Ever wanted to combine the timeless beauty of wood with the unwavering strength of concrete? Picture this: a charming outdoor dining area, where a rustic wooden table sits atop a solid concrete base. Or imagine an accent wall adorned with reclaimed wood, adding warmth and character to a cold concrete surface. But how exactly do you glue wood to concrete?

In this gripping guide, we’ll unravel the secrets of successful wood-to-concrete adhesion. Get ready for a journey that reveals the techniques and tools needed to achieve a seamless and durable bond for your dream project.

Hook:

Imagine stepping into your backyard on a sunny afternoon, savoring your favorite drink while seated at a table that flawlessly marries nature’s elegance with unyielding strength. The allure of such an idyllic scene is enough to ignite your curiosity about gluing wood to concrete.

Main Points:

- Surface preparation: Lay the groundwork for adhesive adhesion by learning essential steps like cleaning, sanding, and priming techniques.

- Adhesive selection: Dive into the world of construction adhesives and explore which types work best for wood-to-concrete applications. Consider factors like wood type, curing time, and weather exposure.

- Application tips and tricks: Unearth professional techniques that ensure a firm and long-lasting bond. From proper adhesive distribution to utilizing clamps and supports, we’ve got you covered.

- Finishing touches: Discover how to perfect the look and feel of your wood-to-concrete masterpiece by sealing and protecting it against the elements.

Choosing the Right Adhesive

Contents

- 1 Choosing the Right Adhesive

- 2 Preparing the Surfaces

- 3 Applying the Adhesive

- 4 Securing the Bond

- 5 Allow Sufficient Curing Time

- 6 Enhancing the Bond with Mechanical Fasteners

- 6.1 Beyond the Limits of Glue:

- 6.2 Concrete Screws: A Match Made in Heaven:

- 6.3 a. Pre-Drilling for Seamless Integration:

- 6.4 Anchoring for Unyielding Strength:

- 6.5 a. Wedge Anchors: Conquering Heavyweight Battles:

- 6.6 b. Sleeve Anchors: Embracing the Power of Grip:

- 6.7 c. Drop-In Anchors: Precision and Flawlessness:

- 7 Factors Affecting Successful Glue Bonding

- 8 Professional Advice and Manufacturer Instructions

- 9 Conclusion

When it comes to bonding wood to concrete, the choice of adhesive plays a critical role in determining the strength and durability of the bond. In this article, we will delve into the importance of selecting the right adhesive and provide you with expert tips to ensure a successful wood-to-concrete connection.

Factors to Consider When Choosing an Adhesive:

- Type of Wood and Concrete: Consider the specific type of wood and concrete you are working with. Different adhesives are formulated to work best with certain materials, ensuring optimal bonding strength.

- Environmental Conditions: Assess the environmental conditions that the bonded materials will face. If your project is outdoors or in a high-moisture area, opt for an adhesive that boasts moisture resistance and can withstand harsh weather conditions.

- Intended Use: Determine the purpose of the bonded materials. If your bond will be subjected to heavy loads or stress, choose an adhesive that offers high strength and durability, ensuring it can withstand the demands placed upon it.

Adhesive Options:

- Epoxy Resin: Renowned for its exceptional bonding properties, epoxy resin is a top choice for bonding wood to concrete. This adhesive creates a robust bond capable of withstanding significant stress, making it ideal for heavy-duty applications.

- Polyurethane Adhesive: If flexibility and moisture resistance are essential, consider using polyurethane adhesive. This versatile option works equally well in indoor and outdoor settings, ensuring strong adhesion even in varying environmental conditions.

Surface Preparation:

- Cleaning: Prior to applying any adhesive, it is crucial to thoroughly clean both the wood and concrete surfaces. Remove any dust, dirt, or debris using a broom or vacuum cleaner. For added cleanliness, wipe the surfaces with a damp cloth to eliminate any lingering contaminants.

- Sanding: Enhance the bonding surface by lightly sanding the wood. This step removes roughness and imperfections, ensuring a smoother and more effective bond.

- Primer or Sealant: Consider applying a primer or sealant to the wood surface. This additional layer of protection not only improves the adhesive’s grip but also strengthens the bond, resulting in increased durability.

Preparing the Surfaces

You’re on the brink of creating something extraordinary – a seamless connection between wood and concrete. But before you embark on this transformative journey, there’s a secret you need to unlock: the art of preparing the surfaces. This pivotal step holds the key to unlocking a rock-solid bond, ensuring the longevity and strength of your project. So, gear up and let’s dive deep into the realm of surface preparation.

The Elixir of Cleanliness:

In this enchanted realm, cleanliness reigns supreme. Begin your quest by banishing all dirt, dust, and debris that dare to challenge your adhesive’s prowess. Armed with your trusty broom, brush, or vacuum cleaner, sweep away these intruders from both wood and concrete surfaces. For those stubborn stains and residues, concoct a potion of mild detergent and water to scrub your way to cleanliness. Rinse off any lingering remnants and grant the surfaces ample time to bask in the glory of complete dryness.

Sanding: Unleash the Texture Beast:

Behold. The beast that breathes life into adhesive magic – sanding. Armed with medium-grit sandpaper, awaken the rough texture that beckons superior adhesion. Caress the wood surface lightly, ensuring that areas destined for intimate contact with concrete receive extra attention. In this dance of sanding, you strip away existing finishes, smoothen rough patches, and pave the way for the adhesive to infiltrate wood fibers with unparalleled might.

Etch or Grind: Conquering Concrete’s Smoothness:

Concrete may seem invincible, but you hold the power to conquer its smooth facade. Enter two valiant warriors: etching and grinding. Enlist the aid of an acid-based solution for etching, as it unleashes its sorcery upon concrete, opening up minuscule pores. Alternatively, embrace the mechanical prowess of grinders and sanders to roughen up the concrete’s stoic surface. Whichever path you choose, armor yourself with safety precautions and protective gear, for this battle demands nothing less.

Applying the Adhesive

In our previous adventure, we unraveled the mysteries of surface preparation and discovered the power of bonding. Today, we shall delve deeper into the enchanting world of applying adhesive, forging an unbreakable union between wood and concrete. Prepare to witness the magic unfold as we unveil the steps to achieve a rock-solid connection. So gather your brooms, trowels, and a sprinkle of curiosity – let us embark on this captivating journey.

Step 1: The Purity Ritual

Before we embark on this bonding quest, purity must reign supreme. Take up your trusty broom, vacuum, or damp cloth and banish any traces of dust, dirt, or debris from both wood and concrete. This sacred act ensures direct contact between the materials, laying the groundwork for an unyielding bond. Remember, cleanliness is the secret ingredient to success.

Step 2: Choosing the Perfect Potion

Ah, the heart of our mystical journey – selecting the ideal adhesive for our mission. With options like epoxy, construction adhesive, and polyurethane adhesive at our disposal, we must consider our project’s unique requirements. Will it face harsh conditions? Must it bear a heavy burden? Consult the manufacturer’s instructions and choose an adhesive capable of handling the magical fusion of wood and concrete.

Step 3: The Brushstroke of Precision

With our chosen adhesive in hand, it is time to work our sorcery and apply it with unwavering precision. Whether wielding a notched trowel or brush, ensure an even distribution across both surfaces. Follow the manufacturer’s instructions diligently regarding application techniques and coverage rates – even sorcerers seek guidance.

Step 4: The Patience of a Sage

Ah, patience – a virtue revered by all mystical beings. After applying the adhesive, grant it the time it needs to cure and work its spell. Consult the manufacturer’s instructions for the specific duration required, refraining from disturbing the bond during this sacred period. Be patient, my friends, for a sturdy and enduring connection awaits.

Step 5: Fortifying the Magic

For those grappling with larger or weightier pieces of wood, a touch of extra magic may be necessary to ensure an unwavering bond. Consider employing clamps or weights to anchor the wood in place while the adhesive sets completely. This added measure of security will further solidify your connection.

Securing the Bond

Embark on an enchanting journey as we unveil the secrets to securing a bond between wood and concrete that is unbreakable. With the right techniques and materials, you can become a master in this magical art. Prepare to wield your brushes and potions, for I have gathered a collection of research notes that will guide you through the steps necessary to create a connection that will withstand the test of time. Let us unlock the power to secure the bond.

Prepare the Surfaces:

Before we delve into the realm of adhesives and enchantments, we must prepare our surfaces for the magical union. Grab your trusty brush or vacuum to banish any loose debris from both the wood and concrete. Then, with a wave of your damp cloth, wipe away any dust, dirt, or grease that may hinder our mystical connection.

Choose Your Potion Wisely:

Now that our surfaces are pristine, it is time to select the perfect adhesive potion for our task. In our magical arsenal, there are several options, each with its own unique properties. Epoxy-based adhesives possess incredible strength and resistance to moisture, making them ideal for outdoor projects or areas prone to water exposure.

Construction adhesives offer versatility and durability, while polyurethane adhesives provide excellent flexibility and resistance to temperature changes. Choose wisely, for the right potion will determine the strength of our bond.

Apply with Precision:

With our potion in hand, it is time to apply it with finesse. Following the instructions provided by the manufacturer, spread a thin layer of adhesive onto both the wood and concrete surfaces. Remember, my fellow craftsmen, even distribution is key – avoid excessive application as it may lead to weak bonds or uneven surfaces. With a swift stroke of your brush or a precise squeeze from your magical tube, let the adhesive work its enchantment.

Press for Perfection:

Now comes the crucial moment – pressing our wood and concrete together to forge an unbreakable connection. Summon your clamps or weights and secure the two surfaces tightly. This will ensure that our bond is strong and true. But beware, my friends, patience is a virtue in this magical realm. Allow the adhesive to cure for the duration specified by the manufacturer. This will grant our bond the time it needs to solidify into an unyielding force.

Allow Sufficient Curing Time

Today, we embark on a journey delving into the art of allowing sufficient curing time when gluing wood to concrete. It may not possess the allure of a masterful brushstroke or the mystique of brewing potions, but rest assured, this step holds the key to forging an unbreakable bond. Prepare your tools and let us unlock the secrets together.

Let us first unravel the enigma of “curing time.” Picture it as the magical maturation period for a spell—here, it represents the adhesive’s ascent to its pinnacle of strength and stability. Just as each spell demands a unique casting time, adhesives too possess varying curing times. Thus, heeding the manufacturer’s instructions becomes paramount, for who knows their concoctions better than they?

Traditionally, when melding wood to concrete, most adhesives mandate a minimum of 24 hours for curing. However, hold your breath. This duration dances on the whims of humidity, temperature, and adhesive type. As if under a spell, higher temperatures and lower humidity accelerate the curing process, while colder temperatures and higher humidity slow it down.

Now, prepare to be astounded—for just because the adhesive feels dry to the touch does not signify its complete cure. We’re venturing into realms of magic here, my friends. The adhesive requires ample time to seep into both wood and concrete, forging an indomitable connection. Patience becomes your ally. Hastening the process by applying pressure or stress prematurely compromises your bond—a fizzling firework rather than a dazzling display.

Yet, there is more enchantment to uncover. Allowing sufficient curing time ensures that any volatile organic compounds (VOCs) lurking within the adhesive disperse into oblivion. These VOCs, akin to elusive imps, evaporate and pose a threat if inhaled. Work your craft in well-ventilated spaces, permitting these mischievous spirits to vanish before embarking on your magical bonding quest.

Enhancing the Bond with Mechanical Fasteners

Today, we shall embark on a journey that unveils the hidden secrets of enhancing this bond using mechanical fasteners. Brace yourselves, for we are about to witness the extraordinary power of screws, anchors, and so much more.

Beyond the Limits of Glue:

While glue serves as a mighty ally in joining wood and concrete, there are moments when its strength alone may falter. When faced with heavy loads or relentless movements, it is time to summon reinforcements – the unsung heroes known as mechanical fasteners.

Concrete Screws: A Match Made in Heaven:

Concrete screws emerge as warriors crafted with utmost precision to conquer concrete with unwavering determination. With their unique thread design and hardened steel construction, they forge an unbreakable connection between wood and concrete.

a. Pre-Drilling for Seamless Integration:

To ensure a flawless alliance, one must first pre-drill pilot holes into the concrete before these screws can take their rightful place. This crucial step prevents the emergence of unwanted cracks or splits. Remember to match the diameter of the pilot hole with that of the screw, allowing for a depth slightly longer than the screw’s length.

Anchoring for Unyielding Strength:

When confronted with larger or weightier wood pieces yearning for stability, mechanical fasteners known as concrete anchors come forth as mighty saviors. These versatile heroes offer unparalleled strength and endurance.

a. Wedge Anchors: Conquering Heavyweight Battles:

In the realm of heavyweight applications, wedge anchors reign supreme. Their expansion clips seize hold of drilled holes’ walls with unrelenting fervor, ensuring a bond fortified by unmatched strength and resilience.

b. Sleeve Anchors: Embracing the Power of Grip:

Sleeve anchors, expanders within their designated holes, unleash a grip that defies even the most extraordinary forces. These anchors, with their unwavering reliability, prove ideal for a multitude of applications.

c. Drop-In Anchors: Precision and Flawlessness:

In the pursuit of perfection and seamless integration, drop-in anchors emerge as steadfast allies. Their unparalleled precision guarantees flawless positioning and a bond forged with utmost finesse.

Factors Affecting Successful Glue Bonding

In our previous endeavors, we unraveled the power of mechanical fasteners in bridging the worlds of wood and concrete. But today, we venture into a realm where strength lies in the invisible bonds created by glue. Join me as we uncover the enigmatic factors that govern successful glue bonding. So don your safety gear and let’s embark on this adhesive adventure.

Factor 1: Surface Preparation – The Pristine Canvas

Before our glue can work its magic, we must prepare a flawless canvas. The surfaces of both wood and concrete must be purged of dust, dirt, grease, or any other pesky contaminants that may hinder our adhesive’s wizardry. Embrace the brush, wield your cleaning tools, and meticulously cleanse these surfaces to create an ideal environment for a triumphant bond.

Factor 2: Porosity – Penetrating the Depths

Wood’s porous nature and concrete’s stoic resistance present us with a challenge. Fear not. We shall overcome this hurdle with the aid of specialized adhesives designed to conquer both porous and non-porous materials. Their penetrating prowess ensures a strong connection between our chosen mediums, breaking boundaries and forging an unyielding alliance.

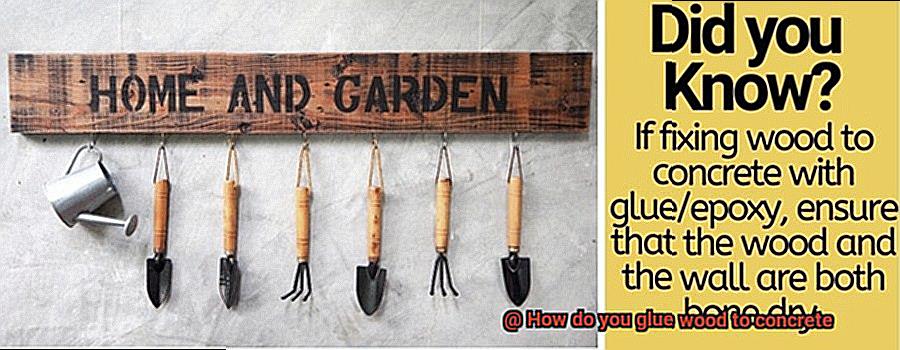

Factor 3: Moisture Content – The Delicate Equilibrium

Ah, moisture, the life force that influences our adhesive’s destiny. Too much dampness disrupts proper curing, weakening our bond. Conversely, dry materials greedily absorb moisture from our adhesive, compromising its long-term strength. Thus, we must achieve equilibrium by carefully regulating moisture levels in both wood and concrete before unleashing our glue upon them. Strive for perfection, just like Goldilocks searching for her ideal porridge.

Factor 4: Choosing the Right Adhesive – The Glue Guru’s Wisdom

In our quest for success, we must select the adhesive that holds the key to our glue bonding triumph. Epoxy, polyurethane, construction adhesive – a myriad of choices await us. But fear not, for we possess the knowledge to unearth the one specifically crafted for wood-to-concrete bonding. Delve into the depths of research, embrace the wisdom of the glue gurus, and make an informed choice that aligns with the needs of your project.

Professional Advice and Manufacturer Instructions

When it comes to gluing wood to concrete, seeking professional advice and following manufacturer instructions are essential steps for success. Let’s dive into why these resources are crucial and how they can help you achieve a strong and durable bond.

Professional Advice:

- It’s like having a glue guru by your side, guiding you through the adhesive adventure.

- Experts can provide valuable insights on choosing the right adhesive for your specific wood and concrete surfaces.

- They’ll help you avoid the pitfall of using the wrong adhesive, which can lead to weak bonds or surface damage.

- Their wisdom ensures you make an informed decision, like Goldilocks finding her perfect porridge.

Manufacturer Instructions:

- The fairy godmothers of bonding, manufacturers provide detailed instructions on using their products effectively.

- These instructions cover surface preparation, application techniques, curing times, and safety precautions.

- Following them meticulously is like sticking to a recipe – it guarantees a strong and durable bond.

Preparing the Surfaces:

- Cleaning both wood and concrete surfaces thoroughly is essential to remove dirt and debris that could hinder the adhesive’s power.

- Dry surfaces are happy surfaces. Make sure they’re dry before applying the adhesive for optimal bonding strength.

Applying the Adhesive:

- Manufacturer instructions come to the rescue again, guiding you on the specific application technique required for your chosen adhesive.

- Spread it evenly across the entire surface or go for bead-like lines or dots – every step matters in this adhesive dance routine.

Bringing Wood and Concrete Together:

- Apply even pressure when joining the materials to ensure maximum contact.

- Think of it as a tight hug between friends – the tighter, the better.

- Clamps or weights can lend a helping hand while the adhesive works its magic.

Waiting for the Cure:

- Curing times can vary depending on the adhesive and environmental conditions.

- Patience is a virtue. Allow sufficient time for the adhesive to fully cure before subjecting the bonded surfaces to stress or load.

KlELi8IaWo0″ >

Conclusion

When it comes to bonding wood and concrete together, there are a few methods you can use.

One popular option is using adhesive glue specifically designed for this purpose. These glues are formulated to create a strong bond between wood and concrete surfaces.

Another method is using epoxy resin, which can provide an incredibly strong and durable bond. This two-part adhesive requires mixing the resin and hardener together before applying it to the wood and concrete surfaces.

It’s important to ensure that both the wood and concrete surfaces are clean, dry, and free from any debris before applying any adhesive or epoxy.