We’ve all been there – you’re ready to tackle a project, reach for your trusty glue, and bam. Mold has taken over, turning your adhesive into a slimy mess. Not only is it gross, but it’s also a health hazard. But fear not, my friend. In this blog post, we’ll uncover the secrets to preventing mold on glue, so you can keep your adhesive materials in tip-top shape.

Mold loves to grow in humid environments with poor ventilation or lousy storage conditions. It’s like they have a secret agenda to ruin our glue-related dreams. But don’t worry – armed with a few simple preventive measures, you can fight back against this sneaky foe. We’ll show you how to keep mold at bay and ensure your glue stays fresh, effective, and safe to use.

Whether you’re an avid DIY enthusiast or a professional who relies on adhesive materials daily, these tips will help extend the life of your glue. We’ll cover everything from understanding the ideal conditions for mold growth to implementing proper storage practices. So get ready to bid farewell to moldy glue and say hello to projects that stick without any setbacks.

Let’s dive in and discover how you can protect your adhesive materials from the clutches of mold. Because let’s face it – nobody likes dealing with slimy surprises when they’re just trying to get things done.

What is Mold and Why Does it Form on Glue?

Contents

- 1 What is Mold and Why Does it Form on Glue?

- 2 How to Store Glue Properly to Prevent Mold

- 3 Ensuring Adequate Ventilation to Control Humidity Levels

- 4 Regularly Inspecting the Glue for Signs of Mold Growth

- 5 Using Mold-Resistant Glues or Additives

- 6 Maintaining Proper Cleanliness and Hygiene Practices when Working with Glue

- 7 Applying Protective Coatings or Sealants for High Risk Areas

- 8 Conclusion

Mold is a type of fungus that can grow on a variety of surfaces, including glue. It is composed of microscopic organisms called spores, which are present in the air and can settle on surfaces under the right conditions. These spores are like tiny seeds, waiting for the perfect environment to grow and spread.

Mold thrives in environments that are damp, warm, and dark, making glue an ideal breeding ground. When glue is exposed to high humidity or water, it creates a moist environment that promotes mold growth. If glue is stored in areas with poor ventilation or subjected to frequent temperature changes, it becomes even more susceptible to mold formation. These conditions create an environment where moisture can accumulate and allow mold spores to flourish.

Furthermore, some glues contain organic materials like starch or sugar, which provide an additional food source for mold. Glues derived from natural substances like plants or animals are more likely to support mold growth because the organic materials present in these glues serve as nutrients for the mold. This makes it easier for the fungus to develop and thrive on these types of glues.

Mold growth on glue is not only unsightly but can also compromise the adhesive properties of the glue. The presence of mold can weaken the bond between surfaces and reduce the effectiveness of the glue. Additionally, mold can release spores into the air, potentially causing respiratory issues or allergies in sensitive individuals.

To prevent mold from forming on glue, it is important to store it in dry and well-ventilated areas. Using airtight containers can help protect the glue from exposure to airborne spores. Choosing glues that are specifically formulated to resist mold growth is also recommended. Regularly inspecting stored glues for any signs of mold and promptly discarding contaminated ones can prevent mold from spreading.

Proper cleaning and maintenance of glue application tools, such as brushes or nozzles, can help prevent the buildup of mold spores and reduce the risk of contamination during the glue application process.

How to Store Glue Properly to Prevent Mold

Glue is a commonly used adhesive that can be found in households, offices, and schools. It is essential to store glue properly to prevent the growth of mold, which can compromise its effectiveness and integrity.

First and foremost, it is crucial to store glue in a cool and dry place. High temperatures and humidity can accelerate the growth of mold. Therefore, avoid storing glue near sources of heat, such as radiators or direct sunlight, as well as areas prone to moisture, like bathrooms or basements. Instead, opt for a storage area that maintains a stable temperature and humidity level.

The next step in storing glue properly is to ensure that the container is tightly sealed. Glue is typically sold in squeeze bottles or tubes with caps, so make sure to close them securely after each use. This will prevent air and moisture from entering the container, which are ideal conditions for mold growth.

Another tip for storing glue is to keep it upright. This helps prevent any potential leakage or spillage that could occur if the container is stored on its side or upside down. Storing glue in an upright position also allows any air bubbles or excess moisture to rise to the top of the container, reducing the risk of mold formation.

Additionally, it is advisable to store glue away from other chemicals or substances that could potentially react with it. Some chemicals can alter the composition of glue and create an environment conducive to mold growth. Therefore, it is best to store glue separately from paints, solvents, or cleaning products.

If you have large quantities of glue or multiple types of glue, consider labeling each container with its expiration date and/or date of purchase. This will help you keep track of when the glue should be used by and ensure that you are not using expired or old glue that may be more susceptible to mold growth.

Lastly, periodically inspect your stored glue for any signs of mold growth. Mold can sometimes develop even under proper storage conditions due to factors beyond our control. If you notice any discoloration, unusual odors, or visible mold growth on the glue or its container, it is best to dispose of it properly and replace it with a fresh supply.

Ensuring Adequate Ventilation to Control Humidity Levels

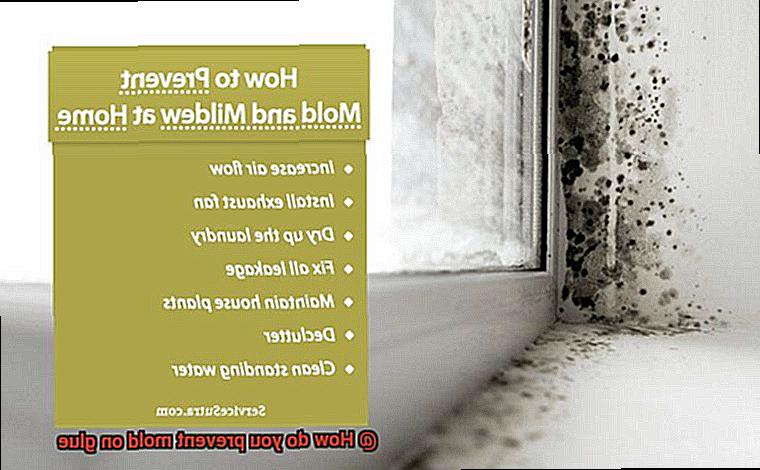

Ensuring adequate ventilation is essential in controlling humidity levels and preventing mold growth on glue. Mold thrives in environments with high humidity, making it crucial to control the moisture content in the air. By implementing the following strategies, you can create a drier environment and reduce the risk of mold growth:

- Use fans or open windows and doors: Promote good airflow by utilizing fans or opening windows and doors in the area where glue is stored or used. This simple action helps to remove excess moisture from the air, creating a drier environment that discourages mold growth.

- Utilize dehumidifiers: In areas prone to high humidity, like basements or bathrooms, using dehumidifiers can be highly effective. These appliances extract moisture from the air, reducing the chances of mold growth on glue.

- Clean and maintain ventilation systems: Regularly inspect and clean any ventilation systems, such as exhaust fans or air conditioning units, to ensure they are functioning properly. Blocked or faulty ventilation systems can contribute to increased humidity levels and provide an ideal breeding ground for mold.

- Control temperature: Mold thrives in warm temperatures, so maintaining a cooler environment can inhibit its growth. Consider using air conditioning or adjusting the thermostat to keep the space cool and discourage mold growth on glue.

- Monitor humidity levels: Use a hygrometer to monitor the humidity levels in the area where glue is stored or used. Ideally, humidity should be maintained below 50% to discourage mold growth. Adjust ventilation or use dehumidifiers accordingly if necessary.

- Address water leaks promptly: Water leaks create a conducive environment for mold growth, making it crucial to address any leaks or sources of moisture promptly. Fixing water leaks and properly drying any affected areas will help prevent mold on glue.

Regularly Inspecting the Glue for Signs of Mold Growth

Regularly inspecting glue for signs of mold growth is of utmost importance for several reasons. Mold growth on glue can have detrimental effects, both in terms of structural integrity and potential health hazards. By conducting regular inspections, one can detect mold growth early on and take appropriate measures to prevent further contamination and ensure the quality and effectiveness of the adhesive materials.

Here are some key points that highlight the significance of regularly inspecting glue for signs of mold growth:

- Structural damage: Mold growth on glue can lead to structural damage and deterioration. If left unchecked, it can compromise the adhesive properties of the glue, rendering it ineffective. This is particularly problematic if the glue is used in construction or manufacturing processes where its integrity plays a vital role.

- Health hazards: Mold poses health risks, especially for individuals with allergies or respiratory conditions. Inhalation of mold spores can trigger allergic reactions, asthma attacks, and other respiratory issues. Regularly inspecting glue for mold growth helps prevent potential health hazards and ensures a safer environment.

- Early detection and prevention: Regular inspections allow for early detection of mold growth. Identifying mold growth at its early stages enables prompt action to prevent its spread and further contamination. Taking immediate steps to address the issue can save time, money, and effort in the long run.

- Maintaining product quality: Mold-infested glue may not perform as intended. It may not adhere properly or provide the desired strength. Regular inspections help ensure that the glue being used is of good quality and free from mold contamination.

- Preventing cross-contamination: Mold growth on glue can spread to other materials or surfaces if not addressed promptly. Regular inspections help identify any potential sources of cross-contamination, allowing for appropriate measures to be taken to contain the mold and prevent its spread.

To effectively inspect glue for signs of mold growth, it is important to be thorough in your examination. Here are some steps to follow:

- Visual inspection: Look for visible signs such as discoloration, fuzzy or powdery growth, or a musty odor. Mold often appears as black, green, or white patches on the surface of the glue.

- Touch and feel: Mold-infested glue may feel slimy or have a different texture than unaffected glue. It is important to wear protective gloves during this process to avoid direct contact with mold spores and potential allergens.

- Consider the environment: Factors such as the storage environment and the type of glue being used can affect the susceptibility to mold growth. In high humidity areas or places with poor ventilation, more frequent inspections may be necessary.

If mold is detected during the inspection, it is crucial to take immediate action to prevent its spread and further contamination. Isolate the infected glue, seal it in a plastic bag or wrap it tightly with plastic wrap, and follow appropriate guidelines for mold removal and disposal.

Using Mold-Resistant Glues or Additives

Using mold-resistant glues or additives offers a range of benefits, making them a valuable choice for various projects and environments. Here are some of the advantages:

- Prevention of mold growth: The primary advantage of using mold-resistant glues or additives is their ability to inhibit the growth of mold and mildew on surfaces where glue is applied. This is particularly important in areas with high humidity or moisture, as these environments are more prone to mold growth.

- Anti-fungal and anti-microbial properties: Mold-resistant glues or additives contain ingredients that have powerful anti-fungal and anti-microbial properties. These properties make them highly effective in preventing the growth of mold and mildew, ensuring a cleaner and healthier environment.

- Versatility: Mold-resistant glues or additives can be used in various applications, including woodworking, construction, and other DIY projects where glue is involved. They can be used on a wide range of materials, such as wood, metal, and plastics, making them versatile and suitable for different projects.

- Allergen reduction: Mold spores can trigger allergies and respiratory conditions in sensitive individuals. By using mold-resistant glues or additives, the risk of mold spores being released into the air is reduced. This makes it safer for people with allergies or respiratory conditions to work or live in the space where the glue is used.

- Long-lasting protection: Mold-resistant glues or additives create a protective barrier on the surface, making it difficult for mold spores to adhere and grow. This provides long-lasting protection against mold and mildew, ensuring the durability and cleanliness of the glued surfaces.

However, it’s important to note that there are some drawbacks to using mold-resistant glues or additives:

- Limited effectiveness: While mold-resistant glues or additives are designed to inhibit mold growth, they are not foolproof. In extreme cases of moisture or humidity, mold may still develop over time. It’s important to address any underlying moisture issues to prevent mold growth.

- Cost: Mold-resistant glues or additives may be more expensive than regular glues due to their additional anti-fungal and anti-microbial properties. However, the added cost can be justified by the benefits they provide in preventing mold growth.

- Proper application required: To ensure the effectiveness of mold-resistant glues or additives, it is essential to follow the manufacturer’s instructions carefully during application. Improper application may reduce their effectiveness in preventing mold growth.

- Does not eliminate the need for moisture control: While mold-resistant glues or additives can help prevent mold growth on surfaces, they do not eliminate the need for proper ventilation and moisture control in the area where glue is being used. It is still important to address any underlying moisture issues to prevent mold growth.

Maintaining Proper Cleanliness and Hygiene Practices when Working with Glue

Maintaining proper cleanliness and hygiene practices when working with glue is crucial for safety and health reasons. Mold growth can be a major concern when dealing with glue, as it thrives in moist and dirty environments. To prevent mold from ruining your projects, it is important to keep your workspace clean and dry.

Firstly, ensure that your hands are clean before handling any glue. Thoroughly wash them with soap and water to remove dirt and bacteria that could contaminate the glue. Clean hands provide a clean start to your project.

In addition, wipe down the surface where you will be applying the glue. Removing dust, debris, and moisture creates a clean and dry environment that discourages mold growth. A clean surface ensures that your projects remain intact.

Moreover, using clean tools is essential. Dirty brushes or spatulas can introduce bacteria or mold spores into the glue, leading to contamination. Clean your tools before and after use with warm soapy water to prevent this.

Proper storage is also key in maintaining the cleanliness of glue. Tightly seal the container after each use and store it in a cool, dry place. This prolongs the shelf life of the glue and reduces the risk of mold development.

Applying Protective Coatings or Sealants for High Risk Areas

Applying protective coatings or sealants to high-risk areas is a crucial step in safeguarding glue surfaces against the relentless threat of mold growth. By following a few key considerations, you can ensure the effectiveness of these protective measures and preserve the integrity of your projects.

The first step in applying protective coatings or sealants is proper surface preparation. This includes meticulously cleaning the surface to eliminate any dirt, dust, or debris that could compromise the adhesion of the coating. It is equally important to address any existing mold or mildew on the surface before application. Utilize a suitable cleaner and adhere to proper cleaning procedures to eradicate any trace of mold. By eliminating existing mold, the protective coating can adhere flawlessly and provide maximum protection against future mold growth.

Choosing the right type of coating or sealant for your specific needs is paramount. There are several options available, including antimicrobial coatings and moisture-resistant sealants. Antimicrobial coatings contain additives that actively inhibit the growth of mold, mildew, and bacteria. Meanwhile, moisture-resistant sealants create an impenetrable barrier, preventing moisture from infiltrating the glue surface and creating an ideal environment for mold growth. To ensure optimal results, select a coating or sealant specifically designed for use on glue surfaces and consult with manufacturers or experts if needed.

Addressing underlying moisture issues is another essential consideration when applying protective coatings or sealants. Mold thrives in moist environments, so it is vital to identify and rectify any sources of excess moisture in high-risk areas. This may involve improving ventilation, fixing leaks, or reducing humidity levels.

Finally, regular inspections and maintenance are necessary to uphold the efficacy of the protective coatings or sealants. Over time, these coatings can wear off or sustain damage, compromising their ability to prevent mold growth. By routinely inspecting and reapplying coatings as needed, you can minimize the risk of mold on glue surfaces and ensure lasting protection.

T6oqje7dUdI” >

Conclusion

In conclusion, preventing mold on glue is absolutely crucial to preserve the effectiveness and integrity of adhesive materials. Mold loves to thrive in humid environments with poor ventilation or lousy storage conditions, which makes it absolutely necessary to implement preventive measures.

To prevent mold growth on glue, proper storage practices are key. Store your glue in a cool and dry place, far away from heat sources and moisture-prone areas. Make sure that containers are tightly sealed to keep air and moisture out. Storing glue upright minimizes the risk of leakage and allows excess moisture to rise to the top.

Don’t underestimate the power of adequate ventilation in controlling humidity levels and reducing mold growth. Use fans, open windows, or even invest in dehumidifiers for those high-humidity areas. Keep your ventilation systems clean and well-maintained to ensure proper airflow.

Regularly inspect your stored glue for any signs of mold growth. Look out for discoloration, strange odors, or visible patches of mold. If you spot any contamination, promptly discard the affected glue to prevent further spread.

Consider using mold-resistant glues or additives that have powerful anti-fungal and anti-microbial properties. These products provide long-lasting protection against mold growth, ensuring that your adhesive materials stay fresh and free from any unwanted invaders.

Maintaining cleanliness and hygiene when working with glue is absolutely crucial. Always wash your hands thoroughly before handling glue, wipe down surfaces regularly, and use clean tools to prevent any contamination.

For added protection against mold growth on high-risk areas, consider applying protective coatings or sealants. But remember – proper surface preparation is key. Choose the right coating or sealant for your needs while addressing any underlying moisture issues. Regular inspections will help ensure that these extra layers of defense remain effective over time.

By following these preventive measures diligently, you can say goodbye to moldy glue once and for all. Rest assured that your adhesive materials will stay fresh, effective, and safe to use for all your projects.