Picture this: you’re whipping up a delicious batch of homemade treats, ready to impress your friends and family. But hold up. Before you dive into that shiny, smooth epoxy resin coating for your edible creations, there’s an important question you need to ask yourself: is it really food safe?

Sure, epoxy resin is like the superhero of crafting materials – strong, durable, and versatile. But when it comes to direct contact with food and drinks, we can’t afford to take any chances with our health. That’s why understanding how to determine if your epoxy resin is truly food safe is absolutely essential.

In this blog post, we’re going to break it down for you. We’ll explore the key factors that go into evaluating the safety of epoxy resin for food contact.

So, whether you’re a DIY enthusiast or a pro working on food-related projects, get ready to arm yourself with the knowledge you need to protect those taste buds and keep everyone happily munching away. Let’s dig in.

What is Epoxy Resin?

Contents

Epoxy resin, a synthetic material renowned for its adhesive and coating properties, presents a world of possibilities across various industries.

Whether you’re an artist seeking to create captivating masterpieces or a construction professional in need of a reliable bonding agent, epoxy resin is a versatile solution worth exploring. In this article, we will delve into the fascinating properties of epoxy resin and its vast range of applications.

Understanding the Power of Epoxy Resin:

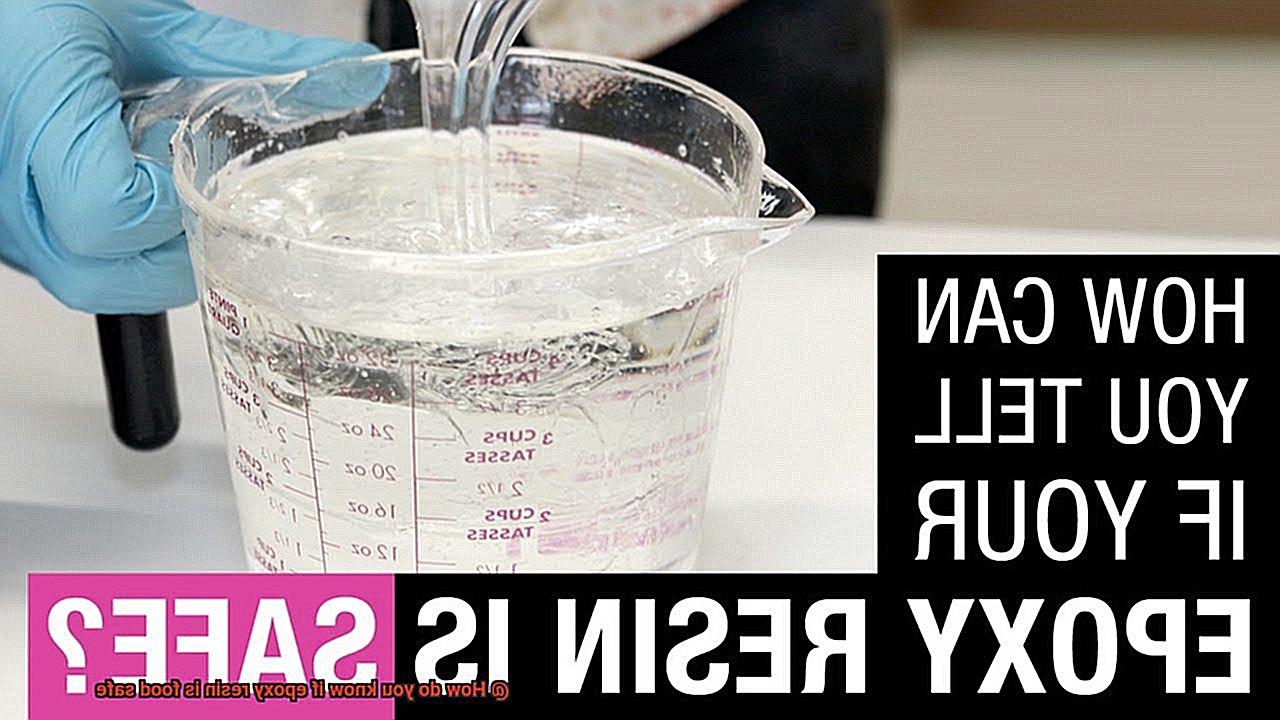

Composed of two key components – a resin and a hardener – epoxy resin undergoes a chemical reaction upon mixing, resulting in a resilient and durable material. Excitingly, this adhesive possesses exceptional adhesion capabilities, boasts high strength, and exhibits resistance against harsh chemicals and moisture.

Unleashing Creativity with Crafts and Artistic Endeavors:

Epoxy resin has rapidly gained popularity in the crafts and art world, enticing enthusiasts with its ability to produce stunning finishes and unique designs. Its self-leveling properties make it ideal for creating glossy, smooth surfaces that showcase the beauty of embedded objects or pigments.

From crafting jewelry and coasters to designing eye-catching tabletops and awe-inspiring artwork, epoxy resin elevates artistic creations to new heights.

Constructing with Confidence in the Construction and Automotive Industries:

The construction industry has embraced epoxy resin as a trusted bonding agent for concrete repairs and as an enduring coating for floors. Its remarkable durability enables it to withstand heavy traffic, chemicals, and abrasion, making it an ideal choice for high-performance flooring solutions. Moreover, epoxy resin plays a vital role in automotive repair and restoration projects by effectively bonding diverse materials together.

Empowering Electronics and Industrial Applications:

In the electronics industry, epoxy resin proves invaluable as an encapsulating material for protecting electronic components against moisture, heat, and mechanical stress. Its exceptional insulating properties make it an optimal choice for circuit boards and electrical systems. Furthermore, epoxy resin finds extensive use in industrial settings for sealing joints, repairing machinery parts, and creating protective coatings.

Ensuring Safety in Food-Safe Applications:

While not all epoxy resins are suitable for food-related applications, specially formulated food-safe epoxy resins offer a solution. These resins adhere to strict safety standards and regulations, ensuring that they do not leach harmful substances into food. From coating countertops and creating food-grade molds to sealing wooden cutting boards, food-safe epoxy resins provide a reliable and safe option.

Potential Contamination from Harmful Chemicals or Additives

Glue – it’s everywhere, holding our world together. But what if I told you that some glues, like epoxy resin, could potentially pose a risk to your health when used in food-related applications? Let’s dive deeper into the potential dangers of contamination from harmful chemicals or additives in epoxy resin and how you can protect yourself.

Contamination Risks:

Epoxy resins are commonly used to coat or seal food containers and create molds for culinary creations. However, not all epoxy resins are created equal when it comes to food safety. Here are the potential risks of contamination:

Bisphenol A (BPA) – One major concern is BPA, a chemical found in plastics and epoxy resins. BPA has been linked to hormone disruption and reproductive problems. Choosing the right epoxy resin is crucial.

Safety Measures:

To reduce the risk of contamination, follow these safety measures:

- Choose Food-Safe Resins – Opt for epoxy resins specifically labeled as “food-safe” or “food-grade.” These resins have undergone rigorous testing and meet safety standards for direct contact with food. Check the ingredients list for BPA or other questionable substances.

- Certifications Matter – Look for epoxy resins certified by reputable organizations like the FDA or EFSA. These certifications provide an extra layer of assurance that the resin is safe for food-related applications.

- Follow Instructions – Always follow the manufacturer’s instructions carefully. Mixing ratios, curing times, and application methods play a vital role in ensuring proper curing and avoiding potential contamination.

- Consider Limitations – Even with food-safe epoxy resin, there may be limitations. Some resins may not be suitable for high temperatures or prolonged exposure to acidic foods. Always refer to the manufacturer’s recommendations for temperature and food compatibility.

The Curing Process of Epoxy Resin

When it comes to food-safe applications, gluing things together becomes a critical task. A crucial factor to consider in this process is the curing process of epoxy resin. In this article, we will dive deep into the captivating world of epoxy resin curing and its significance in ensuring food safety.

Understanding the Curing Process:

The curing process of epoxy resin involves a magical transformation. Epoxy resins consist of two main components – a resin and a hardener. When these components are mixed in specific ratios, a chemical reaction called polymerization occurs. This reaction takes the liquid mixture and turns it into a solid state, creating a durable material with incredible bonding properties.

Methods of Curing:

The curing process can be expedited by applying heat or can occur at room temperature through exposure to air. The choice of method depends on the type of epoxy resin being used. It is essential to follow the manufacturer’s instructions for optimal curing time and conditions, ensuring that the resin reaches its full potential.

Volatile Organic Compounds (VOCs):

As the curing process takes place, any volatile organic compounds (VOCs) present in the epoxy resin may evaporate. VOCs are chemicals that have the potential to pose health risks if inhaled or ingested. To ensure food safety, selecting epoxy resins with low VOC content is crucial, as it reduces the chance of harmful substances leaching into the food.

Impact on Physical Properties:

The curing process plays a pivotal role in determining the final physical properties of epoxy resin. It affects factors such as hardness, durability, and resistance to chemicals and moisture. Through proper curing, epoxy resin forms a strong and stable bond, making it ideal for applications involving direct contact with food.

Cleaning After Curing:

Once the epoxy resin has completed its curing journey, thorough cleaning is essential. This step removes any residual chemicals or contaminants that may be present on the surface. By diligently cleaning the cured epoxy resin, you ensure that it is safe for food contact, providing peace of mind for the end-user.

Look for Food-Safe Labels and Certifications

When it comes to shopping for food, it is important to prioritize food safety. One way to ensure the safety of a food product is to look for food-safe labels and certifications. These labels and certifications indicate that the product has met certain standards and can be safely consumed.

One important label to look for is “FDA-approved.” The FDA (Food and Drug Administration) is a regulatory agency in the United States that sets standards for food safety. If a product is FDA-approved, it means that it has met the requirements set by the FDA and can be safely consumed.

Another label to look for is “food-grade.” This label indicates that the product is specifically formulated and tested to be safe for contact with food. It ensures that the materials used in the product do not leach harmful substances into the food.

In addition to these labels, there are other certifications that can provide assurance of food safety. One such certification is the NSF International certification. This certification ensures that a product meets specific standards for food safety and is widely recognized and trusted in the food industry. Products with this certification have undergone rigorous testing and meet high standards of safety.

It is important to note that not all products with food-safe labels or certifications are suitable for all types of food contact. Some products may be labeled as food-safe but are intended for indirect contact with food, such as lining the interior of beverage containers or coating utensils. It is crucial to read the product description and instructions carefully to ensure that the product is suitable for your intended use with food.

If you have any doubts or questions about the safety of a particular food product, it is always a good idea to contact the manufacturer directly. They should be able to provide you with more information or clarification on the safety of their product.

Following Proper Application and Handling Guidelines

Epoxy resin is a vital component in food-related applications, from coating countertops to creating food-safe molds. However, to ensure the safety and integrity of your culinary creations, it is crucial to follow proper application and handling guidelines when working with food-safe epoxy resin. This comprehensive guide will walk you through the importance of these guidelines and provide essential tips for successful usage.

Choosing Food-Safe Epoxy Resin:

The first step in following proper guidelines is selecting a food-grade epoxy resin. These specialized formulations are devoid of harmful substances that could compromise your food’s quality. When shopping for epoxy resin, look for labels such as “food-safe” or “FDA-approved.” These labels serve as beacons of trust, assuring you that the product has undergone rigorous testing and meets all necessary requirements for safe usage with food.

Application and Handling Instructions:

To maximize safety and durability, it is vital to follow the manufacturer’s instructions for application and handling. These instructions encompass mixing ratios, curing times, recommended temperature ranges, and more. By carefully reading and adhering to these guidelines, you can ensure optimal results and maintain the food safety of your epoxy resin coating.

Ventilation and Safety Measures:

During the curing process, epoxy resin emits fumes that can be harmful if inhaled in high concentrations. Therefore, it is essential to work in a well-ventilated area. Consider utilizing additional ventilation equipment like respirators or exhaust fans to safeguard yourself from these fumes. Prioritizing safety measures ensures a healthy environment during the epoxy resin application process.

Surface Preparation:

Before applying epoxy resin, guarantee the surface or substrate is thoroughly clean. Eliminate any dirt, dust, or debris that could compromise the food safety of your epoxy resin coating. A pristine canvas enhances the longevity and integrity of the final result. Take the time to scrub away any contaminants and create an ideal foundation for your glossy finish.

Regular Inspections and Maintenance:

Once the epoxy resin has cured, regular inspections are crucial to spot any signs of damage. Chips or cracks in the coating can potentially contaminate food. Promptly repair or replace any damaged areas to maintain food safety standards. Regular maintenance ensures the longevity and effectiveness of your epoxy resin coating.

Inspecting the Epoxy Resin for Wear or Degradation

This versatile and durable glue is commonly used in food contact materials such as cutting boards, countertops, and food storage containers. However, like any material, epoxy resin can degrade over time, potentially posing health risks. In this guide, we will walk you through the crucial signs of wear and degradation to watch for when inspecting epoxy resin.

Physical Damage – A Clear Red Flag:

The first step in inspecting epoxy resin is to check for physical damage on the surface. Cracks, chips, or scratches are not just unsightly; they can harbor bacteria and other contaminants that compromise food safety. Additionally, physical damage weakens the structure of the epoxy resin, making it more susceptible to further deterioration.

Discoloration – A Warning Sign:

Keep a keen eye out for any unusual discoloration or yellowing of the epoxy resin. While minor color changes due to sunlight exposure or certain foods are normal, excessive or abnormal discoloration may indicate a chemical reaction or breakdown in the resin. This breakdown can result in harmful substances leaching into your food.

Flaking or Peeling – A Cause for Concern:

Inspect the surface of your epoxy resin for any signs of flaking or peeling. Ideally, the surface should remain intact and smooth, without any loose particles coming off. Flaking or peeling epoxy resin not only contaminates food but also suggests that the protective layer has worn off, leaving the underlying material exposed.

Foul Odors – A Nose Knows:

Trust your sense of smell. If you detect any unusual odors emanating from your epoxy resin, it could indicate microbial growth or chemical deterioration. Both scenarios are red flags that require immediate action to ensure the safety of your food.

Manufacturer’s Guidelines – Your Best Friend:

Always refer to the manufacturer’s instructions and guidelines for cleaning, maintenance, and care. Each epoxy resin product may require specific cleaning solutions or methods to maintain its longevity and safety. Adhering to the manufacturer’s recommendations will prevent any damage or compromise to the resin’s integrity.

Regular Inspections – Stay on Top of It:

To catch any issues early on, it is crucial to conduct regular inspections, especially for epoxy resin items used frequently with food. The frequency of inspections may vary, but a general rule of thumb is to inspect epoxy resin at least once every few months or whenever you notice changes in its appearance or performance.

23hOMH8hskk” >

Conclusion

In conclusion, the safety of epoxy resin in food-related applications cannot be overstated. It is paramount to follow proper guidelines and consider key factors to ensure that your epoxy resin is truly food safe.

First and foremost, understanding the incredible versatility and durability of epoxy resin is essential. Whether you’re using it for crafting, art projects, construction, or industrial purposes, epoxy resin offers a world of possibilities.

However, it’s crucial to be mindful of potential contamination from harmful chemicals or additives lurking in epoxy resin. Bisphenol A (BPA) is a major concern, which is why it’s vital to choose epoxy resins labeled as “food-safe” or “food-grade.” Additionally, certifications from reputable organizations like the FDA or EFSA provide an extra layer of assurance.

The curing process also plays a significant role in ensuring food safety. Proper curing eliminates volatile organic compounds (VOCs) that may pose health risks. Furthermore, it affects the physical properties of the resin, such as hardness and resistance to chemicals.

When seeking out epoxy resin for food-related applications, keep an eye out for labels and certifications indicating its safety. Look for terms like “FDA-approved” that signify adherence to specific safety standards. NSF International certification can offer additional peace of mind within the food industry.

Last but certainly not least, following proper application and handling guidelines is crucial. Choose a food-safe epoxy resin, carefully read and adhere to instructions, ensure proper ventilation during application, prepare surfaces adequately, and conduct regular inspections. These steps are all essential in maintaining food safety.