Have you ever worked with epoxy only to discover a rock-hard blob in your mixing container or on a surface you wanted to reshape? It’s frustrating, but don’t throw it away just yet. Epoxy is a versatile substance that can be liquified and reused with the right methods and tools.

In this article, we’ll guide you through the process of liquifying hardened epoxy, whether it’s a small amount of leftover material or a larger hardened surface that needs repair. We’ll cover the basics of epoxy chemistry and how it hardens, the common reasons for epoxy to become hard, and the materials and equipment needed for the job.

From heating and melting to using solvents and scraping, we’ll explore different approaches for liquifying epoxy, along with their pros and cons. By the end of this article, you’ll have all the knowledge and techniques necessary to restore your epoxy to its liquid state. So grab your tools and let’s get started.

What is Hardened Epoxy?

Contents

If you’re in the construction, automotive, or electronics industries, you’ve probably worked with epoxy before. This two-part adhesive forms an exceptionally strong bond, but sometimes it can cure too quickly, resulting in hardened epoxy that’s tough to remove or alter. But fear not, there are ways to liquify hardened epoxy.

Hardened epoxy is epoxy that has cured and become hard and solid. Once it has hardened, it can be challenging to remove or alter without damaging the underlying surface. However, with the right tools and techniques, it can be liquified.

One of the most popular methods for liquifying hardened epoxy is using heat. Heat can soften the epoxy and make it easier to remove. You can use a heat gun or propane torch to apply heat to the hardened epoxy. It’s important to hold the heat source about 6 inches away and move it back and forth until the epoxy softens. Caution must be exercised not to overheat the epoxy as this can cause it to burn or emit toxic fumes.

Another method for liquifying hardened epoxy is using solvents such as acetone, alcohol, or vinegar. Apply the solvent directly to the hardened epoxy and let it sit for several minutes before using a scraper or putty knife to gently remove the softened epoxy.

A third method for liquifying hardened epoxy is using mechanical means like sanding or grinding. This method involves physically breaking up the hardened epoxy using tools such as a chisel, hammer, or drill. However, this method may also damage the surface underneath the epoxy.

It’s crucial to wear protective equipment like gloves and goggles when working with any method of liquifying hardened epoxy. Proper ventilation should also be used when working with solvents or heat sources.

Why Do You Need to Liquify Hardened Epoxy?

Epoxy is a popular material among DIYers and professionals alike for its versatile uses. However, once it hardens, it can become an unwelcome challenge. This is where the need to liquify hardened epoxy comes in, and it’s an essential process for anyone who works with this type of material.

Here are three reasons why you need to liquify hardened epoxy:

- Easier Cleanup: Removing hardened epoxy from surfaces, tools, or equipment can be a frustrating and time-consuming task. Liquifying it makes cleanup a breeze by allowing for easy removal of the material.

- Adjustments and Repairs: Sometimes adjustments or repairs may be necessary to an existing epoxy application. Liquifying the hardened material can make this process much easier and efficient.

- Reuse Excess Material: If you’ve ever mixed too much epoxy and didn’t want to waste the excess, liquifying it allows you to use it again for future projects instead of throwing it away.

Method 1: Using Heat

We all know that epoxy can be a DIYer’s dream, but once it hardens, it can become a nightmare. Luckily, there is a great solution to this problem: heat.

Using heat is one of the most common methods for liquifying hardened epoxy. By applying heat to the hardened epoxy, it softens and becomes more pliable, allowing you to remove or rework it as desired. But how exactly do you use heat in this process? Let’s dive in.

To begin with, you will need a suitable heat source such as a heat gun, propane torch, or hot water. Whichever heat source you choose, make sure to position it at a safe distance from the epoxy to prevent overheating or damage to surrounding materials.

If you opt for a heat gun or propane torch, start by setting the tool to a low temperature and holding it about 6 inches away from the hardened epoxy. Move the tool back and forth over the epoxy evenly until it begins to soften. Overheating the epoxy can cause it to bubble or burn, so be careful.

Alternatively, if you choose hot water, boil a pot of water and pour it into a container that’s large enough to hold the hardened epoxy. Place the epoxy into the container and let it soak in the hot water for several minutes. The heat from the water will soften the epoxy, making it easier to remove or rework.

It’s essential to keep safety in mind when using heat. Always wear protective gloves and eyewear when working with hot materials and follow all safety precautions recommended for your specific heat source.

Method 2: Using Solvents

In our previous section, we talked about using heat to soften hardened epoxy. Today, we’ll be discussing another effective method: using solvents.

Solvents are a popular choice for removing hardened epoxy because they work by breaking down the bond between the hardened epoxy and the surface it’s attached to. There are several solvents you can use, including acetone, alcohol, and vinegar.

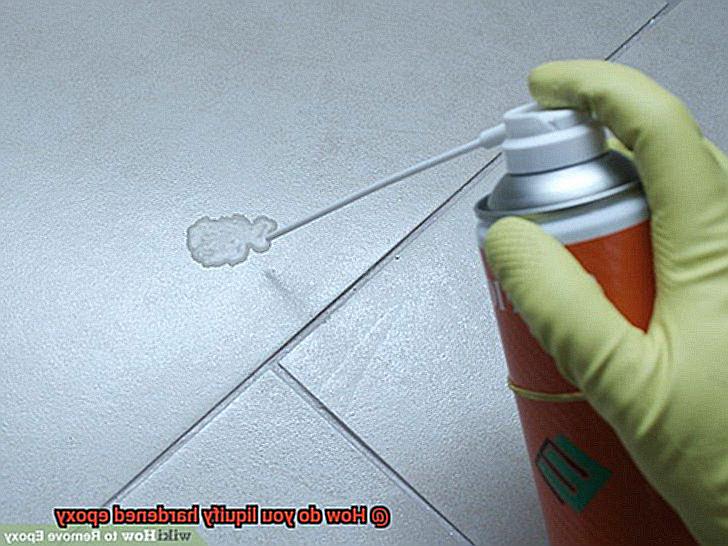

Acetone is a potent solvent that can dissolve hardened epoxy quickly. It’s readily available in most hardware stores and is simple to use. To use acetone, pour it onto the hardened epoxy and let it sit for a few minutes. The acetone will dissolve the epoxy, making it soft and pliable. Once the epoxy has become soft, you can scrape it off with a plastic scraper or wipe it away with a cloth.

Alcohol is a gentler alternative to acetone and is less likely to damage the surface underneath the hardened epoxy. You can use isopropyl alcohol or rubbing alcohol for this purpose. To use alcohol, soak a cloth in it and place it over the hardened epoxy. Let the cloth sit for a few hours or overnight until the epoxy has become soft and pliable. Once soft, scrape it off with a plastic scraper or wipe it away with a cloth.

Vinegar is another safe and natural alternative to harsher solvents like acetone and alcohol. It works by breaking down the bond between the hardened epoxy and the surface it’s attached to. To use vinegar, soak a cloth in it and place it over the hardened epoxy. Let it sit for several hours or overnight until the epoxy has become soft and pliable. Once soft, scrape it off with a plastic scraper or wipe it away with a cloth.

When working with solvents to liquify hardened epoxy, safety should always come first. Protective gloves should be worn, and work should be done in a well-ventilated area. Solvents can be harmful if ingested or inhaled, so it’s important to follow safety precautions when using them. Test the solvent on a small, inconspicuous area before using it on a larger area to ensure it doesn’t damage the surface underneath the hardened epoxy.

Method 3: Mechanical Means

If you’re dealing with a small area of hardened epoxy or just want to remove some excess epoxy after a repair job, this method could be perfect for you.

Mechanical means involve using physical force or energy to liquify hardened epoxy. There are several techniques available, each with its own advantages and challenges.

The first method is by using a scraper or chisel. This method involves scraping off the hardened epoxy layer by layer until it becomes soft and malleable. It is important to use caution when using this method as it can damage the underlying surface if done too aggressively. But with a gentle hand, it can be an effective way to remove small areas of hardened epoxy.

Another mechanical means is by using a heat gun or blowtorch. Applying heat to the hardened epoxy until it becomes soft and pliable can effectively remove it. However, be mindful not to use too much heat as it can cause the epoxy to bubble or burn. Protective gear such as gloves and goggles are essential when using a heat gun or blowtorch.

The third mechanical means is sanding. Sanding involves using sandpaper or a sanding disc to remove the hardened epoxy layer by layer until it becomes soft and malleable. This method may take longer than other mechanical means, but it is effective in removing large areas of hardened epoxy.

It’s important to remember that while mechanical means may be effective in liquifying hardened epoxy, they may also damage the underlying surface. Therefore, exercise caution when choosing the appropriate technique for your project. If you’re working on a delicate surface, a scraper or chisel may not be suitable. Instead, sanding might be the best method for you.

Safety Considerations for Liquifying Hardened Epoxy

Before you dive in, remember that safety should always be the top priority. Here are some important safety considerations for liquifying hardened epoxy.

Firstly, ensure you are working in a well-ventilated area. The fumes from epoxy can be harmful if inhaled in large quantities, so make sure to have proper ventilation. Additionally, wearing protective goggles and gloves is essential to prevent any accidental contact with the skin or eyes.

When selecting a method for liquifying hardened epoxy, it’s important to consider the type of epoxy you’re dealing with. Not all methods may be suitable for certain types of epoxy, and using the wrong method could result in damage to the material or even injury.

One common method for liquifying hardened epoxy is using heat. However, this can be dangerous if not done properly. Overheating the epoxy can cause it to ignite or release harmful fumes. To use this method safely, place the hardened epoxy in a container and heat it with a heat gun or blowtorch, taking care not to overheat it.

Another option is using a solvent like acetone or methyl ethyl ketone (MEK). While this method can be effective, some solvents can be flammable and should be used with caution. Soaking the hardened epoxy in a solvent until it softens can help remove it from surfaces.

Pros and Cons of Different Methods for Liquifying Hardened Epoxy

If you’ve ever dealt with hardened epoxy, you know how frustrating it can be. Luckily, there are several methods for liquifying it, each with its own set of pros and cons.

One popular method is using heat to soften the epoxy. A heat gun or hair dryer can be used to apply heat directly to the hardened epoxy, making it easy to scrape away. This method is quick and relatively easy, but it can be dangerous if not done properly. The heat source needs to be used carefully to avoid damaging surrounding materials or starting a fire.

Another method is using solvents such as acetone, alcohol, or vinegar. These are readily available and can be less dangerous than using heat. They dissolve the epoxy by breaking down its chemical bonds. However, some solvents may not be effective on all types of epoxy, and they may require special handling or disposal.

A third method is using mechanical abrasion, such as sanding or grinding. This method involves manually removing the epoxy and doesn’t require any special equipment. However, it can be time-consuming and may require a lot of effort to remove the epoxy completely.

So which method is best? It depends on your specific situation. If you need to remove small amounts of epoxy quickly and safely, using heat may be your best bet. But if you have larger amounts of epoxy or need to remove it from porous surfaces, solvents may work better. And if you’re willing to put in the effort, mechanical abrasion can be an effective option.

Conclusion

In conclusion, working with epoxy can be a DIYer’s dream until it hardens and becomes an unyielding obstacle. However, there’s no need to throw away your hardened epoxy just yet. With the right methods and tools, you can liquify it and give it a new lease on life.

This article has delved into the basics of epoxy chemistry, common reasons for its hardening, and the materials and equipment needed for the job. From heating and melting to using solvents and scraping, we’ve explored different approaches for liquifying epoxy along with their pros and cons.

Heat is one of the most popular methods for softening hardened epoxy; it’s simple and effective. Solvents like acetone, alcohol or vinegar can also do the trick but require proper ventilation due to their fumes. Mechanical means such as sanding or grinding are another option but may damage the surface beneath.

It’s crucial to wear protective gear like gloves and goggles when working with any method of liquifying hardened epoxy. Safety considerations must always come first.

Knowing how to liquify hardened epoxy is an essential skill for anyone who works with this type of material.