The trusty sidekick of crafters, DIY fanatics, and pros who know what’s up.

This adhesive superstar is like a chameleon – it can do it all. But here’s the real kicker: it sets hard.

And that’s why hot glue is the secret weapon behind countless projects. Whether you’re whipping up some cute little artsy things or tackling big construction jobs, understanding how this magical goo sets is key.

Let’s get sticky and discover the wonders of hot glue together.

What is Hot Glue?

Contents

Hot glue, also known as hot melt adhesive, is a fascinating and versatile adhesive that has become a staple in arts and crafts projects, as well as in various DIY applications. But what exactly is hot glue, and how does it work?

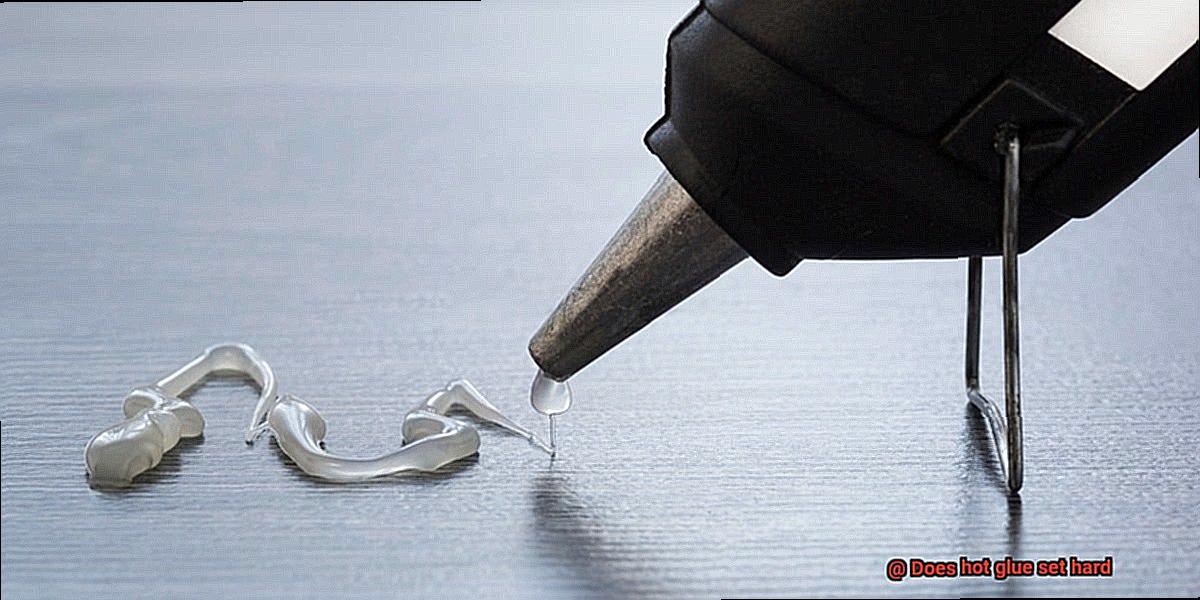

At its core, hot glue is composed of thermoplastic polymers that are melted at high temperatures. This unique composition allows the glue to come in the form of cylindrical sticks or pellets that are loaded into a glue gun. When the glue gun heats the glue, it melts and flows out through a nozzle. Once applied, the hot glue quickly cools and solidifies, forming a strong bond between the surfaces it is applied to.

One of the remarkable properties of hot glue is its ability to set hard. As the hot glue solidifies, it becomes rigid and durable, making it perfect for applications that require a strong and long-lasting bond. Whether you’re joining two pieces of wood, fabric, plastic, or even metal, hot glue can do the job effectively.

But hot glue isn’t just about its adhesive properties. It offers some other advantages as well. For one, it has a quick setting time, typically within seconds or minutes. This allows for efficient workflow in projects, saving both time and effort. Additionally, hot glue is resistant to temperature variations, making it suitable for both indoor and outdoor use.

However, like any adhesive, hot glue does have its limitations. It may not be suitable for applications that require high strength or resistance to extreme conditions. It can soften or melt when exposed to high temperatures, so caution should be taken when using it near heat sources. Furthermore, certain materials such as oily surfaces or silicone-based substances may not bond well with hot glue.

Different Types of Hot Glue

Prepare to immerse yourself in the mesmerizing world of hot glue. Selecting the right type of hot glue can elevate your projects to new heights. Join me as we embark on a journey through the diverse realms of hot glue, discovering their unique properties and powers.

The Standard Superhero – Standard Hot Glue:

Let’s begin with the quintessential hero, Standard Hot Glue. This adhesive sets hard, ensuring a robust bond that triumphs over any crafting challenge. Versatile and reliable, it is perfect for general crafting, DIY projects, and quick repairs. When melted, it transforms into a clear or translucent state, ensuring your masterpiece remains unblemished. Trust this superhero to save the day.

Gentle Giant – Low-Temperature Hot Glue:

Next up, behold the gentle giant, Low-Temperature Hot Glue. This adhesive melts at a lower temperature than its standard counterpart, making it ideal for delicate materials like fabric, foam, and certain plastics. It sets relatively softer but still upholds its duty of holding everything together with unwavering care. Shield those fragile materials with this compassionate superhero.

Mighty Warrior – High-Temperature Hot Glue:

When faced with arduous tasks, we summon the mighty warrior, High-Temperature Hot Glue. This adhesive demands a higher melting temperature to activate and is tailor-made for heavy-duty applications involving metal, wood, and ceramics. It sets hard as stone and delivers a formidable bond capable of withstanding extreme temperatures and weighty loads. Count on this warrior to conquer any formidable project.

Colorful Chameleon – Colored Hot Glue:

Yearning to infuse your creations with vibrancy? Say hello to the colorful chameleon, Colored Hot Glue. Available in a myriad of hues, this adhesive sets hard and bestows a burst of color upon your projects. Perfect for adding accents, crafting decorations, or unleashing your artistic prowess. Let your imagination run wild alongside this vivacious superhero.

Specialty Sidekicks – Specialty Hot Glue:

Last but not least, we encounter the specialty sidekicks. These hot glues are purposefully crafted for specific applications. Need to bond fabric with finesse? There’s a glue for that. Working in a humid environment? Fear not, for we have you covered. These specialty hot glues possess unique properties tailored to their destined tasks. Though they may be sidekicks, their indispensability is indisputable.

Does Hot Glue Set Hard?

Join me as we uncover the secrets behind this versatile adhesive and unlock the factors that influence its hardness.

Hot glue, also known as hot melt adhesive, is a thermoplastic wonder that transforms from a molten state to a solid bond upon cooling. When dispensed from a glue gun, it rapidly solidifies upon contact with a surface, creating a sturdy connection. But how does its hardness vary?

Not all hot glues are created equal. Different formulations offer distinct characteristics. Low-temperature hot glue tends to set with a softer consistency, while high-temperature variants offer a harder set. The choice of hot glue can thus impact the final hardness of your project.

The thickness of your hot glue application plays a pivotal role in its hardness. Thicker layers take longer to cool and solidify, resulting in a comparatively softer finish. Conversely, thinner layers cool rapidly, yielding a harder set. So, consider the thickness of your glue lines for the desired outcome.

The surface you apply hot glue to can influence its hardness. Porous materials like paper, fabric, and wood provide an ideal canvas for hot glue to form strong bonds that set relatively hard. However, on smooth or non-porous surfaces such as glass or metal, hot glue may struggle to adhere effectively and may not set as hard.

The ambient temperature during the setting process also affects hot glue’s hardness. Colder temperatures expedite the cooling and solidification process, resulting in a harder set. In contrast, warmer temperatures prolong cooling time, leading to a softer finish. Consider the environment you’re working in for optimal results.

Factors Influencing the Hardness of Hot Glue

In this enlightening exploration, we will delve into each of these factors to gain a deeper understanding of their profound impact on the final hardness of hot glue.

Temperature:

The temperature at which hot glue is applied holds the key to unlocking its hardness potential. Like alchemists, we must master the art of temperature control. Crank up the heat, and hot glue transforms into a rigid and unyielding bond. Dial it down, and the glue takes on a supple and flexible nature. Thus, by adjusting the temperature, we can shape the hardness of our creations with precision.

Composition:

Within the secret recipe of hot glue lies its composition, a blend of thermoplastic polymers such as EVA or polyurethane. Each polymer blend possesses its own unique properties, influencing the hardness of the glue. Some formulations favor flexibility and rubber-like textures when cooled, while others lean towards rigidity and stiffness. Choose your hot glue wisely, for its composition shall wield great influence over your project’s desired hardness.

Cooling Rate:

As the molten hot glue meets its destined surface, a race against time begins—the dance of cooling commences. The cooling rate, dictated by ambient temperature, surface characteristics, and application thickness, determines the final hardness. A leisurely pace grants the polymers ample time to interlock in a formidable embrace, forging a hardened outcome. Patience becomes our ally as we allow hot glue to cool slowly, paving the way for unyielding bonds.

Thickness of Glue Application:

In this realm of glue craftsmanship, thickness emerges as a formidable ally in shaping hardness. A generous application bestows upon us a slower cooling journey, akin to a languid stroll through a garden of strength. The polymers seize the opportunity to intertwine and solidify, resulting in a hardened and robust bond. If hardness is your desire, embrace the notion of layering hot glue with purpose and precision.

Curing Time:

A symphony of transformation awaits us as hot glue embarks on its journey of self-actualization through curing. Time becomes an essential ally in this process, as the glue continues to harden and strengthen. Each brand and type of hot glue possesses its own prescribed curing time, a sacred ritual to be respected. Grant the glue the necessary moments to mature fully before subjecting it to the rigors of life’s demands. In this patient embrace, we unlock the true potential of hardness and durability.

High Temperature or Clear Hot Glue

Prepare to embark on a journey where we unravel the mysteries behind high temperature and clear hot glue. Get ready to witness the impact of these glues on bond hardness. Grab your trusty glue gun and let’s dive right in.

High Temperature Hot Glue:

- A powerhouse for heavy-duty applications

- Operates at scorching temperatures of around 380°F (193°C) or higher

- Sets into an unyielding and resilient bond

- Best-suited for bonding wood, metal, or plastic

- Unfazed by moderate stress levels

Clear Hot Glue:

- The gentle giant for delicate materials and low heat requirements

- Operates at a relatively cooler temperature of approximately 250°F (121°C)

- Sets with a softer touch compared to high temperature glue

- Retains a touch of flexibility even after cooling

- May not match the strength of high temperature hot glue

Factors Influencing Hardness:

- Thickness of the adhesive layer: Thicker layers take their time to cool down, resulting in a slightly softer bond.

- Ambient temperature during application: Extremely low temperatures render hot glue more brittle, prone to cracking.

Tips for Unbreakable Bonds:

- Surface preparation is paramount: Clean, decontaminate, and roughen surfaces for superior adhesion.

- Don’t skimp on the hot glue: Using too little adhesive may lead to a frail bond.

In the epic clash of high temperature versus clear hot glue, both contenders possess their unique strengths and weaknesses when it comes to hardness and flexibility.

While high temperature hot glue reigns supreme with its rock-solid bond perfect for heavy-duty projects, clear hot glue boasts a softer touch with some flexibility, making it an ideal choice for delicate materials.

So, choose your hot glue wisely based on the demands of your project, and let your creativity soar.

Low Temperature or Colored Hot Glue

Today, we’re going to delve into the intriguing debate of low temperature versus colored hot glue. Whether you’re a crafting connoisseur or a curious novice, this information will prove invaluable when selecting the perfect adhesive for your project.

Let’s begin with low temperature hot glue. This enchanting adhesive melts at a lower temperature than regular hot glue, making it an ideal choice for those sensitive to heat or for crafting with children. Not only does it offer a safer alternative, but its lower melting point also means it sets softer and remains flexible when cooled. Picture delicate fabrics or materials requiring some give – low temperature hot glue is the answer.

However, it’s essential to note that low temperature hot glue may not provide the same robust bond as its regular counterpart. Heavy-duty or high-stress applications may require a stronger adhesive, making low temperature hot glue less suitable.

Now, let’s explore the world of colored hot glue. These vibrant sticks are a bonanza for the artistic soul. Colored hot glue adds a playful and decorative touch to your projects, allowing for greater customization and artistic flair. Imagine the possibilities – colorful jewelry, funky accessories, or whimsical decorations.

Like regular hot glue, colored hot glue hardens when cooled. Yet, keep in mind that bonding strength may vary depending on the specific formulation and brand. Always consult the manufacturer’s instructions to ensure proper application and bonding strength.

One important detail about colored hot glue is its shorter working time before cooling and hardening. To achieve your desired results, work swiftly and efficiently.

When deciding between low temperature and colored hot glue, consider your project’s requirements. Evaluate factors such as bonding strength, flexibility, and desired aesthetic qualities. Determine whether safety, flexibility, or creativity takes precedence.

External Factors Affecting the Drying Time of Hot Glue

The answer lies in the external factors that influence its drying time. Join me as we delve into these secrets and unlock the mysteries of hot glue’s drying process.

Temperature:

Temperature is a mighty force in the realm of hot glue drying time. Higher temperatures accelerate the drying process, while colder temperatures slow it down. In a chilly room, brace yourself for a longer wait as the glue takes its sweet time to set. However, on a scorching summer day, prepare to be amazed at how quickly your hot glue solidifies.

Humidity:

The amount of moisture in the air, known as humidity, also plays a role in hot glue’s drying time. High humidity environments hinder evaporation, prolonging the drying process. Conversely, low humidity conditions can cause hot glue to dry too quickly, resulting in a weaker bond. So take heed of the humidity level when working with hot glue.

Surface Type:

The type of surface you’re bonding can impact how long it takes for hot glue to dry. Non-porous surfaces like glass or metal conduct heat efficiently, allowing the glue to cool and harden swiftly. On the other hand, porous materials such as fabric or wood absorb heat from the hot glue, causing it to take longer to dry. Choose your adhesive wisely and adjust your expectations accordingly.

Thickness of Glue Application:

The thickness of your glue application can also affect drying time. Thicker layers or larger amounts of hot glue require more time to dry compared to thin layers. The additional volume retains more heat and demands extra time to cool and harden. So exercise caution when using copious amounts of glue, especially if you’re working against the clock.

Also Read: What is the best glue for fabric?

Conclusion

In conclusion, hot glue is a force to be reckoned with when it comes to setting hard. This magical adhesive undergoes a mesmerizing transformation from a molten state to a solid bond, creating an unyielding connection between surfaces. It’s like watching a phoenix rise from the ashes, except instead of feathers and fire, you get a sturdy and durable bond.

But here’s the thing – not all hot glues are created equal. Oh no, my friend. Different types offer distinct characteristics and levels of hardness. You’ve got your standard hot glue that sets hard and is perfect for your everyday crafting and DIY projects. Then there’s the low-temperature hot glue that sets relatively softer, ideal for delicate materials that need some tender loving care. And let’s not forget about high-temperature hot glue, which sets hard as stone and can handle heavy-duty applications like a boss.

And guess what? Hot glue doesn’t discriminate when it comes to color either. Colored hot glue sets hard just like its clear counterpart but adds an explosion of vibrant hues to your projects. Talk about taking things up a notch.

Now, let’s talk about the factors that influence how hard your hot glue will set. Temperature plays a role – hotter or colder environments can affect the final hardness. The composition of the glue itself matters too because different formulas have different levels of rigidity once they cool down. The speed at which it cools also makes a difference – slow and steady or quick as lightning? You decide. And don’t forget about the thickness of your application and how long you let it cure – these factors can shape the hardness of your creation with surgical precision.

Sure, hot glue has its limitations – it might not be suitable for Herculean strength applications or extreme conditions – but boy does it have its advantages. It sets in record time, laughs in the face of temperature variations, and can bond together materials you wouldn’t even think were possible. It’s like a superhero in adhesive form, always ready to save the day.

So whether you’re a master of mini crafts or a conqueror of construction projects, knowing how hot glue sets hard is your secret weapon.