Got a fabric project in mind? Whether you’re a craft lover, a DIY enthusiast, or just someone looking to fix their favorite fabric pieces, knowing how to permanently glue fabric together is a game-changer. It’s like having a secret superpower that lets you create seamless bonds that last forever. In this blog post, we’ll walk you through the process of fabric gluing, share some essential tips and tricks, and make sure you’re armed with all the knowledge needed for impeccable results. So grab your fabrics and let’s dive into the wonderful world of fabric bonding.

To start off right, find yourself some fabric glue or adhesive specifically made for fabrics. You can easily get these at your local craft store or online. Also, make sure your fabrics are clean and free from any dirt or debris.

Now that you have everything ready, let’s get down to business:

- Test Before You Attach: Don’t go gluing your entire project just yet. Do a small test on a spare piece of fabric first. This way, you can see how the adhesive reacts with your specific fabric and avoid any unexpected disasters.

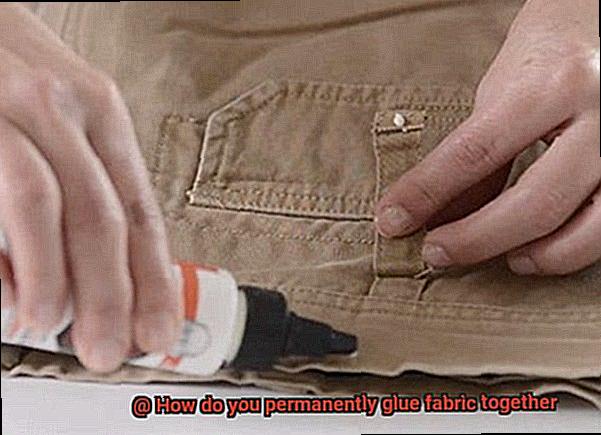

- Apply the Adhesive: Take it easy with the glue now. Apply a thin and even layer onto one of the fabric pieces. Too much glue might seep through or create ugly clumps – we definitely don’t want that.

- Press and Hold: Time to bring those two fabric pieces together. Gently press them so that the glued surfaces align perfectly. Hold them firmly in place for as long as recommended on the adhesive packaging – this helps create a bond so strong it could rival superheroes.

- Allow Time to Dry: Now comes the waiting game – set aside your glued fabric piece and let it dry completely. Depending on the adhesive used, this could take anywhere from a few hours to a whole day. Patience is key here.

- Optional: Reinforce the Bond (if needed): For extra durability, you can stitch along the glued edges. This works wonders for heavy-duty fabrics or items that go through a lot of wear and tear.

Tips and Tricks:

- Always read and follow the instructions provided by the adhesive manufacturer.

- Delicate fabrics or those prone to fraying? Apply a bit of fray stop adhesive on the edges before gluing.

- If possible, choose a fabric glue that is machine washable for added convenience

Types of Fabric Glue

Contents

It offers a convenient and versatile way to bond fabric materials together, whether you’re working on a sewing project, creating crafts, or fixing a tear in your favorite shirt. However, not all fabric glues are created equal.

There are different types of fabric glue available on the market, each with its own unique properties and applications. Let’s explore these types in more detail:

Liquid Fabric Glue

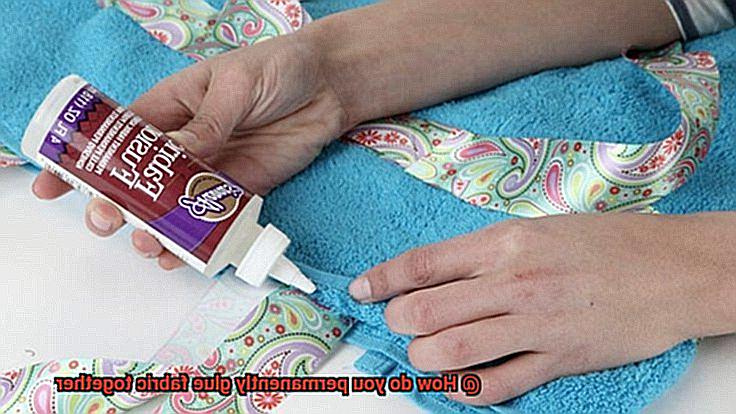

Liquid fabric glue is one of the most common and versatile types of fabric glues available. It typically comes in a bottle with an applicator tip, allowing for precise application. Liquid fabric glue is suitable for both lightweight and heavyweight fabrics and dries clear and flexible.

It is perfect for repairing hems, attaching trims, or adding embellishments to your garments. Its versatility makes it a staple in any crafter’s toolbox.

Stick Fabric Glue

If you’re looking for a quick fix or temporary bonding solution, stick fabric glue is the way to go. Similar to regular glue sticks or glue pens, stick fabric glue is easy to use and provides a convenient option for small repairs or crafts.

However, it may not be as strong as liquid fabric glue, so it’s best suited for lightweight fabrics and temporary fixes.

Spray Fabric Glue

When working on larger projects or delicate fabrics, spray fabric glue can be a lifesaver. It comes in an aerosol can and provides an even coat of adhesive when sprayed onto the fabric.

Spray fabric glue is commonly used in upholstery projects or when adhering fabrics to other surfaces. It offers a quick and convenient way to bond fabrics without the need for precise application.

Fusible Web

If you’re into sewing and want a more permanent bonding solution, fusible web is worth considering. Fusible web is an adhesive that requires heat activation to bond fabrics together. It usually comes in the form of sheets or tapes that are placed between layers of fabric and then fused using an iron or heat press. Fusible web creates a strong and permanent bond that is machine washable, making it ideal for appliqué work or joining fabrics that cannot be stitched together.

Specialty Fabric Glues

In addition to the common types mentioned above, there are also specialty fabric glues designed for specific types of fabric, such as denim or leather. These glues take into consideration the unique properties of these fabrics and provide a strong bond that can withstand wear and tear. They are perfect for repairing jackets, jeans, or leather accessories.

When choosing a fabric glue, it’s important to consider the type of fabric you’re working with. Some glues may work better on certain fabrics than others, so it’s always a good idea to test the glue on a small, inconspicuous area of the fabric before applying it to the entire project. Additionally, make sure to follow the manufacturer’s instructions for proper application and drying times to ensure the best results.

Preparing the Fabric for Adhesion

Today, we embark on a journey into the fascinating realm of fabric adhesion. Whether you’re working on a sewing project or mending a tear in your favorite shirt, knowing how to prepare the fabric properly for adhesion is crucial for achieving a robust and long-lasting bond.

First and foremost, cleanliness reigns supreme. Before applying any glue, it is essential to ensure that your fabric is free from dirt, dust, and oils that can hinder the effectiveness of the adhesive. Give your fabric a thorough cleaning by either hand washing or using a gentle cycle in the washing machine. Remember to use a mild detergent and forgo fabric softener as it can leave behind residues that interfere with our bond.

Once your fabric is squeaky clean, it’s time to tackle those stubborn wrinkles. Ironing the fabric serves two purposes: creating a smooth surface for better adhesion and activating the glue. Set your iron to the appropriate heat setting for your fabric type and gently press out any wrinkles. If you’re working with delicate or heat-sensitive fabrics like silk or synthetic blends, don’t forget to use a pressing cloth to protect them from direct heat.

Now, let’s delve into some special cases. Fabrics with glossy or waterproof coatings may require extra attention. To ensure proper adhesion, lightly sand or roughen the surface of the fabric before applying glue. However, exercise caution and test this technique on a small, inconspicuous area first to avoid any unwanted alterations or damage.

Speaking of special cases, fabrics with high synthetic fiber content, such as polyester or nylon, can benefit from pre-treatment. Enhance adhesion strength and create a more permanent bond by using a fabric primer or bonding agent specifically designed for synthetic materials.

Last but certainly not least, always conduct a glue test before proceeding. Apply the glue to a scrap piece of fabric or an inconspicuous area and observe how it dries and interacts with the fabric. Different glues have varying drying times and may react differently with different fabric types. Testing beforehand will prevent any mishaps and ensure compatibility with your fabric.

Applying Fabric Glue

Applying fabric glue correctly is essential for creating strong and permanent bonds between fabrics. To ensure success, it is important to follow a few key steps.

Firstly, it is crucial to prepare the fabric canvas before applying the glue. Just like a painter cleans their brush before starting a masterpiece, the fabric must be clean and free from any dirt, dust, or oils. Give it a thorough wash and dry it according to the manufacturer’s instructions. This will provide a pristine foundation for the adhesive magic.

Safety is also important when working with fabric glue. The glue can emit fumes, so it is best to work in a well-ventilated area. Additionally, consider wearing gloves to protect your hands from the adhesive.

When it comes to applying the fabric glue, there are several options available. You can use a brush or applicator to evenly spread the glue onto the fabric. It is important not to use too much glue as this can cause the fabric to become stiff or discolored.

For smaller or intricate areas, a syringe or squeeze bottle can be your best friend. These tools allow for precise application, ensuring that every nook and cranny receives its fair share of adhesive love.

After applying the glue, it needs time to work its magic. Follow the manufacturer’s instructions regarding drying time and temperature. Some fabric glues require heat setting to activate their adhesive properties, while others may need time to cure.

Once the glue is dry, it is time to bond those fabrics together. Press them firmly together using your hands or place a heavy object on top – just make sure they don’t slip and ruin all your hard work.

Patience is key here – let the glued fabric dry completely before handling or wearing it. This will ensure that the bond is fully set and prevent any premature damage or loosening of the adhesive.

Congratulations. You have successfully applied fabric glue and created a strong and permanent bond between your fabrics. Now you can use this magical adhesive for a variety of projects, from hemming garments to repairing tears or seams, attaching embellishments or patches, and even creating beautiful fabric crafts.

However, it is important to remember that not all fabrics are created equal. Before diving headfirst into your project, test a small area with the fabric glue to ensure compatibility.

If you ever need to remove fabric glue, don’t fret. There are solvents available that can help, or you can simply wash the fabric according to the manufacturer’s instructions.

Using Fusible Web or Adhesive Tape

Today, we’re diving into the advantages and disadvantages of using fusible web or adhesive tape to join fabric pieces together. Unleash your creativity as we delve into these two methods and discover which one suits your crafting needs.

Let’s begin with fusible web – a magical adhesive material that creates a permanent bond between fabrics. It’s perfect for hemming, appliqué work, and joining fabric pieces together. One of its major advantages is durability. Once heated and melted between two layers of fabric, it can withstand washing and wear like a champ. Say goodbye to loose hems and hello to long-lasting creations.

However, fusible web does have its limitations. It may not be suitable for delicate fabrics or those that can’t handle heat. Before diving into using fusible web, it’s crucial to test a small area of your fabric to ensure compatibility. Don’t let its limitations deter you though, as fusible web can be a game-changer for many projects.

- Now let’s move on to adhesive tape – a nifty invention offering a quick and easy solution for temporary or lightweight fabric bonding. Imagine having a superhero sidekick in your crafting adventures. Adhesive tape creates an instant bond between fabrics, eliminating the need for sewing or waiting for glue to dry. It’s perfect for last-minute DIY projects or when you’re feeling a little impatient.

- But here’s the catch – adhesive tape may not provide as strong of a bond as fusible web. It’s more suited for temporary fixes or lightweight fabrics. So, if you’re looking for something that will withstand the test of time, adhesive tape might not be your best bet. However, it’s still an incredibly handy option to have in your crafting toolbox.

Whether you choose fusible web or adhesive tape, always remember to read and follow the manufacturer’s instructions for the best results. And don’t forget to experiment with different fabrics and projects to find the method that works best for you. The world of fabric gluing is at your fingertips, waiting to be explored.

In conclusion, whether you’re hemming, appliquéing, or just getting crafty, using fusible web or adhesive tape offers versatility and ease of use. Fusible web provides a strong and durable bond, perfect for long-lasting creations. Adhesive tape, on the other hand, offers a quick and temporary solution for lightweight fabrics. Both methods have their advantages and limitations, so it’s important to choose wisely based on your specific needs.

Reinforcing with Sewing

Today, we are diving into the world of fabric reinforcement, exploring the timeless technique of sewing. Whether you’re a casual hobbyist or a professional seamstress, reinforcing fabric with sewing is a reliable and engaging method that adds strength and durability to your creations. So grab your needle and thread, and let’s embark on this exciting journey.

Choosing the Right Stitch Pattern:

To reinforce fabric with sewing, it’s crucial to select a stitch pattern that suits your fabric type. Lighter fabrics call for the elegance of a straight stitch, while heavy-duty fabrics demand the resilience of a zigzag stitch. Experiment with different patterns to find the perfect match for your project and witness the magic unfold.

Preparing the Fabric:

Before you begin sewing, take a moment to align the edges or layers that need reinforcement. Securing the fabric in place with pins ensures it stays aligned during the sewing process, resulting in a neat and professional finish that will make any seamstress proud.

Reinforcing Seam:

Now it’s time to let your creativity flow as you start sewing along the edge or seam that needs reinforcement. To secure the stitches and prevent them from unraveling, don’t forget to backstitch at the beginning and end of each seam. For an extra layer of strength, consider sewing multiple rows of stitches parallel to each other, forming an intricate web of support.

Choosing the Right Thread:

The thread you choose plays a vital role in reinforcing your fabric effectively. Select thread that matches the color of your fabric and is compatible with its material type. Cotton thread gracefully blends with cotton fabrics, while polyester thread harmonizes with synthetic materials. Let your thread become one with the fabric as it weaves its magic.

Finishing Touches:

As you complete your sewing journey, take a moment to trim any excess threads that may linger. Then, press the seam with an iron, allowing the heat to mold the stitches into a flawless bond. This final touch sets the stitches and creates a polished appearance, ensuring your reinforced fabric looks both professional and captivating.

Combining Sewing with Fabric Glue:

For those seeking an even stronger bond, consider the combination of sewing and fabric glue. Apply a thin layer of fabric glue between the layers of fabric, allowing it to seep into the fibers and fortify the connection. As you sew along the glued seam, witness the marriage of strength and creativity, perfect for projects that require extra durability such as bags or upholstery.

Factors to Consider When Choosing an Adhesive Method

When it comes to permanently bonding fabric together, fabric glue can be a game-changer. It offers a quick and convenient alternative to traditional sewing methods, allowing you to create strong and durable bonds in a fraction of the time. But with so many adhesive methods available on the market, how do you choose the right one for your fabric project? Let me guide you through the key factors you should consider when making this important decision.

Firstly, consider the type of fabric you’re working with. Different fabrics have different properties, and some adhesives may work better with certain types of fabric. Delicate fabrics like silk or chiffon may require a gentle adhesive that won’t damage or discolor the fabric, while heavier fabrics like denim or canvas may require a stronger adhesive that can withstand weight and stress.

Next, think about the purpose of bonding the fabric together. Do you need a temporary bond or a permanent one? Do you want the bond to be flexible or rigid? For temporary bonds, options like fusible web or spray adhesives may be suitable, as they can be easily removed or repositioned. For permanent bonds, fabric glues or sewing techniques like stitching or hemming may be more appropriate.

Consider how the adhesive will be applied to the fabric. Spray adhesives are convenient for large projects or intricate designs, providing even and uniform coverage. Liquid or gel adhesives offer more control over the amount and placement of the adhesive.

Drying time is another important factor to consider. Some adhesives require longer drying times before reaching full bonding strength, while others dry quickly. Porous fabrics may absorb adhesives faster, resulting in quicker drying times.

If the fabric item will be subjected to washing or cleaning, choose an adhesive method that is washable. Some adhesives can withstand machine washing, while others may require hand washing or dry cleaning.

Lastly, consider the durability requirements of your project. For frequent use or harsh conditions, choose an adhesive method that can withstand wear and tear. Stronger adhesives or reinforcing the bond with sewing techniques can ensure longevity.

Following Instructions and Guidelines for Optimal Results

Whether you’re a seasoned professional or a novice in your field, following instructions and guidelines is the key to unlocking optimal results. In this passage, we will explore how adhering to instructions and guidelines can lead to success, empowering you to reach new heights of excellence. So, let’s dive in and uncover the secrets of achieving greatness through meticulous guidance.

Clarity and Precision:

Instructions and guidelines provide us with a roadmap, illuminating the path towards our desired destination. By following them diligently, we ensure that every step is executed with clarity and precision. These carefully crafted directions act as a compass, guiding us through complex tasks and helping us avoid potential pitfalls. With each instruction we follow, we inch closer to our goal, building a solid foundation for success.

Efficiency and Productivity:

Instructions and guidelines are not mere suggestions; they are time-tested strategies for achieving efficiency and productivity. By adhering to these principles, we streamline our processes, maximizing our output while minimizing errors. Clear instructions enable us to work smarter, not harder, ultimately saving valuable time and resources. In embracing these guidelines, we unlock our potential to accomplish more in less time.

Consistency and Quality:

Instructions and guidelines serve as benchmarks for consistency and quality. They set the standard by which our work is evaluated and ensure that each task is executed with precision. By following these principles consistently, we establish a reputation for excellence, earning the trust of our peers and clients alike. Optimal results are not achieved through haphazard actions; they are the product of meticulous adherence to established guidelines.

Safety and Risk Mitigation:

Instructions and guidelines are not limited to enhancing performance; they also prioritize safety and mitigate risks. Whether it’s in the workplace or everyday life, following safety protocols ensures the well-being of individuals and minimizes the chances of accidents or mishaps. By adhering to these guidelines, we create a secure environment that fosters confidence, allowing us to focus on achieving exceptional results.

Continuous Improvement:

Instructions and guidelines provide a framework for growth and development. They act as a springboard for innovation, inspiring us to seek better solutions and refine our processes. By evaluating our performance against established standards, we identify areas for improvement and implement necessary changes. Embracing this iterative approach enables us to constantly evolve, pushing the boundaries of what we can achieve.

YlaoksuACO0″ >

Also Read: Can I use normal glue to stick fabric?

Conclusion

When it comes to permanently gluing fabric together, there are a few tried and true methods that can ensure a strong bond.

One option is using fabric glue, which is specifically designed for this purpose. It’s easy to apply and dries clear, creating an invisible seam.

Another option is using fusible web or tape, which requires heat activation to bond the fabric layers together. This method is great for projects that involve ironing.

If you prefer a more heavy-duty approach, you can use epoxy adhesive or super glue. These types of adhesives create an incredibly strong bond but require careful application to avoid any damage to the fabric.

Whichever method you choose, make sure to read and follow the instructions carefully for best results.