Sick of dealing with broken stuff? Wishing for a quick fix that actually works? Well, say hello to Sugru – the moldable glue that’s been causing a DIY frenzy. But here’s the burning question: does Sugru get hard? You betcha. Once you apply it, Sugru cures into a tough and sturdy material that can handle whatever life throws at it.

Sugru has changed the game when it comes to repairs. It starts off all soft and squishy, allowing you to shape it however you want. That means you can fix things, customize things, or even create things from scratch. But what makes Sugru special is its ability to transform from goopy goodness to rock-solid awesomeness.

When it meets the air, Sugru gets down to business. It goes through a chemical reaction called polymerization (fancy word alert.), which basically means its molecules link up and get their act together. This process takes about 24 hours, during which time Sugru becomes firmer and firmer until it reaches its solid state. And let me tell you, this stuff is sticky, stretchy, and totally immune to moisture, heat, and cold.

This miraculous transformation makes Sugru your secret weapon for all sorts of household repairs. From fixing frayed cables and reattaching wobbly handles to sealing cracked phone cases – there’s no limit to what you can do. And once it’s hardened up, you can trust that your fixes will last forever.

So next time life gives you something broken or in need of some TLC, give Sugru a shot. Trust me, once you see how it hardens up and all the amazing things you can do with it, you’ll wonder how on earth you survived without it. Say goodbye to flimsy fixes and say hello to your new best friend – Sugru: the moldable glue that actually gets the job done.

How Does Sugru Work?

Contents

Look no further than Sugru, the revolutionary moldable glue that has taken the DIY world by storm. In this blog post, we will delve into the captivating world of Sugru and explore how it works to create personalized solutions for a wide range of applications.

The Flexible Beginning:

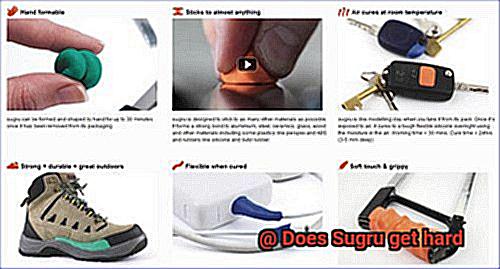

Sugru starts off as a soft and pliable material, much like modeling clay or putty. This initial flexibility allows users to shape and mold it according to their unique requirements. Whether you need to repair a broken handle or customize a tool grip, Sugru provides endless possibilities for crafting tailored solutions.

The Curing Process:

But how does this moldable glue transform from a soft substance into a durable solution? The secret lies in its curing process. When exposed to air, Sugru undergoes a remarkable chemical reaction known as cross-linking. This reaction causes the material to harden and metamorphose into a robust and resilient silicone rubber-like substance.

The Role of Moisture:

Cross-linking occurs due to the moisture present in the air. As the moisture interacts with the silicone molecules in Sugru, it triggers the formation of formidable bonds between them. These bonds create an intricate three-dimensional network structure, endowing Sugru with its rigidity and strength.

Proper Curing:

To achieve optimal results with Sugru, it is crucial to ensure proper curing. The material should be exposed to air and allowed to cure undisturbed for approximately 24 hours. This duration enables the cross-linking process to reach completion, resulting in a fully hardened and functional Sugru repair or creation.

Versatile Applications:

Once fully cured, Sugru retains some flexibility and elasticity, making it ideal for applications that require both strength and adaptability. It can withstand various environmental conditions, including heat, cold, water exposure, and UV radiation. This makes Sugru suitable for both indoor and outdoor use, providing long-lasting repairs and solutions.

Adhesion to Various Materials:

In addition to its adhesive properties, Sugru adheres remarkably well to a wide range of materials, including plastics, ceramics, glass, metal, and fabric. This versatility makes it the go-to solution for repairing and enhancing everyday objects. From reinforcing frayed cables to fixing broken household items, Sugru offers an easy and effective way to make enduring repairs.

Does Sugru Get Hard?

Sugru, the moldable glue that has captured the attention of DIY enthusiasts and crafters everywhere, is known for its unique ability to transform from a soft and pliable material into a hard and durable rubber-like substance. But how exactly does Sugru achieve this impressive transformation? Let’s dive into the details and explore what factors affect its hardness.

When you first open a pack of Sugru, it feels like a malleable clay that can be shaped and molded to fit your needs. This initial softness allows for easy manipulation and fine-tuning of your project. Once you’ve shaped Sugru to your desired form, it’s time to let it cure.

During the curing process, which typically takes around 24 hours, Sugru undergoes a chemical reaction that causes it to harden and transform into a solid material. This transformation is influenced by various factors, such as temperature and humidity. In warmer conditions, Sugru tends to cure faster, while cooler temperatures can prolong the curing time. Similarly, higher humidity levels can also affect the curing process.

Even during the curing period, Sugru maintains its flexibility. This means you can make adjustments or fine-tune the shape or position of the material if needed. However, once fully cured, Sugru becomes solid and rigid, providing a strong bond and excellent durability.

The hardened Sugru is resistant to water, heat, cold, UV radiation, and most common household chemicals. It can withstand temperatures ranging from -50°C to 180°C (-58°F to 356°F), making it suitable for both indoor and outdoor applications. So whether you need to repair a leaky pipe or create a custom grip for your tools, Sugru has got you covered.

It’s important to note that the hardness of cured Sugru can vary depending on the thickness of the applied layer. Thicker layers will result in a harder material compared to thinner layers. So, if you need an extra-strong bond or a more rigid structure, consider applying a thicker layer of Sugru.

But what about flexibility? While Sugru does get hard once cured, it retains some level of flexibility. This unique characteristic allows it to absorb shocks and vibrations without cracking or breaking. It also makes Sugru suitable for applications that require some degree of movement or bending.

If you need to further shape or modify your cured Sugru, don’t worry. Standard tools like sandpaper or a craft knife can be used to achieve the desired result. This versatility allows for endless possibilities when it comes to creating and repairing with Sugru.

The Curing Process of Sugru

Sugru, that amazing moldable glue that can fix just about anything, undergoes a magical transformation from a soft and pliable consistency to a rock-solid material. This transformation is made possible by a chemical reaction called cross-linking.

When Sugru is exposed to air, the moisture in the environment triggers the cross-linking reaction. It’s like watching a superhero come to life. The individual molecules in Sugru start bonding together, forming a solid and durable material. This process takes time, but within the first 30 minutes of exposure to air, Sugru begins to form a skin. And this skin becomes stronger and harder as the curing process continues. So, if you’re impatient like me, you can already see progress within the first half an hour.

During the curing process, it’s important to handle Sugru with care. Excessive movement or manipulation can disrupt the cross-linking reaction and result in an uneven or incomplete cure. Think of it like a delicate flower that needs time and space to blossom into something beautiful.

The full curing process of Sugru takes around 24 hours to reach its maximum hardness. Once fully cured, Sugru becomes a firm and resilient material that can withstand everyday wear and tear. It retains its flexibility to some extent, allowing it to adapt and conform to different shapes and surfaces.

It’s worth mentioning that the hardness of fully cured Sugru may vary slightly depending on the specific formulation and color. Some variations might have a slightly softer or harder finish, but all of them become solid and durable materials once they’ve completed their curing journey.

Factors That Influence Sugru’s Hardening Process

Prepare to witness the mesmerizing transformation of Sugru, as it evolves from a soft and malleable substance into a rock-solid wonder. In this article, we will delve into the secrets behind Sugru’s incredible hardening process, exploring the factors that influence its magical metamorphosis.

Temperature: The Power of Heat

Sugru thrives in room temperature conditions, between 20-25 degrees Celsius (68-77 degrees Fahrenheit). Extreme temperatures disrupt its enchanting transformation. Higher temperatures expedite hardening, while lower temperatures slow it down. Find the sweet spot for Sugru’s magic to unfold.

Time: Patience is Key

Sugru requires patience to reach its full potential. It becomes touch dry after 24 hours and fully cures within 48 hours. However, curing times vary based on layer thickness and environment. Relax and let Sugru work its magic over time.

Humidity: A Balancing Act

Humidity levels affect Sugru’s hardening process. High humidity slows it down, while low humidity speeds it up. Avoid applying Sugru in excessively humid conditions to ensure optimal results.

Thickness: Thin is In

Thin layers cure faster than thick ones. Apply Sugru in thin layers not exceeding 6mm (1/4 inch) for the best results. If a thicker layer is necessary, adjust the curing time accordingly.

Surface Preparation: The Foundation for Success

Cleanliness is crucial for effective hardening. Ensure the surface is clean, dry, and free from dust or grease that hinders adhesion. Soap and water should suffice, but some surfaces may benefit from light sandpaper roughening.

Mixing: Blend with Finesse

Thoroughly mix Sugru’s components to achieve an even distribution of curing agents. Incomplete mixing leads to uneven hardening and compromised adhesion. Follow the manufacturer’s instructions for proper mixing and curing.

UV Exposure: Let the Sun Work Its Magic

Exposure to ultraviolet (UV) light accelerates Sugru’s hardening process. Utilize UV light sources to speed up curing. But beware prolonged exposure to direct sunlight or intense UV light, as it may affect the cured Sugru over time.

Benefits of Sugru After It Has Fully Cured

Today, we dive into the captivating world of Sugru and explore the remarkable benefits it offers after it has fully cured. Prepare to be awed as this magical substance transforms into a durable material with a host of practical advantages. Let’s dig in.

Extreme Temperature Resistance:

Fully cured Sugru is an adhesive superhero that can withstand scorching heat and freezing cold without breaking a sweat. With a temperature range of -50°C to 180°C (-58°F to 356°F), it’s perfect for both Arctic adventures and desert explorations.

Immune to Liquids:

In its fully cured form, Sugru becomes impervious to water and other liquids. Fix that leaky showerhead or craft a watertight seal on your favorite coffee mug – Sugru has got you covered. Dive into the pool or even take it on your next snorkeling adventure – Sugru can handle it all.

Unmatched Adhesion:

Versatility is Sugru’s middle name. Once fully cured, it bonds with a variety of materials like plastics, ceramics, glass, metal, and even fabric. Repair a broken toy or customize your beloved gadgets – Sugru’s got your back.

Flexibility and Strength:

Sugru’s fully cured form boasts rubber-like flexibility combined with impressive strength. It can bend, stretch, and absorb vibrations without losing its grip. From cable management to creating custom grips on tools, Sugru is your trusty sidekick.

Electrical Insulation:

Safety first. Sugru’s fully cured form offers excellent electrical insulation properties. Cover exposed wires or insulate electrical connections with confidence, knowing Sugru provides peace of mind and added protection.

UV Radiation Resistant:

No need to worry about your Sugru masterpiece fading away in the sunlight. Fully cured Sugru stands strong against UV radiation, making it perfect for outdoor applications that require long-lasting durability.

Long-Lasting Durability:

Once Sugru has fully cured, it becomes a superhero among adhesives. It resists impact, abrasion, and general wear and tear, ensuring your repairs hold up well over time. Say goodbye to quick fixes and hello to lasting solutions.

Aesthetically Pleasing:

Who says repairs can’t be beautiful? Sugru comes in a range of vibrant colors that allow you to seamlessly blend your repairs or modifications with the original item. Fixing never looked so good.

Infinite Possibilities:

With Sugru’s fully cured form, your creativity knows no bounds. Fix household items or create custom grips, organize cables, or craft unique DIY projects – Sugru opens up a world of possibilities limited only by your imagination.

Shrinkage of Sugru During the Curing Process

Sugru, the incredible moldable glue, undergoes a captivating transformation from a soft and pliable substance to a solid and durable material. This process, known as curing, involves a certain degree of shrinkage. Shrinkage refers to the reduction in size or volume of a material as it dries or cures. In the case of Sugru, this shrinkage occurs due to the evaporation of moisture and the crosslinking of its polymer chains.

But why does shrinkage happen in the first place? The amount of shrinkage experienced by Sugru can vary depending on factors such as temperature, humidity, and the thickness of the applied layer. Higher temperatures and lower humidity levels generally lead to more significant shrinkage. So if you find yourself using Sugru in a hot and dry environment, expect a bit more shrinkage than usual.

The recommended curing time for Sugru is 24 hours. During this time, it gradually hardens and shrinks. It’s crucial to give Sugru enough time to fully cure to ensure maximum strength and durability. Patience is key.

While the shrinkage of Sugru may pose challenges for certain applications, it is relatively minimal compared to other materials. Its unique formulation allows for some flexibility and elasticity even after it has cured, helping mitigate any potential issues caused by shrinkage.

To minimize shrinkage during the curing process, there are a couple of tricks you can employ. First, apply Sugru in thin layers rather than thick ones. Thicker layers tend to experience more significant shrinkage as there is more moisture to evaporate and polymerize. So take it easy and apply a thin, even layer.

Secondly, controlling the environmental conditions during curing can also help reduce shrinkage. Avoid extreme temperatures and try to maintain a moderate level of humidity. By creating a more controlled curing environment, you’ll have better control over the shrinkage process.

Additional Hardening Options for Sugru

Sugru, the remarkable moldable glue, possesses the ability to transform from a pliable substance into an unyielding bond. However, there are methods to further fortify and solidify its properties. This article explores additional hardening options for Sugru that can elevate your projects to new levels of strength and durability.

Mixing with other materials:

One simple approach to enhance the hardness of Sugru involves blending it with other materials. By incorporating a small amount of fine sand or powdered glass, the resulting mixture gains increased abrasiveness and hardness. This technique is ideal for projects necessitating a rigid and robust finish, such as repairing outdoor equipment or fashioning DIY tools.

Heat acceleration:

If you desire a swifter curing time and a harder final outcome, heat can be your ally. Exposing Sugru to heat, whether through direct flame or a heat gun, significantly reduces curing time and promotes a firmer bond. Exercise caution to avoid overheating the Sugru, as it may result in discoloration or burning.

Applying pressure:

Applying pressure during the curing process is another technique worth considering. By clamping or compressing the Sugru between surfaces until it fully cures, air bubbles are eliminated, ensuring a compact and dense end result. This method proves particularly valuable for projects requiring high-strength bonds or the ability to withstand heavy loads.

Post-curing techniques:

To further enhance the hardness of Sugru, post-curing techniques can be employed. After the initial curing period, exposing the cured Sugru to extended periods of UV light facilitates cross-linking of polymer chains, resulting in a denser and tougher material. Outdoor applications benefit greatly from this method, capitalizing on readily available sunlight exposure.

Applications of Hardened Sugru

Hardened Sugru is not just your average glue. This revolutionary moldable adhesive has the power to transform your everyday life and revolutionize various industries. From automotive repairs to arts and crafts, from medical applications to outdoor adventures, hardened Sugru has a wide range of applications that will blow your mind.

In the automotive industry, hardened Sugru works wonders. Cracked bumpers or broken side mirrors? No problem. This magical glue can repair and reinforce damaged parts, providing a strong and durable bond that can withstand the harsh conditions of the road. Say goodbye to costly repairs and hello to DIY solutions.

Electronics lovers, rejoice. Hardened Sugru is a game-changer for you. No more frayed wires or tangled cables. This magical glue can be used for cable management, repairing frayed wires, or creating custom grips for handheld devices. Its electrical insulation properties make it a reliable material for these applications. Plus, it’s super easy to use.

But wait, there’s more. In the household, hardened Sugru can fix and improve various items. Broken handles? Weak joints? No problem. This versatile glue can reinforce weak spots, repair broken items, and even create custom hooks and holders. Its waterproof and heat-resistant properties make it suitable for use in kitchens and bathrooms. Who knew a little glue could do so much?

Artists and crafters, listen up. Hardened Sugru opens up a world of possibilities for your creative endeavors. Mold it into different shapes and forms to create unique sculptures, jewelry, or decorative items. Its ability to bond with various materials makes it a versatile medium for artistic expression. Let your imagination run wild.

But what about the medical field? Hardened Sugru has got you covered there too. It can be used to create custom grips for medical instruments, cushioning pads for prosthetic limbs, or ergonomic handles for assistive devices. Its non-toxic and flexible nature makes it safe and comfortable for patients and healthcare professionals alike.

Outdoor enthusiasts, pay attention. Hardened Sugru can be a valuable tool for your adventures. Repair camping equipment, reinforce hiking boots, or create custom grips for fishing rods. Its resistance to UV radiation and extreme temperatures ensures that it remains durable even in challenging outdoor conditions. No more worrying about gear breaking on your next adventure.

Home improvement projects? DIY enthusiasts, this one’s for you. Hardened Sugru can fix household appliances, seal gaps around windows and doors, or create custom mounts for organizing tools. Its adhesive properties make it a reliable solution for various DIY projects. Say goodbye to loose handles and hello to sturdy repairs.

Last but not least, hardened Sugru has applications in engineering and prototyping. Create custom components, repair prototypes, or enhance the grip and comfort of tools. Its ability to bond with different materials and its flexible yet durable nature make it an ideal material for rapid prototyping and product development.

uNyONZvoSi8″ >

Conclusion

Sugru, the versatile moldable glue, is no stranger to getting hard. In fact, it’s one of its most impressive qualities. Once applied and left to cure, Sugru transforms from a soft, pliable substance into a solid and durable material. Its unique formulation allows it to harden while retaining flexibility, making it perfect for a wide range of applications.

But what exactly makes Sugru get hard? It all comes down to a chemical reaction known as cross-linking. When exposed to air, the silicone-based putty begins to cure and form strong bonds between its molecules. Over time, these bonds become more and more rigid, resulting in a hardened surface that can withstand the test of time.

The transformation from soft to hard is not only practical but also visually satisfying. Watching Sugru change from a malleable blob into a solid object is like witnessing a magical metamorphosis right before your eyes. It’s this captivating process that adds an extra layer of excitement and wonderment to using Sugru.

Once fully hardened, Sugru maintains its strength and durability even in challenging conditions. It can withstand extreme temperatures, water exposure, UV rays, and everyday wear and tear without losing its structural integrity. This means you can trust Sugru to hold up under pressure and provide long-lasting repairs or creations.

So whether you’re fixing broken household items or unleashing your creativity through DIY projects, rest assured that Sugru will get hard in all the right ways. Its ability to transform from soft to solid gives you the confidence that your repairs will last and your creations will endure.

In conclusion, Sugru does indeed get hard – but not just any kind of hardness. It undergoes a remarkable transformation that combines strength with flexibility.