Have you ever poured your heart and soul into a DIY project, only to have it ruined by a sudden downpour or accidental splash? It’s enough to make you want to throw in the towel. But fear not, because we’ve got the solution to your water-resistant woes – and it all starts with PVA glue.

PVA glue is a staple adhesive for many crafting and home improvement projects due to its strength and versatility. However, its Achilles heel is its vulnerability to water. Luckily, there are several methods you can use to make PVA glue resistant to moisture.

In this blog post, we’ll take you on a step-by-step journey of how to create water-resistant PVA glue. We’ll explore various techniques and materials that you can use, including additives like silicone, acrylic, or latex. Plus, we’ll share some insider tips and tricks for applying the waterproof glue effectively.

Whether you’re building a wooden boat, sculpting a garden masterpiece, or simply constructing a kitchen shelf, our guide will help you protect your creations from the elements. So sit back, relax (but not too much), and read on as we reveal the secret recipe for making PVA glue water-resistant.

What is PVA Glue?

Contents

PVA glue, also known as white glue, school glue, or carpenter’s glue, is a versatile adhesive that has become a staple in many households and classrooms. Made from polyvinyl acetate, PVA glue is a popular choice for its ease of use and ability to bond various surfaces together.

One of the major benefits of PVA glue is its ability to dry clear, making it an excellent choice for projects where the glue line needs to be invisible. It’s also water-soluble, which means that it’s easy to clean up with water. However, this also means that it’s not naturally waterproof and can be washed away when exposed to water.

But fear not. There are ways to make PVA glue more water-resistant. You can add certain additives to the glue, which create a chemical reaction that makes it more resistant to water. Acrylics, vinyl acetate ethylene (VAE), and urea formaldehyde resin are commonly used additives that can make PVA glue more flexible or durable.

It’s important to note that adding these additives can change the properties of the glue. For example, adding acrylics can make the glue more flexible but slower to dry. So it’s crucial to choose the right additive based on your specific needs.

There are also different methods you can use to make PVA glue water-resistant. You can mix in a small amount of silicone caulk or waterproofing powder into the PVA glue, apply a waterproof sealant over the top of the dried PVA glue, or even mix in a small amount of acrylic paint.

However, keep in mind that while these methods can help make PVA glue more water-resistant, they may also affect its bonding strength. So before using them on a larger project, it’s essential to test any modifications on a small sample first to ensure that they won’t compromise the integrity of the glue bond.

The Need for Water Resistance

Without it, PVA glue can easily lose its adhesive properties and structural strength when exposed to moisture. This shortcoming can pose a severe disadvantage in many applications where longevity and durability are paramount.

For instance, woodworking projects demand sturdy and dependable bonds that can withstand exposure to moisture and humidity. Lacking water resistance, PVA glue joints can weaken or fail over time, jeopardizing the structural integrity of the entire project. Similarly, bookbinding requires glue that can endure repeated handling and exposure to moisture without deteriorating or losing its adhesive properties.

Apart from structural concerns, water resistance is also vital for aesthetic purposes. PVA glue that is not water-resistant can become cloudy or hazy when exposed to water, thereby diminishing the clarity and transparency of the glue line. This effect can be undesirable in applications where the glue joint is visible or requires a clear and glossy finish.

Adding a Waterproofing Agent to the Glue

Adding a waterproofing agent to your PVA glue can be the solution you’ve been searching for. With a variety of options available on the market, including silicone, wax, and acrylic polymers, it’s important to choose the right one for your project.

Silicone is a popular choice for its ability to withstand extreme temperatures and provide excellent protection from moisture. When mixed thoroughly with PVA glue, it creates a barrier that repels water, ensuring that your project stays strong and adhesive.

Wax is another option for making PVA glue water-resistant. It creates a protective layer on the surface of the glue that prevents water from penetrating it. However, be aware that wax can alter the color and texture of the final product, so it’s crucial to test it before using it on a large scale.

Acrylic polymers are also highly effective at making PVA glue water-resistant. They form a protective layer on the surface of the glue that repels water and provides exceptional durability and resistance to UV light. This makes them ideal for outdoor applications.

To ensure optimal results, follow the manufacturer’s instructions closely when adding a waterproofing agent to your PVA glue. Adding too much or too little can affect its performance and lead to problems with adhesion or durability. Additionally, it’s crucial to test your waterproofed glue before using it on a large scale, ensuring it meets your specific needs and requirements.

Applying a Waterproof Sealant Over the Glue

This common method creates a protective barrier over the glue, preventing water from penetrating the surface and weakening the bond.

To ensure the best results, it’s crucial to wait until the glue has fully dried before applying a waterproof sealant. This step typically takes around 24 hours, depending on the thickness of the glue and environmental conditions. Once dry, you can use a brush or spray to apply the sealant evenly over the surface.

There are various types of waterproof sealants available, such as silicone-based, polyurethane-based, and epoxy-based sealants. Each type has its unique properties and application methods, so be sure to choose the right one for your project.

It’s important to follow the manufacturer’s instructions carefully when applying a waterproof sealant over PVA glue. Doing so will ensure that you achieve the best results and that the bond remains strong and durable over time. Keep in mind that some sealants may require multiple coats to achieve full water resistance.

Mixing in Acrylic Paint

As an expert in mixing acrylic paint and PVA glue, I can share with you some tips on how to achieve the perfect balance for your project.

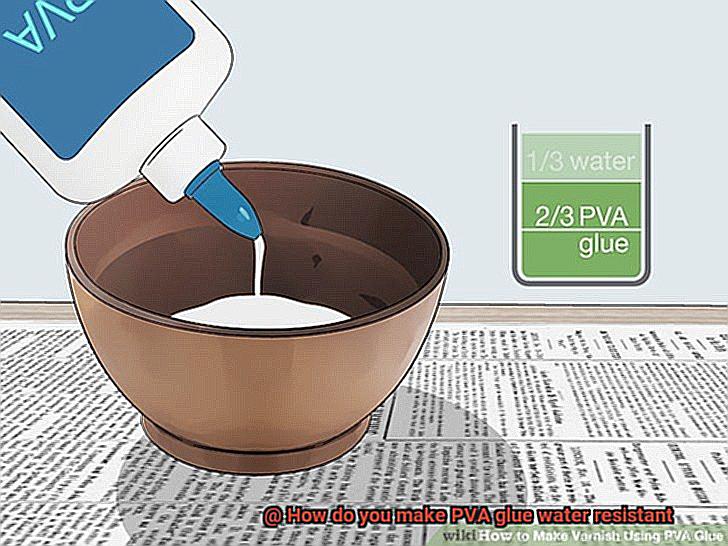

Acrylic paint is naturally water-resistant, making it a great addition to PVA glue. To get started, add a small amount of acrylic paint to your PVA glue and mix it thoroughly. It may take some experimentation to find the right amount of paint – too much can make the glue too thick and difficult to work with.

Once you’ve achieved the desired level of water-resistance, use your new glue as you normally would. However, keep in mind that while this method can make your glue more resistant to water damage, it may not make it completely waterproof. If you need a completely waterproof adhesive, consider using a different type of glue altogether.

To mix acrylic paint and PVA glue:

Step 1: Gather Your Materials

You’ll need PVA glue, acrylic paint, and a mixing bowl or container.

Step 2: Mix the Acrylic Paint and PVA Glue

Add a small amount of acrylic paint to your PVA glue and mix it well. Experiment with the amount of paint until you find the right balance.

Step 3: Test Your Mixture

Test your mixture on a small area before using it on your project to ensure that it has the desired level of water-resistance.

Step 4: Use Your Water-Resistant Glue

Once you’ve found the perfect balance, use your newly mixed glue as you normally would.

Testing Modifications Before Use

There are a variety of modifications that can be made to achieve this, but before you start mixing and experimenting, it’s crucial to test them out.

Testing modifications before use is the key to ensuring that your PVA glue is water-resistant. One way to do this is by applying the modification on a small surface and allowing it to dry completely. After it has dried, expose it to water or moisture. This will allow you to observe how well the glue resists water and determine if your modification has been successful.

Comparing the modified glue with regular PVA glue is another important aspect of testing modifications. Apply both types of glue on different surfaces and expose them to water or moisture. By doing this, you can observe the differences in their water-resistant properties and determine which modification works best for your needs.

It’s important to note that not all modifications work for every project or surface. Therefore, testing each modification thoroughly before using it on a larger scale is crucial to avoiding any potential issues. Imagine completing an entire project with a modification that does not work as expected; it would be a waste of time, effort, and resources.

RTS_hPXzrBk” >

Also Read: Is white glue waterproof when dry?

Conclusion

In conclusion, PVA glue is a versatile adhesive that has become a household and classroom staple. However, its vulnerability to water can be a significant disadvantage in applications where longevity and durability are crucial. Fortunately, there are several methods you can use to make PVA glue resistant to moisture.

By adding certain additives like silicone, acrylic or latex to the glue, you create a chemical reaction that makes it more resistant to water. You can also apply a waterproof sealant over the top of the dried PVA glue or even mix in a small amount of acrylic paint. But remember, always test any modifications on a small sample first before using them on a larger project.

Water resistance is not only essential for practical purposes but also for aesthetics. Non-water-resistant PVA glue can become cloudy or hazy when exposed to water, diminishing the clarity and transparency of the glue line.

Overall, modifying PVA glue with waterproofing agents or applying waterproof sealants over it provides exceptional durability and resistance to UV light. This makes them ideal for outdoor applications such as building wooden boats or constructing kitchen shelves. With our guide’s help, your creations will withstand the elements and last for years to come.