Do you ever stop and think about what happens to that glue or adhesive when it gets wet? Does it disappear or stick around forever, causing harm to our environment? PVA, also known as Polyvinyl Acetate, is one such adhesive that raises these questions.

PVA is a synthetic polymer that’s widely used as an adhesive in woodworking, bookbinding, and construction industries. It’s popular for its strong bonding properties and ease of use. But when it comes to its biodegradability, the answer isn’t always clear: does PVA break down in water or leave behind harmful residues that pollute our water sources?

In this blog post, we’ll explore the properties of PVA and how it behaves when exposed to water. We’ll examine the factors that influence its degradation and the different conditions that promote or hinder the breakdown of PVA. Plus, we’ll discuss the impacts of PVA on the environment and possible alternatives.

So come along with us as we uncover the truth about PVA’s behavior in water and its impact on our planet.

Is PVA Water-Soluble?

Contents

- 1 Is PVA Water-Soluble?

- 2 Does PVA Break Down Completely in Water?

- 3 Factors That Affect the Rate of PVA Dissolution in Water

- 4 Types of PVA That Are Designed to be Water-Resistant

- 5 How Long Does It Take for PVA to Degrade in Aquatic Environments?

- 6 Benefits of Using PVA Glue

- 7 Safety and Precautions When Working with PVA Adhesive

- 8 Conclusion

Polyvinyl acetate, commonly known as PVA, is a synthetic polymer that is widely used in the manufacturing of adhesives, paints, and coatings. One of the most crucial properties of PVA is its water solubility. PVA is highly water-soluble, which means that it can be easily dissolved in water.

When PVA comes into contact with water, the hydrophilic nature of the polymer chains within the glue causes it to weaken, leading to a breakdown of the bonds between the chains. The rate at which PVA breaks down in water depends on various factors, including temperature, pH level, and concentration of PVA in the solution.

Temperature plays a significant role in the solubility of PVA in water. Warmer temperatures lead to faster solubility than colder temperatures. The pH level of water can also affect how quickly PVA dissolves. Water with a higher pH level will cause PVA to degrade more quickly than water with a lower pH level.

It’s important to note that not all PVAs are the same when it comes to water solubility. Some PVAs are designed to be more water-resistant than others, depending on their intended use. For instance, outdoor applications or wet environments require PVAs that are more resistant to water.

Even though PVA will eventually break down in water over time, the degradation process may take some time. Studies have shown that it can take anywhere from a few weeks to several months for PVA to fully degrade in aquatic environments.

Does PVA Break Down Completely in Water?

PVA, also known as polyvinyl acetate, is a synthetic polymer that is commonly used in adhesives, coatings, and sealants. Although PVA is water-soluble, the extent to which it breaks down depends on various factors.

One of the most significant factors affecting PVA’s solubility is the specific formulation of the product. Some types of PVA may be more resistant to water than others, based on their chemical composition. Additionally, the temperature and pH of the water can also have an impact on how quickly PVA breaks down. Heat and acidic conditions can accelerate the process of PVA breaking down into smaller molecules that are more easily dispersed in water.

Even after extended exposure to water, residual PVA may still remain due to its non-biodegradable properties. Therefore, if you’re searching for a more environmentally friendly and biodegradable adhesive option, there are other alternatives available on the market.

Factors That Affect the Rate of PVA Dissolution in Water

Polyvinyl Alcohol (PVA) is a ubiquitous synthetic polymer that can be found in adhesives, coatings, and films. But did you know that the rate at which PVA dissolves in water can be affected by various factors? As an expert on this topic, let me share some fascinating insights with you.

Temperature is a crucial factor in the dissolution of PVA. The higher the temperature of the water, the faster the PVA will dissolve. This is because heat causes the PVA molecules to move around more quickly, enabling them to break apart and dissolve readily. So, if you need to dissolve PVA quickly, hot water is your best bet.

Besides temperature, the concentration of PVA in water also affects its dissolution rate. A higher concentration of PVA will dissolve slowly because there are more molecules present competing for space in the water. In contrast, lower concentrations dissolve quickly.

The pH level of water can also affect PVA’s solubility. Neutral or slightly acidic conditions are ideal for quick dissolution, while highly alkaline conditions can slow down or prevent dissolution entirely. So it’s essential to know the pH level of the water when dissolving PVA.

Molecular weight and degree of hydrolysis are also critical factors that affect PVA’s solubility. Generally, higher molecular weight or lower degree of hydrolysis PVA dissolves more slowly than lower molecular weight or higher degree of hydrolysis PVA. Therefore, it’s vital to choose the right type of PVA for your specific application.

Types of PVA That Are Designed to be Water-Resistant

Luckily, there are several types of PVA adhesives that are specially formulated to be water-resistant. Let’s explore some of these types in more detail.

Type II PVA is a commonly used water-resistant adhesive that meets the standards set forth by the American National Standards Institute (ANSI) for water resistance. This type of glue is perfect for outdoor woodworking projects such as decks and furniture. Type II PVA adhesives contain special ingredients that make them more resistant to moisture than regular PVA glue.

Another type of water-resistant PVA adhesive is cross-linking PVA. This adhesive is formulated by adding a cross-linking agent to the glue formula, creating a stronger bond that resists water and moisture. Cross-linking PVA adhesives are commonly used in boat building and other marine applications where exposure to water is likely.

Polymer-modified PVA adhesives are another type of water-resistant adhesive designed for use with materials such as concrete, tile, and other surfaces that may be exposed to moisture or humidity. These adhesives are specially formulated to provide a strong bond that resists water and moisture.

It’s important to remember that while these types of PVA adhesives can provide added protection against moisture, no adhesive is completely impervious to water damage. Therefore, it’s still crucial to take proper precautions to protect your project from excessive exposure to water whenever possible.

How Long Does It Take for PVA to Degrade in Aquatic Environments?

is complex, as many factors can affect the process.

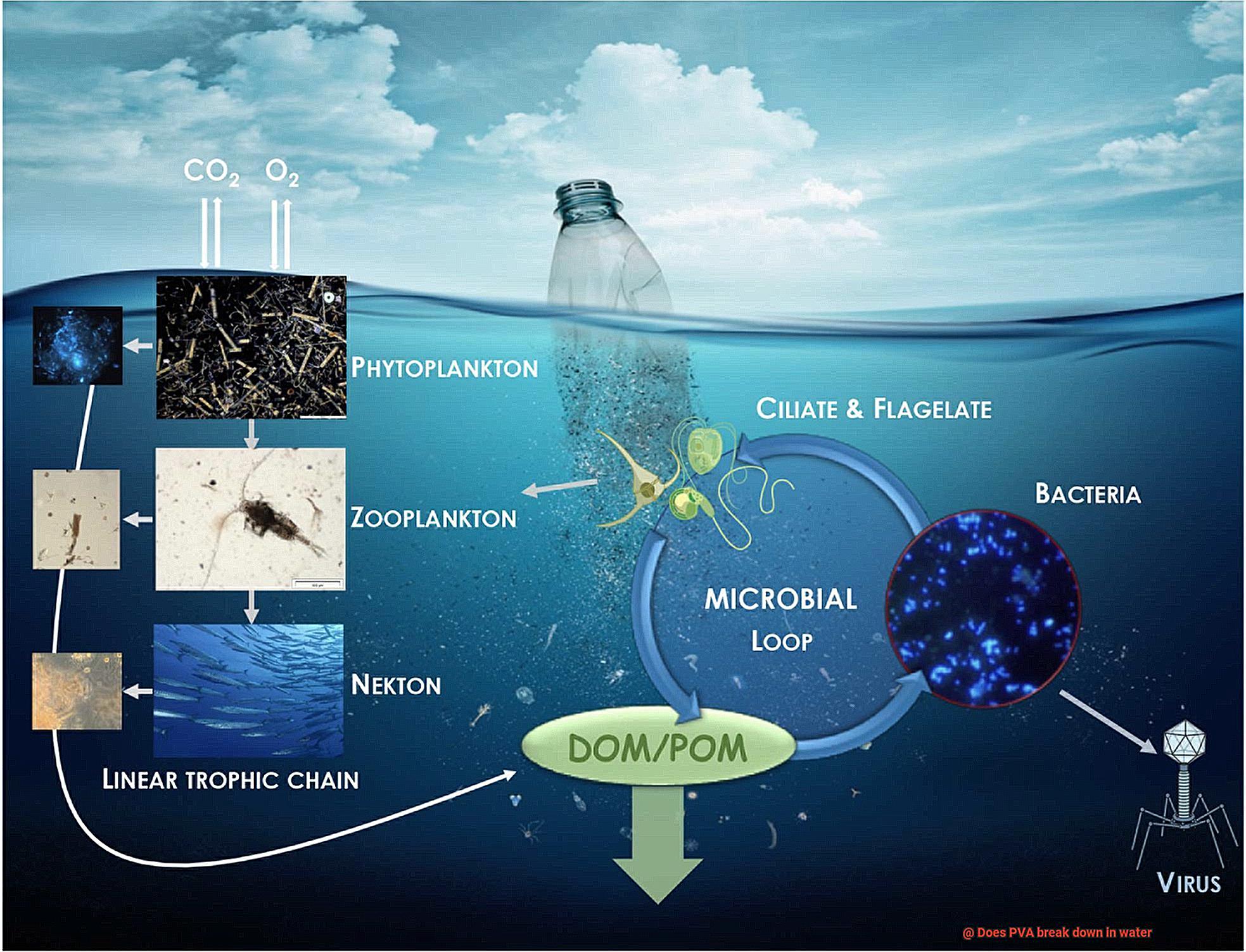

Temperature is the primary factor that affects PVA degradation in water. Higher temperatures can cause PVA to break down more quickly, while lower temperatures can slow down the process. Depending on the specific conditions, PVA can take anywhere from a few days to several months to biodegrade.

The concentration of PVA in the water is another crucial factor. Higher concentrations can slow down the degradation process, while lower concentrations can speed it up. Additionally, the presence of other chemicals or contaminants in the water can also affect PVA’s degradation rate.

It’s important to note that some forms of PVA may be more resistant to degradation than others. Therefore, it’s essential to consider the specific type of PVA being used when evaluating its potential impact on aquatic environments.

Despite its eventual biodegradability in water, it’s crucial to use PVA responsibly and minimize its impact on our ecosystems. Properly disposing of any excess PVA or using alternative adhesives that may be less harmful can help reduce our ecological footprint.

Benefits of Using PVA Glue

Look no further than PVA glue, also known as polyvinyl acetate glue. This popular adhesive has gained a massive fan base among crafters and DIY enthusiasts due to its many benefits.

One of the most significant benefits of PVA glue is its water-soluble nature. This means that cleanup is a breeze, making it a great option for children’s crafts or projects that require frequent clean-up. With just water, you can easily clean up spills and messes without any hassle.

In addition to its water-solubility, PVA glue also dries clear, giving your projects a professional look. Whether you are working on paper, wood, fabric, or even some plastics, PVA glue creates a strong bond between surfaces that is flexible and durable. This makes it an ideal choice for projects that require strength and durability, such as woodworking or home repairs.

But that’s not all – one of the most significant benefits of PVA glue is its strong bonding properties. It creates a bond that is both strong and flexible, making it perfect for a range of crafting and DIY projects. Whether you are working on scrapbooking or building furniture, PVA glue can handle it all.

And the best part? PVA glue is non-toxic and safe for children to use. It has no harmful fumes or chemicals like some other types of adhesives, making it an excellent option for classrooms or homes with young children.

Safety and Precautions When Working with PVA Adhesive

It’s versatile, non-toxic, and creates a strong bond between surfaces. However, it’s crucial to take safety and precautionary measures when working with this adhesive to avoid any potential hazards.

Firstly, always wear protective gear when working with PVA adhesive. Gloves and safety goggles are essential to prevent any accidental contact with the skin or eyes. These simple measures can save you from painful and potentially dangerous injuries.

In addition to personal protective equipment, it’s also crucial to work in a well-ventilated area. The fumes from the glue can be harmful if inhaled for an extended period. Therefore, avoid working in confined spaces such as closed rooms or basements. An open space with good airflow will help you breathe easy while working on your project.

Another important precaution to take is to avoid consuming food or drink while using the adhesive. It might sound like common sense, but it’s easy to forget when you’re engrossed in your work. Keep your food and drinks away from your workspace to avoid any accidents that could lead to inadvertent ingestion.

In addition to these precautions, store the adhesive in a safe location out of reach of children and pets. Accidental ingestion by children or pets can lead to severe health issues. A high shelf or locked cabinet is an ideal place for storage.

Lastly, read and follow all instructions provided on the adhesive packaging carefully. The instructions will guide you on how to use the product safely and correctly. If you accidentally come into contact with the glue, seek medical attention immediately.

RTS_hPXzrBk” >

Conclusion

To sum up, PVA, also known as Polyvinyl Acetate, is a highly popular adhesive that boasts impressive bonding capabilities and ease of application. However, the question of whether PVA breaks down in water or leaves behind harmful remnants that can harm our planet remains unanswered.

Studies indicate that PVA is extremely soluble in water and can dissolve effortlessly. The rate at which it decomposes depends on various factors such as temperature, pH level, concentration of PVA in the solution, molecular weight, and degree of hydrolysis. Although PVA will eventually break down over time when exposed to water, residual PVA may still linger due to its non-biodegradable nature.

Although there are several types of PVA adhesives that are specially formulated to be water-resistant such as Type II PVA, cross-linking PVA, and polymer-modified PVA adhesives, no adhesive is entirely immune to water damage.

It’s essential to use PVA responsibly and minimize its ecological impact by disposing of excess properly or using alternative adhesives that may be less detrimental. When working with PVA adhesive, it’s crucial to take safety measures such as wearing protective gear, working in a well-ventilated area, avoiding consuming food or drink while using the adhesive, storing it in a safe location out of reach of children and pets and reading all instructions provided on the adhesive packaging carefully.