Are you itching to start your next DIY project with resin epoxy, but can’t decide which materials to use? Perhaps you’re considering PVC, but are unsure whether resin epoxy will stick to it. Fear not, dear reader – we’ve got your back.

Resin epoxy is a jack-of-all-trades adhesive that can work wonders on various materials, from glass to wood. However, when it comes to PVC, things can get a bit tricky. PVC is a type of plastic that boasts a smooth surface and low adhesion properties – making it difficult for epoxies to bond effectively.

But don’t throw in the towel just yet. There are ways to make resin epoxy stick to PVC. In this blog post, we’ll delve into the different factors that impact the adhesion of resin epoxy to PVC. We’ll also provide some nifty tips and tricks on how to prep PVC surfaces for epoxy application and what types of epoxy to use for PVC.

If you’re looking to create durable and long-lasting projects using PVC, then this blog post is tailor-made for you. So buckle up and join us as we explore the fascinating world of resin epoxy and PVC – and discover how these two materials can work in perfect harmony.

What is Resin Epoxy?

Contents

- 1 What is Resin Epoxy?

- 2 What is PVC?

- 3 Do Resin Epoxy and PVC Bond Together?

- 4 Benefits of Using Resin Epoxy on PVC

- 5 Preparing the Surface of PVC for Resin Epoxy Bonding

- 6 Choosing the Right Type of Epoxy for PVC Bonding

- 7 Tips for Ensuring a Strong Bond Between Resin Epoxy and PVC

- 8 Factors That Affect the Strength of the Bond Between Resin Epoxy and PVC

- 9 Conclusion

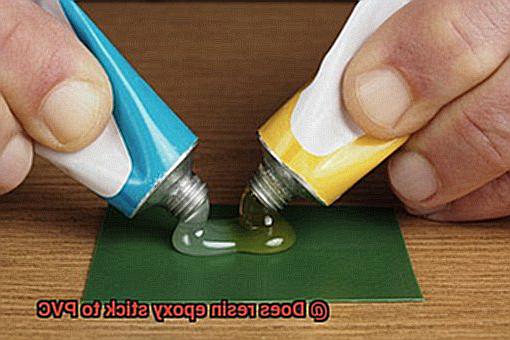

Resin epoxy is a powerful adhesive that has revolutionized the construction and automotive industries. It is a two-part system that consists of a resin and a hardener, which, when mixed together, creates a bond that is incredibly strong and durable. The resin component is derived from petroleum and is a light-colored, viscous liquid, while the hardener component is a darker liquid that contains an amine compound.

One of the most impressive features of resin epoxy is its ability to cure or harden at room temperature or under heat. This happens through a chemical reaction between the resin and the hardener, creating cross-linked polymers that form a robust and stable bond. Resin epoxy can be used on many substrates, including metal, wood, ceramics, and plastics.

Resin epoxy usually contains bisphenol-A (BPA) and epichlorohydrin (ECH), which are reacted together to form a polymer chain. However, other types of resin epoxy are formulated with different ingredients for specific applications.

Resin epoxy is known for its high strength, excellent adhesion properties, and resistance to water and chemicals. These qualities make it ideal for many industrial and commercial applications where durability and reliability are essential. Some of the most common uses of resin epoxy include bonding metals, plastics, ceramics, and wood.

When bonding PVC with resin epoxy, it’s essential to take some precautions to ensure a long-lasting bond. The surface of the PVC must be clean and free from any dirt or debris. The surface may need to be roughened up using sandpaper or an abrasive material to create a rough surface that the epoxy can grip onto. It’s also vital to use high-quality epoxy specifically designed for use with plastics like PVC.

What is PVC?

Get ready to explore the world of PVC, the synthetic polymer that’s making waves in the construction and other industries. PVC, or polyvinyl chloride, is a thermoplastic material that can be shaped into different forms and sizes, making it an ideal choice for pipes, fittings, and other building materials. With its exceptional durability, strength, and resistance to chemicals and weathering, PVC is a go-to material for DIY enthusiasts and professionals alike.

But how is PVC made? It all starts with vinyl chloride monomer, a toxic gas that undergoes polymerization to become a solid material safe for use. Once transformed, PVC can be manufactured in various grades suited to specific applications. For instance, rigid PVC is perfect for pipes and fittings, while flexible PVC is ideal for electrical cables and garden hoses.

One of the most significant advantages of PVC is its ability to be easily joined together using adhesives or solvent welding. This means that different pieces of PVC can be bonded together to create a seamless joint. However, not all adhesives are created equal when it comes to bonding PVC. It’s crucial to choose an adhesive specifically designed for PVC that can provide a strong and durable bond.

Resin epoxy is one such superhero adhesive that creates a robust bond between various substrates, including PVC. But what factors affect the bond strength between resin epoxy and PVC? We’ll delve into that in the next section.

Do Resin Epoxy and PVC Bond Together?

While it’s possible for these materials to bond together, it’s not always a straightforward process. Let’s dive into some expert tips on how to successfully bond these two materials.

The first crucial step is surface preparation. Both surfaces need to be thoroughly cleaned and degreased before applying any adhesive. This is particularly important with PVC, which is known for its resistance to chemicals and weathering. Use a solvent like acetone or rubbing alcohol to ensure there’s no dirt or grease that could interfere with the adhesive.

Once the surfaces are prepped, it’s time to choose the right adhesive. Look for specific types of epoxy adhesives that are designed to bond with PVC, such as “PVC epoxy” or “plastic welder.” These adhesives contain special additives that help them adhere to the smooth surface of PVC. Don’t opt for a generic epoxy adhesive, as it may not be strong enough for PVC.

When applying the adhesive, follow the manufacturer’s instructions carefully. Apply it evenly and allow sufficient time for curing before handling or using the bonded materials. Rushing this step could weaken the bond and compromise the durability of your project.

Benefits of Using Resin Epoxy on PVC

PVC, known for its durability and versatility, can be challenging to bond with adhesives due to its smooth surface and low surface energy. However, resin epoxy comes to the rescue with its impressive properties.

First and foremost, resin epoxy creates a strong and permanent bond that is not affected by external factors such as temperature changes or moisture exposure. This provides a reliable and long-lasting bond that can withstand harsh conditions.

Moreover, resin epoxy has high viscosity, making it an ideal solution for filling gaps and cracks commonly found in irregular PVC surfaces. This property makes it perfect for repairing broken PVC pipes or sealing leaks.

Resin epoxy’s resistance to chemicals and corrosion is another benefit that makes it an excellent choice for industrial settings. It can withstand exposure to harsh chemicals, acids, and bases without degrading or losing its adhesive properties. This makes it an ideal choice for bonding or repairing PVC materials used in chemical processing plants or other industrial settings.

Another advantage of using resin epoxy on PVC is its ease of application. It can be applied using a brush, roller, or spray gun, depending on the size of the surface being bonded. The adhesive also has a long working time, which allows for adjustments to be made before it sets.

Preparing the Surface of PVC for Resin Epoxy Bonding

To ensure that your repair work lasts over time, it’s essential to prepare the surface of your PVC for resin epoxy bonding properly. A strong and durable bond begins with proper preparation.

The first step in preparing the surface of PVC for resin epoxy bonding is to clean it thoroughly. Dirt, grease, or other contaminants on the surface can prevent the epoxy from adhering properly. To clean your PVC surface, start by wiping it down with a clean cloth or paper towel. Next, use warm water and a mild detergent or soap to scrub the surface thoroughly. Be sure to rinse the surface well with clean water and allow it to dry completely before moving on to the next step.

Once your PVC surface is clean and dry, it’s time to roughen it up a bit. This may seem counterintuitive, but roughening up the surface will actually help the epoxy adhere better to it. You can use sandpaper or a wire brush to roughen up the surface. Start by sanding or brushing in one direction and then switch to another direction to create a crosshatch pattern on the surface. This will provide something for the epoxy to grip onto.

After roughening up your PVC surface, wipe it down again with a clean cloth or paper towel to remove any dust or debris. It’s crucial that you ensure the surface is entirely clean and dry before applying any epoxy.

To recap, preparing the surface of PVC for resin epoxy bonding involves three straightforward steps:

- Thoroughly clean the surface

- Roughen up the surface with sandpaper or a wire brush

- Wipe down again to remove any dust or debris

Choosing the Right Type of Epoxy for PVC Bonding

If you are planning to repair your PVC using epoxy resin, choosing the right type of epoxy is crucial for a successful bond. As an expert in this field, let me guide you through some important factors to consider when selecting an epoxy for PVC bonding.

Curing time is a critical factor to consider when selecting an epoxy for PVC bonding. Some types of epoxy cure faster than others, and choosing one that cures too quickly may not allow enough time for proper adhesion to occur. Therefore, it’s essential to select an epoxy with a suitable curing time for your application.

In addition to curing time, viscosity or thickness also plays a significant role in bonding PVC. To achieve a strong bond, it is recommended to choose a thin or low-viscosity epoxy. This type of epoxy can penetrate into the pores of the PVC surface, resulting in a stronger bond. Therefore, be sure to select an epoxy that has a low viscosity for bonding PVC.

Moreover, adhesion strength is crucial for a strong and durable bond between PVC and other materials. When selecting an epoxy for PVC bonding, consider choosing one that has good adhesion strength to both PVC and the material it will be bonded to. This will ensure that the bond is strong and long-lasting over time.

It’s essential to read the manufacturer’s instructions carefully before selecting an epoxy for PVC bonding. Make sure the chosen product is suitable for both materials and follow the instructions diligently. Additionally, consulting with an expert or doing some research online can also help you find the best type of epoxy for your specific application.

Tips for Ensuring a Strong Bond Between Resin Epoxy and PVC

If you want to ensure a strong and durable bond between resin epoxy and PVC, there are several key steps you need to follow. Let’s take a closer look at each of these steps and how they can help you achieve the best possible results.

Clean the surface thoroughly

Before you start applying resin epoxy to PVC, it’s essential to clean the surface thoroughly. This means using soap and water to remove any dirt or debris, followed by a degreaser to get rid of any oils or other contaminants that may be present. Make sure the surface is completely dry before moving on to the next step.

Roughen up the surface

To help the epoxy grip onto the PVC more effectively, it’s a good idea to roughen up the surface with sandpaper or a wire brush. This will create tiny grooves and scratches that will provide more surface area for the epoxy to bond with. Just be careful not to use too much force or a solvent-based cleaner that could damage the PVC.

Use a primer

Applying a primer to the PVC surface before applying resin epoxy can also improve adhesion. The primer creates a base layer that the epoxy can adhere to more easily. Be sure to choose a primer that is designed specifically for use with PVC.

Mix the epoxy thoroughly

It’s important to follow the manufacturer’s instructions carefully when mixing your resin epoxy. Be sure to mix the components thoroughly so that you have a uniform consistency throughout. A well-mixed epoxy will bond more effectively with PVC and create a stronger bond overall.

Apply the epoxy evenly

When applying resin epoxy to PVC, it’s important to spread it evenly over the entire surface. This will help ensure that there are no gaps or air pockets that could weaken the bond over time. Use enough pressure to make sure the epoxy fully adheres to the PVC surface.

Allow ample curing time

Finally, be sure to allow the resin epoxy ample time to cure before using the bonded item. This may take several hours or even several days, depending on the specific type of epoxy you’re using. Follow the manufacturer’s recommended curing time to ensure a strong and durable bond between the two materials.

Factors That Affect the Strength of the Bond Between Resin Epoxy and PVC

When it comes to bonding PVC and resin epoxy, there are several critical factors to keep in mind to ensure a strong and durable bond. The strength of the bond can make a significant difference in various industries such as construction, automotive, and marine. In this passage, we will dive deeper into each factor that affects the bond’s strength and provide tips on how to achieve a successful bond.

One of the most crucial factors that affect the bond’s strength is surface preparation. Both PVC and resin epoxy must be completely clean and dry before bonding. Any dirt, oil, or debris on either surface can create a barrier between the two materials, weakening the bond. Therefore, it is recommended to use a solvent like acetone or alcohol to clean both surfaces thoroughly. This ensures that there is no residue left behind that could compromise the bond.

Another factor that can impact the bond’s strength is temperature and humidity. Resin epoxy cures through a chemical reaction that requires heat and moisture. If the temperature or humidity is too low, it can slow down or even stop the curing process, resulting in a weak bond. On the other hand, if the temperature or humidity is too high, it can cause the resin to dry out too quickly, leading to an incomplete bond. Thus, it’s essential to keep the temperature and humidity within optimal ranges during bonding.

The type of PVC also plays a vital role in achieving a strong bond with resin epoxy. There are different types of PVC available in the market, such as rigid PVC and flexible PVC. Rigid PVC is harder and more brittle than flexible PVC. Therefore, the bond between resin epoxy and rigid PVC tends to be stronger than that of flexible PVC due to its harder surface. It is crucial to choose the right type of PVC for your project carefully.

Lastly, choosing the right type of resin epoxy is also crucial in achieving a strong bond with PVC. Different variations of resin epoxy are available in the market, each with varying properties and curing times. It is essential to select a resin epoxy that is compatible with PVC and has a similar curing time to ensure a strong bond.

3Qw-D2A_t2U” >

Conclusion

In conclusion, achieving a strong bond between PVC and resin epoxy requires proper surface preparation and the right type of adhesive. PVC’s smooth surface and low adhesion properties can make it challenging to bond with epoxies, but with some elbow grease and the right tools, you can create a robust and durable bond.

Resin epoxy is a potent adhesive that cures at room temperature or under heat, creating cross-linked polymers that form a stable and long-lasting bond. Its high strength, excellent adhesion properties, and resistance to water and chemicals make it an ideal choice for bonding PVC materials in various industrial applications.

To ensure success when bonding PVC with resin epoxy, you must clean the surface thoroughly, roughen it up with sandpaper or an abrasive material, use a primer if necessary, mix the epoxy thoroughly before applying it evenly on the surface, and allow ample curing time before handling or using the bonded materials. Temperature and humidity also play crucial roles in achieving a strong bond between these two materials.

Choosing the right type of resin epoxy is also critical in achieving a strong bond. With different variations available in the market that have varying properties and curing times, it’s essential to select an epoxy that is compatible with PVC and has similar curing times. Proper preparation and care during application will ensure that resin epoxy can be an effective adhesive for bonding PVC materials for various industrial applications such as construction, automotive, marine industries among others.

In summary, while bonding PVC with resin epoxy may require some extra effort compared to other materials due to its smooth surface texture; following proper preparation techniques will help you achieve an exceptionally robust bond.