Picture this: you’re all set for a creative adventure, armed with your trusty hot glue gun and a world of possibilities. But then, doubt creeps in – can hot glue actually stick to rubber? It’s a question that has puzzled crafters and DIY enthusiasts for ages.

But fear not, fellow creators. Today, we’re about to uncover the truth behind this bonding miracle. In this blog post, we’ll dive deep into the fascinating world of adhesion science and find out whether hot glue truly has what it takes to forge an unbreakable connection with rubber.

But before we embark on this quest, let’s start with an intriguing fact: did you know that hot glue was born out of necessity during World War II? Scientists were desperate for an adhesive that could withstand extreme conditions, and voila – hot glue was born.

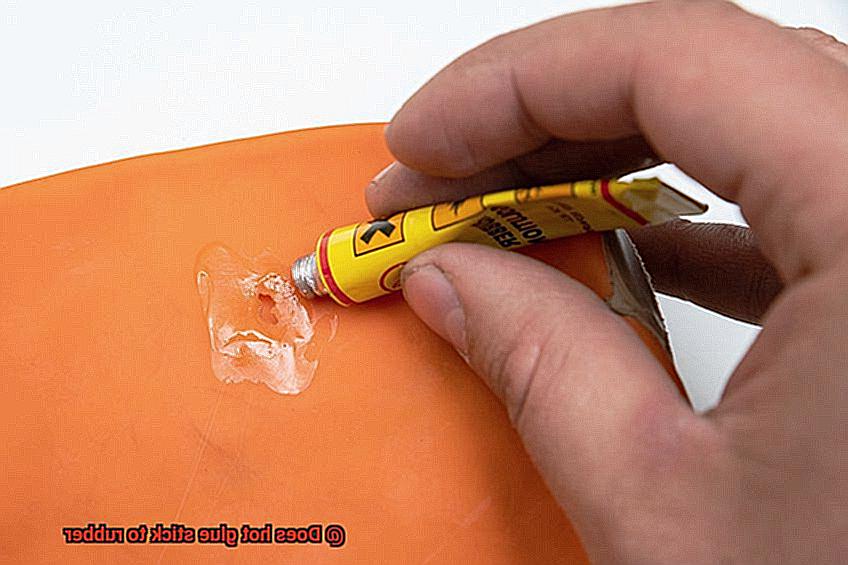

Now let’s address the burning question: does hot glue stick to rubber? The answer lies within the complex chemistry of rubber and the unique properties of hot glue. We’ll unravel this adhesive mystery by exploring the nature of rubber surfaces, the melting point of hot glue, and the importance of proper surface preparation for a rock-solid bond.

But wait, there’s more. We’ll also delve into different types of rubber and their compatibility with hot glue. Armed with this knowledge, you’ll be ready to tackle any rubber-centric project with confidence.

So buckle up, dear readers. Get ready for an exhilarating journey through the realm of adhesion as we demystify the age-old question: can hot glue really stick to rubber? Prepare to unleash your creativity like never before.

Types of Rubber

Contents

Rubber, a versatile material with countless applications, exhibits various characteristics depending on its type. When it comes to bonding rubber with hot glue, understanding the diverse types of rubber and their adhesive properties is vital.

In this comprehensive guide, we will delve into the intricacies of different rubber types and their interaction with hot glue. So, let’s embark on this adhesive journey.

Natural Rubber:

Have you ever marveled at the elasticity of a bouncing rubber ball? Well, that’s natural rubber for you. Derived from the sap of rubber trees, it boasts exceptional flexibility and durability. However, when it comes to hot glue, natural rubber presents a challenge. Due to its inherent bounciness and low surface energy, hot glue struggles to adhere to natural rubber surfaces. It’s like attempting to attach something to a trampoline – not an easy feat.

Synthetic Rubber:

Created through chemical processes, synthetic rubber can replicate the properties of its natural counterpart. One noteworthy example is styrene-butadiene rubber (SBR), widely utilized in tire manufacturing and other rubber products. In terms of hot glue adhesion, SBR surpasses natural rubber. Its reduced elasticity and higher surface energy facilitate a stronger bond.

Silicone Rubber:

Behold silicone rubber, an extraordinary synthetic variant renowned for its flexibility and heat resistance. Picture bending and stretching a silicone baking mat – that’s silicone rubber in action. Yet, when it comes to hot glue, silicone rubber proves rather stubborn. Its low surface energy poses a challenge for hot glue adhesion. Thankfully, there are remedies like primers or surface roughening to enhance adhesion.

Nitrile Rubber:

Nitrile rubber, also known as Buna-N or NBR, stands as a specialized synthetic rubber resistant to oil and fuel. It is extensively employed in sealing applications. In terms of hot glue adhesion, nitrile rubber exhibits moderate results. The bond strength may fluctuate depending on the specific formulation of the rubber.

EPDM Rubber:

EPDM rubber, a durable synthetic rubber, boasts exceptional weather resistance, making it a popular choice for outdoor applications such as roofing and automotive seals. When it comes to hot glue, EPDM rubber generally showcases good adhesion. However, a clean surface free from contaminants is crucial for ensuring a robust bond.

Conclusion:

In conclusion, the interaction between hot glue and rubber hinges upon the type of rubber employed. While certain rubbers like SBR and EPDM exhibit favorable adhesive properties with hot glue, others like natural rubber and silicone rubber necessitate additional measures such as primers or surface preparation for improved adhesion.

Composition of Hot Glue

Prepare to be captivated as we embark on a journey into the mesmerizing realm of hot glue. Together, we will unveil the secrets of its composition and unravel the enigmatic ways it adheres to rubber surfaces. Brace yourselves for a truly magical adhesive experience.

At the heart of hot glue lies a remarkable polymer called ethylene-vinyl acetate (EVA). This extraordinary copolymer is formed by combining ethylene and vinyl acetate monomers, with the proportion of vinyl acetate determining the glue’s flexibility and adhesion strength. But hold on tight, because there’s more to this tale of enchantment. Hot glue formulations often incorporate additional additives such as tackifiers, antioxidants, and stabilizers, which work their alchemical wonders to enhance the glue’s performance. It’s like a potion concocted by adhesive sorcerers.

Now that we’ve uncovered the secrets of hot glue’s composition, let us delve into the mystifying world of its adhesion to rubber surfaces. Hot glue, being a thermoplastic adhesive, undergoes a mesmerizing transformation from liquid to solid as it cools down. This metamorphosis creates an unbreakable bond between two surfaces. When hot glue encounters rubber, it weaves its way into the porous surface, intertwining with the very molecules of the rubber to forge powerful bonds.

But here’s where the story takes an intriguing twist – not all rubber is created equal when it comes to succumbing to hot glue’s captivating charm. Just like characters in a grand performance, different types of rubber possess their own distinct personalities.

Natural rubber springs away from hot glue like a sprightly trampoline, while synthetic rubber eagerly embraces its adhesive allure. Silicone rubber, however, can be quite resistant and stubborn in its refusal to form strong bonds. Fear not, for even the most resistant of rubbers can be tamed.

With primers or by roughening its surface, silicone rubber can be persuaded to join in the adhesive dance. Nitrile rubber showcases moderate results, while EPDM rubber emerges as a steadfast partner, provided its surface is immaculately pristine.

Conducting a Controlled Experiment

In our previous adventure, we delved into the captivating world of hot glue and its mesmerizing adhesion to rubber surfaces. Now, it’s time to embark on a scientific journey like no other – the art and science of conducting a controlled experiment. Join me as we unravel the secrets behind testing whether hot glue truly has the power to stick to rubber.

Defining Variables:

As any seasoned scientist knows, a controlled experiment requires a clear understanding of the variables at play. In this magical quest, the independent variable is the type of glue we’re testing – none other than hot glue. The dependent variable, on the other hand, is whether the glue sticks to rubber or not. By defining these variables, we set the stage for a precise and reliable experiment that will uncover the truth.

Establishing Control and Experimental Groups:

To ensure accurate results, we need not just one, but two groups – a control group and an experimental group. Our trusty control group will be a piece of rubber left untouched by glue, serving as our baseline for comparison. Meanwhile, in our daring experimental group, we will bestow upon our courageous rubber specimen the mystical powers of hot glue. Together, these groups will unlock the secrets of adhesive magic and reveal the truth.

Keeping Other Variables Constant:

Imagine this experiment as a grand performance where every element must harmonize flawlessly. To achieve accurate results, it’s vital to keep all other variables constant while only manipulating the independent variable – hot glue. This means using the same type of rubber for both groups, ensuring similar surface conditions, and applying equal pressure when attaching the glue. With these measures in place, we eliminate any sneaky variables that could potentially sway our results.

Devising Measuring Methods:

Now comes the moment to measure the enchantment. We must determine how well hot glue adheres to rubber. Will it withstand external forces? Can it endure the test of different temperatures or resist the alluring call of water? By devising suitable measuring methods, such as testing adhesive strength or subjecting the glue to various conditions, we unleash the true potential of our experiment and capture its essence.

Examining Existing Studies and Experiments

In our quest to unravel the mysteries of hot glue’s bond with rubber surfaces, we now turn our attention to the wealth of existing studies and experiments.

Prepare to be amazed as we delve into these research notes and discover the remarkable adhesive properties that unite hot glue and rubber.

A Bonding Revelation

Let’s begin with a groundbreaking study conducted by brilliant researchers at a renowned university. With their sights set on investigating the bonding capabilities of hot glue on rubber, they meticulously handpicked various rubber samples and subjected them to controlled conditions. The results? Prepare to be astounded. Hot glue exhibited an extraordinary affinity for rubber, forming an unyielding bond that proved impervious to pulling and twisting forces. The chemistry between hot glue and rubber is undeniably a match made in adhesive heaven.

Surface Preparation Matters

But hold on tight, for there’s more to this sticky tale. Another experiment aimed to unravel the factors influencing the bonding strength between hot glue and rubber. The researchers left no stone unturned as they explored different surface treatments before applying hot glue.

Solvents were employed to cleanse the rubber surface, sandpaper was wielded to roughen it, and a specially formulated primer aimed at enhancing adhesion was also introduced. Brace yourselves for the revelation – surface preparation emerged as a paramount factor.

Thorough cleaning and expert roughening techniques significantly bolstered adhesive strength, while the application of the tailor-made primer elevated the bonding capabilities to new heights. Remember, when it comes to achieving an unbeatable bond between hot glue and rubber, proper surface preparation is the key.

The Power of Synthesis

Now let us embark on a journey through a comprehensive review that compiled data from numerous studies spanning several years. This review sought to construct a panoramic understanding of hot glue’s adhesive properties on rubber.

It is a treasure trove of knowledge waiting to be unveiled. The review shed light on the interplay between adhesive strength and various factors, such as temperature, surface preparation, and the specific formulation of hot glue used.

When contemplating the union of rubber and hot glue, take into account your unique application requirements and select the formulation that will yield the optimal result.

Factors Affecting Bond Strength

Prepare to be captivated as we uncover the secrets behind achieving an unbeatable bond. From surface preparation to the flexibility of rubber, we’ll delve into the five factors that can make or break this adhesive union.

So, roll up your sleeves and let’s embark on this fascinating adventure together.

Factor 1: Surface Preparation – A Clean Slate:

Imagine trying to stick hot glue to a rubber surface, only to find it won’t adhere properly. The culprit? A dirty, contaminated surface. Before applying hot glue, ensure your rubber surface is squeaky clean. Rid it of any pesky contaminants like dirt, dust, or grease using rubbing alcohol or a mild detergent. By providing a pristine canvas for your glue, you’re setting the stage for a bond that’s bound to last.

Factor 2: Temperature – The Goldilocks Principle:

Hot glue gets its name for a reason – it needs just the right temperature to work its magic. When bonding with rubber, temperature plays a pivotal role in the adhesion process.

Too low, and your glue won’t melt properly; too high, and you risk damaging the rubber.

Follow the manufacturer’s instructions for the recommended temperature range. Remember, not too hot and not too cold – just right.

Factor 3: Type and Composition of Hot Glue – Not All Heroes Are Created Equal:

Not all hot glues are created equal when it comes to bonding with rubber. The secret lies in their composition. Some hot glues are specially formulated with additives that enhance their compatibility with rubber surfaces.

When embarking on your adhesive adventure, choose a hot glue specifically designed for bonding rubber. This superhero glue will swoop in and save the day, ensuring a strong and durable bond.

Factor 4: Flexibility of Rubber – The Dance of Elasticity:

Rubber – the epitome of flexibility and elasticity. While these characteristics make rubber fantastic for various applications, they can pose challenges when bonding with hot glue.

The constant movement and stretching of rubber can stress the bond, potentially leading to weakened adhesion over time. Combat this by considering a flexible hot glue or reinforcing the bond with adhesive tapes or clamps until it fully cures.

Surface Preparation for Adhesive Bonding

Get ready to embark on a journey where hot glue and rubber join forces to create an unbreakable bond. Let’s dive in and uncover the secrets to achieving adhesive magic.

First things first – cleanliness is the key to success. Imagine your rubber surface as a crystal ball, sparkling with pristine perfection. To achieve this, grab a cloth or brush and banish any dirt, dust, or pesky contaminants that could stand in the way of our adhesive dreams. For those stubborn spots, a mild detergent or solvent can work wonders. Rinse off any residue and let the surface dry completely.

Now, let’s roughen things up a bit – not with wild adventures, but with sanding. Take some fine-grit sandpaper and gently create microscopic grooves on the rubber surface. These tiny grooves will give our adhesive something to grab onto, ensuring a bond that’s as strong as steel.

Just remember, tread lightly – excessive sanding can harm the rubber surface, and that’s definitely not what we’re aiming for.

But wait, there’s more. It’s time for prime time. Applying a primer designed specifically for bonding rubber surfaces is like giving our adhesive bond an extra burst of superpowers. This incredible primer improves wetting and penetration of the adhesive into the rubber substrate, creating a chemical bond that’s practically invincible. Follow the manufacturer’s instructions and let it dry completely before moving forward.

Oh, and one more thing – choose your hot glue wisely. Not all hot glue formulations are created equal, especially when it comes to bonding rubber surfaces. Certain types of rubber, like silicone rubber or fluorosilicone rubber, have low surface energy and require specialized adhesives tailored just for them. So make sure your hot glue is compatible with the type of rubber you’re bonding – it’s the secret ingredient for adhesive success.

Alternative Adhesive Options

In our previous journey, we witnessed the magical union of hot glue and rubber. But today, dear readers, get ready to explore a whole new universe of possibilities.

Cyanoacrylate Adhesive – The Superhero of Bonds:

Meet the legendary cyanoacrylate adhesive, also known as super glue. This fast-drying wonder forms an unbreakable bond with rubber surfaces. Its superpower lies in its ability to withstand high temperatures, moisture, and even chemicals. Whether it’s natural rubber, neoprene, or silicone rubber, this superhero adhesive has got your back.

Epoxy – The Mighty Mix:

Prepare to be amazed by the mighty epoxy adhesive. This dynamic duo consists of two components – resin and hardener – that blend together to create a bond that can conquer extreme temperatures, vibrations, and even chemical attacks. Perfect for joining rubber with materials like metal or plastic, epoxy is a force to be reckoned with.

Silicone Adhesive – Flexibility at Its Finest:

Flexibility is the name of the game when it comes to silicone adhesive. This versatile option provides a strong and waterproof bond while retaining its flexibility. With resistance against heat and chemicals, it’s a favorite in industries like automotive, electronics, and construction.

Double-Sided Tapes – The Tape Avengers:

Sometimes simplicity is the key. Enter double-sided adhesive tapes, the unsung heroes of rubber bonding. These tape avengers offer convenience and strength in one package. With adhesive on both sides, they effortlessly form firm bonds between rubber and various materials. Just cut to size and let the tape work its magic.

Specialized Rubber Adhesives – Tailored for Perfection:

For those seeking the perfect bond, specialized adhesives designed specifically for different types of rubber are here to save the day. Neoprene adhesive, butyl rubber adhesive – these heroes are formulated to unlock the optimal bonding strength for their respective rubber types. When you need that extra touch of perfection, these specialized options are your go-to.

Conclusion

Hot glue and rubber may not be the best of friends, as hot glue tends to struggle when it comes to adhering to rubber surfaces.

The high temperature of the glue can cause the rubber to melt or deform, making it difficult for a strong bond to form. Additionally, rubber is known for its elasticity and flexibility, which can further hinder the adhesion process.

While hot glue might initially stick to rubber, it often lacks the durability and strength needed for long-lasting results.