Imagine this: you’re knee-deep in a mesmerizing craft project, painstakingly piecing together a magnificent masterpiece, when suddenly, you’re faced with the challenge of joining two glass pieces. Panic sets in as you ponder, “Can rubber cement really hold glass together?” It’s a question that has left countless DIY enthusiasts scratching their heads.

Glass, with its delicate and sleek nature, might not seem like an obvious candidate for adhesive experiments. However, the quest for the perfect glue that can conquer all materials remains an eternal puzzle. In this captivating blog post, we embark on a thrilling journey to demystify the enigma surrounding rubber cement’s bond with glass.

Hook:

From ancient Egypt’s groundbreaking discovery of glassblowing to the awe-inspiring architectural and artistic wonders of today, glass has captivated our imaginations with its innate beauty and remarkable versatility. But how can we ensure a secure and enduring connection between glass surfaces?

Main Points:

- Unveiling the chemistry behind rubber cement: Take a deep dive into the mesmerizing world of rubber cement’s composition, unraveling its adhesive properties and exploring the key factors that determine its bond strength with various materials.

- Practicality meets functionality: Explore real-life scenarios where rubber cement proves its worthiness when it comes to bonding glass objects. However, discover the limitations it may face in certain applications – after all, no adhesive is perfect.

- Insider tips for success: Unlock expert secrets and clever techniques to maximize adhesion between rubber cement and glass surfaces. Learn about surface preparation methods and compatibility considerations that can make all the difference in achieving a rock-solid bond.

- Exploring alternative adhesive options for glass: Peek into a few alternatives that might outshine rubber cement in specific circumstances when it comes to bonding those elusive glass surfaces.

As we venture further into the captivating realm of adhesive prowess, the mystery of whether rubber cement can truly stick to glass will be laid bare.

By the end of this enlightening exploration, you’ll possess invaluable insights that will empower you to fearlessly navigate uncharted waters when it comes to gluing glass – and who knows, you might even create breathtaking works of art or effortlessly restore cherished glassware.

So, let’s dive right in and uncover the secret behind the invisible bond that unites glass and rubber cement.

Does Rubber Cement Stick to Glass?

Contents

- 1 Does Rubber Cement Stick to Glass?

- 2 Factors that Affect the Bonding Performance of Rubber Cement on Glass

- 3 Advantages and Disadvantages of Using Rubber Cement on Glass

- 4 Preparing the Surface for Optimal Bonding with Rubber Cement

- 5 Alternative Adhesives for Bonding Glass

- 6 Tips for Selecting an Appropriate Adhesive for Bonding Glass

- 7 How to Apply Rubber Cement to a Glass Surface

- 8 Troubleshooting Common Issues when Applying Rubber Cement to Glass

- 9 Conclusion

When it comes to glass, a tantalizing question emerges – can rubber cement truly stick to this smooth surface? Prepare to embark on a journey through the enigmatic composition of rubber cement and unravel the factors that determine its efficacy on glass.

Decoding Rubber Cement’s Composition:

At its core, rubber cement is a captivating blend of synthetic rubber particles floating harmoniously in a solvent, often acetone or hexane.

These rubber particles exude adhesive prowess, while the solvent grants the cement effortless application, evaporating gracefully as the adhesive dries.

As the solvent bids adieu, it leaves behind a whisper-thin layer of rubber that binds surfaces together.

The Glass Conundrum:

Glass, with its sleek and impermeable nature, presents a formidable challenge for adhesives. Its smooth texture and chemical resilience make it an unyielding surface for rubber cement’s affections. While rubber cement may initially embrace glass with open arms, its bond on this particular material may falter over time, succumbing to peeling and detachment.

Factors Influencing Adhesion:

A symphony of factors conducts the dance between rubber cement and glass adhesion. First and foremost, the cleanliness of the glass surface takes center stage. Oils and residues lurking on the glass can disrupt the adhesive’s courtship, weakening the bond. Thus, before applying the adhesive, ensuring a pristine glass surface becomes paramount.

Next, the amount of adhesive applied choreographs the strength of the bond. A delicate balance ensues as a thin and even layer of rubber cement graces both surfaces. This intimate connection fosters better contact and adhesion between the adhesive and glass, setting the stage for maximum bonding strength.

Last but not least, pressure emerges as the secret ingredient to a triumphant union. As the adhesive and glass embrace, applying pressure or employing clamps adds a touch of vigor, solidifying the bond and ensuring a secure connection.

Factors that Affect the Bonding Performance of Rubber Cement on Glass

In our previous chapter, we alluded to the factors that govern the success of this union. Today, we shall unravel these factors and delve into the intricate world of rubber cement’s bonding performance on glass. So, don your lab coats and secure your safety goggles as we embark on this thrilling scientific expedition.

Factor 1: Surface Preparation – The Quest for Pristine Purity:

Picture this: attempting to apply rubber cement to a grimy glass surface is akin to placing a post-it note on an oily frying pan – a sure recipe for failure. The preparation of the glass surface holds immense sway over the bonding performance of rubber cement. Prior to application, meticulous cleansing is imperative. Rid the glass of any dirt, dust, or oil by gently washing it with a mild detergent and water.

Follow this with thorough rinsing and drying, creating an ideal landscape for the rubber cement to showcase its adhesive prowess.

Factor 2: Temperature and Humidity – The Goldilocks Conditions:

Much like humans, rubber cement thrives within an environment that caters to its needs. Extreme temperatures can disrupt the adhesive’s curing process, leading to either excessively long drying times or incomplete bonding. To achieve optimal results, maintain a temperature range between 60°F (15°C) and 80°F (27°C). Similarly, high humidity levels can also impede the adhesive properties of rubber cement, resulting in delayed drying or weakened bond strength. By providing controlled temperature and humidity conditions during application, we grant rubber cement the perfect stage for its remarkable performance.

Factor 3: Application Technique – Brushing Excellence:

The application of rubber cement demands finesse and precision. To forge an unbreakable bond, it is crucial to administer a thin and even layer of the adhesive, employing a brush or applicator. Uneven application risks weak spots or areas devoid of sufficient adhesive, compromising the overall bond strength. Adhere to the manufacturer’s instructions regarding drying time and any specific techniques recommended for bonding rubber cement to glass surfaces. Remember, a stroke of brilliance with the brush goes a long way in fostering an everlasting connection.

Advantages and Disadvantages of Using Rubber Cement on Glass

Get ready to be enchanted as we delve into the alluring advantages and the not-so-glamorous disadvantages of using rubber cement on glass. So, grab your magnifying glasses and embark on this adhesive adventure with me.

Advantages of Using Rubber Cement on Glass:

Easy Application:

Imagine a delicate glass art project beckoning you, and time is of the essence. Fear not. Rubber cement comes to the rescue with its liquid form, effortlessly spreading across the glass surface. Whether you wield a brush or prefer the tactile sensation of your fingers, applying rubber cement on glass is an absolute breeze. It’s a convenient choice for crafters and glass aficionados alike.

Temporary Bond:

Life is full of surprises, demanding adhesive flexibility. Enter rubber cement with its remarkable knack for temporary bonding. This characteristic makes it an ideal choice for projects that require repositioning or eventual removal. Need to adjust your stained glass masterpiece? No worries. Rubber cement empowers you to make changes without leaving a trace.

Non-Damaging:

We treasure our beloved glass items, don’t we? That’s why it’s crucial to choose an adhesive that treats them with utmost care. Rest assured, rubber cement passes this test with flying colors. When used correctly and in moderation, it can be peeled off effortlessly without causing any harm to your cherished glass surfaces. Bid farewell to residue and unsightly marks.

Disadvantages of Using Rubber Cement on Glass:

Not Suitable for Heavy Loads:

As much as we adore rubber cement’s versatility, let’s acknowledge its limitations. If you’re embarking on a project involving heavy loads or longing for a strong permanent bond, rubber cement might not be the hero you’re seeking. Its adhesive strength is not designed to withstand substantial weight or pressure, making it wise to explore alternative options.

Limited Weather Resistance:

Ah, the great outdoors can be a challenging environment, and unfortunately, rubber cement isn’t a fan of extreme weather conditions. Be it scorching heat or relentless moisture, rubber cement may lose its adhesive prowess when faced with these adversities. So, if your project involves braving the elements, consider opting for a more weather-resistant adhesive.

Preparing the Surface for Optimal Bonding with Rubber Cement

Today, we are delving into the captivating world of rubber cement and its mesmerizing bond with glass. But before we become spellbound by this enchanting union, let us unlock the secrets of preparing the glass surface for optimal bonding with rubber cement. These steps are like casting a powerful spell that guarantees a strong and long-lasting connection.

Step 1: Cleanliness is Vital

In our quest for the perfect bond, we must first cleanse our glass canvas thoroughly. Any dirt, dust, or grease lurking on the surface could hinder our beloved rubber cement from adhering effectively. Grab a mild detergent or glass cleaner and give your glass a thorough scrub. Rinse it off with water, ensuring it is completely dry before we proceed.

Step 2: Embrace Roughness

Now that our glass is clean and dry, let’s add a touch of roughness to help our rubber cement cling on like a tenacious warrior. Take some fine-grit sandpaper and gently caress the surface in circular motions. Remember, gentle strokes are all that’s needed here – no need to go overboard and risk damaging the glass.

Step 3: Bid Farewell to Dust

After our sanding ritual, grab a clean, lint-free cloth and sweep away any lingering dust or debris. We want our glass surface to be as smooth as freshly polished crystal before we take the next step.

Step 4: Unlock the Magic – Primer.

Now it’s time to unveil the secret elixir that will elevate our bonding strength to extraordinary heights – primer. Choose a primer or adhesive promoter specifically designed for glass bonding. This magical potion of adhesion will enhance the bond between our rubber cement and the glass. Follow the manufacturer’s instructions when applying this mystical elixir, ensuring an even and thin layer.

Alternative Adhesives for Bonding Glass

In our previous exploration, we discovered the limitations of rubber cement when it comes to bonding glass. Today, we embark on an enchanting journey, where we unveil the secrets of adhesives that possess the power to create robust and enduring bonds between glass surfaces. So, let us wield our adhesive wands and delve into this magical odyssey.

Clear Epoxy Adhesive:

Behold the mighty clear epoxy adhesive, a true sorcerer in the art of bonding glass. Renowned for its unwavering strength, epoxy adhesives are crafted to forge bonds that defy time’s relentless passage.

With its two-part composition – resin and hardener – these adhesives unleash their potent magic only when united. Applying this elixir to glass surfaces initiates a transformational process, gradually curing into an indomitable bond that withstands all trials.

UV-Curable Adhesive:

Prepare to be spellbound by the captivating UV-curable adhesive. This mystical concoction harnesses the power of ultraviolet light to bring forth its enchanting properties. Its transparent and formidable bonds make it a coveted choice in industries such as electronics and optics.

Offering exceptional adhesion to glass surfaces, this adhesive delivers swift curing times, weaving its sorcery with effortless efficiency and unwavering quality.

Silicone Adhesive:

Step into the realm where flexibility meets thermal resistance – the captivating domain of silicone adhesives. While not suitable for every glass bonding endeavor, these adhesives possess extraordinary capabilities in uniting materials with disparate coefficients of expansion. However, heed this cautionary advice: select a silicone adhesive specially crafted for glass bonding, for only then shall you unlock a bond of true strength. Ordinary silicone adhesives lack the mystical prowess required for this task.

Acrylic Adhesives:

Prepare to be enchanted by the resilience and potency of acrylic adhesives. These magical elixirs are renowned for their resistance to the ravages of weathering and the relentless march of time. Offering liquid or tape form, acrylic adhesives grant versatility and ease of application. Whether your quest takes you indoors or outdoors, these loyal companions in the realm of glass bonding shall never fail you.

Tips for Selecting an Appropriate Adhesive for Bonding Glass

When choosing an adhesive to bond glass, it is essential to carefully assess the specific requirements of your project. Take into account factors such as the type of glass being used, the intended use of the bonded surface, and the environmental conditions it will be exposed to. By considering these factors, you can ensure that the adhesive you select is well-suited to meet the unique demands of your project.

Epoxy for Unyielding and Lasting Bonds

Epoxy adhesives are a popular choice for bonding glass due to their ability to provide strong and durable bonds. Whether you are working with clear, colored, or textured glass, epoxy adhesives offer exceptional bonding capabilities. Their resilience makes them suitable for a wide range of applications where long-lasting bonds are required.

Silicone for Flexibility and Moisture Resistance

If your project involves bonding glass in environments exposed to water or fluctuating temperatures, silicone adhesives are an excellent option. Renowned for their flexibility and resistance to moisture, silicone adhesives can withstand challenging conditions. They are particularly ideal for applications such as aquariums or projects where a flexible bond is crucial.

Swift Bonding with UV-Curing Adhesives

In time-sensitive projects, UV-curing adhesives offer a practical solution. These adhesives cure rapidly upon exposure to ultraviolet light, instantly creating a strong bond. Industries like electronics and optics often rely on UV-curing adhesives when fast bonding is necessary.

Surface Preparation and Compatibility

To ensure a successful bond when working with glass, thorough surface preparation is paramount. Prior to applying the adhesive, clean the glass surface meticulously using a glass cleaner or rubbing alcohol. Additionally, it is vital to confirm the compatibility of the adhesive with your specific type of glass to prevent any adverse effects during the bonding process.

Subtopic 6: Test Before Applying

Before committing to a specific adhesive for your project, perform a test bond on a small, inconspicuous area. This step allows you to verify the compatibility of the adhesive with your glass and assess whether it meets the desired bond strength. By conducting this test, you can avoid potential issues and ensure a successful bond.

How to Apply Rubber Cement to a Glass Surface

Rubber cement is a remarkable adhesive with countless applications, but what about its compatibility with smooth glass surfaces? In this comprehensive guide, we will delve into the intricacies of applying rubber cement to glass and provide you with an expert-driven, step-by-step approach to ensure flawless results.

Gather the Necessary Materials:

To embark on this adhesive adventure, assemble all the essential tools. You’ll need top-quality rubber cement designed for glass surfaces, a disposable brush or applicator, glass cleaner for thorough cleaning, a lint-free cloth for optimal surface preparation, and protective gloves to shield your hands from any potential irritation.

Prepare the Glass Surface:

Before diving into the application process, it is crucial to prepare the glass surface meticulously. Begin by wiping down the glass with a glass cleaner and a lint-free cloth, eliminating any remnants of dirt, dust, or oils that may hinder the adhesive’s effectiveness. A pristine surface is the foundation for a strong bond.

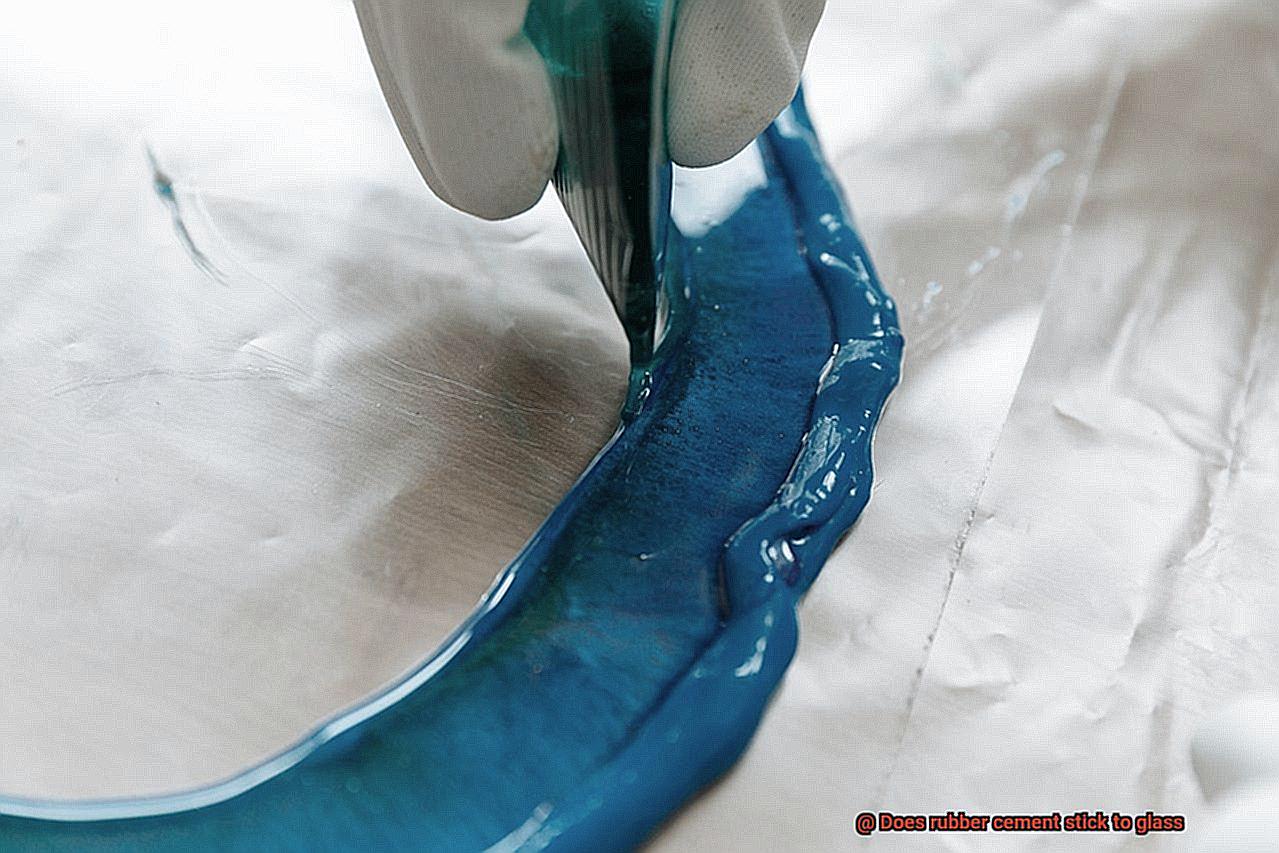

Apply the Rubber Cement:

Now comes the moment of truth – it’s time to apply the rubber cement. Shake the bottle vigorously, ensuring that the contents are mixed thoroughly. Dip your chosen brush or applicator into the rubber cement, making sure it is evenly coated without excessive dripping.

With anticipation in your heart and precision in your hand, commence your artistic endeavor. Start at one corner of the glass surface and proceed with smooth and even strokes, gradually traversing your way across. Remember, less is more – a thin layer of rubber cement is sufficient. Avoid succumbing to temptation and over-applying, as excessive amounts may prolong drying time and compromise adhesion uniformity.

Allow for Drying Time:

After gracefully applying the rubber cement, grant it the time it needs to dry gracefully. Adhere strictly to the manufacturer’s instructions, as drying times may vary. Typically, it takes around 15-30 minutes for rubber cement to dry completely. During this period, resist the urge to intervene, lest you risk jeopardizing the surface’s immaculateness with smudging or unevenness.

Test Adhesion:

Once the drying period has concluded, embark on a gentle exploration of your creation. Lightly touch the surface to gauge the adhesive’s adhesion. A perfect balance awaits your fingertips – it should feel tantalizingly tacky without being excessively sticky. In the event that stickiness prevails or the bond seems fragile, exercise patience and allow additional drying time. Remember, haste is the enemy of a robust and enduring bond.

Troubleshooting Common Issues when Applying Rubber Cement to Glass

Rubber cement is a versatile adhesive that can work wonders when it comes to bonding materials to glass surfaces. However, like any other adhesive, there are common issues that may arise during the application process. In this troubleshooting guide, we’ll explore these issues and provide expert tips on how to overcome them, ensuring flawless results every time.

Poor Adhesion: Cleanliness is Key

When rubber cement doesn’t adhere properly to the glass surface, it can be frustrating. But fear not – there’s a simple solution. To improve adhesion, start by thoroughly cleaning the glass surface with a glass cleaner or rubbing alcohol. This will remove any dirt, dust, or oils that may hinder the bond, ensuring a clean surface for the rubber cement to stick to.

Slow Drying or Incomplete Drying: Optimal Conditions

If you find that the rubber cement takes too long to dry or doesn’t dry completely, don’t panic – we’ve got you covered. This issue often arises from applying too much rubber cement or working in a cold or humid environment. To troubleshoot this problem, apply a thin layer of rubber cement and ensure that the room is well-ventilated with moderate temperature and humidity levels. This will speed up the drying process and ensure a complete bond.

Visible Residue or Marks: Even Application is Key

Unsightly residue or marks left behind after applying rubber cement to glass can be frustrating. But don’t let them ruin your project. The secret lies in applying a thin and even layer of rubber cement using a brush or applicator. This prevents excess rubber cement from pooling or spreading unevenly on the glass surface. If you do notice any excess rubber cement, gently remove it with a clean cloth or cotton swab before it dries.

Brittle or Peeling Rubber Cement: Quality and Storage Matter

If you find that the rubber cement becomes brittle and starts peeling off from the glass surface over time, it’s time for troubleshooting. This issue often stems from using poor-quality rubber cement or exposing it to extreme heat or cold conditions. To avoid this problem, opt for high-quality rubber cement specifically designed for bonding glass surfaces. Additionally, store the rubber cement in a cool and dry place to maintain its effectiveness.

WyM9JtRZuvc” >

Conclusion

Rubber cement and glass may seem like an unlikely pair, but does this adhesive truly have the power to stick to such a smooth surface?

The answer, my friend, is a resounding yes. Rubber cement does indeed adhere to glass, forming a strong bond that can withstand the test of time.

Its sticky properties allow it to firmly grip onto the glass surface, creating a reliable hold that won’t easily let go.