Today, we’re plunging headlong into a question that has puzzled DIY enthusiasts, everyday handyfolk, and inquisitive minds alike: Does superglue possess the mystical power to stick to everything?

Superglue, also known as cyanoacrylate adhesive, has earned itself a legendary status thanks to its mind-boggling bonding prowess. But can it truly conquer any material that dares cross its path? From plastic and metal to wood and fabric, we’ve arrived armed with facts and ready to debunk the myths surrounding this wonder-goo.

In this riveting blog post, prepare yourself for a deep dive into the enigmatic chemistry behind superglue. We’ll unravel its limitations and unveil surprising insights into its ability to form unbreakable bonds with various surfaces. Brace yourself for mind-blowing revelations as we tackle this seemingly straightforward yet astonishingly complex question.

So come along on this thrilling adhesive adventure as we uncover the truth about whether superglue is truly invincible or if there are secret adversaries it simply cannot vanquish. Let’s settle in, quench our thirst for knowledge, and finally put an end to our curiosity about this sticky subject once and for all.

What is Superglue?

Contents

- 1 What is Superglue?

- 2 What Materials Can Superglue Stick To?

- 3 Adhesion on Porous Materials

- 4 Surface Condition and Environmental Factors

- 5 Special Formulations for Plastics

- 6 Adhesion on Moisture and Oil Exposed Surfaces

- 7 Temperature Effects on Superglue Performance

- 8 Techniques to Enhance Adhesion of Superglue

- 9 Conclusion

In the realm of adhesives, one product reigns supreme for its incredible bonding capabilities and versatility – Superglue. Also known as cyanoacrylate adhesive, this remarkable invention has revolutionized the world of repairs, creations, and crafts.

In this article, we will explore the fascinating world of Superglue, from its accidental discovery to its rapid bonding power and amazing applications.

The Accidental Discovery:

Superglue’s story begins with a stroke of luck. In the 1940s, Dr. Harry Coover was researching clear plastics for wartime applications when he stumbled upon a substance with extraordinary bonding properties. Little did he know that his accidental creation would become one of the most widely used adhesives in the world.

Lightning-Fast Bonding Power:

Superglue’s most impressive feature is its lightning-fast bonding speed. Within seconds of application, it solidifies, creating an almost instant bond. This characteristic makes it ideal for quick repairs and urgent projects.

The Science Behind the Bond:

Superglue’s secret lies in its unique chemical composition. It undergoes polymerization when exposed to moisture in the air, forming long chains of polymers. These chains intertwine with the surface molecules of the materials being bonded, resulting in an incredibly strong and durable connection.

Versatility at its Finest:

Superglue’s versatility is another reason behind its popularity. It bonds various materials such as metal, glass, ceramics, and certain plastics effortlessly. However, it’s important to note that not all materials are compatible with Superglue. Porous materials like wood or fabric may not provide optimal bonding results due to their ability to absorb the adhesive.

Surface Preparation Matters:

To achieve the best results with Superglue, proper surface preparation is vital. Surfaces must be clean, dry, and free from oils or contaminants. Roughening the surface or using a primer designed for enhancing adhesion can also improve bond strength.

Temperature and Environmental Considerations:

Superglue performs best within a moderate temperature range. Extreme heat or cold can affect its bonding capabilities. Additionally, constant exposure to moisture or oils can weaken the bond. It’s crucial to consider these factors when choosing Superglue for specific applications.

What Materials Can Superglue Stick To?

Superglue, also known as cyanoacrylate adhesive, is a superhero in the glue universe. It thrives on smooth surfaces, making it ideal for bonding various plastics like acrylic, polycarbonate, and ABS. Imagine repairing your favorite plastic toy or building intricate models with ease.

Metals and Wood – No Problem:

When it comes to metals, superglue shows off its strength on clean and dry surfaces. Whether you’re mending a broken piece of jewelry or assembling metal sculptures, aluminum, steel, and copper are no match for this adhesive’s superpowers.

Woodworkers rejoice. Superglue is a reliable partner for joining hardwoods such as oak, mahogany, and maple. However, beware when dealing with softwoods like pine or cedar – their porous nature may not provide the best bonding experience.

The Magic Touch on Glass and Ceramics:

Ever wondered how to mend broken glass or repair delicate ceramics? Superglue is here to save the day. It forms strong bonds on smooth glass surfaces, allowing you to fix your favorite glassware or create stunning mosaic art.

Fabric Love Affair:

While superglue may not be the perfect match for heavy fabrics or those with a loose weave, it works wonders on lightweight materials like cotton and polyester. From quick fixes to creative fabric projects, superglue ensures a secure bond that stands up to everyday wear and tear.

Rubber and Silicone Challenges:

Rubber and silicone may put up a fight, but superglue can still offer temporary bonding on certain rubber-like materials such as neoprene and nitrile rubber. However, it’s important to note that natural rubber and silicone rubber may not respond well to its powers.

Porous Materials and More:

Superglue triumphs on porous materials like paper and cardboard. From fixing torn pages to crafting intricate paper models, this adhesive is a reliable ally. Just remember not to go overboard with the glue application, as excessive saturation can weaken the bond.

Adhesion on Porous Materials

Today, we’re going to take a deep dive into the fascinating world of adhesion on porous materials when using superglue. So put on your lab coat and get ready to become an expert in the art of bonding.

Porous materials, those sneaky little things with their small holes and spaces, like wood, fabric, paper, and certain types of stone, can be quite challenging to bond. Superglue, also known as cyanoacrylate adhesive, is a fast-drying adhesive that forms a strong bond when it comes into contact with moisture. But here’s the catch – its ability to adhere to porous materials can vary.

One of the key factors influencing adhesion on porous materials is the surface area available for bonding. Porous materials typically have a larger surface area compared to non-porous ones. This means more contact between the adhesive and the material, which can enhance adhesion.

However, the porosity of the material can also pose challenges. Those pesky little holes in porous materials can absorb or wick away the moisture in the superglue, preventing it from fully penetrating and creating a strong bond.

But don’t despair. We have some tricks up our sleeves to improve adhesion on porous materials. First, pre-treatment is key. Before applying the superglue, consider using a primer or an activator that helps seal the pores and create a receptive surface for bonding. This step ensures better penetration and stronger adhesion.

Another option is to use a specialized superglue formulation specifically designed for porous materials. These formulations often contain additives or modifiers that enhance penetration and adhesion on porous surfaces. So instead of using your regular superglue, give these specialized formulations a try for optimal results.

Now, let’s not forget about the nature of the porous material itself. Different types of porous materials have different levels of absorbency and surface characteristics that can affect adhesion. For example, certain types of wood may have a higher natural oil content, making them more resistant to adhesion. In these cases, it’s crucial to sand or clean the surface thoroughly before applying the superglue to improve bonding.

Surface Condition and Environmental Factors

Superglue is a remarkable adhesive renowned for its rapid drying and powerful bonding capabilities. However, the effectiveness of superglue adhesion is influenced by various surface conditions and environmental factors.

In this article, we will delve into the intricate world of glue and explore how temperature, humidity, UV light, and chemicals can significantly affect its bonding properties.

Surface Condition:

The surface condition plays a pivotal role in determining the success of superglue adhesion. To achieve optimal bonding, it is imperative to begin with a smooth and pristine surface. The presence of dirt, dust, or oil can impede the glue from adhering properly. To ensure a formidable bond, thoroughly clean the surfaces using a mild detergent or rubbing alcohol to eliminate any contaminants.

Challenges may arise when attempting to bond rough or porous surfaces with superglue. In such instances, lightly roughening the surface with sandpaper or a file can enhance the bonding area, allowing the glue to penetrate deeper and create a stronger bond.

Temperature and Humidity:

Temperature and humidity also exert a considerable influence on superglue’s adhesion. Moderate temperatures and low humidity conditions provide an ideal environment for achieving optimal bonds. High temperatures can cause the glue to cure too rapidly, compromising its ability to form a robust bond. Conversely, extremely low temperatures can decelerate or even prevent the curing process from occurring altogether.

Moisture Sensitivity:

Superglue exhibits sensitivity to moisture, rendering excessive moisture in the air or on the surfaces being bonded detrimental to adhesion. In humid environments, it is advisable to employ a dehumidifier or wait for drier conditions before attempting to use superglue.

UV Light and Chemicals:

Exposure to UV light can gradually degrade superglue over time, weakening its adhesive properties. To safeguard against this, it is advisable to minimize prolonged exposure to sunlight or utilize UV-resistant glues for applications susceptible to direct sunlight.

Additionally, certain chemicals can react with the adhesive, compromising its bond strength. It is imperative to be cognizant of any chemicals present in the environment or on the surfaces being bonded.

Special Formulations for Plastics

Special formulations for plastics are a game-changer when it comes to bonding these versatile materials. Not all glues are up to the challenge of creating a strong and durable bond with plastics, which have their own unique set of characteristics. Because special formulations are here to save the day.

One superhero in the world of plastic bonding is cyanoacrylate superglue. This fast-drying adhesive forms a chemical bond with the plastic surface, creating a bond that’s as tough as nails. However, not all plastics are created equal. Some plastics have low surface energy and are non-polar in nature, making them quite tricky to bond with traditional superglues.

To overcome this challenge, proper preparation is key. Start by thoroughly cleaning the plastic surface to remove any dirt or grease. Then, roughen it slightly to increase the bonding surface area. This will give the glue more to hold onto and create a stronger bond.

But wait, there’s more. Some plastics may require additional help in the form of primers or activators. These magical substances enhance the bond strength by providing an extra boost of adhesion power. So don’t be shy about using them if your plastic needs a little extra persuasion.

Now, let’s talk about those stubborn plastics like polypropylene and polyethylene. They’re notorious for their low surface energy and can be quite the headache when it comes to bonding. But special adhesives have been designed specifically for these tricky materials. These specialty glues contain additives or modifications that allow them to effectively bond with these stubborn plastics.

And let’s not forget about our UV-curing friends. These special adhesives are perfect for certain types of plastics. When exposed to ultraviolet light, they cure and create a strong bond between the plastic surfaces. It’s like magic, except it’s science.

Adhesion on Moisture and Oil Exposed Surfaces

When it comes to adhesion, moisture and oil can be the villains that make superglue’s job difficult. In this blog post, we will delve into the effects of moisture and oil on superglue adhesion. So, grab a drink and join us as we explore this sticky situation together.

Moisture: The Sneaky Saboteur

Moisture acts like a sneaky saboteur that compromises the effectiveness of superglue. Water molecules, with their polar nature and positive and negative charges, create a barrier between the adhesive and the surface. This barrier hinders proper bonding and instead forms weak hydrogen bonds with water molecules.

To overcome this challenge, dryness is key. Wipe away any moisture using a clean cloth or tissue before applying superglue. Additionally, specialized variants of superglue are designed for bonding in moist conditions, containing additives that counteract moisture for better adhesion even in humid environments.

Oil: The Slippery Intruder

Oil is another adversary that prevents superglue from establishing a strong bond. With its non-polar nature and lack of positive and negative charges, oil forms a slippery barrier on the surface. This low surface energy hampers proper bonding between the adhesive and the material.

To conquer this challenge, banish the oil. Clean the surface with an appropriate solvent or degreaser to remove oil residue before applying superglue. Some superglue types are formulated to provide better adhesion on oily surfaces, so choose the right variant for your specific application.

Consider the Alternatives

In cases where moisture levels or oil presence are too high for superglue to handle, fear not. There are alternative adhesive solutions available. Epoxy adhesives, known for their excellent resistance to moisture and oil, consist of two components that need to be mixed before application. These adhesives provide a strong and durable bond even on challenging surfaces.

Temperature Effects on Superglue Performance

Ever wondered why your superglue doesn’t seem to work as well in extreme temperatures? The answer lies in the fascinating world of adhesive science. Temperature has a significant impact on superglue performance, and understanding this relationship is key to achieving optimal bonding strength and durability.

Superglue, or cyanoacrylate adhesive, is designed to work best at room temperature, typically around 20 to 25 degrees Celsius (68 to 77 degrees Fahrenheit). At this temperature range, the curing process occurs at a moderate speed, allowing the glue to bond effectively. However, when temperatures drop below this range, the curing process slows down significantly. This means it may take longer for the glue to fully bond and achieve maximum strength.

In extremely cold temperatures, such as below freezing, superglue may not bond at all or may take an extended period to cure. The low temperatures affect the chemical reaction that causes the glue to harden, resulting in weak or nonexistent bonds. So, when working in freezing temperatures, it’s better to opt for alternative adhesive solutions.

Conversely, high temperatures can speed up the curing process of superglue. Sounds good, right? Well, not exactly. Excessive heat can make the glue brittle and cause it to lose its adhesive strength. So while it may cure faster in high temperatures, it may not provide the long-lasting and strong bond you desire.

When using superglue, it is crucial to consider the temperature of the surfaces being bonded. If they are too hot or too cold, it can affect bonding strength and durability. Temperature variations during the curing process can also result in uneven bonding or weak bonds.

For applications requiring a strong bond in high-temperature environments, specialized superglues formulated for those conditions are available. These glues can withstand higher temperatures without losing their adhesive properties.

Techniques to Enhance Adhesion of Superglue

If you’ve ever been frustrated with superglue not sticking as effectively as desired, fear not. In this comprehensive guide, we will explore various techniques that can enhance the adhesion of superglue and ensure stronger, more reliable bonds. So, let’s dive in and unlock the secrets to making your superglue stick better.

Clean Surfaces:

To achieve optimal adhesion, cleanliness is key. Make sure the surfaces to be bonded are squeaky clean and free from any contaminants. Dirt, oil, or grease can interfere with bonding and reduce effectiveness. So, before applying superglue, give the surfaces a thorough cleaning using a mild detergent or alcohol solution to ensure a perfect bond.

Roughen the Surfaces:

Smooth surfaces are like slippery slopes for superglue – they provide fewer contact points for the adhesive to grip onto, resulting in weaker bonds. Don’t let your bond slide away; instead, grab some sandpaper or a file and roughen up those surfaces. Creating a rough texture increases the surface area and enhances the bonding strength.

Use Primers:

When it comes to achieving ultimate adhesion, primers are your secret weapon. These specialized substances are designed to promote bonding between the adhesive and the materials being bonded. They improve wetting and penetration of the adhesive into the surfaces, resulting in stronger bonds that stand the test of time. Select a primer that is compatible with both the adhesive and materials being bonded for maximum effectiveness.

Control Temperature:

Don’t let extreme temperatures put a freeze on your bonding success. For optimal results, bond materials at room temperature (around 20-25 degrees Celsius). Avoid bonding in scorching hot or freezing cold environments as these can weaken superglue bonds. Ensure that the materials are at room temperature before applying the adhesive for a strong and secure bond.

Apply Pressure:

Squeeze it, clamp it, weigh it down – applying pressure during bonding is the key to a tight grip. By exerting force on the bonded surfaces, you allow the superglue to penetrate deeper into the materials, creating stronger and more reliable bonds. So, grab those clamps or weights and hold the surfaces together while the adhesive cures. This will ensure a secure bond and prevent any movement that could compromise adhesion.

Allow Sufficient Curing Time:

Patience is a virtue when it comes to achieving optimal adhesion with superglue. Just like a fine wine, superglue needs time to mature and form strong bonds. Follow the manufacturer’s instructions regarding curing time for the specific type of superglue you are using. Rushing the process may result in weaker bonds, so be patient and give it ample time to cure.

GvWoqfr-_cE” >

Conclusion

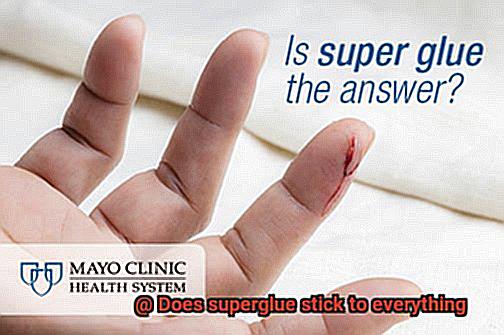

In conclusion, it is safe to say that superglue has an uncanny ability to adhere to almost anything it comes into contact with.

From metals to plastics, ceramics to fabrics, and even skin to skin, this mighty adhesive knows no bounds. Its tenacious grip can withstand immense pressure and extreme temperatures, making it a reliable choice for countless applications.

However, while superglue may stick to nearly everything, there are a few exceptions. Surfaces coated with certain types of oils or waxes may pose a challenge for the adhesive’s bonding capabilities.

Nevertheless, when it comes to sticking power, superglue reigns supreme in the world of adhesives.