why recycling old PVC pipes might just be the better option rather than removing the joint altogether. It’s all about making sustainable choices while saving both time and resources.

So buckle up, aspiring pipe magicians. Get ready for a thrilling adventure filled with discovery, determination, and the satisfaction of fixing your mistakes like a true expert. Together, we’ll conquer the mysteries of removing glued PVC joints and empower you to reclaim your DIY prowess. Let’s embark on this journey of liberation and do-it-yourself mastery.

What is a Glued PVC Joint?

Contents

- 1 What is a Glued PVC Joint?

- 2 Heat Method for Removing Glued PVC Joints

- 3 Safety Measures When Using Heat

- 4 Solvent Method for Removing Glued PVC Joints

- 5 Choosing the Right Solvent

- 6 Applying the Solvent

- 7 Separating the Joint After Applying the Solvent

- 8 Safety Precautions When Working with Solvents or Heat

- 9 Conclusion

Embark on a journey through the fascinating world of glued PVC joints, where reliable connections are forged between PVC pipes and fittings. In this article, we will explore the intricate process of creating these joints, their numerous advantages, and most importantly, how to skillfully remove them when the need arises.

Unveiling the Essence of a Glued PVC Joint:

- A glued PVC joint is the harmonious fusion of two PVC pipe or fitting surfaces using a solvent-based adhesive.

- Through chemical bonding, these joints establish an unyielding and everlasting connection.

The Art of Crafting a Glued PVC Joint:

- Immaculate cleanliness is paramount; ensure the pipe and fitting surfaces are free from dirt, grease, and moisture.

- Employ a solvent cement specifically formulated for PVC pipes to evenly coat both surfaces.

- Exhibit finesse by inserting the pipe into the fitting with a twisting motion, ensuring comprehensive adhesive coverage.

- Exercise patience as you hold the joint in place until the adhesive sets.

The Marvels of Glued PVC Joints:

- Simplicity reigns; these joints are effortlessly created with minimal tools and equipment.

- Indomitable strength is their hallmark, enabling them to withstand high pressure and temperature variations.

- Extraordinary chemical resistance makes them ideal for deployment in harsh environments prone to corrosion or abrasion.

Liberating a Glued PVC Joint – Method 1: The Power of Heat:

- Embrace caution and prioritize safety at all times.

- Harness the potency of a heat gun or hairdryer set at its highest temperature to soften the glue.

- Gently twist and separate the joint, utilizing pliers or a pipe wrench to achieve liberation.

Liberating a Glued PVC Joint – Method 2: The Elixir of Solvent:

- Pay homage to the manufacturer’s wisdom by meticulously adhering to their instructions.

- Anoint the glued area with a solvent specifically designed to dissolve PVC glue.

- Grant the solvent time to penetrate and dissolve the adhesive bond, patiently waiting for a few minutes.

- Summon your strength as you twist and separate the joint, employing pliers or a pipe wrench as your allies.

Heat Method for Removing Glued PVC Joints

Today, we embark on a thrilling adventure into the world of the heat method for removing glued PVC joints. Imagine facing a stubborn connection, desperately seeking freedom. Fear not, for the power of heat is here to rescue you. Grab your trusty heat gun or hairdryer and join us on this exhilarating journey.

Harnessing the Power of Heat:

Prepare to be amazed by the sheer effectiveness of the heat method in liberating glued PVC joints. By applying heat, we unlock the secret to softening the adhesive and effortlessly parting ways with our steadfast connections.

Safety First: A Dance with Caution:

Before we delve into this captivating dance with heat, let us ensure our safety compass guides us on this path. Ensure proper ventilation in the vicinity and remove any flammable materials from sight. Shield yourself with safety goggles and gloves, guarding against any unforeseen mishaps.

The Enchanting Dance of Heat:

With our safety stage perfectly set, it’s time to ignite our heat gun or hairdryer and commence our mesmerizing performance. As you direct your heat source back and forth like a graceful dancer, witness the adhesive surrender to the alluring warmth, yielding effortlessly.

Gentle Persuasion:

As warmth works its magic, it’s time for a gentle coaxing to separate the joint. With finesse and grace, employ a pair of pliers or a similar tool to twist and pull delicately, mindful of avoiding excessive force that could harm the pipe or fitting. Remember, gentle persuasion is your key to success.

Embracing Persistence:

Should your joint still cling stubbornly together, do not despair. Continue applying heat until the adhesive succumbs to its pliable nature, surrendering to your unwavering determination. Patience, dear adventurers, is a virtue that rewards the persistent.

Celebrating a Clean Break:

As your joint is liberated from its binding embrace, pause to revel in your glorious triumph. But our quest is not yet complete. Arm yourself with a solvent specifically designed for PVC pipes, and with this magical elixir, cleanse any remnants of adhesive. Witness your newly separated joint gleaming in the radiant light of victory.

Safety Measures When Using Heat

Embark on an exhilarating journey into the world of PVC joint removal, where heat becomes your trusty sidekick in freeing stubborn connections. But before you dive headfirst into this adventure, let’s prioritize safety. In this guide, we’ll explore essential safety measures to consider when using heat for PVC joint removal. So gear up and let’s ensure a safe and successful mission.

Equip Yourself:

Like a superhero donning their armor, it’s crucial to equip yourself with the right protective gear. Wear heat-resistant gloves, safety goggles or glasses, and long-sleeved clothing. This ensemble shields you from potential burns or injuries, ensuring you’re ready to conquer any challenge.

Clear the Air:

Working in a well-ventilated area is a must when using heat for PVC joint removal. Fumes released during the process can be harmful if inhaled. Open windows and doors to let fresh air flow through, or consider using fans and ventilation systems to ensure proper airflow.

Fire Safety First:

As thrilling as this adventure may be, fire safety should never be overlooked. Heat can ignite a fire hazard if not handled properly. Keep a trusty fire extinguisher nearby and make sure it’s in good working condition. Take a moment to familiarize yourself with its usage – it might just save the day. Before you begin, remove any flammable materials from the surrounding area to eliminate any unexpected surprises.

Choose Your Heat Source Wisely:

Selecting the right heat source is crucial for a safe and effective PVC joint removal mission. Two popular options are the heat gun and the blowtorch. When choosing a heat gun, opt for one with adjustable temperature settings and a precise nozzle that directs heat solely at the joint without affecting other components. If you choose a blowtorch, ensure it has a flame control valve and a secure grip handle for maximum control.

Maintain a Safe Distance:

Keep your distance from danger by maintaining a safe distance between the heat source and the PVC joint. The appropriate distance varies depending on the heat source and the specific PVC pipe you’re working on. Consult the manufacturer’s instructions or seek professional guidance to determine the ideal distance. Remember, we want optimal results without risking damage.

Solvent Method for Removing Glued PVC Joints

Well, strap on your safety gear and prepare to be amazed as we explore the captivating solvent method for removing those pesky glued PVC joints. Get ready for an adventure like no other.

First things first, let’s make sure we have all the tools and materials we need. Grab your trusty PVC pipe cutter or hacksaw, a clean cloth, a specially formulated PVC solvent, and of course, don’t forget your gloves and goggles for protection.

Now that you’re geared up and ready to go, let’s ensure we’re in a well-ventilated area. We don’t want to inhale any harmful fumes, so crack open a window or take the action outside. Safety is our top priority.

Alright, it’s time to dive into the action. The first step is to cut that PVC pipe on both sides of the glued joint using your pipe cutter or hacksaw. This will give us two separate pieces to work with. Precision and patience are key here.

Once the cuts are made, grab that trusty clean cloth and wipe away any dirt or debris from both ends of the cut pipe. We want a pristine surface for our solvent to work its magic.

And now, ladies and gentlemen, introducing the star of our show: the PVC solvent. Apply it generously to both ends of the cut pipe. This powerful potion will gradually dissolve the adhesive holding those joints together. Allow it some time to work its way through by letting it sit for a few minutes.

Now comes the thrilling part. Firmly grip one end of the pipe and begin twisting it back and forth while gently pulling it away from the other end. This twisting motion is like a spell that breaks the bond between those stubborn PVC joints. If they refuse to budge, fear not. Apply more solvent and give it another try. Persistence pays off.

Remember, my fellow adventurers, patience is a virtue. Keep applying the solvent and repeating the twisting motion until that joint finally loosens up and can be separated. It may require multiple attempts, but don’t lose hope. Victory is within reach.

Once you’ve triumphantly removed the joint, give yourself a well-deserved pat on the back. But wait, we’re not done just yet. Take that trusty clean cloth once again and meticulously clean both ends of the pipe.

Choosing the Right Solvent

Prepare to embark on an exhilarating quest, brave adventurers. As we venture forth in our mission to free those stubborn PVC joints, we must arm ourselves with the ultimate tool: the perfect solvent. Today, we shall unravel the enchanting world of solvents and discover the myriad options at our disposal. So gather your solvent goggles, fasten your seatbelts, and let us embark on this enthralling journey together.

Acetone: A Flammable Force to Be Reckoned With

In our arsenal of solvents, acetone reigns as a stalwart warrior in the battle against PVC glue. This potent elixir possesses the power to dissolve PVC glue bonds effortlessly. Available in most hardware stores at a modest price, it won’t drain your coffers. However, heed this warning: acetone is highly flammable. Don your solvent cape cautiously and take adequate safety measures. Work in a well-ventilated area and don protective gloves to safeguard your valorous spirit.

Methyl Ethyl Ketone (MEK): The Indomitable Gladiator of Industry

For those seeking a solvent with industrial-grade strength, MEK stands tall as the champion of choice. This formidable gladiator swiftly annihilates PVC glue bonds, making it a favored weapon in industrial arenas. Yet, like its counterpart acetone, MEK bears the mark of high flammability. Prepare yourself accordingly by toiling in well-ventilated realms and keeping all open flames at an unassailable distance from your solvent battlefield.

Citrus-based Solvents: Gentle Allies With Unyielding Might

Should you yearn for a gentler option without compromising efficacy, take solace in citrus-based solvents, valiant allies in this journey. Crafted from natural citrus extracts, these miracles of nature are generally less toxic than their acetone or MEK counterparts. They possess the ability to dismantle the adhesive properties of PVC glue, rendering its removal a breeze. And lo and behold, they bestow upon us a delightful citrus aroma, lending an olfactory enchantment to our noble endeavor.

Applying the Solvent

In our quest to conquer the challenges of freeing stubborn PVC joints, we have armed ourselves with a powerful weapon – solvents. Today, I will guide you through the process of applying solvents to break down the adhesive bond and achieve victory in our noble endeavor. So, buckle up and prepare to become a solvent application expert.

Choose Your Solvent Wisely:

In the battle against stubborn PVC joints, selecting the right solvent is crucial. Acetone, MEK, or PVC pipe cleaner are your trusted allies. These solvents, available at hardware stores or plumbing supply shops, vary in strength. Choose one that matches your specific needs.

Prepare for Battle:

Ventilation is key in this fight. Ensure your battleground is well-ventilated to disperse any potent fumes released by the solvents. Open windows or use fans to welcome fresh air and keep those pesky vapors at bay. Safety first, brave adventurers.

Coat the Joint with Solvent:

With your chosen solvent in hand, grab a brush or cloth and generously coat the glued joint. Ensure every inch of the joint and its surrounding areas are covered. This ensures maximum penetration and effectiveness.

Patience is a Virtue:

Allow time for the solvent to work its magic. The duration will depend on the type of solvent and glue strength. Typically, wait for around 15-30 minutes for the solvent to seep deep into the joint and weaken the adhesive bond.

Give It a Little Nudge:

While waiting, assist your solvent by gently tapping or twisting the joint with a hammer or wrench. This helps loosen the grip of the glue and allows the solvent to penetrate further. It’s like providing a gentle encouragement for the solvent to do its job.

Test the Waters:

After the waiting period, it’s time to assess if the joint has loosened. Apply gentle pressure or a twisting motion to check for any movement. If the joint remains stubborn, don’t lose hope. Reapply more solvent and give it some additional time – persistence pays off.

Separating the Joint After Applying the Solvent

In our previous post, we armed ourselves with the perfect solvent to conquer those stubborn PVC joints. Today, we’re taking it up a notch as we discuss the crucial steps for separating a glued PVC joint after applying the solvent. So, grab your tools and let’s dive into this exhilarating journey.

Step 1: Allowing the Solvent to Set:

After generously coating the joint with your chosen PVC pipe solvent, it’s time to unleash its power. Patience is key here. Different solvents have different recommended setting times, so consult the instructions on the product carefully. During this waiting period, the solvent works its magic by stealthily softening the glue that binds the joint together.

Step 2: Applying Pressure:

Now that the solvent has had sufficient time to work its wonders, it’s time to flex those muscles. Grab a trusty pair of pliers or a sturdy pipe wrench and firmly grip one end of the pipe. With a determined resolve, twist it in a clockwise motion while keeping the other end of the joint steady. Remember, slow and steady wins this battle of separation.

Step 3: Embrace the Twist:

As you apply pressure and twist the pipe, don’t be disheartened by initial resistance. It’s only natural as some stubborn glue might still cling to the joint. Stay committed. Keep twisting gently but firmly until you feel that tenacious bond between the pipes begin to relent. And if needed, don’t hesitate to incorporate a back-and-forth motion to shatter that unyielding connection.

Step 4: More Solvent Power:

Should you encounter an indomitable joint that refuses to yield, fear not. Your trusty solvent is here to save the day once again. Reach for a clean rag or paper towel and douse it with more solvent. Apply it directly onto the joint, allowing the liquid to seep in and work its magic for a few minutes. Remember, a little extra solvent can go a long way in conquering even the most stubborn of joints.

Safety Precautions When Working with Solvents or Heat

In our previous adventure, we explored the power of solvents in conquering stubborn PVC joints. But before we dive into the exhilarating world of removing glued PVC joints, let’s gear up with some safety precautions to ensure a hazard-free journey. After all, safety should always be our trusty sidekick in any DIY mission. So grab your PPE and let’s get started.

Suit Up with the Right Gear:

Don your gloves, safety glasses or goggles, and if needed, a respirator. These superhero accessories shield you from chemical splashes, fumes, and the occasional rogue glue splatter. Safety is our armor.

Breathe Easy in a Well-Ventilated Space:

Ventilation is key when working with solvents or heat. Find a well-ventilated area to avoid inhaling any potentially harmful fumes or gases that might escape during the process. Open a window or bring out the big guns – a fume hood – for maximum protection. Let fresh air be our ally.

Get to Know Your Solvent or Heat Method:

Each solvent or heat method for removing glued PVC joints has its own unique powers. Read and understand the manufacturer’s instructions carefully. Knowledge is power. Different methods have different application techniques, safety considerations, and potential hazards. Let’s be the masters of our craft.

Storing Solvents: Out of Sight, Out of Danger:

Keep solvents away from ignition sources, direct sunlight, or any heat-emitting devices. Store them securely in labeled, tightly sealed containers when not in use. We won’t allow accidental spills or leaks to sabotage our mission.

Avoid Skin and Eye Contact:

Solvents can be sneaky adversaries, so keep a safe distance. Stay vigilant and avoid direct contact with your skin, eyes, or clothing. But, if you happen to have an accidental encounter, don’t panic. Rinse the affected area immediately with plenty of water and seek medical attention if necessary. Always be prepared for unexpected battles.

UPzUBxvB8jo” >

Conclusion

Removing a glued PVC joint can be a challenging task, but with the right approach and some patience, it can be done. Here are some methods you can try to effectively remove a glued PVC joint.

One method is using heat. By applying heat to the joint using a heat gun or a hairdryer set on high, you can soften the glue and make it easier to separate the pipes. Be cautious not to overheat the PVC as it may warp or melt.

Another option is using a solvent. There are specific solvents available that can dissolve PVC glue, such as acetone or PVC pipe cleaner. Apply the solvent to the joint and let it sit for a few minutes before attempting to separate the pipes. Remember to work in a well-ventilated area and follow all safety precautions when handling solvents.

If these methods don’t work, you can also try using mechanical force. Using pliers or adjustable wrenches, grip one pipe firmly while twisting and pulling on the other pipe. This method requires strength and may cause damage to the pipes, so use caution.

In some cases, cutting out the joint entirely may be necessary. Using a hacksaw or reciprocating saw, carefully cut through the pipe on either side of the joint. This will allow you to replace the section of pipe without having to remove the glued joint itself.

It’s important to note that removing a glued PVC joint requires careful attention and precision. Take your time and proceed with caution to avoid any injuries or further damage to your plumbing system.

In conclusion, removing a glued PVC joint may seem daunting at first, but by utilizing methods like heat application, solvent usage, mechanical force, or even cutting out the joint entirely if necessary, you can successfully remove it.