Rubber – the unsung hero of materials, capable of bouncing back from any challenge. It’s found in our shoes, our gadgets, and even in those trusty old rubber bands that hold our lives together. But what happens when this resilient material needs a little extra help? Enter super glue – the knight in shining armor, ready to save the day with its legendary adhesive powers. But does this dynamic duo truly work hand in hand?

In this captivating blog post, we embark on an exploration into the captivating world where super glue meets rubber. We’ll unravel the mysteries behind their interaction and discover if super glue lives up to its reputation as a reliable bonding agent for rubber. Along the way, we’ll share some insider tips and tricks that will leave you feeling like an adhesive aficionado.

So grab your magnifying glass and put on your DIY detective hat. Whether you’re a craft connoisseur or simply intrigued by the science of stickiness, we’ve got you covered. Together, let’s embark on an adhesive adventure and uncover the true power of super glue on rubber.

What is Super Glue?

Contents

Unleashing the Power of Super Glue: The Secret to Bonding Rubber Surfaces

Super glue, also known as cyanoacrylate adhesive, is a remarkable substance that has revolutionized the world of adhesives. Its ability to create strong and instant bonds has made it a staple tool in countless projects and repairs. But what about its effectiveness on rubber surfaces? In this blog post, we will explore the fascinating world of super glue and its relationship with rubber, uncovering tips and tricks to achieve optimal bonding results.

Super glue’s secret lies in its main ingredient, cyanoacrylate. This clear liquid transforms into a solid polymer when exposed to moisture, resulting in a tight grip between surfaces. Its rapid polymerization process allows for quick repairs, making it ideal for those “need-it-now” moments.

Rubber is a versatile material that comes in various forms, such as natural rubber and synthetic rubber. Super glue can bond to both types, but their unique properties and composition must be considered.

Natural rubber offers elasticity and flexibility but achieving a long-lasting bond with super glue can be challenging due to these characteristics. The bond may break under stress or prolonged exposure to moisture.

Synthetic rubbers like neoprene and nitrile rubber mimic natural rubber’s properties while enhancing durability. Super glue generally works well on synthetic rubbers, providing a strong and reliable bond.

Silicone rubber presents its own set of challenges when it comes to bonding with super glue. Silicone’s resistance to extreme temperatures and chemicals requires specialized adhesives formulated specifically for silicone rubber.

To achieve successful bonding on rubber surfaces, follow these top tips:

- Cleanliness is Key: Ensure the rubber surface is clean and free from contaminants or oils. Use a mild detergent or solvent designed for rubber cleaning.

- Apply Sparingly: Super glue sets quickly, so apply the adhesive sparingly to avoid excess spreading onto unwanted areas.

- Align and Press: Before the glue sets, align the rubber surfaces accurately and apply even pressure to create a strong bond.

Types of Rubber

In this comprehensive explanation, we will explore the fascinating world of rubber and its interactions with super glue. Rubber is a versatile material with unique properties, and understanding how it interacts with super glue is essential for successful bonding. So, let’s dive in and discover the different types of rubber and their compatibility with super glue.

Natural Rubber: Elasticity at Its Best

Natural rubber, also known as latex, is derived from the sap of rubber trees. It is renowned for its exceptional elasticity and flexibility, making it ideal for applications such as tires and gaskets. When it comes to bonding natural rubber with super glue, its porous nature allows for a strong bond. However, it is crucial to ensure that the surface is clean and free from any oils or dirt to ensure optimal adhesion.

Synthetic Rubber: Mimicking Nature

Synthetic rubbers are man-made materials designed to replicate the properties of natural rubber. They offer improved durability and resistance to environmental factors. Neoprene and nitrile rubber are examples of synthetic rubbers that work well with super glue. Whether it’s automotive parts or industrial hoses, super glue forms a sturdy bond with synthetic rubber, ensuring reliability and strength.

Silicone Rubber: Slippery When Glued

Silicone rubber is a special type of synthetic rubber renowned for its high-temperature resistance and chemical resistance. However, due to its low surface energy and non-porous nature, super glue may not always adhere effectively to silicone rubber. Specialized adhesives like silicone-based or cyanoacrylate-based primers may be necessary for bonding silicone rubber successfully.

EPDM Rubber: Weathering the Storm

EPDM rubber is a synthetic rubber known for its exceptional resistance to weathering, ozone, and UV exposure. It is commonly used in roofing membranes and automotive seals. Super glue generally adheres well to EPDM rubber, but it is essential to ensure that the surface is clean and free from oxidation or contaminants to achieve optimal bonding. With super glue, you can trust that your EPDM rubber applications will withstand the elements.

Butyl Rubber: Keeping It Airtight

Butyl rubber is famous for its ability to provide airtight seals, making it ideal for inner tubes, adhesives, and seals. Super glue is generally compatible with butyl rubber, ensuring a reliable bond that keeps air and gases from escaping. Whether you’re repairing an inner tube or sealing a joint, super glue and butyl rubber make the perfect pairing.

Does Super Glue Work on Natural Rubber?

The versatility of super glue, also known as cyanoacrylate adhesive, makes it a go-to choice for bonding different materials together. But when it comes to natural rubber, does super glue hold up? Let’s dive into the factors that determine whether super glue is an effective adhesive for natural rubber.

Understanding the chemical composition of both materials is crucial. Super glue forms strong bonds by initiating a chemical reaction upon contact with moisture. Natural rubber, on the other hand, contains water molecules within its structure, potentially aiding in the bonding process with super glue.

However, the success of super glue on natural rubber also hinges on the specific formulation of the glue and the condition of the rubber surface. For optimal adhesion, it is essential to thoroughly clean and dry the rubber surface before applying super glue. This step removes any dirt or oils that might impede the bonding process.

To enhance bond strength between super glue and natural rubber, using a primer specifically designed for rubber surfaces is recommended. This primer acts as an intermediary layer, promoting better adhesion between the two materials.

It’s important to note that while super glue may initially bond with natural rubber, long-term durability can be a concern. Natural rubber’s flexibility and susceptibility to degradation over time may compromise the adhesive strength. In certain cases, specialized adhesives like rubber cement or adhesive tapes tailored for rubber materials may offer superior adhesion and durability compared to super glue.

Does Super Glue Work on Synthetic Rubber?

The burning question on the minds of many is whether super glue can effectively bond synthetic rubber. With its fast-drying and strong bonding properties, super glue seems like the perfect solution for a variety of applications involving synthetic rubber, such as automotive parts, seals, and gaskets. However, before reaching for that trusty tube of super glue, let’s delve into the research to uncover the truth about its effectiveness on different types of synthetic rubber.

Neoprene: A Bonding Buddy

Neoprene, known for its versatility and resistance to heat, oil, and chemicals, is a synthetic rubber that often requires strong adhesive bonds. Luckily, super glue rises to the occasion when it comes to bonding neoprene. Its ability to form robust bonds with this material makes it an excellent choice for neoprene-based applications.

Nitrile Rubber: Sticking Strong

When it comes to bonding nitrile rubber, commonly used in automotive parts and fuel hoses due to its exceptional resistance to oil and fuel, super glue is a reliable option. It creates a strong and durable bond that ensures your automotive components stay put.

EPDM: A Tricky Connection

EPDM rubber offers excellent resistance to weathering and UV radiation, making it popular for roofing membranes and automotive seals. While super glue can bond to EPDM rubber, it may not provide the same level of adhesion as with other types of rubber. For EPDM bonding, specialized adhesives designed for this material are recommended.

Silicone Rubber: A No-Go Zone

Silicone rubber boasts high-performance capabilities, especially its resistance to extreme temperatures and chemicals. Unfortunately, super glue does not adhere well to silicone rubber surfaces due to their low surface energy. To achieve successful silicone rubber bonding, it’s best to opt for silicone-specific adhesives or two-part silicone adhesive systems.

Does Super Glue Work on Silicone Rubber?

When it comes to bonding materials, super glue boasts a reputation as the adhesive superhero. But does it have what it takes to conquer the unique challenge of bonding with silicone rubber? Let’s unravel the mystery and determine if super glue can successfully bond with this resilient material.

Factor 1: Surface Preparation

Silicone rubber poses a formidable obstacle with its smooth and non-porous surface. Super glue thrives on rough or porous surfaces, making a strong bond seem impossible. However, by meticulous surface preparation, we can pave the way to success.

Start by thoroughly cleaning the silicone rubber surface using mild detergent or rubbing alcohol to banish dirt, grease, and contaminants. This step boosts the surface energy of silicone rubber, enhancing adhesion.

Additionally, roughening the surface with sandpaper or a scouring pad creates tiny scratches and grooves, providing more grip for the adhesive to embrace.

Factor 2: The Right Super Glue

Not all super glues are created equal, especially when it comes to bonding silicone rubber. Some super glues are specially formulated for low surface energy materials like silicone rubber. These gems contain additives that promote superior adhesion, making them ideal for this particular task. When selecting a super glue, seek one that explicitly mentions compatibility with rubber and proudly claims to tame silicone rubber in its instructions or product description.

Factor 3: Test Bonding

Before embarking on a grand project, wise warriors perform a test bond on a small, inconspicuous area of the silicone rubber. This step allows evaluation of bond strength and compatibility between the adhesive and the material. Remember, it’s better to be safe than sorry.

Preparing the Surface for Bonding

Get ready to embark on an epic bonding battle between super glue and rubber. We all know that rubber can be a tricky material to bond, but fear not. With these expert tips and tricks, you’ll be able to prepare the surface for a super-powered bond that’ll withstand the test of time.

Step 1: Cleanliness is Key:

Before entering the battlefield, our heroes must be pristine and ready for action. Leave no room for dirt, dust, or grease to hinder the bond. Arm yourself with a gentle detergent or an alcohol-based cleaner to scrub away any impurities. Remember, a spotless surface ensures a stronger bond.

Step 2: Roughen the Surface:

Now it’s time to give our rubber surface some texture. Equip yourself with sandpaper or a file, and gently unleash their power on the surface. Let them create small grooves and ridges, providing ample area for the glue to grip onto. Just remember, moderation is key – don’t go overboard and damage the rubber.

Step 3: Priming for Success:

Every superhero needs a primer, right? Unleash the power of a rubber-specific primer onto the prepared surface. Apply a thin and even coat, allowing it to dry completely before moving forward. This mighty primer will enhance the adhesion of your super glue, ensuring an unbreakable bond.

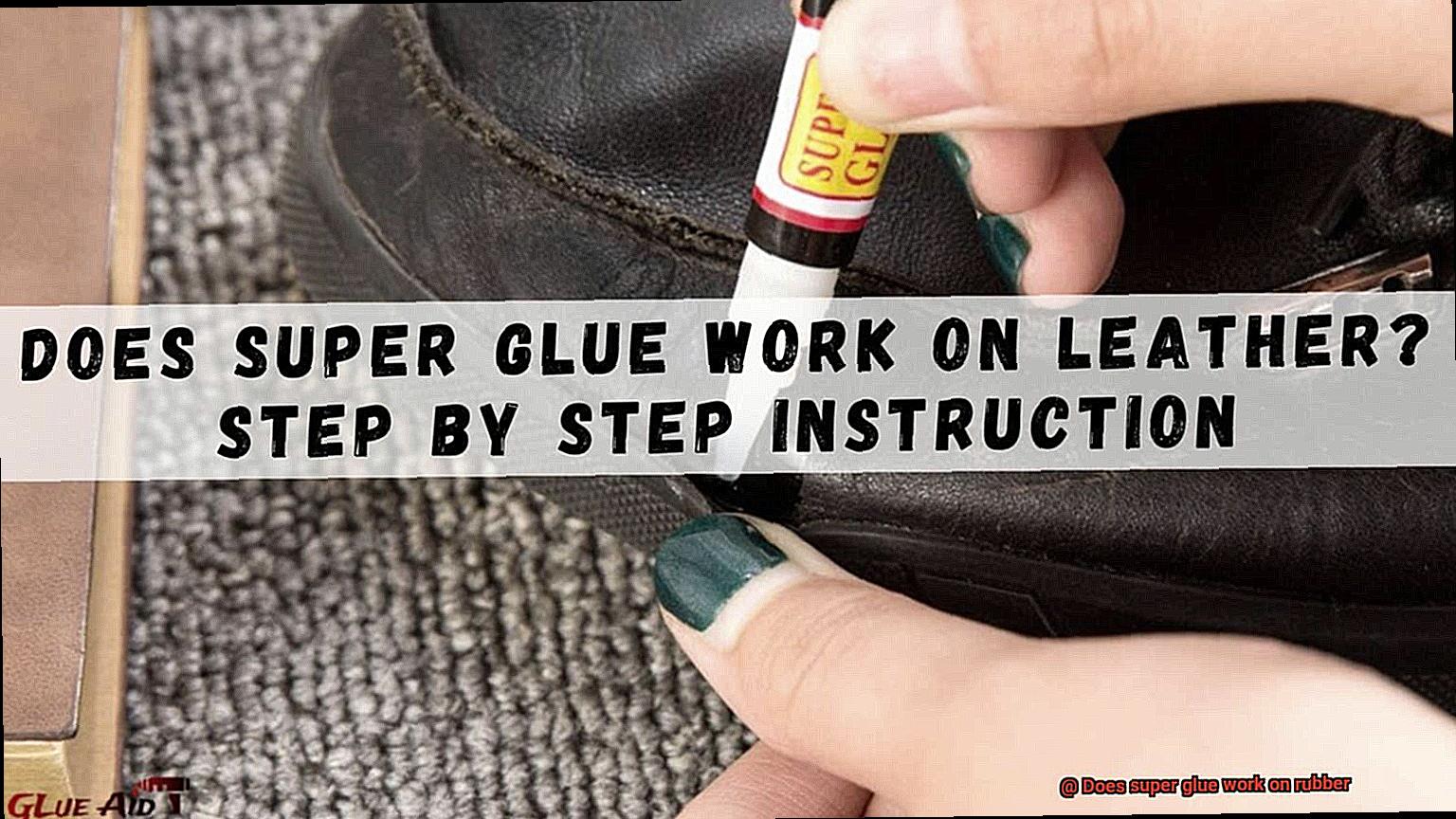

Step 4: Super Glue Application:

It’s time for our superhero, super glue, to take center stage. With precision and finesse, apply a thin layer of super glue evenly onto one of the surfaces you want to bond. Remember, too little won’t do the trick, but too much can create a sticky situation. Find the perfect balance and unleash its power.

Step 5: The Power of Pressure:

Activate the ultimate powers of super glue by exerting pressure on the surfaces. Press them together firmly for several seconds, allowing the adhesive to spread evenly and create a formidable bond. Employ clamps or other tools if needed to hold the pieces together while the glue cures. Remember, this is where strength is born.

Step 6: Patience is a Virtue:

Our heroes need time to recharge and reach their full potential. Exercise patience and allow the super glue to cure completely before subjecting the bonded object to any stress or strain. While some glues dry quickly, achieving maximum strength may take several hours or even days. Embrace patience, and victory will be yours.

Applying the Adhesive

Well, get ready because we’re about to reveal the secrets to applying adhesive to a rubber surface like a pro. Whether you’re fixing a rubber sole on your favorite sneakers or creating a DIY rubber project, we’ve got you covered.

First things first, let’s talk about preparing the rubber surface for maximum bonding power. Think of it as giving your rubber a little spa treatment. Grab some isopropyl alcohol or a mild detergent solution and gently scrub away any dirt, dust, or oils that might hinder the bond. A soft cloth or brush will do the trick, ensuring that your rubber is squeaky clean and ready for action.

Now that your rubber surface is pristine, it’s time to bring out the star of the show – the super glue. But hold your horses, cowboy. Remember, a little goes a long way. Starting with a small amount of adhesive will help you avoid any messiness or excessive spreading. You want just enough to create a strong bond without overwhelming the surface.

Now comes the fun part – applying the glue itself. The key here is to cover the entire rubber surface evenly. You can use a brush applicator for a smooth and precise application or carefully dispense small drops of glue onto the rubber. Just make sure you don’t miss any spots. Pay attention to the edges and corners, as these are often overlooked but crucial areas for bonding.

After you’ve applied the adhesive, it’s time to bring those rubber surfaces together and give them a big bear hug. Firmly press them together for a few minutes to create a bond that even Hercules would be proud of. This step is crucial for ensuring maximum strength and durability in your adhesive bond.

But hold your horses once again. Don’t expect instant results. Depending on the type of super glue you’re using, it may take a few seconds to several minutes for the bond to fully set. Patience is key here, so be sure to follow the manufacturer’s instructions for specific drying times. Rushing the process could result in a weaker bond, and nobody wants that.

It’s worth mentioning that while super glue bonds are known for their strength, they can be quite rigid. If you need some flexibility in your project involving rubber, consider using adhesives specifically designed for rubber. These specialized adhesives will give you the freedom to bend, twist, and turn without compromising the bond.

And hey, if you ever need to break that bond or make some adjustments, acetone is your best friend. Just be cautious when using it on certain types of rubber as it may cause damage or discoloration. Safety first, my friends.

Best Practices for Bonding with Super Glue

Bonding rubber with super glue can be a tricky task, but fear not. With these best practices, you’ll become a pro at sticking things together in no time. So let’s dive in and discover the secrets to successful bonding with super glue.

- Cleanse and prepare: Before applying super glue, ensure that the rubber surface is clean and free from any dirt or oils. Think of it like giving your rubber a spa day. Use a mild detergent or rubbing alcohol to cleanse away the impurities and create a clean slate for your glue.

- Roughen up: To achieve a strong bond, roughen the rubber surface using sandpaper or an abrasive pad. This step creates more surface area for the adhesive to grip onto, ensuring a secure bond. So don’t skip this crucial step.

- Less is more: Remember, when it comes to super glue, less is more. Apply a thin and even layer of adhesive to the rubber surface. Using too much glue can weaken the bond, so resist the urge to go crazy with the glue gun.

- Squeeze tight: Once you’ve applied the glue, press the surfaces firmly together. Imagine you’re playing a game of “This Little Piggy” and squeeze those parts together like your life depends on it (well, maybe not that dramatic, but you get the idea). Applying pressure helps ensure a strong bond and improves overall adhesion.

- Patience is key: Now comes the hard part – waiting. Let those bonded parts cure for at least 24 hours before subjecting them to any stress or load. Just like waiting for your favorite TV show to come back from hiatus, it requires patience, but the end result is worth it.

- Flexibility matters: If you’re working on a project that requires flexibility or movement, consider using a flexible super glue specifically designed for rubber bonding. These special glues are formulated to maintain their bond strength even under dynamic conditions. It’s like giving your rubber a superpower.

- Know your rubber: Not all rubber is created equal. Some types, like silicone rubber or fluorosilicone rubber, may require specialized adhesives. So make sure to check with the manufacturer or do some research to find the right glue for your specific rubber.

- Handle with care: Super glue is great for bonding rubber, but not so great for bonding skin. If you accidentally get it on your skin, don’t panic. Avoid pulling or forcing the bonded skin apart. Instead, soak the affected area in warm soapy water to weaken the bond and gently separate. And if things get sticky (pun intended), seek medical advice.

5ecE-EiZruY” >

Also Read: Super Glue – Glue Things

Conclusion

In conclusion, the answer to the question “Does super glue work on rubber?”

is a resounding yes. Super glue is an incredibly effective adhesive for bonding rubber materials together.

Its strong and fast-acting formula ensures a secure and long-lasting bond that can withstand various pressures and conditions. Whether you need to repair a torn rubber sole on your favorite shoes or fix a leak in a rubber hose, super glue will come to your rescue.

Its versatility makes it an essential tool for any DIY enthusiast or professional repair person.