Get ready to dive headfirst into the captivating realm of bonding clear plastic. Whether you’re a craft aficionado, a repair wizard, or simply someone with a creative streak, mastering the art of gluing two pieces of clear plastic together is an essential skill that will undoubtedly come in handy.

Imagine stumbling upon an acrylic display case or a mesmerizing plastic sculpture that seems magically fused without any visible signs of adhesive. You can’t help but wonder, “How on earth did they achieve such an impeccable bond?”

Fear not. In this blog post, we’ll unveil mind-blowing techniques and share invaluable tips for achieving seamless and invisible bonds when working with clear plastic.

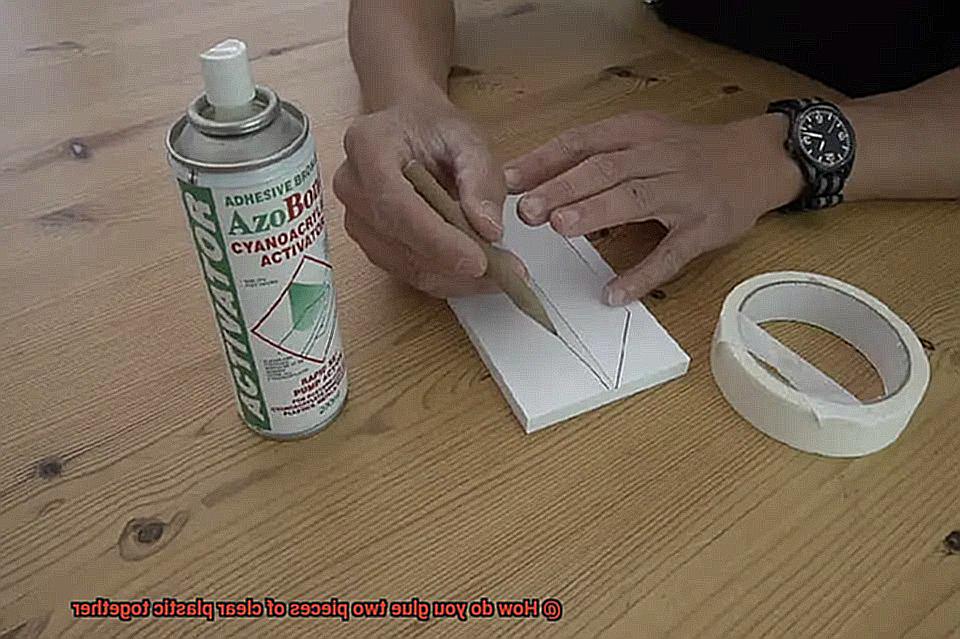

Let’s kick things off by exploring the diverse range of adhesives that work wonders on clear plastic. From cyanoacrylate glue to epoxy and specialized plastic adhesive, we’ll delve into the unique properties of each option, helping you select the perfect one for your project.

But wait, there’s more. We’ll also dive deep into the crucial preparatory steps that lay the foundation for a strong bond. We’ll emphasize the significance of clean surfaces and proper alignment while equipping you with ingenious techniques for preparing your plastic pieces like a pro.

And that’s not all. We’ll shed light on the importance of clamping and offer brilliant solutions for holding your pieces together during the curing process. Plus, we’ll discuss potential risks and how to minimize them because safety first.

So whether you’re an experienced crafter or just dipping your toes into the world of bonding plastics, grab your goggles and prepare to unravel the secrets of seamlessly gluing two pieces of clear plastic together. Get ready to astonish yourself and others as you achieve flawless joints that will make you a true DIY virtuoso.

Types of Adhesives for Gluing Clear Plastic

Contents

- 1 Types of Adhesives for Gluing Clear Plastic

- 2 Epoxy Adhesive

- 3 Silicone Adhesive

- 4 Specialized Glue for Clear Plastics

- 5 Preparing the Surfaces for Gluing

- 6 Applying the Adhesive

- 7 Other Methods of Joining Clear Plastic Pieces

- 8 Considerations When Gluing Clear Plastic Together

- 9 Testing the Adhesive on a Small Area First

- 10 Challenges in Gluing Certain Types of Plastic Together

Discovering the perfect adhesive for bonding clear plastic can be a game-changer for your projects. In this comprehensive guide, we will explore the different types of adhesives available and the safety precautions you need to consider. Let’s dive into the world of clear plastic adhesives.

Cyanoacrylate Adhesive – The Super Glue:

When it comes to bonding small areas or thin pieces of clear plastic, nothing beats the power of cyanoacrylate adhesive, often referred to as super glue. This adhesive forms an incredibly strong and transparent bond in no time. However, keep in mind that cleanliness is key – ensure the surfaces are free from dirt or grease to maximize the bond’s strength.

Epoxy Resin – A Bond That Lasts:

If you’re working with larger areas or thicker pieces of clear plastic, epoxy resin is your best bet. This two-part adhesive requires mixing before use but rewards you with a bond that is not only strong but also incredibly durable. Take the time to carefully follow the manufacturer’s instructions for application and curing, and your bond will stand the test of time.

Polyurethane Adhesive – Mastering Plastic Bonding:

When it comes to bonding plastics, including clear plastic, polyurethane adhesive takes center stage. Renowned for its high bond strength and flexibility, this adhesive is ideal for gluing clear plastic components that may be subject to movement or stress. Just ensure that you select an adhesive specifically designed for your type of plastic for optimal results.

Specialized Adhesives for Clear Plastics:

Certain types of clear plastics, such as acrylic or polycarbonate, demand specialized adhesives tailored to their unique properties. These adhesives are formulated to provide exceptional bonding strength and crystal-clear clarity. Look for two-part formulas that require meticulous mixing and application. Following the manufacturer’s instructions will help you achieve the best results with these specialized adhesives.

Surface Preparation is Key:

Before applying any adhesive, proper surface preparation is crucial for a successful bond. Thoroughly clean the plastic surfaces, removing any dirt, grease, or residue that could hinder adhesion. Some adhesives may also require roughening or sanding the surfaces to enhance the bond. Take the time to prepare the surfaces properly, and your adhesive will have a solid foundation for creating a strong bond.

Safety First:

While working with adhesives, safety should always be a top priority. Ensure you are in a well-ventilated area to avoid inhaling fumes, as some adhesives can emit strong odors. Protect your skin and eyes by wearing gloves and safety glasses. Additionally, keep adhesives out of reach of children and pets to prevent accidental ingestion or exposure.

Epoxy Adhesive

Today, we embark on an extraordinary journey into the realm of epoxy adhesive and its unrivaled ability to bond clear plastic. Whether you’re a DIY guru or an industry pro, unlocking the secrets to using epoxy adhesive is vital for achieving flawless results. So, roll up your sleeves and prepare to witness the creation of an unbreakable bond between two pieces of clear plastic.

The Mighty Epoxy Adhesive:

Prepare to be amazed by the sheer power of epoxy adhesive, a true legend in the world of adhesives. Its reputation precedes it, thanks to its exceptional bonding capabilities and impressive versatility. This dynamic duo, consisting of resin and hardener, unleashes a chemical reaction upon mixing, resulting in an adhesive that defies time itself.

Preparation: The Foundation for Success:

Before diving headfirst into the wonders of epoxy adhesive, we must ensure our canvas is pristine. Clear plastic surfaces must be stripped of any impurities such as dirt, grease, or moisture. A gentle cleanse with mild detergent and water followed by thorough drying sets the stage for an impeccable bond.

Mixing: Uniting Elements with Precision:

Embrace your inner chemist as you embark on the magical journey of mixing epoxy adhesive. Resin and hardener stand side by side, awaiting their moment to shine. Follow the manufacturer’s instructions meticulously, blending equal amounts of these two elements like a maestro conducting a symphony.

Application: Spreading the Epoxy Magic:

Now that our concoction is prepared, it’s time to put it to work. Armed with a brush or disposable applicator, we gracefully apply the epoxy adhesive to one of the surfaces. Every stroke counts as we ensure an even spread, leaving no crevice untouched. Our goal? A bond that can withstand any challenge.

Joining Forces: The Dance of Perfect Alignment:

Like two celestial bodies gravitating towards each other, bring your clear plastic pieces together with precision. Witness the beauty of perfect alignment before pressing them together firmly. The secret to success lies in applying even pressure, allowing the surfaces to connect flawlessly. And fear not, as excess adhesive may escape through the edges – a minor detail we’ll address later.

Silicone Adhesive

Hold on tight because we’re about to take a thrilling journey into the realm of this versatile adhesive.

Silicone adhesive is the superhero of clear plastic bonding. With its strength and durability, it forms an unbreakable bond that will make your clear plastic surfaces stick together like best friends. Let’s explore some key features of this adhesive and how it revolutionizes the art of bonding clear plastic.

First, let’s delve into its chemical composition. Silicone adhesive is a perfect blend of a silicone polymer base, additives, and curing agents. This unique combination offers flexibility to withstand extreme temperatures and enhances its adhesion and bonding properties.

But here’s where the magic happens – silicone adhesive dries clear and remains transparent even after curing. Wave goodbye to unsightly bonds that mar the beauty of your clear plastic surface. With silicone adhesive, your bond will be virtually invisible, allowing your plastic to shine flawlessly.

Strength and durability are the hallmarks of silicone adhesive. It forms a robust bond that can brave moisture, heat, and even UV exposure. No matter what environmental challenges your clear plastic faces, this adhesive will hold strong.

Flexibility is another superpower of silicone adhesive. It effortlessly accommodates the movement and bending of clear plastic surfaces without cracking or breaking the bond. Your plastic will remain intact and secure, no matter how much it twists and turns.

Applying silicone adhesive is a breeze. It comes in various user-friendly forms such as tubes, cartridges, or syringes. Whether you prefer a brush, spatula, or direct application, you’ll find a method that suits your needs.

Now let’s talk about curing time. Generally, silicone adhesive takes around 24 to 48 hours to reach its maximum strength. But hey, if you’re in a rush, there are fast-curing options available that significantly reduce the waiting time. Time is money, after all.

Before applying silicone adhesive, it’s crucial to prepare your surfaces properly. Cleanliness is paramount. Both surfaces should be pristine – clean, dry, and free from any dust, grease, or contaminants that could hinder adhesion. Lightly sanding the surfaces can further enhance the bond’s strength.

Specialized Glue for Clear Plastics

If you’ve ever embarked on the mission of bonding clear plastic surfaces together, you know it can be a bit of a challenge. But fret not, because we have the inside scoop on the different types of glues and their extraordinary benefits. So buckle up and get ready for a deep dive into the world of clear plastic bonding.

Let’s start our journey with the superhero of clear plastic bonding – cyanoacrylate adhesive, also known as super glue. This incredible glue is famous for its lightning-fast drying time and its ability to create an unbreakable bond. Whether you’re working with acrylic, polycarbonate, or PETG, super glue has got your back. Just remember to give those surfaces a thorough cleaning to remove any dirt, grease, or moisture. Then apply a small amount of this magic glue and hold those pieces firmly together for a few seconds. Voila. You now have a bond that is secure, quick, and as strong as steel.

Next on our list is the mighty epoxy resin adhesive. This glue requires a bit more effort as it consists of two components – resin and hardener – that need to be mixed together before application. But trust us, the extra step is worth it. Epoxy resin adhesives offer unparalleled bonding strength and are perfect for various types of clear plastics, including those that resemble glass. While they may take longer to cure compared to super glue, the result is a bond that is not only durable but also long-lasting. With epoxy resin adhesive, your clear plastics will stick together like soulmates.

If speed is what you’re after, look no further than UV-curing adhesive. This magical glue requires exposure to ultraviolet light to initiate the curing process. And boy, does it work fast. It bonds in an instant and maintains its transparency over time without any yellowing. UV-curing adhesive is a favorite choice in industries such as electronics and medical devices, where precision and clarity are of utmost importance. With this glue in your arsenal, you can achieve bonds that are not only strong but also visually stunning.

Preparing the Surfaces for Gluing

Get ready to embark on an exhilarating journey into the world of gluing clear plastic surfaces together. Buckle up because I’m about to reveal the key to achieving a bond as unbreakable as steel. But before we dive into the depths of gluing, let’s discuss the critical importance of preparing the surfaces for this epic bonding mission.

Step 1: The Power of Purity

When it comes to gluing clear plastic surfaces, cleanliness is not just a virtue, it’s an absolute necessity. Picture your surfaces indulging in a luxurious spa treatment as you eliminate every speck of dirt, dust, and grease. Grab a clean cloth or unleash the power of a mild detergent solution to wipe away any impurities and ensure a pristine surface fit for the ultimate bonding experience.

Step 2: Rough Love

Now that your surfaces are squeaky clean, it’s time to give them a tantalizing roughness that will intensify their connection. We’re not talking about a painful breakup here; we’re talking about roughening the surfaces to create an unbreakable bond. Embrace the power of fine-grit sandpaper or enlist the aid of a plastic primer specially crafted for this purpose. This step ensures that the glue adheres better and fortifies the strength of the bond. It’s like giving your surfaces a stunning makeover to make them irresistible to the glue.

Step 3: Cleanse and Purify (Again.)

After all that roughness, it’s crucial to grant your surfaces another round of cleansing. This time, we’re banishing any debris or dust that may have emerged during the roughening process. A swift swipe of a clean cloth or a burst of compressed air is all it takes. Think of it as giving your surfaces one final spa treatment before they embark on their extraordinary bonding adventure.

Step 4: Tender Loving Care (If Needed)

If your clear plastic surfaces bear any scars or imperfections, it’s time to shower them with a little TLC. Reach for a suitable plastic filler and lovingly fill in any gaps or cracks that mar their beauty. Once the filler has dried, delicately sand it down to create a flawlessly smooth surface. It’s like giving your surfaces a glamorous makeover to prepare them for their grand debut.

Applying the Adhesive

Get ready to dive into the world of gluing clear plastic surfaces together and learn the secrets of achieving a bond that’s not only strong but visually stunning. In our previous section, we discovered that cleanliness is key and roughness intensifies the connection between clear plastic pieces. Now, armed with these research notes, let’s explore how to apply adhesive like a pro.

Step 1: Cleanliness is Next to Glueliness

Before embarking on your adhesive adventure, ensure both surfaces are squeaky clean. Bid farewell to dirt, dust, and grease using a mild soap and water solution or rubbing alcohol. Give those clear plastic pieces a refreshing makeover so they become irresistible to the glue.

Step 2: Choosing the Right Adhesive

Now that your surfaces are pristine, it’s time to pick the perfect adhesive for the job. Let’s meet our three contenders: cyanoacrylate (super glue), epoxy, and acrylic adhesives. Each has its own unique qualities, so choose wisely based on your needs.

Step 3: The Magic of Cyanoacrylate Adhesive

Need speed and strength? Cyanoacrylate adhesive (super glue) is your go-to option. Apply it sparingly and evenly to avoid any unsightly excess glue. Remember, less is more.

Step 4: Embrace the Power of Epoxy

For a strong and durable bond, epoxy adhesives are your best bet. These two-part wonders consist of a resin and a hardener that must be mixed before application. While they may take longer to cure than cyanoacrylate adhesives, their strength is worth the wait.

Step 5: Unleashing the Acrylic Adhesives

Designed specifically for bonding acrylic or plastic materials, acrylic adhesives are a force to be reckoned with. These solvent-based adhesives dissolve the plastic’s surface, creating a powerful bond once the solvents evaporate. Remember to follow proper ventilation and the manufacturer’s instructions.

Other Methods of Joining Clear Plastic Pieces

In our previous discussion, we delved into the captivating world of gluing clear plastic pieces together. But did you know that there are other methods you can use to achieve a strong and visually captivating bond? Today, we’re going to explore the exciting realm of other methods of joining clear plastic pieces together. So, grab your glue guns and let’s embark on this fascinating journey.

Let’s begin with the powerful technique of heat welding. By using a heat source to melt the edges of the clear plastic pieces and then pressing them together, a bond is created that is as strong as it is durable. This method is the go-to choice in industries like automotive and electronics, where strength and reliability are paramount.

Next on our list is solvent bonding. This method involves using a solvent or chemical adhesive to dissolve the surfaces of the clear plastic pieces before pressing them together. As the solvent evaporates, it leaves behind a robust bond that also boasts resistance against various environmental factors. Solvent bonding works wonders with acrylic and polycarbonate plastics, which have a high resistance to solvents.

Now, let’s dive into the world of ultrasonic welding. By utilizing ultrasonic vibrations to generate heat at the joint between the clear plastic pieces, this method melts the plastic and forms a bond that solidifies as it cools. Ultrasonic welding is lightning-fast and highly efficient, making it perfect for high-volume production.

Moving on, we have laser welding. With laser precision, this technique melts the edges of the clear plastic pieces using a laser beam. As the plastic solidifies, a bond is formed that is both strong and visually seamless. Laser welding offers excellent control and can be used with various types of clear plastics.

If you’re looking for an option that allows for easy disassembly and reassembly, mechanical fasteners are your go-to companions. Think screws, nuts, bolts, or clips. These trusty allies provide a reliable bond while still offering the flexibility to take things apart when needed. Perfect for applications that require frequent maintenance or repairs.

Last but certainly not least, we have adhesive tapes or films specially designed for bonding clear plastics. These incredible products come with a strong adhesive backing that forms a reliable bond without leaving any unsightly residue. Easy to use and oh-so-reliable.

Considerations When Gluing Clear Plastic Together

Prepare to be enthralled as we delve deep into the realm of seamless bonds and uncover the crucial considerations that will elevate your gluing endeavors to new heights. Grab your favorite adhesive as we embark on this exhilarating journey.

The Power of Plastics:

Before we commence our gluing adventure, let us unravel the mystery of clear plastics. Each type possesses unique properties that demand specific adhesives for optimal bonding. Take a moment to acquaint yourself with the type of plastic you’re working with, ensuring the perfect adhesive match for a flawless union.

Crystal Clear Transparency:

Picture this – delicately joining two pieces of clear plastic only to discover a clouded or hazy result. Quite the disappointment, wouldn’t you agree? To avoid such heartache, seek out adhesives explicitly designed for use on clear plastics. These remarkable solutions maintain the pristine transparency of your plastic, preserving its intended purpose.

Unyielding Strength and Endurance:

In the realm of clear plastics, strength and durability reign supreme. Whether constructing a display case or assembling a protective enclosure, a robust and enduring bond is essential. Seek out adhesives specially formulated for bonding clear plastics, boasting exceptional tensile and shear strength that will withstand even the most demanding applications.

The Art of Surface Preparation:

The smooth surfaces of clear plastics may present a challenge when it comes to optimal adhesion. Fear not, for there is an enchanted ritual to overcome this obstacle. Begin by meticulously cleaning the surfaces, banishing any trace of dirt, dust, oils, or contaminants that dare to hinder our bond. For an added touch of magic, gently scuff or roughen the surface, providing the adhesive with an extended canvas upon which to work its wonders.

Testing the Adhesive on a Small Area First

Today, we embark on a journey to unravel the secrets of testing adhesive on a small area before taking on the grand task of gluing your precious clear plastic. This step is vital to ensure a flawless bond that won’t leave you with regrets or unsightly blemishes. So, let’s delve into the importance of this process and discover how to execute it like a true pro.

Why Testing on a Small Area is Crucial:

Compatibility with Clear Plastic:

Not all adhesives are created equal, especially when it comes to clear plastic. The wrong adhesive can lead to weak bonds or even cloudiness and discoloration. By testing on a small area, you can determine if the adhesive is compatible with your specific type of clear plastic, avoiding any disastrous consequences.

Assessing Strength and Durability:

Clear plastic often finds itself in applications where strength and durability are paramount, such as windows or display cases. By subjecting the adhesive to stress and pressure on a small area, you can evaluate its ability to withstand the challenges it will face in its intended use. After all, nobody wants their masterpiece falling apart at the first sign of trouble.

How to Expertly Test Adhesive on a Small Area:

Cleanse the Surface:

Before diving into the gluing process, ensure your clear plastic surface is immaculately clean. Use a gentle soap and water solution or rubbing alcohol to banish any dust, dirt, or oils that could hinder optimal bonding.

Apply a Modest Amount of Adhesive:

With a clean brush or applicator, delicately apply a thin layer of adhesive to an inconspicuous spot on your clear plastic surface. Remember, less is more – excessive adhesive can lead to unsightly buildup or troublesome dripping.

Allow Ample Drying Time:

Patience is a virtue in this endeavor. Follow the manufacturer’s instructions regarding drying time. Give the adhesive enough time to fully cure, as this will ultimately impact its bond strength.

Put Bond Strength to the Test:

Once the adhesive has dried, it’s time to examine its mettle. Gently apply pressure or stress to the bonded area. Attempt to separate the two pieces of clear plastic or subject the bonded area to a small amount of force. This will provide valuable insight into how well the adhesive holds up under scrutiny.

Challenges in Gluing Certain Types of Plastic Together

Have you ever wondered how certain types of plastic are successfully bonded together? The process of gluing plastic can be quite complex, as there are several challenges that need to be overcome. In this article, we will explore the various obstacles faced when gluing different types of plastic and discuss effective solutions to these challenges.

Conquering Low Surface Energy:

One of the major challenges in bonding plastic is dealing with low surface energy, which is common in plastics like polyethylene (PE) and polypropylene (PP). These plastics have a smooth surface that makes it difficult for adhesives to adhere effectively. To tackle this challenge, specialized adhesives containing cyanoacrylates or polyurethanes are often used. These adhesives possess unique properties that enable them to form strong bonds with low surface energy plastics.

Translucent Troubles:

Another hurdle arises when attempting to bond transparent plastics such as polycarbonate (PC) and acrylic (PMMA). These plastics are frequently used in applications that require clarity, like windows or display cases. It is crucial to employ an adhesive that dries transparently and leaves no visible residue or cloudiness behind. Furthermore, these plastics can be brittle, so the adhesive must possess flexibility to prevent cracking or breaking.

Battling Temperature Sensitivity:

Certain types of plastic have a low melting point, making them susceptible to deformation or even melting when exposed to high temperatures during the bonding process. This poses a significant challenge when attempting to glue such plastics together. To overcome this obstacle, it is imperative to select an adhesive that can withstand the temperature requirements of the application. Adhesives with high-temperature resistance or alternative bonding methods like mechanical fasteners may be necessary in these cases.

Overcoming Chemical Resistance:

Chemical resistance is another critical factor to consider when bonding certain types of plastic. Some plastics exhibit resistance to certain chemicals, including common adhesives. To address this challenge, it is essential to choose an adhesive that is compatible with the specific type of plastic and the environment it will be exposed to. Conducting compatibility tests and utilizing specialized adhesives formulated for chemical-resistant plastics can help overcome this hurdle.

Mastering Surface Preparation:

Proper surface preparation plays a vital role in achieving a successful bond. Before applying the adhesive, it is crucial to thoroughly clean and prepare the plastic surfaces by removing any dirt, oil, or residue. Roughening or treating the surfaces with primers or adhesion promoters can also enhance adhesion. Taking the time to meticulously prepare the surfaces ensures that the adhesive can establish a strong bond with the plastic.

hT6Ow_cBTps” >