Picture this: a pristine concrete wall or floor, longing to be embellished with sleek metal fixtures or eye-catching decorations. But the mere thought of drilling into that flawless surface sends shivers down your spine. Fear not. There’s an ingenious technique that lets you attach metal to concrete without drilling, preserving your concrete’s integrity and keeping its aesthetic intact.

In this captivating blog post, we’ll unravel the secrets behind this advanced method and arm you with the knowledge to effortlessly attach metal to concrete, leaving no trace of damage behind. So grab a seat and let’s dive into the world of hassle-free metal-to-concrete attachment.

Main Points:

- The Marvels of Adhesive Anchoring: Move over drilling. Adhesive anchoring is a groundbreaking technique that harnesses the power of high-strength epoxy adhesives specially designed for bonding concrete and metal. These adhesives boast incredible shear and tensile strength, ensuring a secure and long-lasting connection.

- Preparing the Surface: Before diving into the bonding process, it’s crucial to prepare the concrete surface properly. This involves meticulous cleaning to rid it of dust, debris, and any previous coatings. Smooth surfaces may need a gentle roughening up to enhance adhesive bonding.

- Mastering Application Technique: Applying the adhesive correctly is key to achieving a flawless attachment. We’ll guide you through every step – from selecting the perfect adhesive to nailing the mix ratio and achieving optimal curing time.

- Load Capacity Considerations: Depending on weight and load-bearing requirements, choosing the right adhesive and attachment method is critical. We’ll explore various options like mechanical anchors or adhesive anchors with embedded rods.

Adhesive Options for Attaching Metal to Concrete

Contents

- 1 Adhesive Options for Attaching Metal to Concrete

- 2 Preparing Surfaces Before Applying Adhesive

- 3 Using Epoxy Adhesives for Metal-Concrete Bonding

- 4 Using Construction Adhesives for Bonding Metal to Concrete

- 5 Mechanical Fastening Options for Attaching Metal to Concrete

- 6 Anchor Bolts and Anchors for Secure Attachment Points

- 7 Clamps and Brackets for Adjustable Attachment Points

- 8 Factors to Consider When Choosing an Attachment Method

- 9 Conclusion

Gone are the days of drilling holes to attach metal to concrete. Thanks to adhesive options, we now have a convenient and versatile solution. These specially formulated adhesives create an unbreakable bond between metal and concrete surfaces, eliminating the need for drilling. In this article, we will delve into an array of adhesive options, each with its own remarkable properties, to help you find the perfect fit for your specific application.

Epoxy Adhesives:

Witness the epitome of bonding strength and durability with epoxy adhesives. These powerhouses consist of two components – resin and hardener – that must be blended prior to application. Unyielding to moisture, chemicals, and temperature fluctuations, epoxy adhesives thrive in both indoor and outdoor settings. They are the go-to choice for attaching metal hardware, brackets, or fixtures to concrete surfaces.

Polyurethane Adhesives:

Embrace flexibility and vibration absorption with polyurethane adhesives. Designed for metal components that experience movement or stress, these adhesives forge an indestructible union between metal and concrete surfaces. Their exceptional resistance to water and weathering makes them a favorite in construction, automotive, and industrial applications.

Acrylic Adhesives:

Experience lightning-fast curing times coupled with high bond strength using acrylic adhesives. Boasting impact resistance, chemical resistance, and age-defying qualities, these adhesives are ideal for both indoor and outdoor projects. From metal signage to brackets and small hardware, acrylic adhesives offer a reliable attachment solution on concrete surfaces.

Hybrid Adhesives:

Unleashing the best of multiple worlds, hybrid adhesives merge the finest qualities of different adhesive types. This results in a harmonious balance of bonding strength, flexibility, and resistance to environmental factors. With hybrid adhesives, you can confidently attach metal to concrete without drilling, knowing that you have a dependable solution at hand.

Surface Preparation:

To ensure the utmost effectiveness of adhesive bonding, proper surface preparation is crucial. Begin by guaranteeing that the concrete surface is pristine – clean, dry, and free from any loose particles or contaminants that could hinder the bonding process. Similarly, prepare the metal surface by banishing rust and debris, maximizing the adhesive’s efficacy.

Preparing Surfaces Before Applying Adhesive

Are you ready to conquer the challenge of attaching metal to concrete without drilling? Before you embark on this adhesive adventure, it’s vital to prepare your surfaces like a seasoned pro. In this comprehensive guide, I will unveil the secrets to surface preparation, ensuring that your bond is as unyielding as a fortress. By the end of this journey, you’ll possess the skills to transform ordinary surfaces into adhesive masterpieces.

Step 1: Purge and Polish for Perfect Adhesion:

To lay the foundation for success, banish all dirt, dust, and debris that dare to obstruct your adhesive’s potential. Armed with a broom or vacuum cleaner, vanquish loose particles from both the concrete and metal surfaces. Then, armed with a damp cloth or sponge, meticulously wipe away any lingering impurities. Remember, cleanliness is the gateway to an unwavering bond.

Step 2: Embrace the Roughness:

Now that purity reigns supreme, it’s time to unleash the power of texture. Imagine creating a playground where your adhesive can frolic and cling with unyielding determination. Equip yourself with sandpaper or a wire brush and embark on a journey of roughening both the concrete and metal surfaces. This act of roughness enhances the bonding area, forging an unbreakable connection between these materials.

Step 3: The Vanishing Act of Debris:

After indulging in the roughening ritual, tiny particles may dance in celebration. However, we cannot allow them to disrupt our adhesive extravaganza. With an elegant sweep of a clean cloth or brush, obliterate any trace of dust or debris from both the concrete and metal surfaces. A pristine canvas is our secret weapon in achieving adhesive mastery.

Step 4: The Dance of Dryness:

Moisture, the arch-nemesis of adhesive prowess, must be vanquished before it can sabotage our bond. Patience becomes our ally, as we wait for the surfaces to air dry naturally. Should time be of the essence, call upon the forces of nature – a fan or hairdryer – to expedite the drying process. Remember, a dry surface ensures unyielding adhesion.

Using Epoxy Adhesives for Metal-Concrete Bonding

Prepare to witness the marvels of epoxy adhesives as we delve into the world of metal-concrete bonding. Say goodbye to cumbersome drilling and embrace the strength and durability of epoxy adhesives. Brace yourself for an expedition into the art of creating rock-solid connections. Let’s embark on this journey together.

The Magic Behind Epoxy Adhesives:

Epoxy adhesives possess an unparalleled strength that makes them the superheroes of bonding. Consisting of resin and hardener, these dynamic duos create an unbeatable bond between metal and concrete surfaces.

Surface Preparation: The Foundation of Success:

To lay the groundwork for a successful bond, meticulous surface preparation is key. Start by meticulously cleaning both the metal and concrete surfaces, eliminating any dirt, dust, or grease that could compromise the adhesive’s performance. Remember, cleanliness is next to bondliness.

Embracing Roughness: A Stronger Connection:

In the quest for a robust bond, roughness becomes your ally. Employ sandpaper or a wire brush to gently roughen the surfaces, providing increased surface area for the epoxy adhesive to grip onto with unwavering strength.

The Art of Mixing and Application:

Now it’s time to concoct your epoxy adhesive potion. Follow the manufacturer’s instructions diligently, ensuring accurate proportions of resin and hardener. Once mixed, apply the adhesive evenly onto both surfaces using a brush or notched trowel, spreading its magic like an artist on canvas.

Securing the Future: Bonding with Confidence:

To safeguard your bond’s future, secure the metal and concrete together during the adhesive’s curing process. Clamp or secure them tightly to prevent any movement, allowing for a seamless connection that will withstand the test of time.

Time: The Elixir of Strength:

Patience is the secret ingredient to unlocking the full potential of epoxy adhesives. The curing time varies, influenced by temperature and humidity. Grant the adhesive ample time to cure fully before subjecting it to stress or load. Remember, good things come to those who wait.

Using Construction Adhesives for Bonding Metal to Concrete

Today, we embark on an exciting adventure, exploring the incredible power of these adhesives in bonding metal to concrete without the need for drilling. Say goodbye to unsightly holes and hello to seamless perfection. Grab your tools, as we unlock the secrets to creating everlasting bonds.

Unleashing the Marvels of Construction Adhesives

- Step into a world where construction adhesives reign supreme, specially formulated to forge unyielding bonds between diverse materials, including metal and concrete.

- Embrace the beauty of a clean and seamless finish that rivals even the most precise drilling techniques.

Preparing the Surface for Victory

- Before diving into adhesive application, embrace the importance of surface preparation. Immerse yourself in a thorough cleaning process, banishing dust, dirt, and grease that threaten bond strength.

- Remember, a pristine and dry surface is the foundation for achieving unparalleled bonds.

Choosing Your Weapon: The Perfect Adhesive

- Arm yourself with an adhesive specifically tailored for metal-to-concrete bonding. Seek out labels boasting “metal-to-concrete” or “concrete bonding” at your local hardware haven.

- Venture forth, but heed the unique curing times and application instructions bestowed upon you by the adhesive’s manufacturer.

Unveiling the Art of Application

- Take hold of your notched trowel or trusty putty knife as you apply the adhesive evenly across both surfaces yearning for unity.

- Let each stroke create a symphony of perfect coverage, an essential ingredient in forging an unbreakable bond.

Harnessing the Power of Pressure

- As your adhesive masterpiece takes shape, press the metal and concrete surfaces together with unwavering determination. By doing so, you ensure maximum contact and reinforce the strength of your bond.

- Embrace the intensity for a few minutes, allowing the adhesive to set firmly and cement your success.

Section 6: The Art of Patience

- In this realm, patience is rewarded. Depending on the adhesive’s nature, curing time may range from a few hours to an entire day. Follow the manufacturer’s wisdom and savor the journey towards optimal results.

- Remember, great achievements are born from waiting.

Mechanical Fastening Options for Attaching Metal to Concrete

Prepare to be amazed as we unveil a plethora of secure and efficient methods that will elevate your projects to new heights. No drilling required. So, let’s roll up our sleeves and embark on a journey of exploration into these groundbreaking techniques.

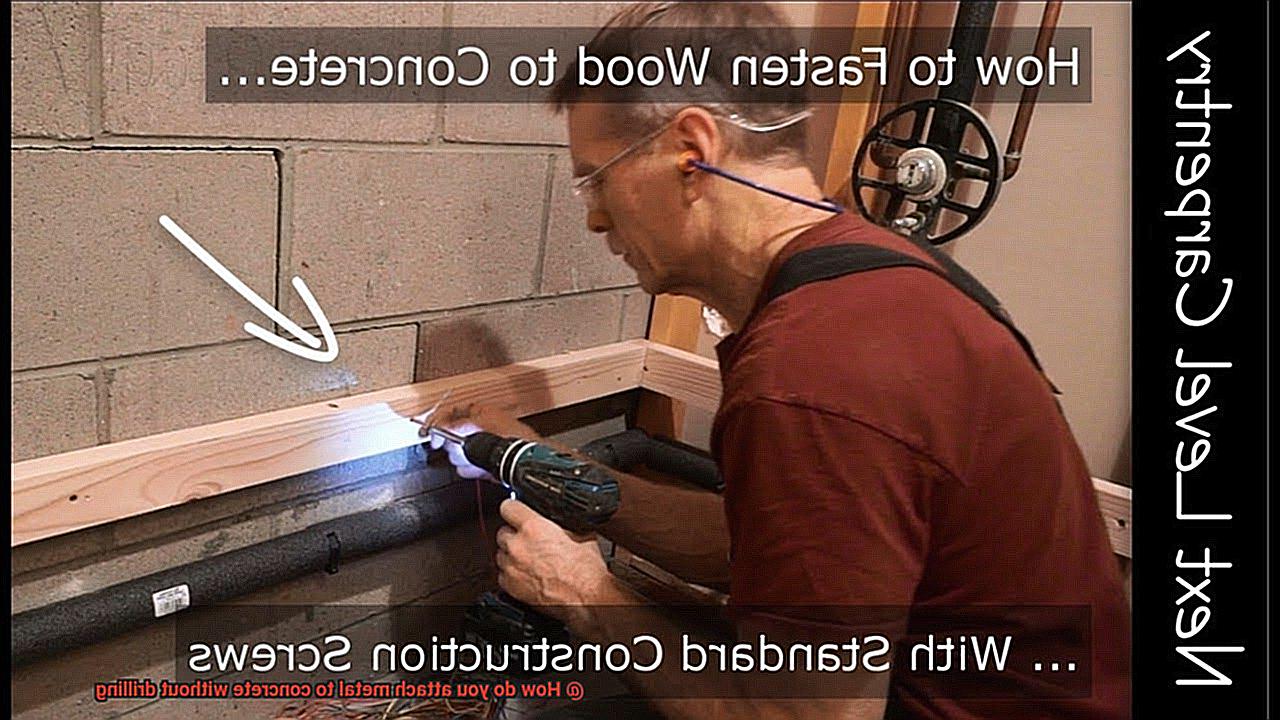

Concrete Screws: The Unyielding Heroes of Fastening

Concrete screws, the unsung heroes of mechanical fastening, possess an extraordinary ability to penetrate and grip into concrete surfaces. With their specialized thread design and hardened steel construction, these mighty screws bypass the need for pre-drilling. Armed with your trusty power drill, unleash their power as they effortlessly sink deep into concrete, forming an unbreakable connection with the metal.

Masonry Anchors: Expanding Horizons of Possibility

Behold the masonry anchors or expansion bolts, versatile fasteners that offer unparalleled strength and reliability. Though they require a touch of pre-drilling, their worth is proven by their ability to expand when tightened. By inserting them into pre-drilled holes in the concrete, they create an unshakeable bond between metal and concrete. Wedge anchors, sleeve anchors, or drop-in anchors – choose your weapon and conquer any challenge with confidence.

Concrete Clips: Wrapping Success in Versatility

For those seeking adjustable yet steadfast attachment options, let us introduce you to concrete clips or clamps. Forged from robust materials like stainless steel, these clips elegantly envelop the metal before firmly attaching to the concrete surface. They gift you with a seamless installation process and can be effortlessly removed when necessary. With concrete clips by your side, flexibility merges harmoniously with strength in every project you undertake.

Specialized Fasteners: Unlocking Solutions for Unique Applications

In this vast construction cosmos, we face extraordinary tasks that demand extraordinary solutions. Enter the realm of metal brackets and hangers. These bespoke fasteners are tailor-made to attach to concrete walls or ceilings, serving as sturdy connection points for metal objects. Be it hanging signs, supporting pipes, or securing heavy-duty equipment; these fasteners stand as sentinels, ensuring enduring and safe installations.

Anchor Bolts and Anchors for Secure Attachment Points

In our quest to conquer concrete connections, we now venture into the realm of anchor bolts and anchors. These mighty tools hold the key to secure attachment points between metal and concrete, without the need for drilling. So gather your gear and prepare to unlock the secrets of unbeatable connections.

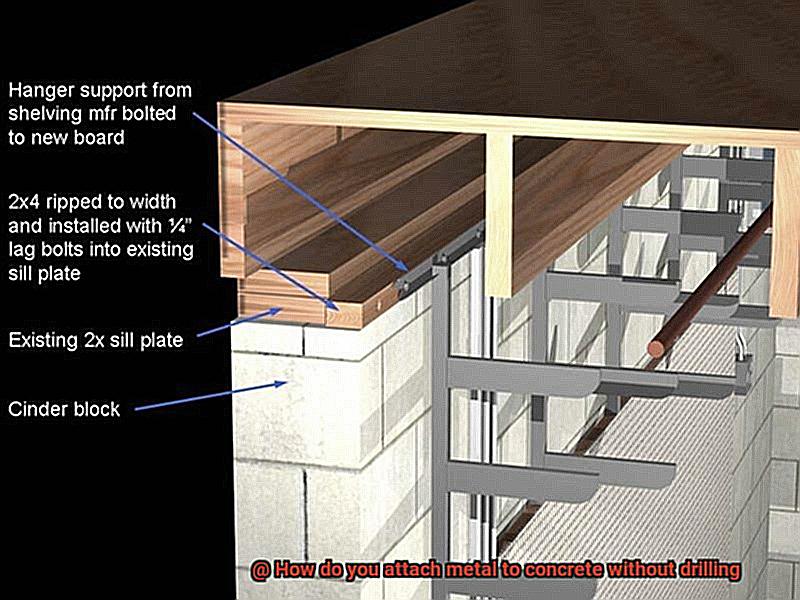

Anchor Bolts: The Titans of Dependability

When it comes to creating unbreakable bonds, anchor bolts reign supreme. These heavy-duty warriors are embedded into the concrete during construction, with their threaded ends defiantly protruding above the surface. By simply threading a nut onto these exposed bolts, you can forge an unyielding connection that will withstand the test of time.

Diverse Types of Anchors:

Now, let us delve into the marvelous world of anchors – ingenious devices designed to attach metal to concrete with unparalleled efficiency. Brace yourselves as we explore a treasure trove of options, each possessing its own unique strengths.

Wedge Anchors: Masters of Grip

Behold the wedge anchor – a bolt armed with a cone-shaped expansion wedge on one end and threads on the other. To unleash its power, drill a hole into the concrete and insert this mighty warrior. As you tighten the nut, watch in awe as the wedge expands, gripping the sides of the hole with an iron grip. This unyielding hold ensures your metal remains steadfastly attached.

Sleeve Anchors: Embracing Strength

Joining our ranks is the formidable sleeve anchor, ready to demonstrate its unwavering strength. Like its wedge counterpart, this anchor demands pre-drilled holes. However, it boasts an outer sleeve that amplifies its gripping power when tightened. This added strength guarantees that your metal will never waver in the face of adversity.

Drop-in Anchors: The Epitome of Reliability

Imagine an anchor, humble and unassuming, installed flush with the concrete surface. That humble anchor is the drop-in anchor, a true symbol of dependability. It provides the perfect foundation for securing threaded rods or bolts. Simply insert your chosen fastener into this unyielding anchor, and you’ll forge a connection that can withstand any challenge.

Clamps and Brackets for Adjustable Attachment Points

Are you tired of the hassle of drilling into concrete to attach metal components? In this post, we’ll explore the world of clamps and brackets, powerful tools that allow you to create secure attachment points between metal and concrete without the need for drilling.

These versatile solutions offer adjustable options for easy installation and removal, ensuring unbeatable connections that stand the test of time. Let’s dive in.

Beam Clamps:

Beam clamps are the go-to choice for securely attaching metal beams or structural components to concrete. With their adjustable threaded rods, these clamps can be easily customized to fit the desired height or position.

You can find beam clamps in various sizes and configurations, including hinged designs that make installation a breeze, even in tight spaces. Crafted from top-tier materials like stainless steel or galvanized steel, beam clamps guarantee long-lasting performance.

Pipe Clamps:

When it comes to holding pipes, tubes, or metal brackets in place on concrete surfaces, pipe clamps are the champions. These clamps feature a convenient screw mechanism that allows for effortless adjustment and tightening, ensuring a secure attachment.

Whether you’re working with different pipe diameters or specific applications, various sizes of pipe clamps are available. Made from heavy-duty materials like cast iron or steel, they are built to withstand demanding conditions.

Brackets:

For a stable attachment point without drilling, brackets are the answer. These reliable fasteners can be fixed in place using concrete anchors or screws, providing a sturdy foundation for your metal components.

Available in shapes such as L-shaped, T-shaped, or U-shaped, brackets offer versatility for different installation needs. Crafted from robust materials like steel, aluminum, or stainless steel, they provide the strength and durability required for long-term performance.

Some brackets even feature adjustable slots or holes, allowing for flexible positioning and accommodating changes in your installation layout.

Proper Installation:

To ensure a secure attachment, it’s crucial to follow proper installation guidelines.

This includes using the appropriate fasteners, carefully reading and adhering to manufacturer instructions, and considering load capacity and structural requirements.

When in doubt, consult with a professional or structural engineer to ensure that the chosen clamps or brackets are suitable for your specific project and meet relevant building codes or regulations.

Factors to Consider When Choosing an Attachment Method

When it comes to attaching metal components to concrete without drilling, selecting the right attachment method is the key to a secure and durable connection. In this captivating article, we will explore the essential factors that should be taken into account when choosing an attachment method. So, let’s embark on this journey of discovery.

Load-bearing capacity:

The first factor to consider is the load-bearing capacity of the attachment method. It must have the strength to bear the weight and stress that will be placed upon it. Each application has its own unique load requirements, so it’s crucial to select a method that aligns with your specific needs.

Type of metal and concrete:

The type of metal and concrete being used plays a significant role in determining the appropriate attachment method. Different metals exhibit distinct properties such as weight and corrosion resistance, which need to be carefully considered. Likewise, the type of concrete, whether it’s regular or reinforced, can impact the choice of attachment method.

Environmental conditions:

Don’t overlook the environmental conditions in which the attachment will be placed. Factors such as temperature fluctuations, exposure to moisture or chemicals, and UV radiation can all influence the performance and durability of the attachment method. It is vital to choose a method that is specifically designed to withstand your unique environmental conditions for long-lasting stability.

Installation requirements:

Consider the ease of installation when selecting an attachment method. Some methods may demand specialized tools or expertise, while others may offer simplicity and straightforwardness. Assess your available resources and capabilities to determine which method is most practical and feasible for installation.

Aesthetic considerations:

In certain applications where visibility is key, such as architectural or decorative installations, the appearance of the attachment becomes critical. Opt for an attachment method that provides a clean and aesthetically pleasing finish if the metal-to-concrete connection will be on display. Let style be an integral part of your decision-making process.

Cost-effectiveness:

Last but certainly not least, cost-effectiveness should be taken into consideration. Different attachment methods vary in terms of material costs, labor requirements, and maintenance needs. Evaluate the overall cost, including both upfront and long-term expenses, to ensure it aligns with your budgetary constraints.

LlFDgYj65fk” >

Conclusion

When it comes to attaching metal to concrete without drilling, there are several methods you can consider. One option is to use adhesive anchors, which provide a strong bond between the metal and the concrete surface. These anchors come in various forms, such as epoxy or chemical-based adhesives, and they are designed to withstand heavy loads and ensure long-lasting durability.

Another technique is using mechanical fasteners like concrete screws or anchors. These fasteners have specialized threads that allow them to grip into the concrete securely. They require minimal effort to install and can be easily removed if needed.

For a more versatile approach, you can also explore magnetic attachments. Magnetic mounting systems utilize powerful magnets that adhere to both the metal and concrete surfaces, creating a reliable connection without any drilling required. This method is particularly useful for temporary installations or situations where frequent adjustments are necessary.

Furthermore, there are innovative solutions available, such as adhesive tapes specifically designed for bonding metal to concrete surfaces. These tapes offer a quick and hassle-free installation process while maintaining a strong hold over time.

In conclusion, when you’re faced with the challenge of attaching metal to concrete without drilling, remember that there are multiple effective options at your disposal. Whether it’s adhesive anchors, mechanical fasteners, magnetic attachments, or adhesive tapes – each method offers its own advantages depending on your specific needs.